A kind of polyethylene powder for anti-corrosion pipeline and preparation method thereof

A polyethylene powder and polyethylene technology, applied in powder coatings, anti-corrosion coatings, coatings, etc., can solve the problems of lack of contrast in anti-corrosion effects of steel pipes, inconsistent anti-corrosion ideas, and high energy consumption, achieve good dry powder fluidity, improve Anti-corrosion effect, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

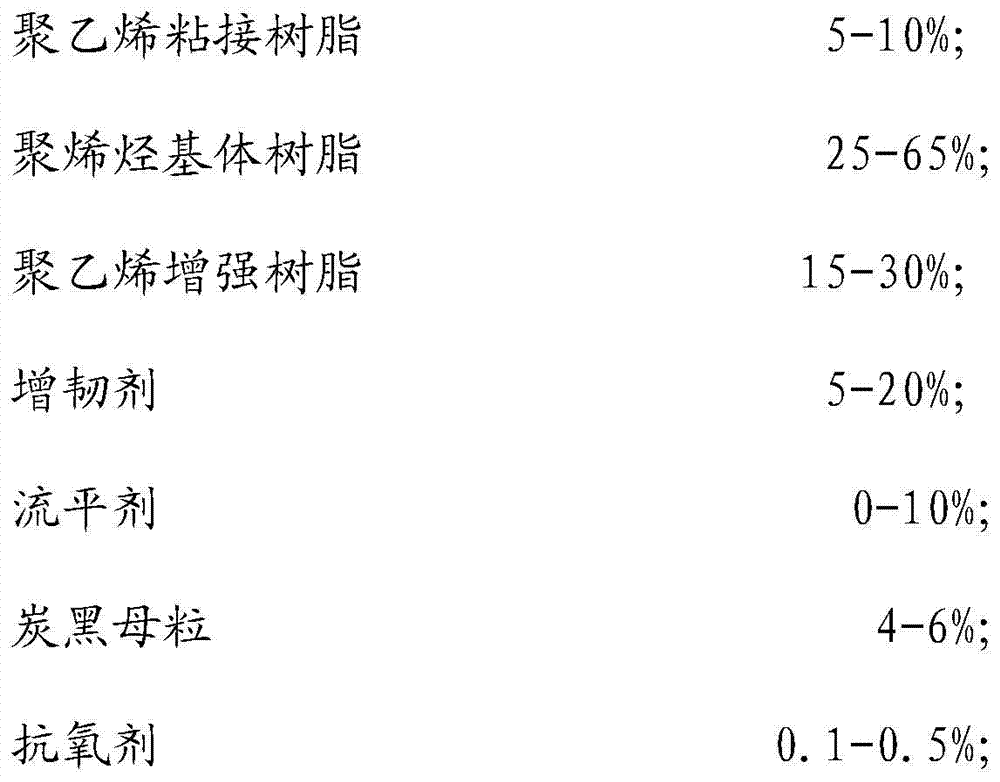

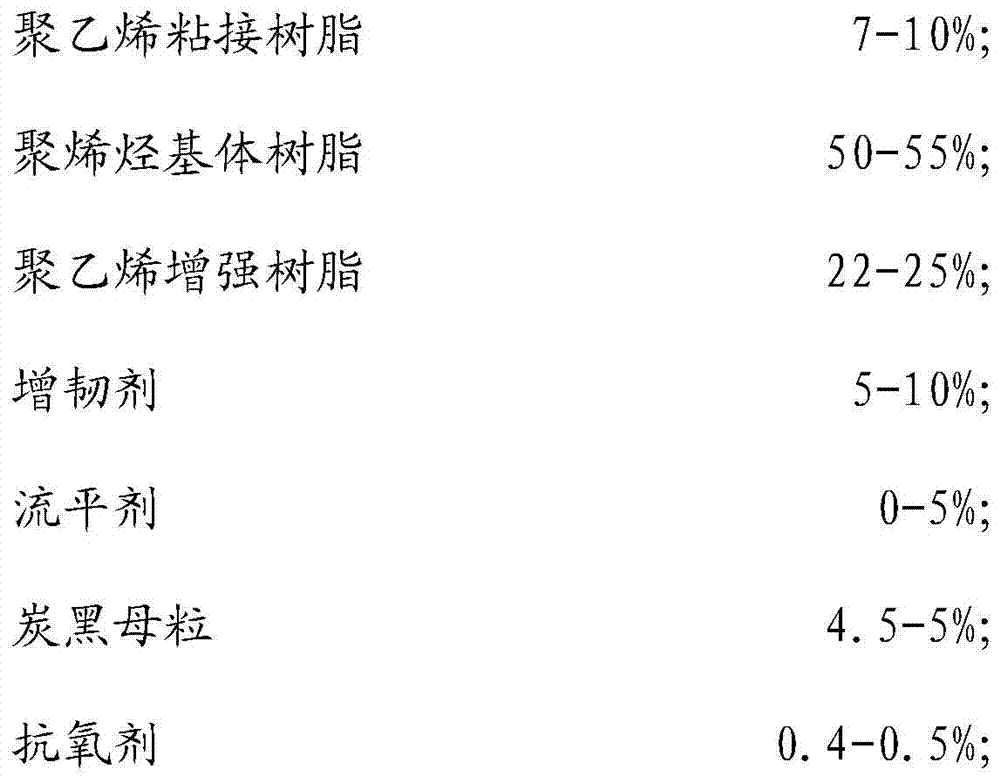

Method used

Image

Examples

Embodiment 1

[0029] A polyethylene powder for anti-corrosion pipelines, prepared from the following raw materials by weight percentage: 7% polyethylene graft adhesive resin, 55% polyolefin matrix resin, 23% polyolefin reinforced resin, toughened Agent 10%, polyacrylate (leveling agent) 0%, carbon black masterbatch 4.5%, antioxidant 0.5%.

[0030] Wherein, the formula (100%) of polyolefin matrix resin:

[0031] HDPE 70%;

[0032] LDPE 30%;

[0033] Wherein, the composition of toughening agent is (100%):

[0034] POE 75%;

[0035] SEBS 25%;

[0036] Wherein the composition of antioxidant is (100%):

[0037] Antioxidant 1010 30%;

[0038] Antioxidant 168 60%;

[0039] Light stabilizer 10%.

[0040] A preparation method of polyethylene powder for anticorrosion pipelines, comprising the following steps:

[0041] 1) Add the raw materials into the high-speed blender according to the formula ratio, and after mixing evenly, extrude and granulate through the twin-screw extruder at a tempera...

Embodiment 2

[0044]A polyethylene powder for anti-corrosion pipelines, prepared from the following raw materials by weight percentage: 8% polyethylene graft adhesive resin, 50% polyolefin matrix resin, 22% polyolefin reinforced resin, toughened Agent 10%, polyacrylate leveling agent 5%, carbon black masterbatch 4.6%, antioxidant 0.4%.

