Shell for sound production device and sound production device

A sounding device and housing technology, applied in the direction of the transducer shell/cabinet/bracket, etc., can solve the problems of large space resistance, difficult to form thin walls, high density, etc., and achieve high assembly accuracy, small deformability, and strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

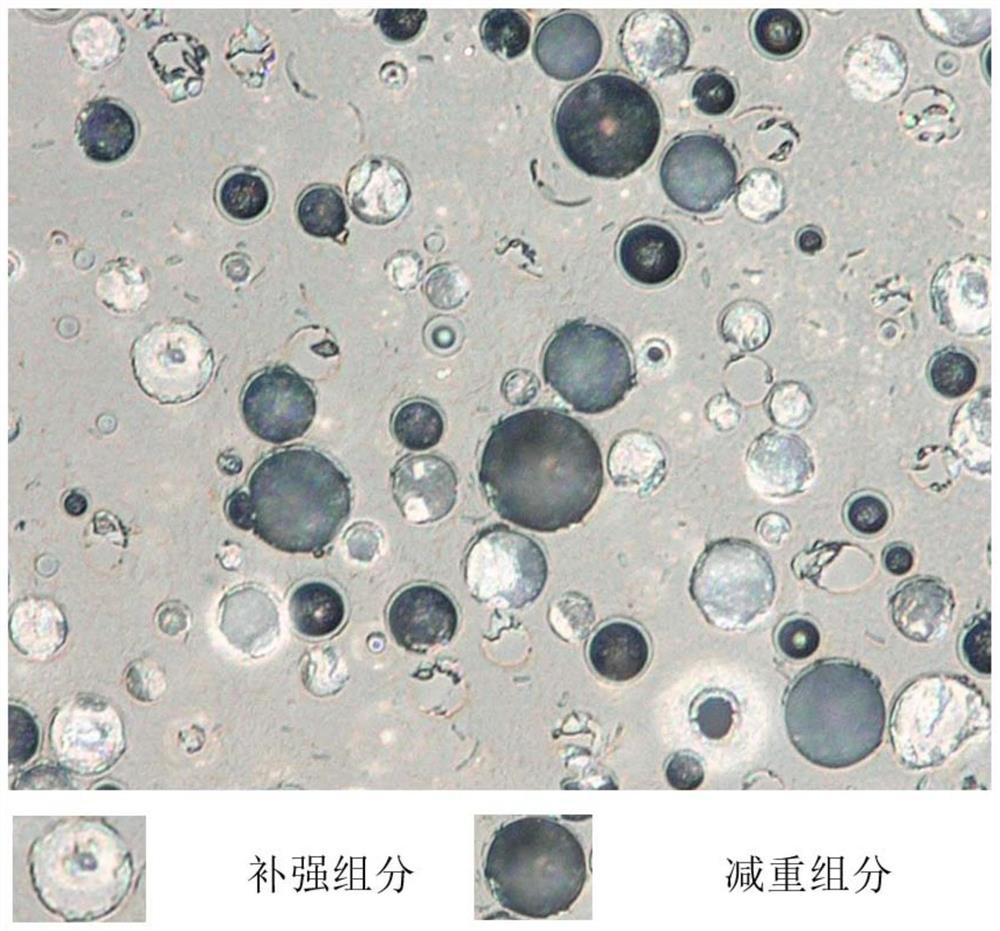

Method used

Image

Examples

Embodiment 1

[0081] Engineering plastics: syndiotactic polystyrene 90g;

[0082] Reinforcing components: glass fiber 22.5g, carbon fiber 0g;

[0083] Hollow glass beads 0g.

Embodiment 2

[0085] Engineering plastics: syndiotactic polystyrene 90g;

[0086] Reinforcing components: glass fiber 0g, carbon fiber 45g;

[0087] Hollow glass beads 0g.

Embodiment 3

[0089] Engineering plastics: syndiotactic polystyrene 90g;

[0090] Reinforcing components: glass fiber 0g, carbon fiber 5g;

[0091] Hollow glass beads 63g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com