Hot melt adhesive for acrylic hot-fix rhinestone and preparation method thereof

An acrylic hot-drilling and hot-melt adhesive technology, which is applied in the direction of adhesives, adhesive types, mineral oil-hydrocarbon copolymer adhesives, etc. Acrylic hot drilling and other problems, to achieve the effect of good optical performance, wide range of hardness, resistance to environmental stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

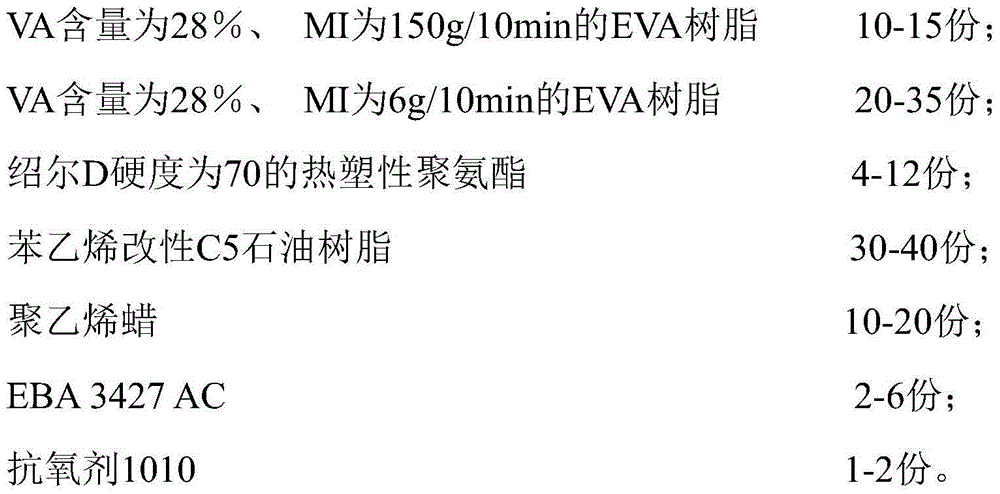

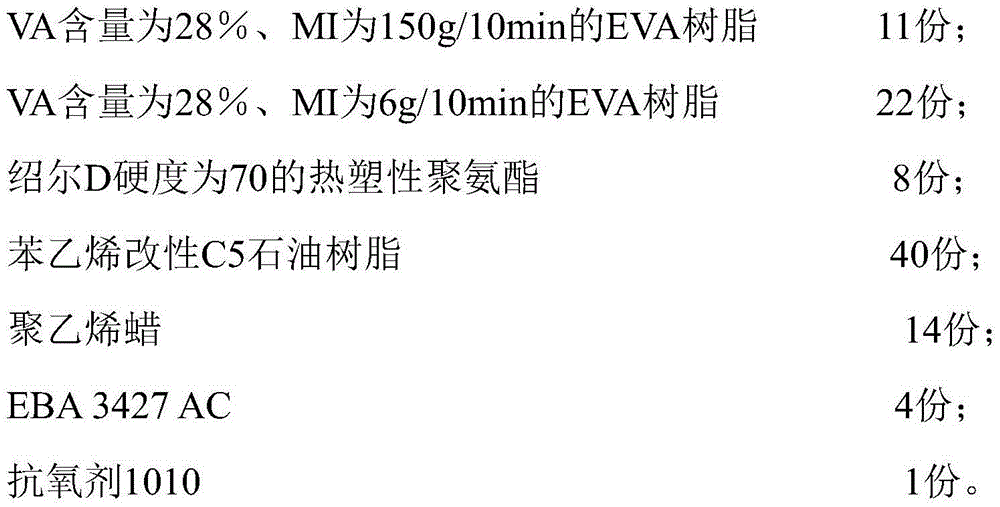

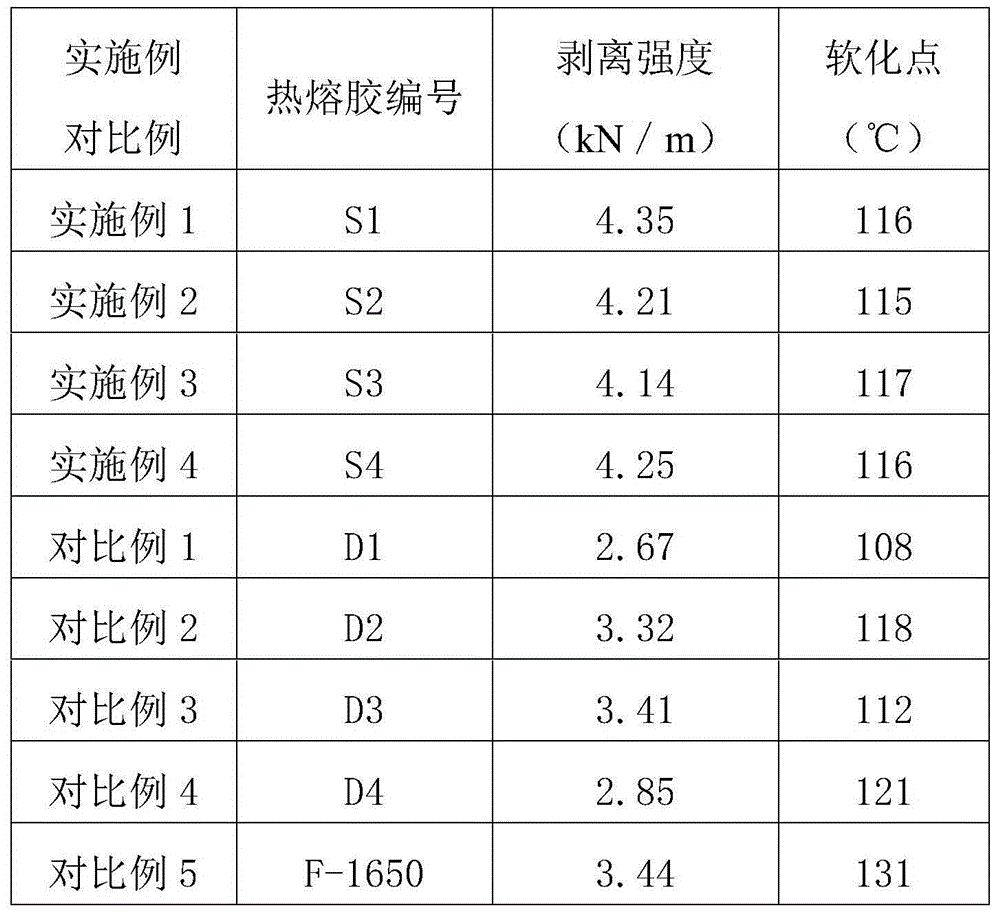

[0026] Embodiment 1: The present invention provides the composition and preparation method thereof of hot-melt adhesive

[0027] Add 14 parts by weight of polyethylene wax to the ribbon-stirred hot-melt adhesive reaction kettle, heat it to 160°C, and after it is completely melted, add 11 parts by weight of EVA resin (VA content is 28%, MI: 150g / 10min) , the EVA resin of 22 parts by weight (VA content is 28%, MI:6g / 10min), the antioxidant 1010 of 1 part by weight, the thermoplastic polyurethane of 8 parts by weight, the ethylene-butyl acrylate copolymer EBA3427AC of 4 parts by weight, Under the protection of nitrogen, control the temperature at 180°C, stir for 2 hours, add 40 parts by weight of styrene-modified C5 petroleum resin, control the temperature at 160°C, stir for 1 hour, vacuumize, enter the strip, cooling, Pelletizing process, hot-melt hot melt adhesive S1 can be obtained.

Embodiment 2

[0028] Embodiment 2: The present invention provides the composition and preparation method thereof of hot-melt adhesive