[0045] Wherein, the formula (100%) of polyolefin matrix resin:

[0046] HDPE 60%;

[0047] Low density polyethylene 40%;

[0048] Wherein, the composition of toughening agent is (100%):

[0049] POE 100%;

[0050] Wherein the composition of antioxidant is (100%):

[0051] Antioxidant B245 80%;

[0052] Light stabilizer 20%;

[0053] A preparation method of polyethylene powder for anticorrosion pipelines, comprising the following steps:

[0054] 1) Add the raw materials into the high-speed blender according to the formula ratio, and after mixing evenly, extrude and granulate through the twin-screw extruder at a temperature of 190°C to obtain polyethyl...

Embodiment 3

[0057] A polyethylene powder for anti-corrosion pipelines, prepared from the following raw materials by weight percentage: 10% polyethylene graft adhesive resin, 50% polyolefin matrix resin, 25% polyolefin reinforced resin, toughened Agent 5%, polyacrylate leveling agent 5%, carbon black masterbatch 4.6%, antioxidant 0.4%.

[0058] Wherein, the formula (100%) of polyolefin matrix resin:

[0059] HDPE 50%;

[0060] LDPE 50%;

[0061] Wherein, the toughening agent is composed of:

[0062] POE 50%;

[0063] EVA 50%;

[0064] Wherein the composition of antioxidant is:

[0065]

[0066] A preparation method of polyethylene powder for anticorrosion pipelines, comprising the following steps:

[0067] 1) Add the raw materials into the high-speed blender according to the formula ratio, and after mixing evenly, extrude and granulate through a twin-screw extruder at a temperature of 220°C to obtain polyethylene pellets; the screw speed of the extruder is 400rpm, and the twin-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com