Polyolefin resin composition for pipe

A technology of polyolefin resin and resin composition, which is applied in the field of resin composition for micro-crosslinked modified polyethylene pipes, can solve the problems of unavailable price and grade, limited use range, complicated technology, etc., so as to reduce safety problems and avoid The effect of excessive cross-linking or insufficient cross-linking and reasonable dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

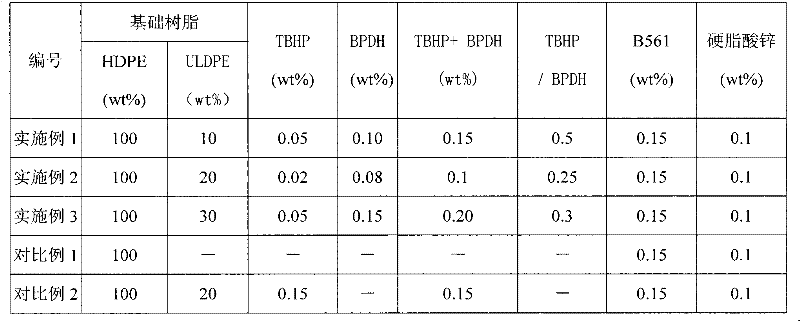

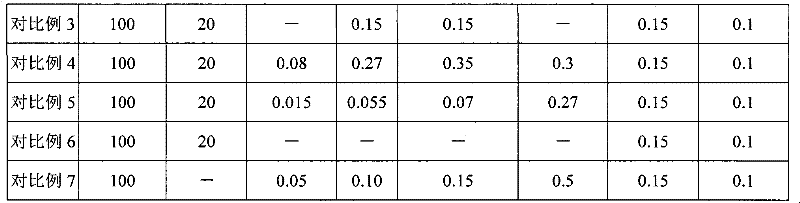

[0024] 1 raw material

[0025] resin

HDPE

ULDPE

MFR, g / 10min

0.17

1.5

ρ, g / cm 3

0.945

0.880

ESCR / hr

338

1460

manufacturer

China Petroleum

Jilin Petrochemical Company

ExxonMobil

company

[0026] Tert-Butyl Hydroperoxide Half-life T=264℃ / 1min, Lanzhou Auxiliary Factory

[0027] 2,5-Dimethyl-2,5-di-tert-butylperoxyhexane, half-life T=186℃ / 1min, Lanzhou Auxiliary Factory

[0028] Antioxidant B561 (1:4 compound mixture of antioxidant 1010 and antioxidant 168) Ciba, Switzerland

[0029] Zinc Stearate Chongqing Changjiang Chemical Plant

[0030] 2 performance test standard

[0031] Melt flow rate MFR (g / 10min) GB / T3682-2000

[0032] Density (g / cm 3 )GB / T1033-1986

[0033] Resistance to environmental stress cracking (h) GB / T 1842-2008

[0034] Tensile strength (MPa) GB / T 2567-2008

[0035] Izod impact strength (J / m) GB / T 1843-2008

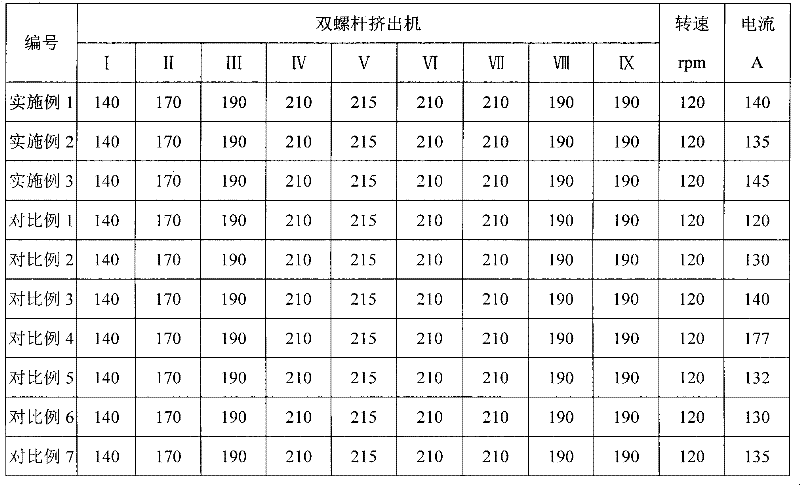

[0036] 3 Equipment and inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com