Diesel engine cylinder block of sedan and casting method thereof

A technology for cylinder blocks and diesel engines, which is applied to cylinders, cylinder heads, mechanical equipment, etc. It can solve the problems of not meeting the requirements of high strength, poor material density, and many casting defects, so as to achieve control of casting defects and high sand mold strength and hardness. , the effect of small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

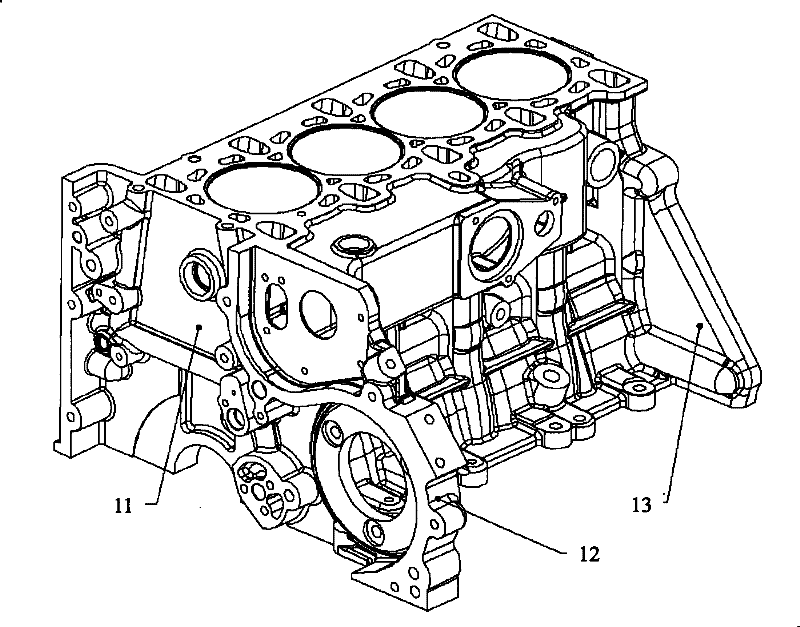

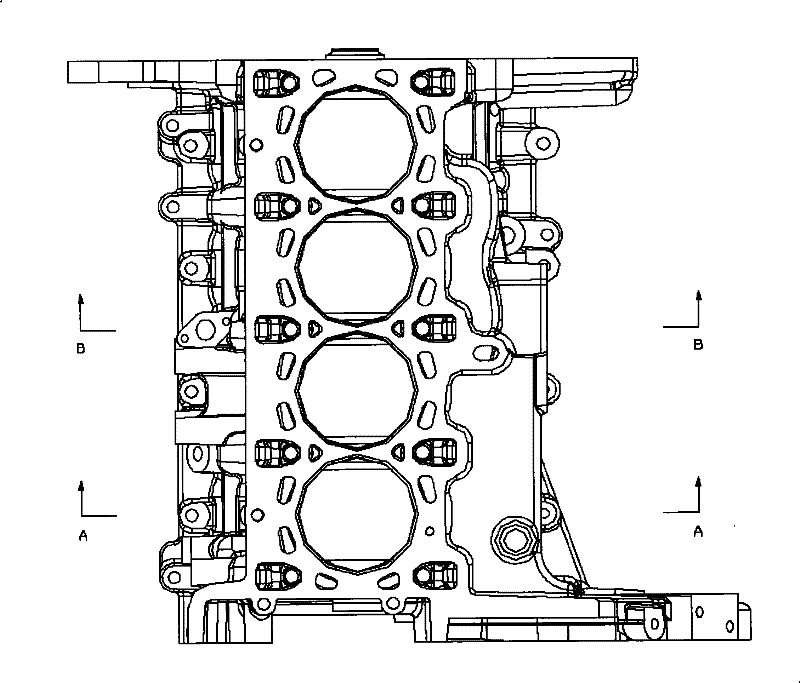

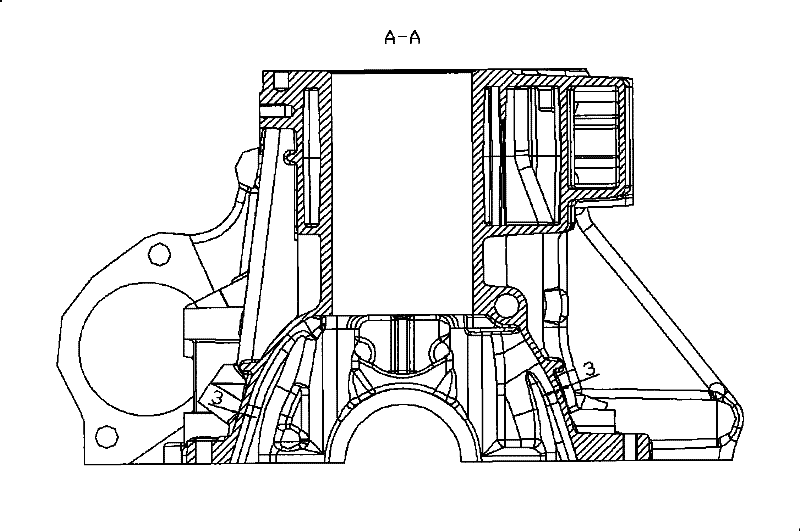

[0028] The invention discloses a cylinder block of a car diesel engine, which adopts vermicular graphite cast iron material, and simultaneously uses two vermicular agents of rare earth magnesium ferrosilicon and rare earth ferrosilicon, wherein the dosage of the rare earth magnesium ferrosilicon vermicular agent is 0.2% of the mass fraction of molten iron % to 0.3%; the amount of rare earth ferrosilicon vermicular agent is 0.3% to 0.5% of molten iron mass fraction (adjusted according to the sulfur content of molten iron), and the creep rate of the main parts of the casting is controlled between 80% and 95%. The formulations of the two vermicular agents can be determined according to the knowledge in the art.

[0029] At the same time, the goal of thin wall, light weight and high strength is realized by controlling the pouring process, and the wall thickness of the cylinder block is 3mm. The cylinder block castings are poured by gravity pouring with the top of the cylinder faci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com