Preparation method of poly ethylene (PE) hot melt glue powder for 3PE anti-corrosion pipelines

A hot melt adhesive and powder technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problem of unmentioned PE hot melt adhesive powder, unmentioned elastomer tackifying resin PE heat The peel strength and flexibility of the melt adhesive powder, and the preparation method of the PE hot melt adhesive powder are not mentioned, so as to achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a preparation method of PE hot-melt adhesive powder for 3PE anti-corrosion pipelines, which comprises the following raw material components in percentage by weight: polyethylene graft adhesive resin 10-40%; polyolefin matrix resin 30- 80%; Elastomer tackifying resin 5-30%; Polyacrylate leveling agent 5-30%.

[0025] With polyethylene mixture or polyethylene, ethylene copolymer mixture as the base resin, 0.5-2.5wt% of maleic anhydride (MAH), acrylic acid (AA), ethyl acrylate (EA), butyl acrylate (BA) One or the blend is a graft monomer, with one or the blend in 0.15-0.25wt% dicumyl peroxide (DCP), benzoyl peroxide (BPO) as initiator, by High-mixer pre-mixing ensures uniform dispersion of each component, and graft modified adhesive resin is obtained through reactive extrusion process. Premix the weighed adhesive resin, matrix resin, tackifier resin, and leveling agent, then knead with a twin-screw extruder to obtain PE hot melt adhesive particles....

