Polypropylene powder for 3PP anticorrosion pipeline coating external layers, and preparation method thereof

A polypropylene and pipeline technology, used in anti-corrosion coatings, coatings, powder coatings, etc., can solve problems such as different innovative ideas, and achieve the effect of simplifying production processes, thin anti-corrosion layers, and good dry powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

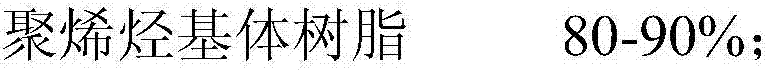

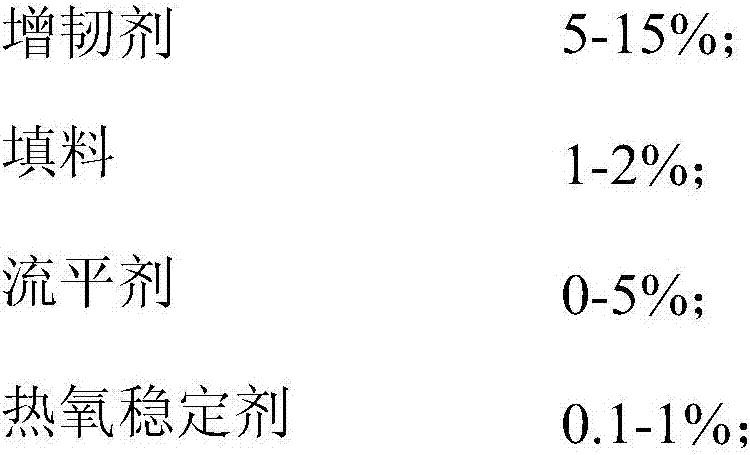

[0026] A kind of polypropylene powder for the outer layer of 3PP anticorrosion pipeline coating, each raw material is as shown in Table 1 by weight percentage:

[0027] Raw material composition weight percent of table 1 embodiment 1

[0028]

[0029] The above-mentioned 3PP anti-corrosion pipeline coating outer layer is prepared with polypropylene powder through the following steps:

[0030] 1) After mixing the raw materials according to the proportion, under the condition of 210°C, extrude and granulate through the twin-screw extruder, the screw speed of the twin-screw extruder is 400rpm, and the aspect ratio of the twin-screw L / D=35:1 , to obtain polypropylene pellets;

[0031] 2) Grinding the polypropylene pellets obtained in step 1) under the condition of liquid nitrogen freezing at a temperature of -50° C. to obtain polypropylene powder.

Embodiment 2

[0033] A kind of polypropylene powder for the outer layer of 3PP anticorrosion pipeline coating, each raw material is as shown in Table 2 by weight percentage:

[0034] Raw material composition weight percent of table 2 embodiment 2

[0035]

[0036] The above-mentioned 3PP anti-corrosion pipeline coating outer layer is prepared with polypropylene powder through the following steps:

[0037] 1) After mixing the raw materials according to the proportion, under the condition of 200°C, extrude and granulate through the twin-screw extruder, the screw speed of the twin-screw extruder is 400rpm, and the aspect ratio of the twin-screw L / D=35:1 , to obtain polypropylene pellets;

[0038] 2) Grinding the polypropylene pellets obtained in step 1) under the condition of liquid nitrogen freezing at -40° C. to obtain polypropylene powder.

Embodiment 3

[0040] A kind of polypropylene powder for the outer layer of 3PP anticorrosion pipeline coating, each raw material is as shown in table 3 by weight percentage:

[0041] Raw material composition weight percent of table 3 embodiment 3

[0042]

[0043] The above-mentioned 3PP anti-corrosion pipeline coating outer layer is prepared with polypropylene powder through the following steps:

[0044] 1) After mixing the raw materials according to the proportion, under the condition of 220℃, extrude and granulate through the twin-screw extruder. , to obtain polypropylene pellets;

[0045] 2) Grinding the polypropylene pellets obtained in step 1) under the condition of liquid nitrogen freezing at a temperature of -60° C. to obtain polypropylene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com