Dismountable assembly push-assisting and pull-assisting device

A puller and component technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient operation, inability to realize the push-pull function well, and achieve the effect of reducing weight and realizing light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

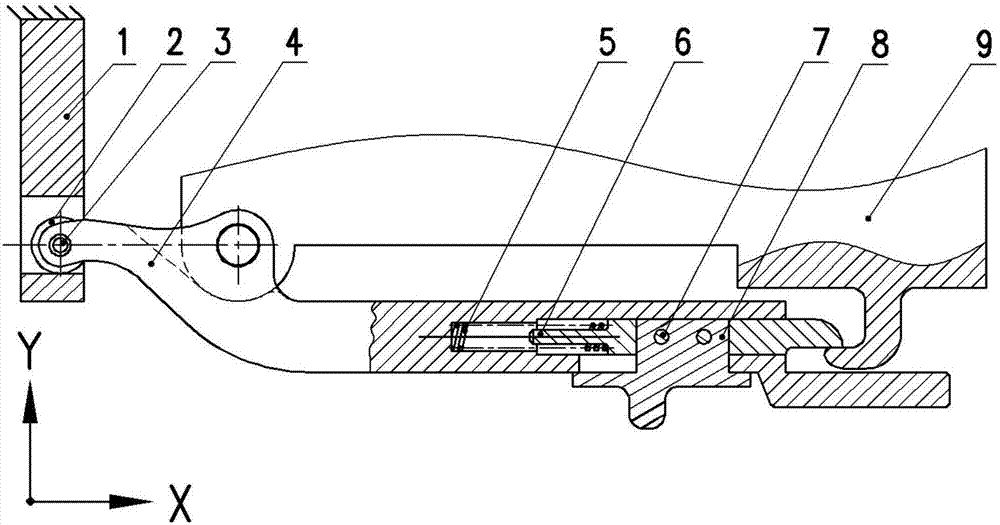

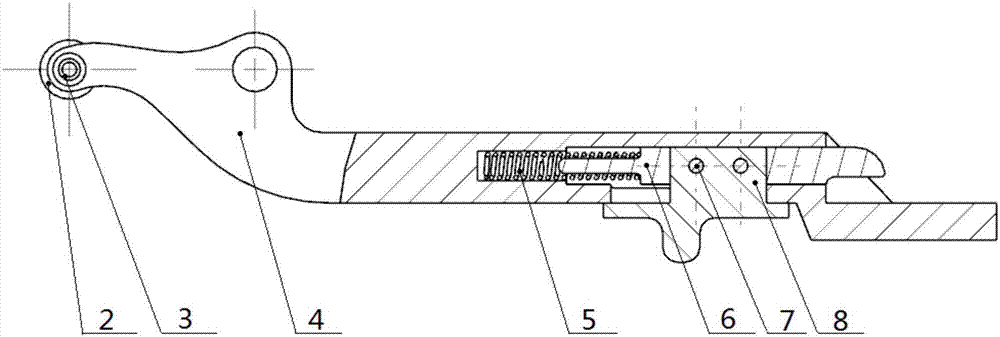

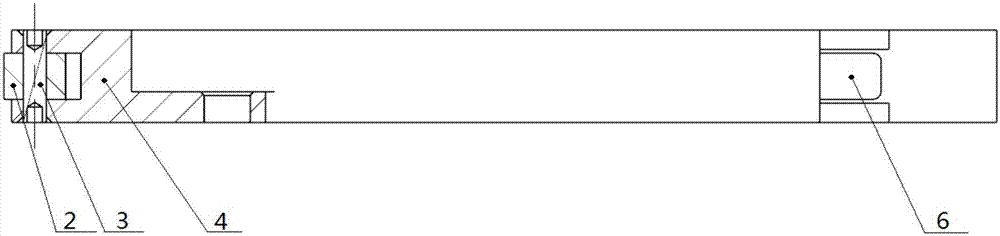

[0016] A detachable component booster and puller disclosed by the present invention includes a fixed base, a handle, and a component. The handle is connected with a roller, a card pin, and a pusher. The handle and the roller are riveted together by a bolt to form a rotating pair. The card pin and the pusher are riveted together through the latch, and there is a guide groove inside the handle for placing the spring and the card pin, and the card pin establishes a mobile pair connection relationship with the handle through the spring. The component can only move along the direction of the guide rail through the restriction of an external sliding guide rail. The component has a hook-shaped structure that cooperates with the card pin and locks, and a cylindrical boss that matches the through hole on the handle. The base is fixed, and there are grooves inside it that interact with the rollers.

[0017] In order to more clearly illustrate the specific solutions of the embodiments of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com