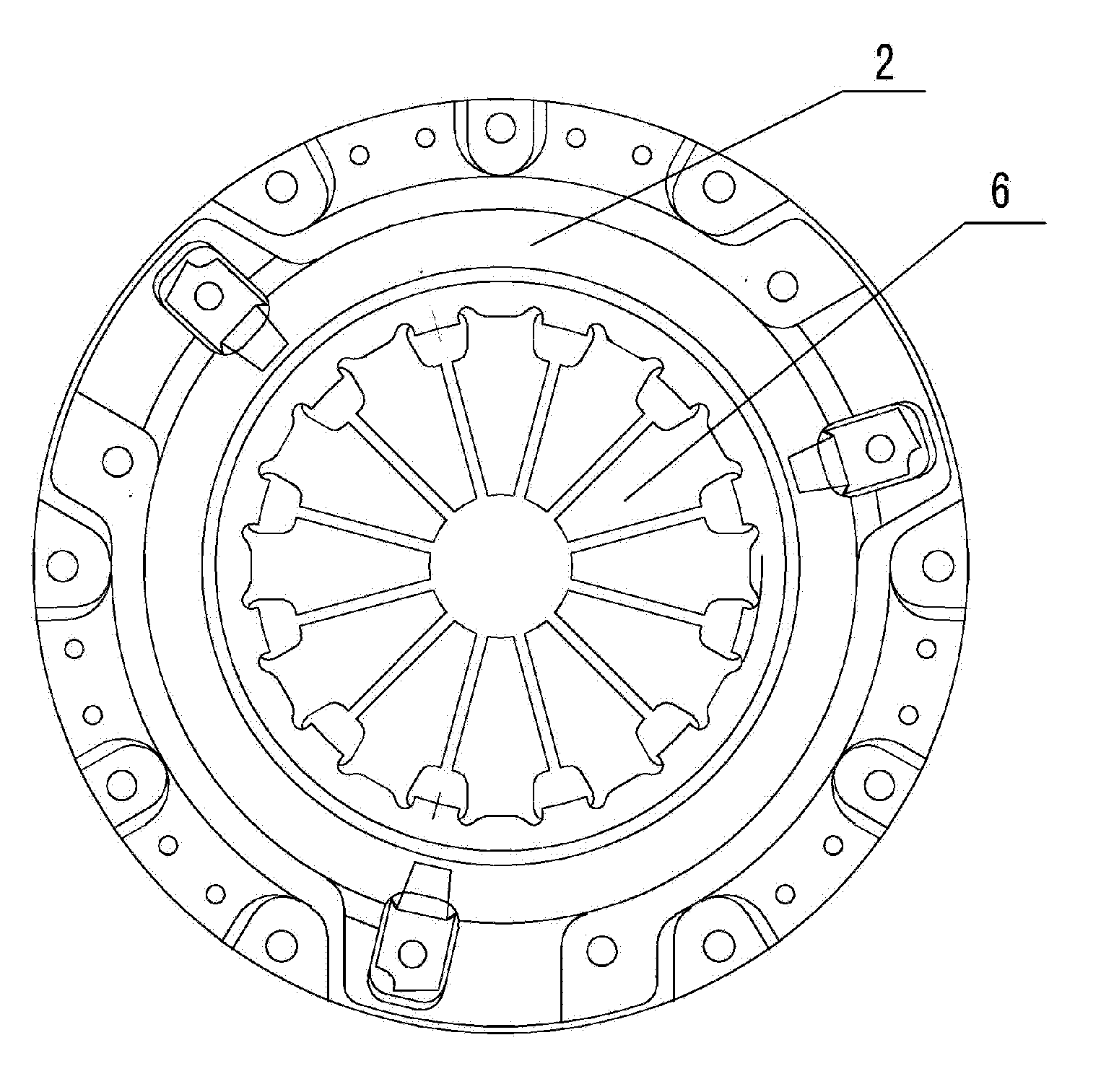

Separation finger jumping correction and detection device for automobile diaphragm spring clutch

A diaphragm spring and detection device technology, applied in measuring devices, instruments, metal processing, etc., can solve the problems of poor product consistency and low efficiency, and achieve the effects of high product consistency, high efficiency, and reliable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

