A kind of high-performance environment-friendly adhesive and preparation method thereof

An adhesive and environment-friendly technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor peel strength and flexibility of adhesives, poor flame retardancy of adhesives, and high cost, and eliminate Effect of gel phenomenon, improvement of flame retardancy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

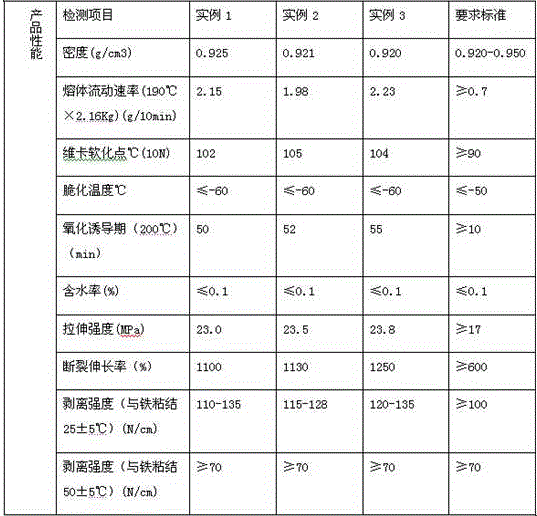

Examples

Embodiment 1

[0020] PE adhesive formula (100%) is as follows:

[0021] Polyolefin graft adhesive resin 60%, polyester elastomer 12%, tackifying resin 12%, polymerization inhibitor 3%, auxiliary agent 3%, modifier 5%, viscosity regulator 4%, antioxidant 1%, wherein, the formula (100%) of polyolefin graft bonding resin: high-density polyethylene 50%, linear low-density polyethylene 30%, copolymerized polypropylene 15.8%, maleic anhydride monomer 4%, 2 , 3-dimethyl-2, 3-diphenylbutane (DMDPB) 0.2%; Wherein, the composition of polyester elastomer is: TPES50%, EVA50%; Wherein the composition of tackifying resin is: C5 petroleum resin 50% %, terpene resin 25%, modified rosin resin 25%; the composition of the polymerization inhibitor is 50% dimethylacetamide (DMAC), 50% dimethyl sulfoxide (DMSO), and the auxiliary agent is ABX (two rubber and a certain sulfur compound) 50%, trimethylolpropane triacrylate 50%, the modifier is vinyl cage silsesquioxane, and the polyolefin graft is bonded The poly...

Embodiment 2

[0023] PE adhesive formula (100%) is as follows:

[0024] Polyolefin graft adhesive resin 50%, polyester elastomer 14%, tackifying resin 15%, polymerization inhibitor 3%, auxiliary agent 3%, modifier 10%, viscosity regulator 4.5%, antioxidant 0.5%, of which, the formulation of polyolefin graft adhesive resin (100%): high-density polyethylene 50%, linear low-density polyethylene 30%, copolymerized polypropylene 15.8%, maleic anhydride monomer 4%, tertiary Butyl hydroperoxide (BHPO) 0.2%; Among them, the composition of elastomer tackifying resin is: TPES25%, EVA75%; Wherein the composition of tackifying resin is: C5 petroleum resin 25%, terpene resin 50%, modified Rosin resin 25%; the raw materials of polyethylene and polypropylene components in the polyolefin graft adhesive resin formula are accurately weighed and then pulverized by a milling device, and then pre-mixed with other components by a high-speed mixer to ensure that each group The dispersion is uniform, and then the...

Embodiment 3

[0026] PE adhesive formula (100%) is as follows:

[0027] Polyolefin graft adhesive resin 55%, polyester elastomer 14%, tackifying resin 10%, polymerization inhibitor 3%, auxiliary agent 3%, modifier 10%, viscosity regulator 4.5%, antioxidant 0.5%, of which, the formulation of polyolefin graft adhesive resin (100%): high-density polyethylene 50%, linear low-density polyethylene 30%, copolymerized polypropylene 15.8%, maleic anhydride monomer 4%, tertiary Butyl hydroperoxide (BHPO) 0.2%; Among them, the composition of elastomer tackifying resin is: TPES25%, EVA75%; Wherein the composition of tackifying resin is: C5 petroleum resin 25%, terpene resin 50%, modified Rosin resin 25%; the polyethylene and polypropylene component raw materials in the polyolefin graft adhesive resin formula are accurately weighed and then pulverized by a milling device, and then pre-mixed with other components by a high-speed mixer to ensure that each group The dispersion is uniform, and then the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com