[0029] Add 20 parts by weight of polyethylene wax to the ribbon-stirred hot-melt adhesive reaction kettle, heat it to 160°C, and add 15 parts by weight of EVA resin (VA content: 28%, MI: 150g / 10min) after melting is complete , the EVA resin of 30 parts by weight (VA content is 28%, MI:6g / 10min), the antioxidant 1010 of 1 part by weight, the thermoplastic polyurethane of 8 parts by weight, the ethylene-butyl acrylate copolymer EBA3427AC of 2 parts by weight, Under the protection of nitrogen, control the temperature at 180°C, stir for 2 hours, add 40 parts by weight of styrene-modified C5 petroleum resin, control the temperature at 160°C, stir for 1 hour, vacuumize, enter the strip, cooling, Pelletizing process, that is hot-melt hot melt adhesive S2.

Embodiment 3

[0030] Embodiment 3: The present invention provides the composition and preparation method thereof of hot-melt adhesive for ironing diamonds

[0031] Add 10 parts by weight of polyethylene wax to the ribbon-stirred hot-melt adhesive reaction kettle, heat it to 160°C, and after it is completely melted, add 11 parts by weight of EVA resin (VA content is 28%, MI: 150g / 10min) , the EVA resin of 26 parts by weight (VA content is 28%, MI:6g / 10min), the antioxidant 1010 of 1 part by weight, the thermoplastic polyurethane of 4 parts by weight, the ethylene-butyl acrylate copolymer EBA3427AC of 4 parts by weight, Under the protection of nitrogen, control the temperature at 180°C, stir for 2 hours, add 40 parts by weight of styrene-modified C5 petroleum resin, control the temperature at 160°C, stir for 1 hour, vacuumize, enter the strip, cooling, The pelletizing process yields hot-melt hot melt adhesive S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com