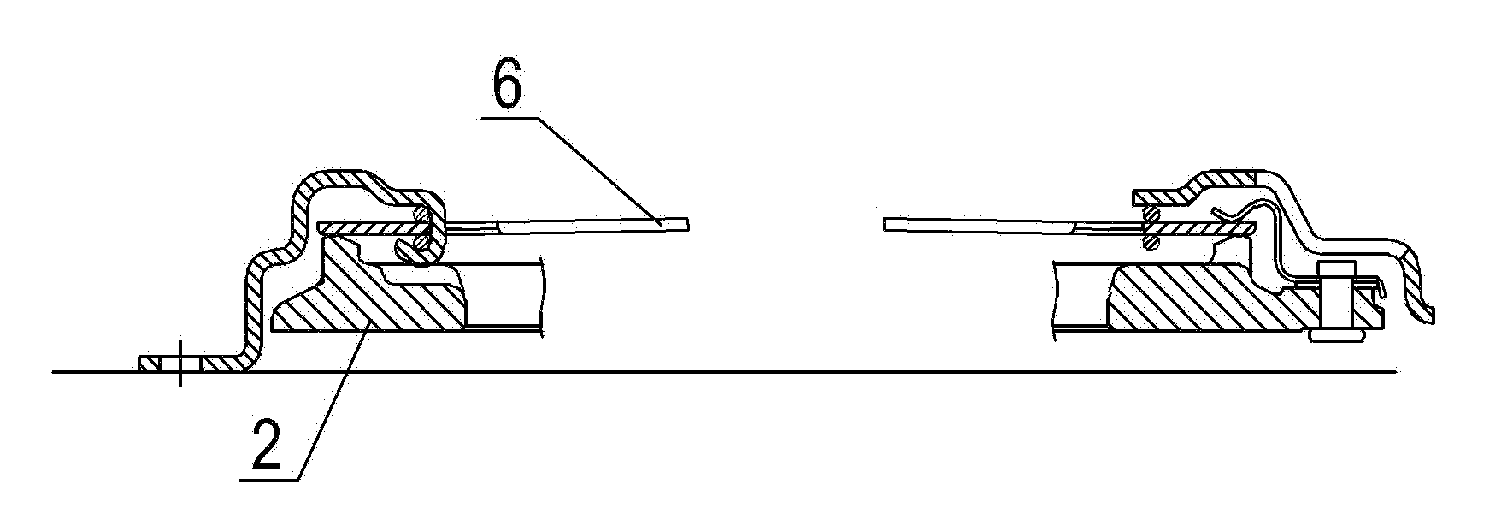

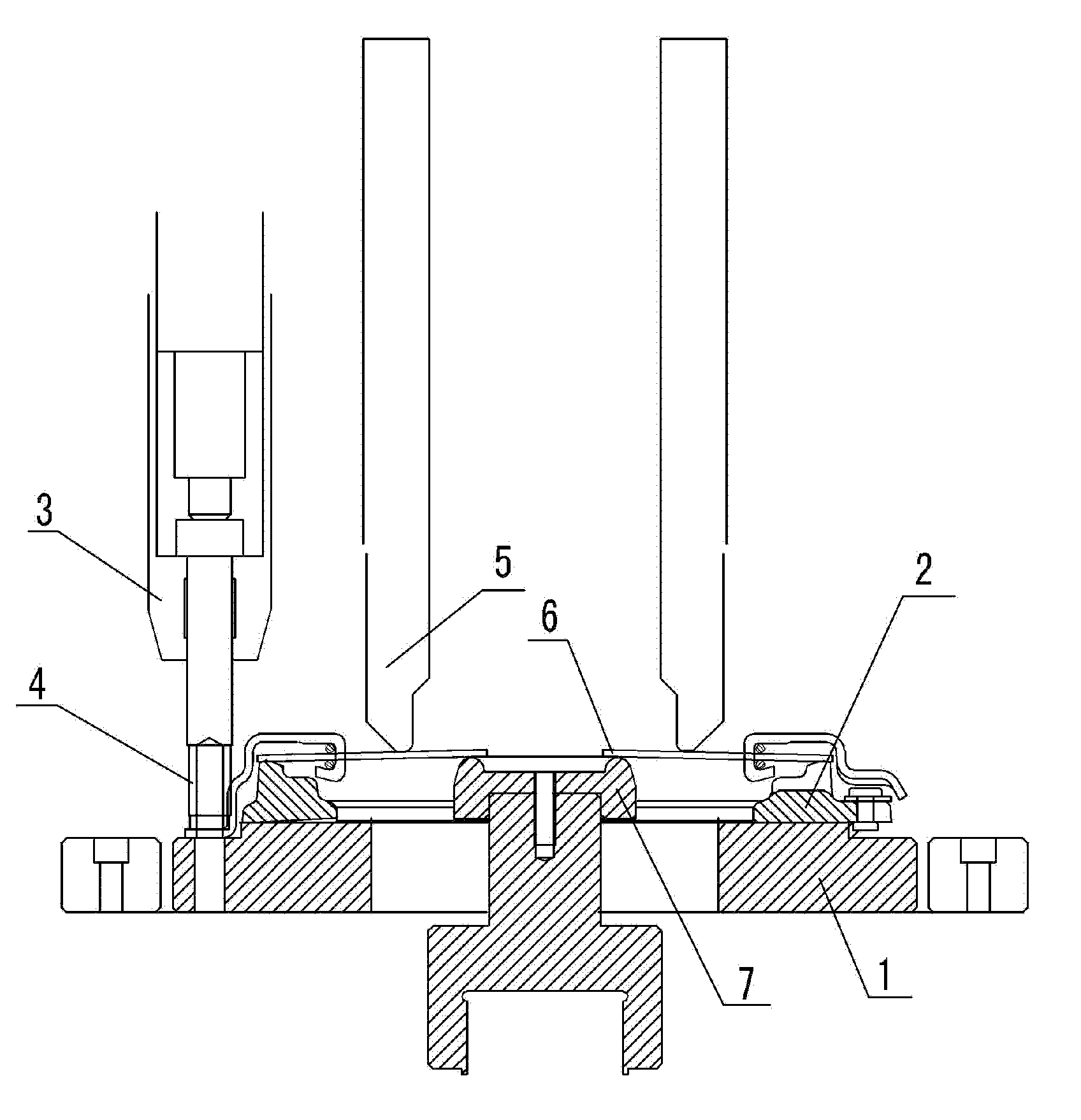

[0019] In the present embodiment, the jump correction and detection method of the separation finger of the automobile diaphragm spring clutch are as follows: at first, through product and tolerance design, the engagement height of the separation finger of the diaphragm spring clutch is controlled within the range of (L-1) ± 1; then correction and Detection, the correction and detection is to use the servo motor to drive the screw jack to push the separation point of the diaphragm spring clutch upward, so that the separation finger is deformed, and the joint height of the separation finger reaches the specified size range through deformation, ensuring The beating of the separation finger is within the specified tolerance range, where L is the standard value of the joint height of the separation finger.

[0020] In the present embodiment, the separation finger of the automobile diaphragm spring clutch is corrected and the detection method is carried out according to the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com