Dummy shaft for machining of doubly-fed wind generator collecting ring

A technology for wind power generators and collector rings, which is applied in the direction of collector maintenance, etc. It can solve the problems of collector ring surface burns, collector ring slideway burning, and cost increase, so as to ensure repair accuracy and quality, and make manufacturing convenient and practical , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

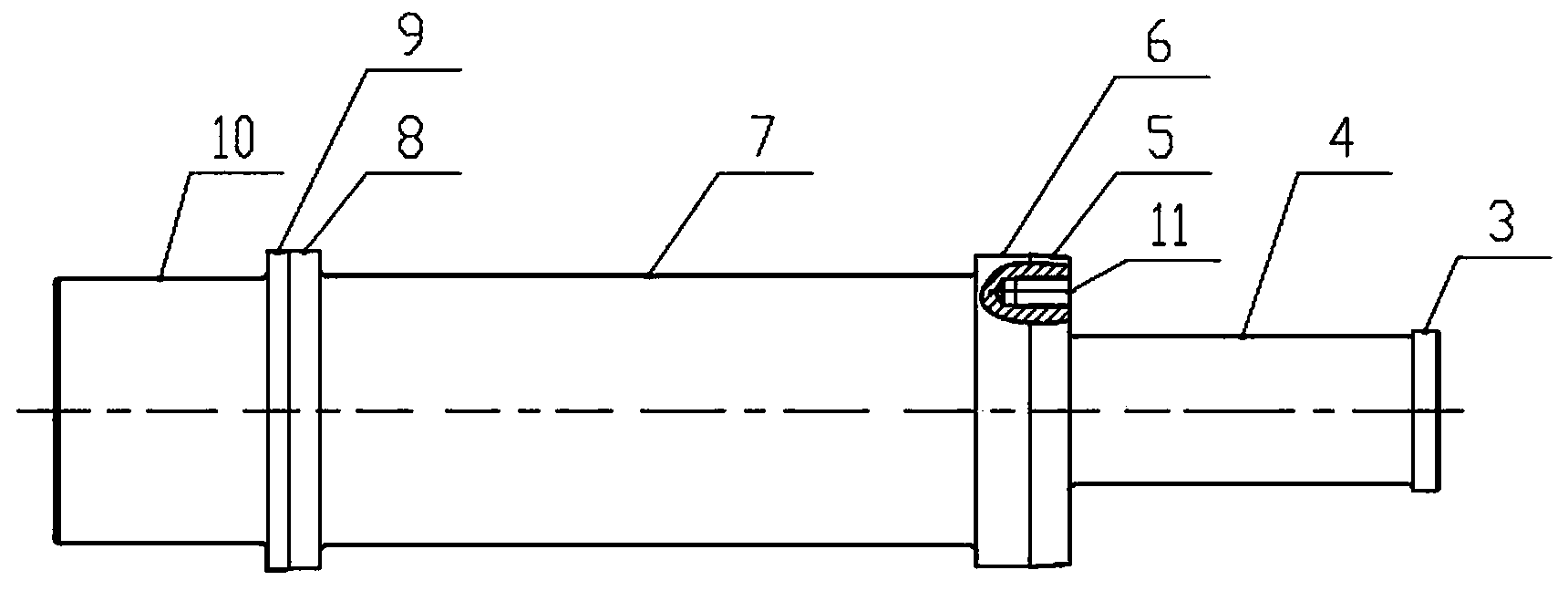

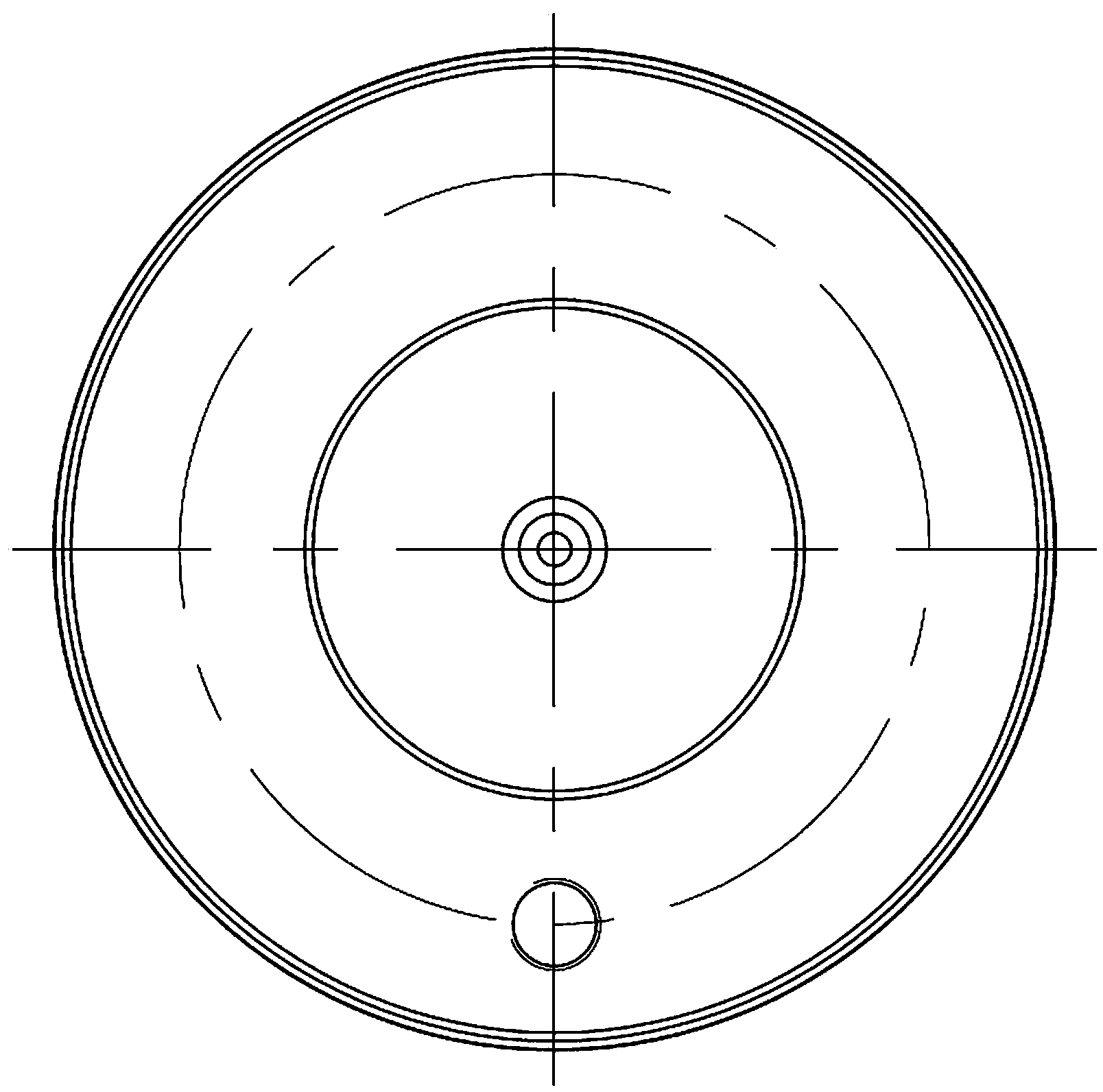