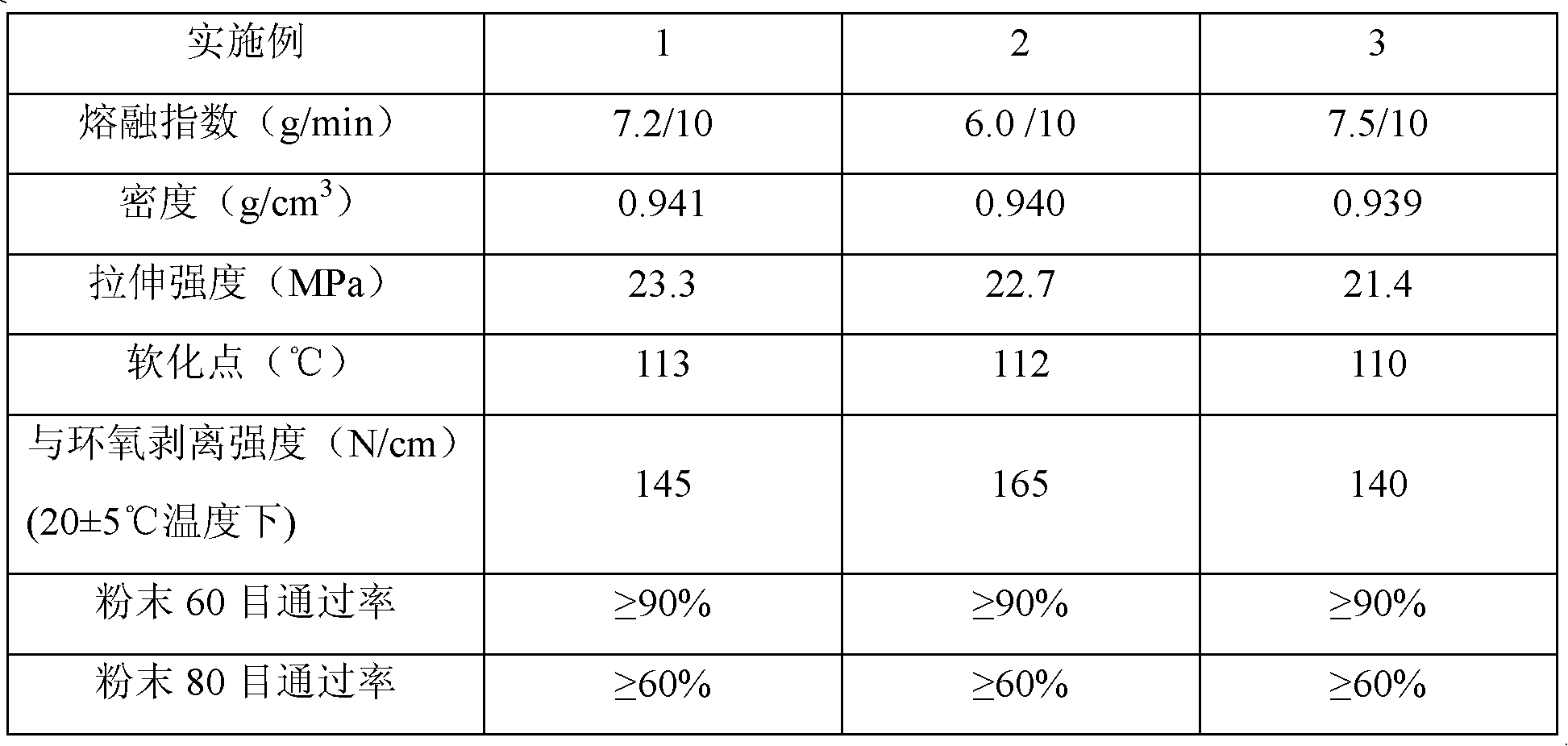

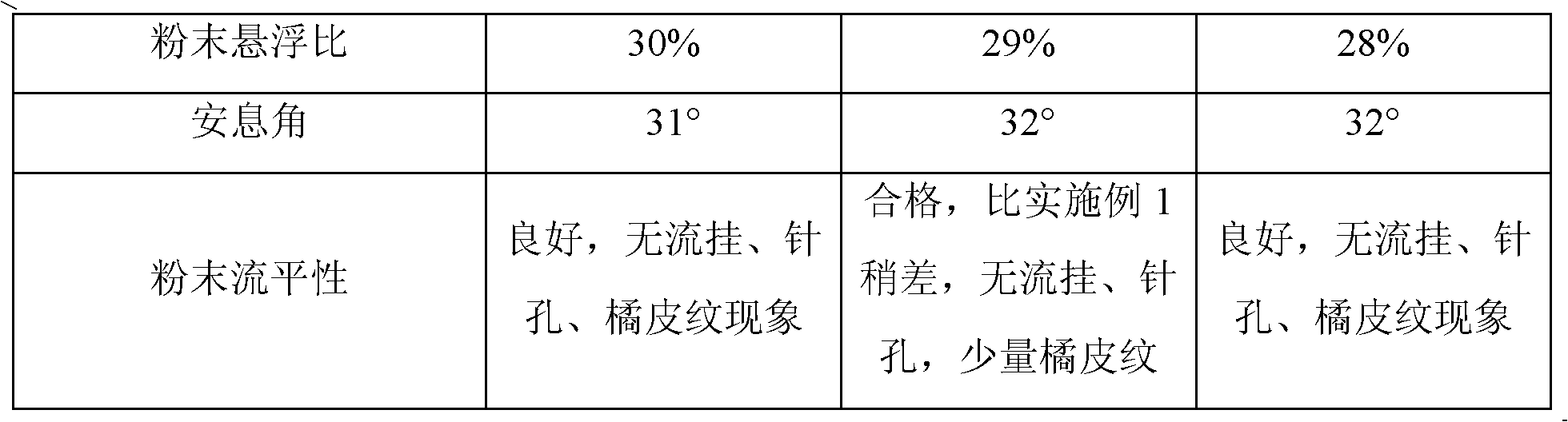

Embodiment 1

[0041] PE hot melt adhesive powder formula (100%) is as follows:

[0042] Polyethylene graft adhesive resin 15%

[0043] Polyolefin matrix resin 65%

[0044] Elastomer Tackifying Resin 14%

[0045] Polyacrylate leveling agent 6%

[0046] Wherein, the formula (100%) of polyethylene graft bonding resin:

[0047] HDPE 60%

[0048] Linear Low Density Polyethylene 38.55%

[0049] Maleic anhydride monomer 1.3%

[0050] Dicumyl peroxide 0.15%;

[0051] Wherein, the formula (100%) of polyolefin matrix resin:

[0052] HDPE 70%

[0053] Low-density polyethylene 30%;

[0054] Wherein, the composition of elastomer tackifying resin is:

[0055] Ethylene-octene copolymer 75%

[0056] EVA25%;

[0057] The raw materials of each component in the polyethylene graft adhesive resin formulation are accurately weighed and pre-mixed by a high-speed mixer to ensure that the components are uniformly dispersed, and then the polyethylene graft adhesive resin is obtained through twin-screw re...

Embodiment 2

[0059] PE hot melt adhesive powder formula (100%) is as follows:

[0060] Polyethylene graft adhesive resin 20%

[0061] Polyolefin matrix resin 57%

[0062] Elastomer Tackifying Resin 18%

[0063] Polyacrylate leveling agent 5%;

[0064] Wherein, the formula (100%) of polyethylene graft bonding resin:

[0065] HDPE 65%

[0066] Linear Low Density Polyethylene 33.22%

[0067] Maleic anhydride monomer 1.6%

[0068] Dicumyl peroxide 0.18%;

[0069] Wherein, the formula of polyolefin matrix resin is identical with embodiment 1;

[0070] Wherein, the composition of polyolefin tackifying resin is ethylene-octene copolymer;

[0071] The raw materials of each component in the polyethylene graft adhesive resin formulation are accurately weighed and pre-mixed by a high-speed mixer to ensure that the components are uniformly dispersed, and then the polyethylene graft adhesive resin is obtained through twin-screw reaction extrusion. Premix the weighed adhesive resin, matrix resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com