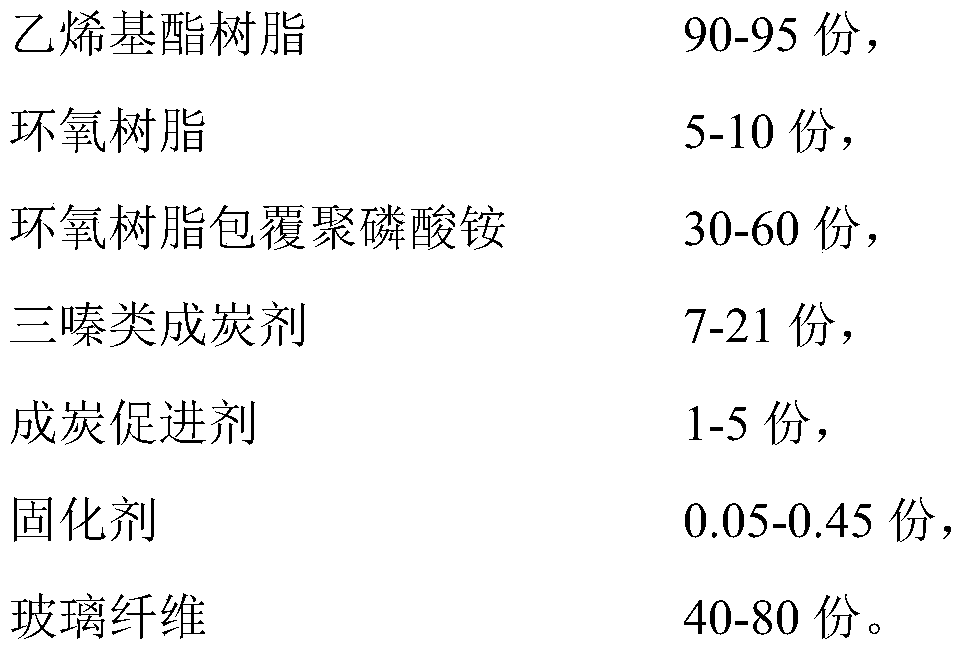

A kind of halogen-free flame-retardant vinyl ester resin compound and preparation method thereof

A technology of vinyl ester resin and compound, which is applied in the field of halogen-free flame retardant vinyl ester resin compound and its preparation, can solve the problems of enhancing the strength of the carbon layer, and achieve enhanced compatibility, enhanced physical structure and smoke suppression , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

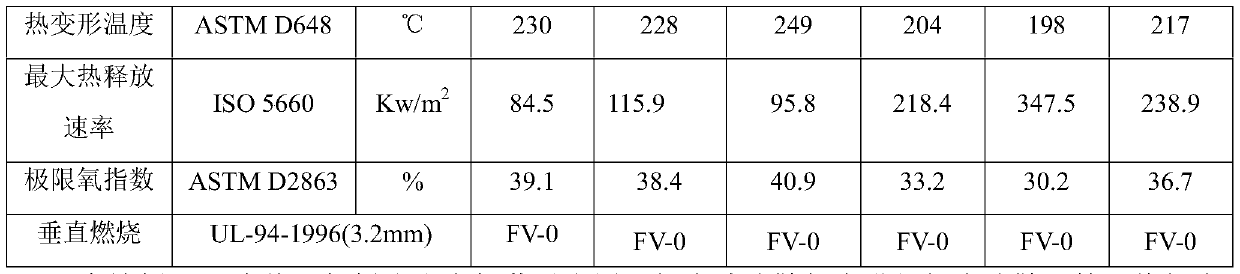

Examples

Embodiment 1

[0034] A halogen-free flame-retardant vinyl ester resin compound, made of the following components by weight: 90 parts of bisphenol A epoxy acrylic vinyl ester resin, 10 parts of bisphenol A epoxy resin, bisphenol Type A epoxy resin coated ammonium polyphosphate 45 parts (the degree of polymerization of ammonium polyphosphate is 2000), poly 2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent 14 parts , 5 parts of organic montmorillonite char-forming accelerator, 0.20 part of cyclohexanone peroxide, 0.05 part of diaminodiphenyl sulfone, and 60 parts of glass fiber.

[0035] Preparation:

[0036] (1) Coating bisphenol A type epoxy resin with ammonium polyphosphate, poly 2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent and organic montmorillonite The charring accelerator was dried in a drying oven at 80°C for 5 hours;

[0037](2) 10 parts of bisphenol-A epoxy resin and 5 parts of dried organic montmorillonite char-forming accelerator were accurately weigh...

Embodiment 2

[0041] A halogen-free flame-retardant vinyl ester resin compound, made of the following components by weight: 92.5 parts of bisphenol A epoxy methacrylic vinyl ester resin, 7.5 parts of bisphenol A epoxy resin, 45 parts of ammonium polyphosphate coated with bisphenol A epoxy resin (the degree of polymerization of ammonium polyphosphate is 2000), poly 2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent 14 parts, 3 parts of organic montmorillonite char formation accelerator, 0.20 part of dibenzoyl peroxide, 0.05 part of diaminodiphenyl sulfone, 60 parts of glass fiber.

[0042] Preparation:

[0043] (1) Coating bisphenol A type epoxy resin with ammonium polyphosphate, poly 2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent and organic montmorillonite to promote char formation The agent was dried in an oven at 80°C for 5 hours;

[0044] (2) Accurately weigh 7.5 parts of bisphenol A epoxy resin and 3 parts of dried organic montmorillonite according to the ab...

Embodiment 3

[0048] A halogen-free flame-retardant vinyl ester resin compound, which is made of the following components by weight: 95 parts of novolac epoxy vinyl ester resin, 5 parts of glycidylamine epoxy resin, glycidylamine ring 45 parts of ammonium polyphosphate coated with oxygen resin (the degree of polymerization of ammonium polyphosphate is 2000), 14 parts of poly-2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent, organic 1 part of desoiling and carbonization accelerator, 0.20 part of methyl ethyl ketone peroxide, 0.05 part of diaminodiphenyl sulfone, 60 parts of glass fiber.

[0049] Preparation:

[0050] (1) Coating ammonium polyphosphate, poly-2-ethylenediamine-4-phenoxy-1,3,5-triazine char-forming agent and organic montmorillonite char-forming agent with glycidyl amine epoxy resin The agent was dried in an oven at 80°C for 5 hours;

[0051] (2) Accurately weigh 5 parts of glycidylamine epoxy resin and 1 part of dried organic montmorillonite char-forming accelera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com