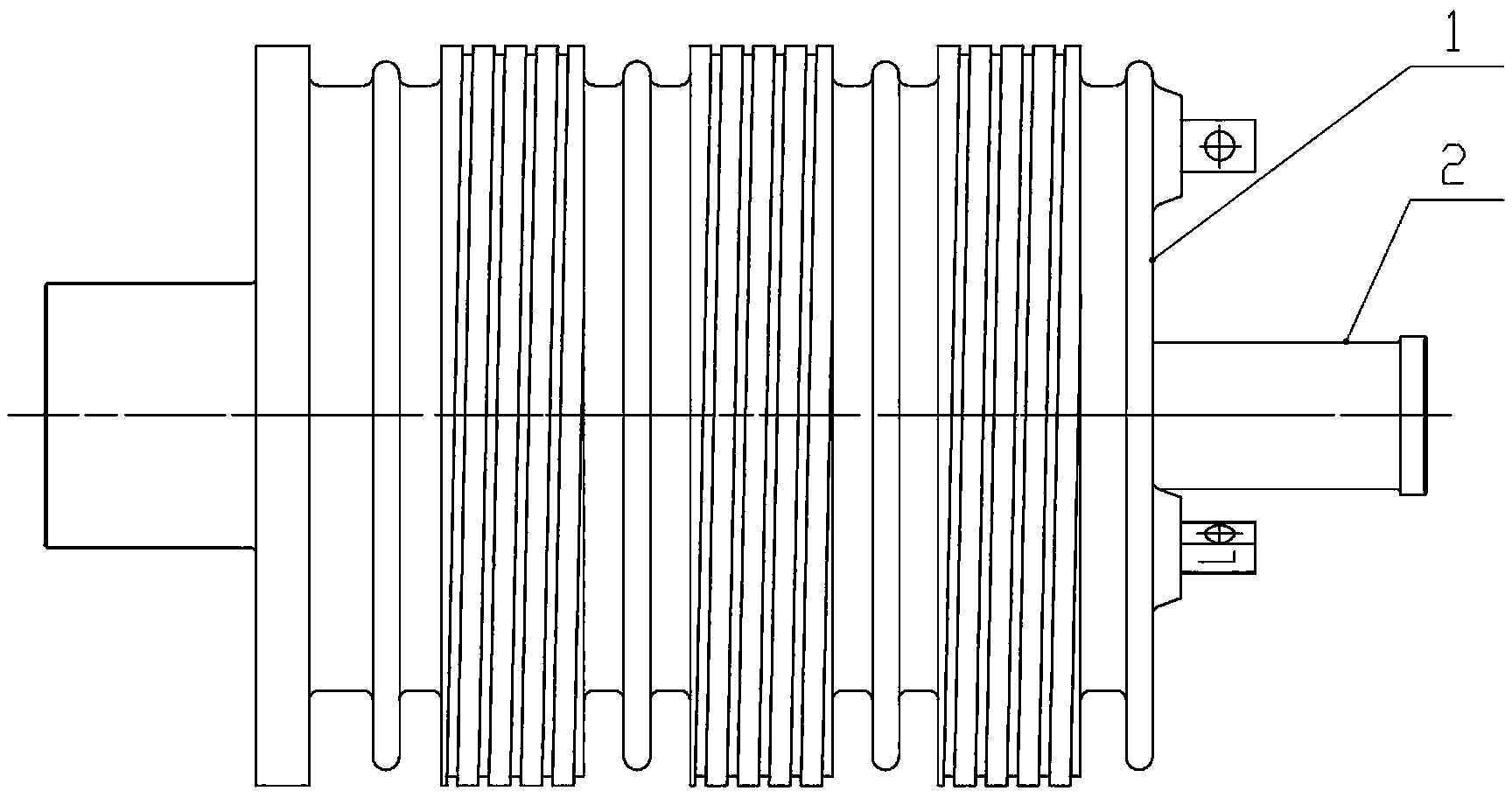

[0016] Such as figure 1 , 2 , 3, 4, and 5, the slip ring processing dummy shaft 2 consists of protruding shafts 8 and 6 respectively arranged on the two ends of the concave shaft 7 to form an I-shaped structure, and the two slip ring processing dummy shafts 2 The diameter of the protruding shafts 8, 6 matches the diameter of the inner hole of the collector ring 1, the axial distance between the two protruding shafts 8, 6 matches the axial length of the concave shaft 7 of the collector ring 1, when the collector When the electric ring processing dummy shaft 2 is installed in the inner hole of the collector ring 1, a small gap can be formed between the collector ring processing dummy shaft 2 and the inner hole of the collector ring 1, and the collector ring processing dummy shaft 2 has an I-shaped The type structure can reduce the contact area between the collector ring 1 and the collector ring processing dummy shaft 2, so as to reduce the resistance; the outer side of the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com