Double-screw pulp-milling mechanism statistical tolerance design method

A twin-screw refiner and design method technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of long design cycle and high manufacturing cost, and achieve the goal of reducing processing cost, ensuring assembly quality, and reducing manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further described below in conjunction with embodiment; Following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

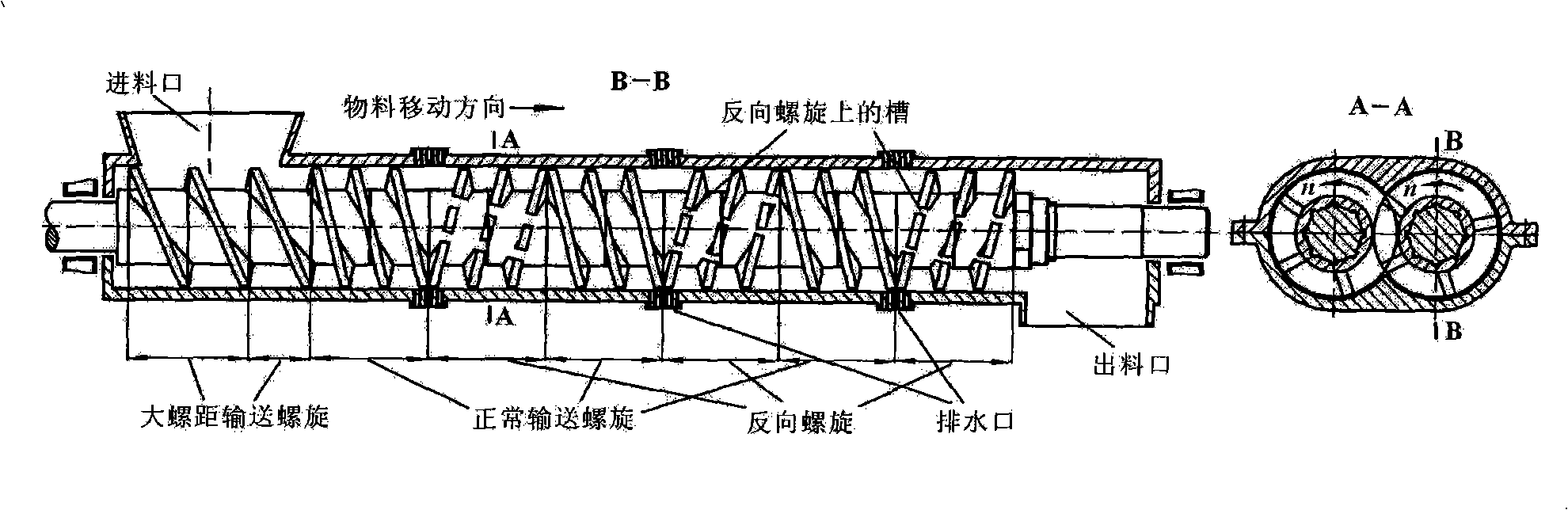

