Vehicle body auxiliary clamping method for assisting robot in automatic arc welding

An automatic arc and auxiliary clamping technology, applied in arc welding equipment, welding equipment, welding accessories, etc., to achieve the effect of reducing manufacturing cost, improving production efficiency, and excellent engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

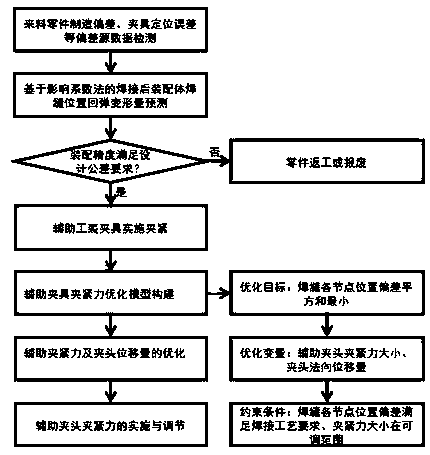

[0051] Example figure 1 As shown, the vehicle body auxiliary clamping method for assisting robotic automatic arc welding of the present invention comprises the following steps:

[0052] Step 1. Clamp the incoming parts of the body with welding fixtures, and collect the manufacturing deviation data of all incoming parts;

[0053] Step 2. Judging the phenomenon of separation of the incoming parts clamped on the welding fixture. If there is no separation between the incoming parts, the arc welding robot will automatically weld the target weld, otherwise it means that the incoming parts There is a large deviation compared to its standard value, resulting in a departure;

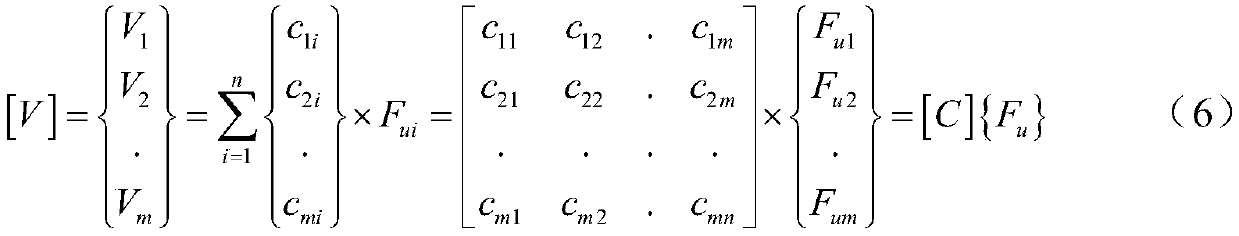

[0054] Step 3. According to the collected manufacturing deviation data of the incoming parts, the springback deformation of the weld position of the assembly after welding is calculated through the sensitivity matrix;

[0055] Step 4. If the springback deformation meets the design tolerance requirements, use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com