Dashboard beam assembly for pure electric vehicles

A pure electric vehicle and beam assembly technology, applied in the superstructure sub-assembly, vehicle components, superstructure and other directions, can solve the problems of complex fixture design, poor welding quality, low welding efficiency, etc., and achieve a good installation and matching relationship. , The effect of improving welding quality and reducing the rate of defective parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

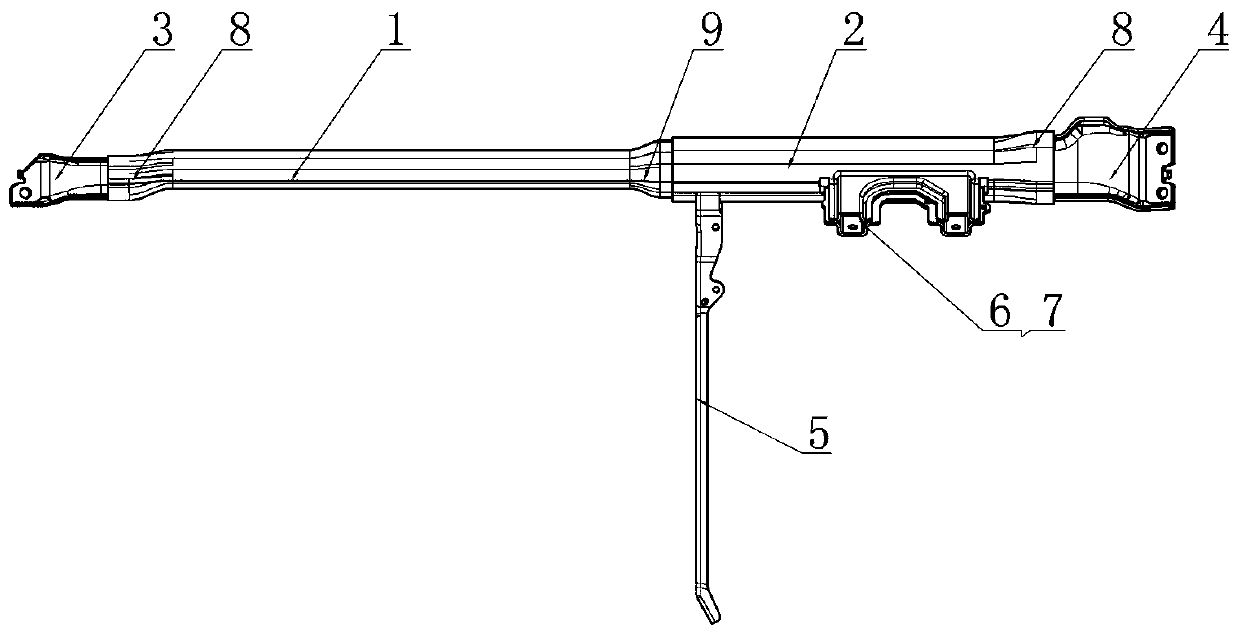

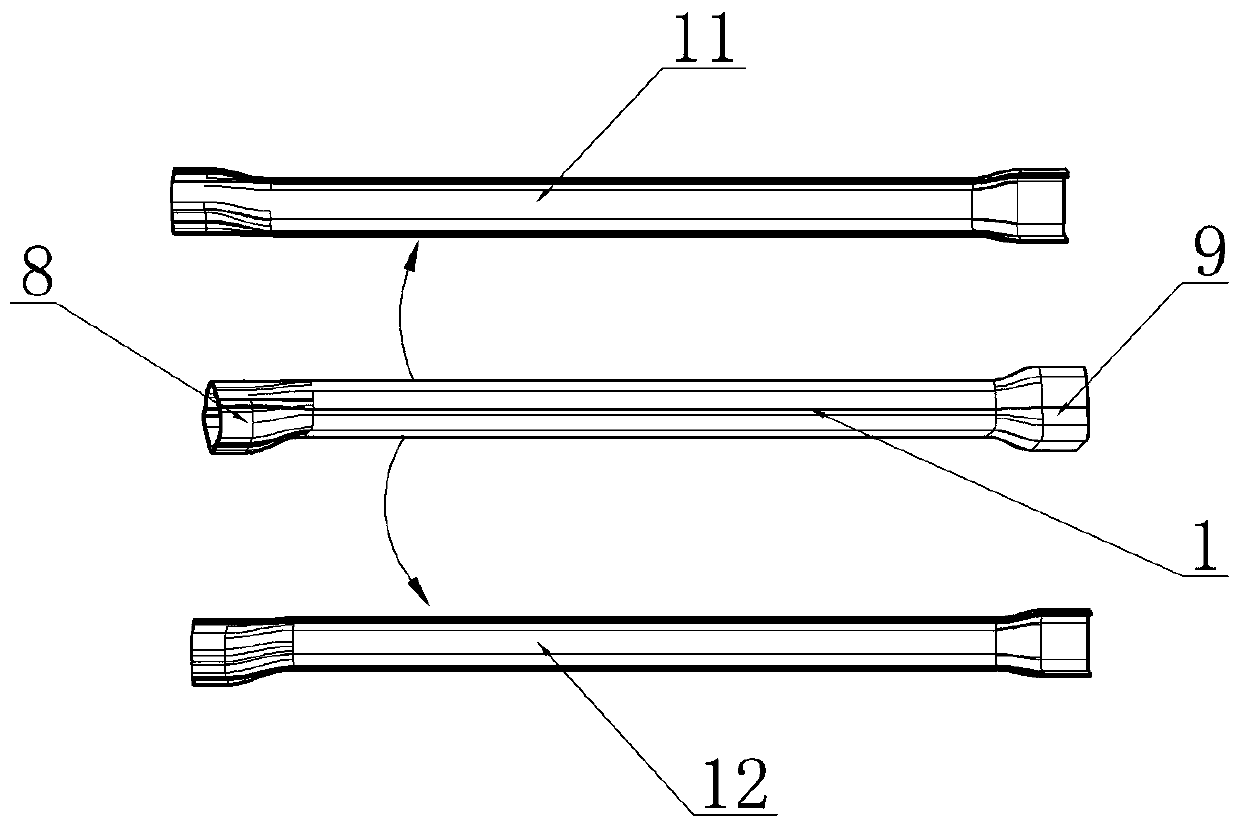

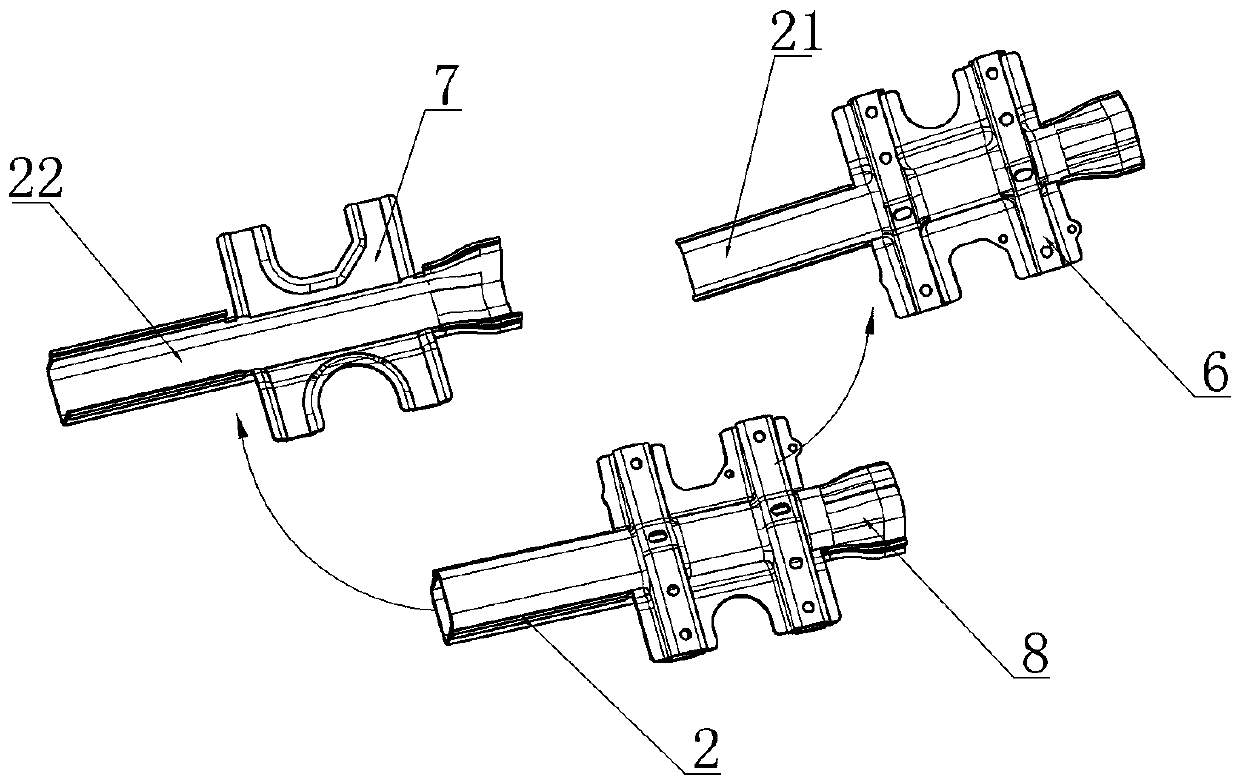

[0027] See Figure 1-Figure 6 , An instrument panel beam assembly of a pure electric vehicle, comprising a beam body, a left instrument panel beam connecting plate 3 arranged at the left end of the beam body, a right instrument panel beam connecting plate 4 arranged at the right end of the beam body, and a fixed arrangement In the longitudinal arm beam 5 in the middle of the beam body, the beam body includes a left tube beam 1 and a right tube beam 2 that are matched and sleeved and fixed, and the left tube beam 1 includes a U-shaped groove-shaped upper left and opposite openings. The tube beam 11 and the lower left tube beam 12, the right tube beam 2 includes an upper right tube beam 21 and a lower right tube beam 22 which are U-shaped grooves and open opposite to each other, and are arranged at the right end of the left tube beam There is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com