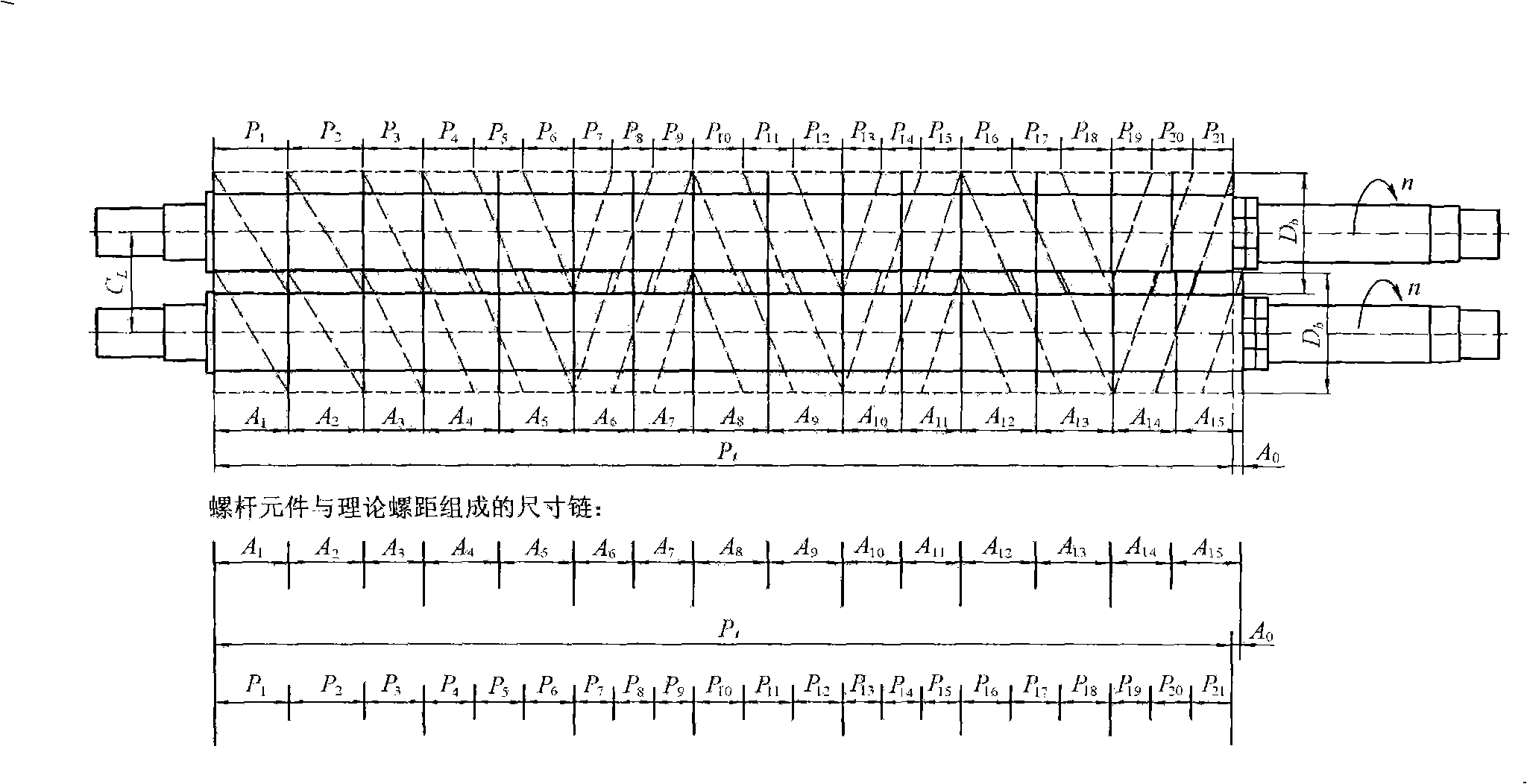

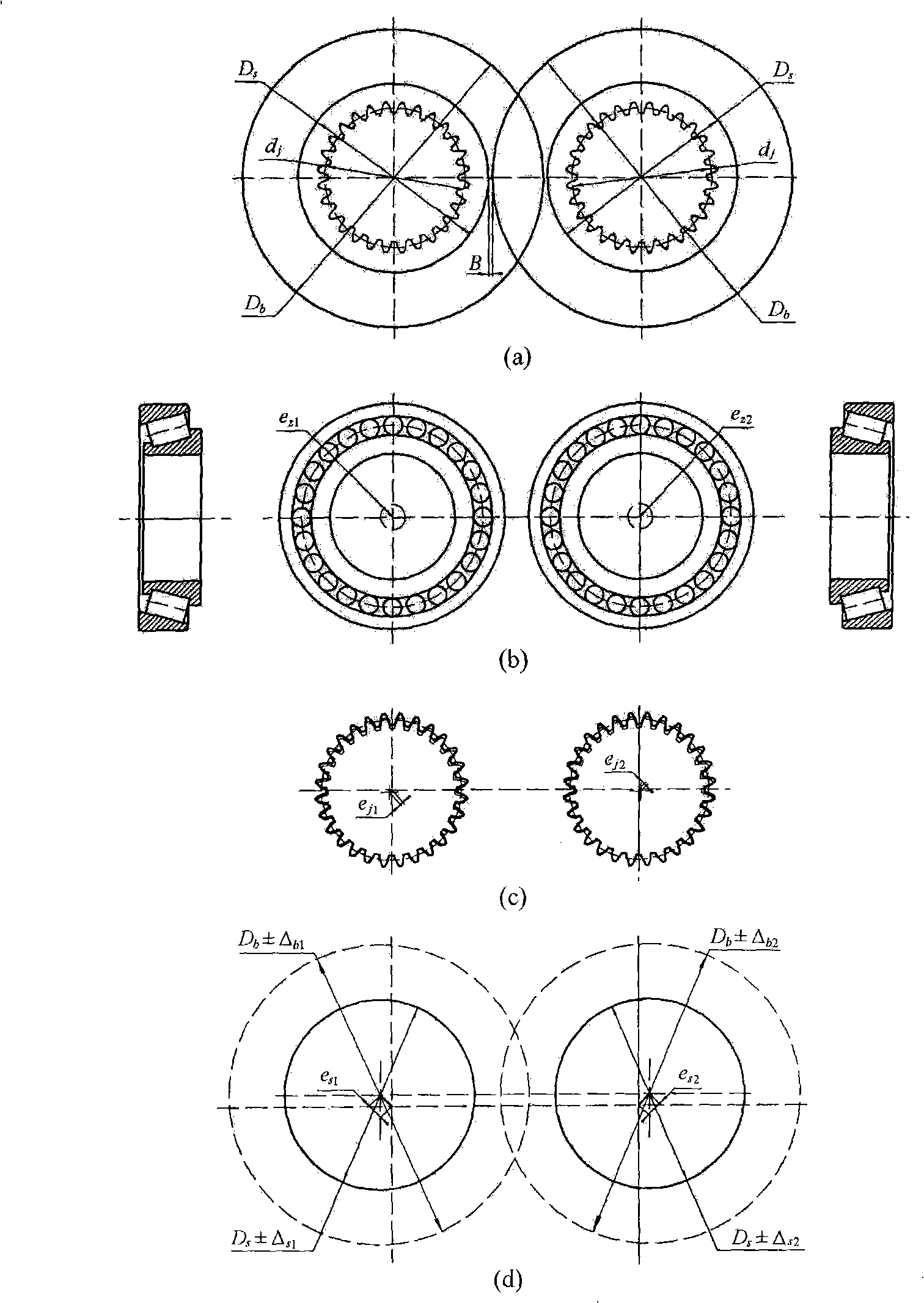

[0034] A statistical tolerance design method for a twin-screw refining mechanism is to combine the side clearance of the twin-screw refiner, the length of the threaded elements on the screw and the theoretical pitch of the thread to form a linear dimension chain in the axial direction of the twin-screw refining mechanism. The following expression:

[0035] A 0 = Σ i = 1 n + 1 ξ i A i = Σ i = 1 n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com