A New Structure of Trailer Suspension System

A suspension system, a new type of technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of limited height, insufficient strength and small height of the longitudinal beam above the suspension, so as to increase the strength, improve the performance, The effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

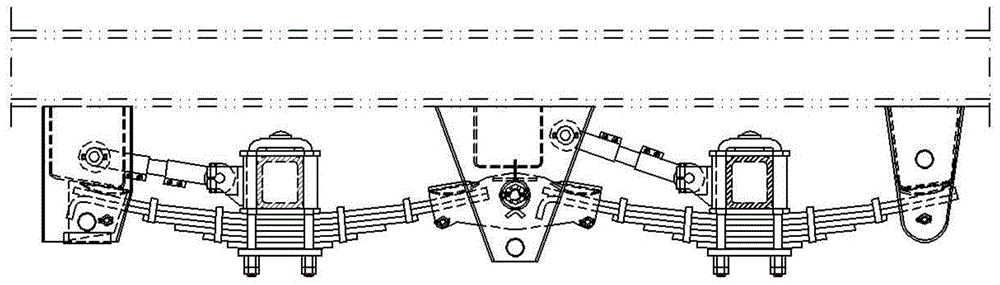

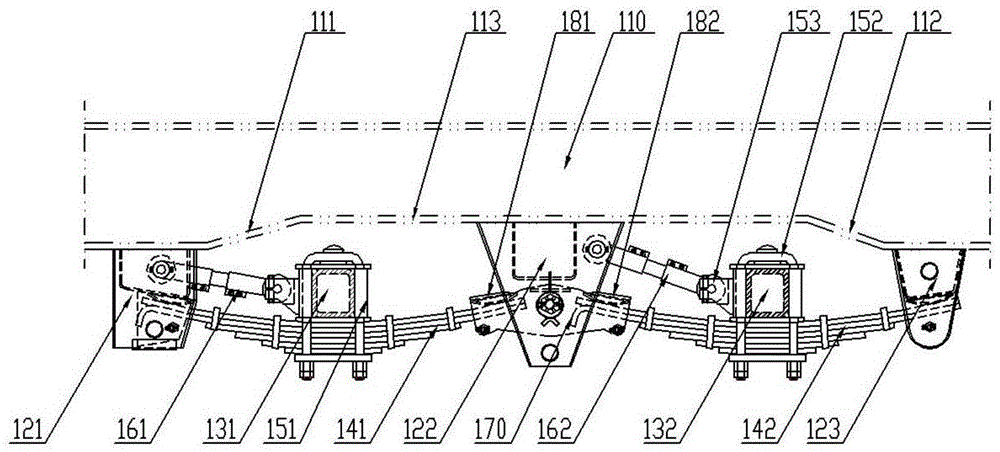

[0022] A kind of novel trailer suspension system structure of the present embodiment is two-axle suspension, such as figure 2 As shown, it has a front axle 131 and a rear axle 132 .

[0023] The trailer suspension system includes: the first support 121 of the front suspension, the second support 123 of the rear suspension, the first leaf spring 141, the second leaf spring 142, the first torsion bar 161, the second torsion bar 162, and the balance arm 170 and other parts. The balance arm 170 is arranged on the balance support 122 of the middle connection mechanism. The front end of the balance arm 170 has a front connection point 181 for connecting the first leaf spring 141, and the rear end of the balance arm 170 has a connection point 181 for connecting the second leaf spring 142. The rear end connection point 182 of the first leaf spring 141 is connected to the first support 121 at the front end, the rear end of the first leaf spring 141 is connected to the front end conne...

Embodiment 2

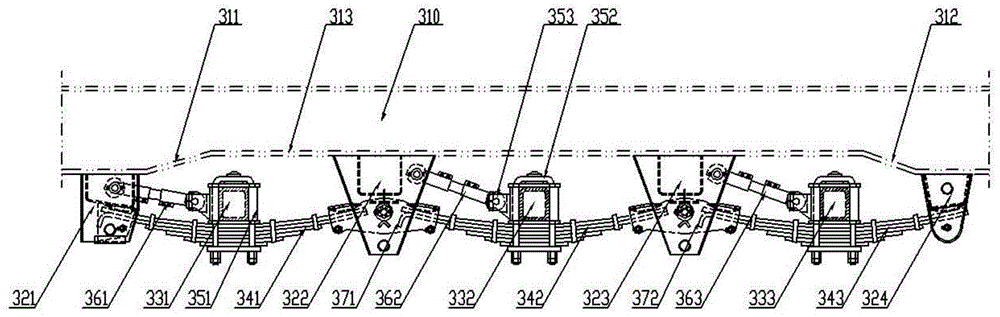

[0026] Such as image 3 As shown, a novel trailer suspension system structure of the present embodiment is a three-axle suspension, which has a front axle 331, a central axle 332 and a rear axle 333, and the central axle 332 is located at the middle of the frame longitudinal beam of the trailer. 331 and the central axis 332 .

[0027] The trailer suspension system includes: first support 321, front support 322, rear support 323 and second support 324, first leaf spring 341, third leaf spring 342, second leaf spring 343, first torsion bar 361 , the third torsion bar 362, the second torsion bar 363, the first balance arm 371, the second balance arm 372 and other components. The first balance arm 371 and the second balance arm 372 are respectively arranged on the supports 322, 323. The manner is the same as in the first embodiment. The installation methods of the first torsion bar 361 , the third torsion bar 362 and the second torsion bar 363 are also the same as those in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com