Reactive polyurethane hot melt adhesive for TWS earphone bonding and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of many production and assembly processes, complex structure of TWS earphones, and large number of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

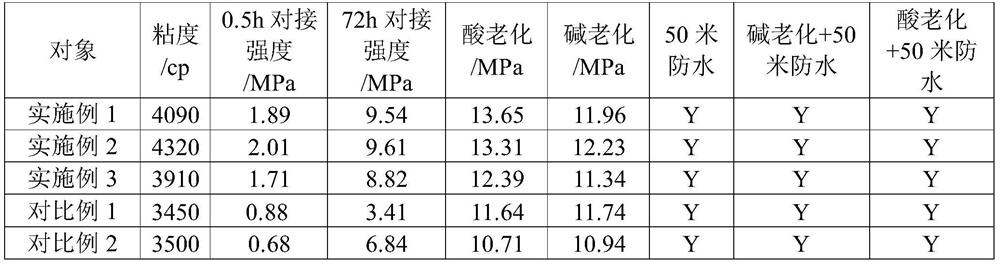

Examples

Embodiment 1

[0033] 10 parts of polyoxypropylene diol with molecular weight of 1000, 10 parts of crystalline polyester polyol (polycaprolactone polyol with molecular weight of 1000), 10 parts of liquid polyester polyol (molecular weight of 1000), high glass transition temperature Add 20 parts of acrylic resin (molecular weight 8000, Tg at 65°C) into the reaction kettle, vacuum dehydrate at 140°C for 2-h until the water content is less than 200ppm, then cool down to 80°C; add toluene diisocyanate into the system while stirring under nitrogen protection 15 parts and 15 parts of modified perovskite wire, after the addition is completed, vacuumize the reaction, slowly raise the temperature to 105 ° C, keep for 2 hours, add 0.01 part of bismorpholino diethyl ether agent, γ-aminopropyl trimethyl ether under the protection of nitrogen 0.1 part of oxysilane, 0.01 part of antioxidant 245, and vacuum reaction for 0.5-h to obtain polyurethane adhesive;

[0034] Wherein the preparation method of the m...

Embodiment 2

[0036] 20 parts of polyoxypropylene-oxyethylene diol with molecular weight of 2000, 20 parts of crystalline polyester polyol (polycarbonate diol with molecular weight of 3000), 20 parts of liquid polyester polyol (molecular weight of 3000), high vitrification Transition temperature: Add 25 parts of acrylic resin (molecular weight: 20000, Tg at 75°C) into the reaction kettle, vacuum dehydrate at 145°C for 2.5 hours until the water content is less than 200ppm, then cool down to 85°C; add diphenyl into the system while stirring under nitrogen protection 20 parts of methyl methane diisocyanate and 20 parts of modified perovskite wire. After the addition, vacuumize the reaction, slowly raise the temperature to 110°C, keep it for 2.5 hours, add 0.5 parts of triethyldiamine, γ-mercaptopropyl 1 part of triethoxysilane, 0.5 part of antioxidant 1035, and vacuum reaction for 0.7h to obtain a polyurethane adhesive;

[0037] Wherein the preparation method of the modified perovskite wire is...

Embodiment 3

[0039]30 parts of polyoxypropylene-oxyethylene diol with molecular weight of 4000, 30 parts of crystalline polyester polyol (polycaprolactone polyol with molecular weight of 6000), 30 parts of liquid polyester polyol (molecular weight of 6000), high glass Transformation temperature Acrylic resin (molecular weight 80000, Tg at 85°C) 30 parts into the reaction kettle, vacuum dehydration at 150°C for 3 hours until the water content is less than 200ppm, then lower the temperature to 90°C; add toluene into the system while stirring under nitrogen protection 25 parts of isocyanate and 30 parts of modified perovskite wire, after the addition is completed, vacuumize the reaction, slowly raise the temperature to 115 ° C, keep for 3 hours, add 1 part of triethyldiamine, γ-isocyanate propyl triethoxy 3 parts of silane, 1 part of antioxidant 245, and vacuum reaction for 1 hour to obtain polyurethane adhesive;

[0040] Wherein the preparation method of the modified perovskite wire is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com