Guide cylinder-free automatic inclinator of unmanned helicopter

An automatic tilter, unmanned helicopter technology, applied in the direction of motor vehicles, rotorcraft, aircraft, etc., can solve the problems of poor reliability and maintenance, high cost, inconvenient maintenance, etc., to improve reliability and fatigue life, reduce design The effect of manufacturing cost and convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

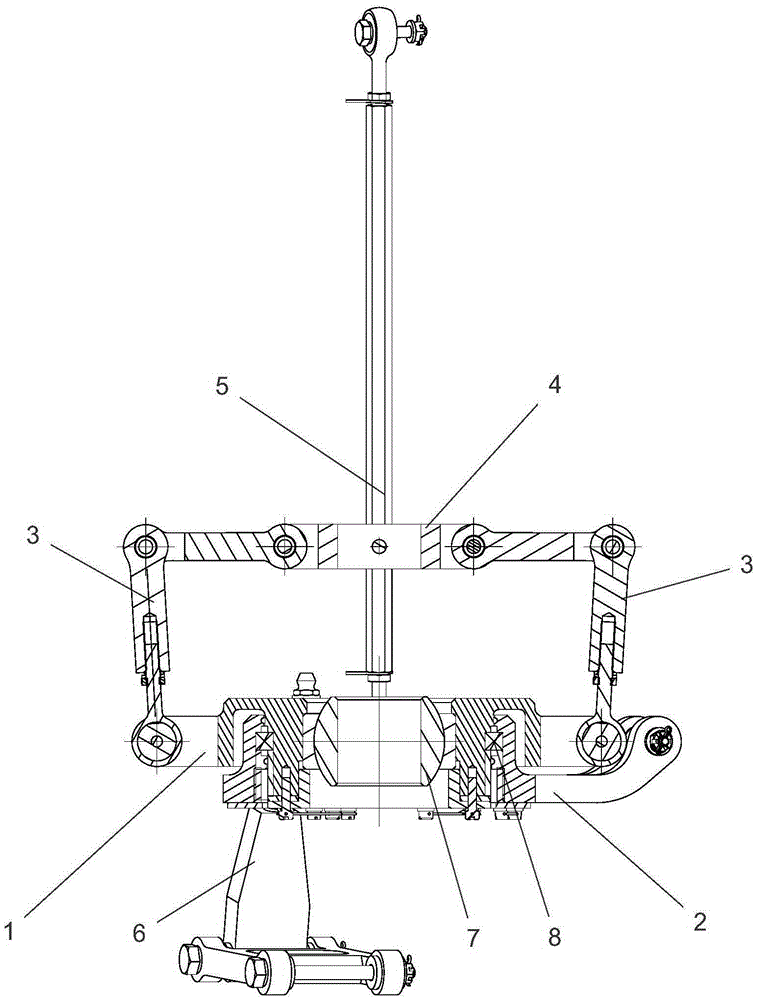

[0020] A cylinder-free automatic tilter for an unmanned helicopter includes a moving ring 1 , a stationary ring 2 , a pitch-variable pull rod assembly 5 , a torque arm assembly 3 , a snap ring 4 , an anti-twist arm assembly 6 and a ball joint assembly 7 .

[0021] The pitch-variable pull rod assembly 5 includes a rod body of the pitch-variable pull rod and shank joint bearings at both ends of the rod body, and the rod body and the shank joint bearings are fixedly connected by threads.

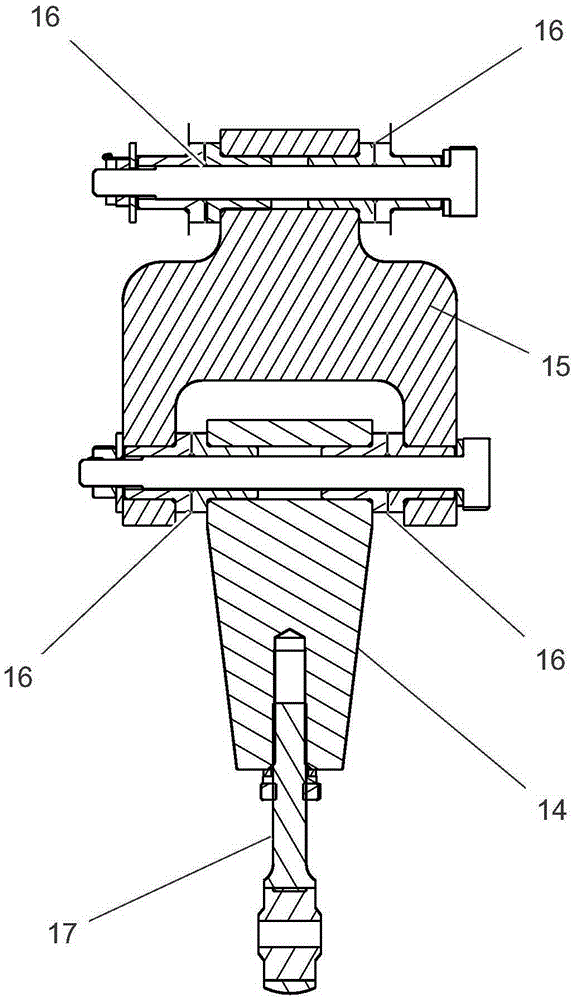

[0022] The torque arm assembly 3 includes a torque arm square arm 15 , a torque arm triangular arm 14 and six self-lubricating bushes 16 . Four self-lubricating bushings 16 are installed in the bolt holes of torque arm square arm 15, and two self-lubricating bushings 16 are installed in the bolt holes of torque arm triangular arm 14, between torque arm square arm 15 and torque arm triangular arm 14 connected by bolts. Using the self-lubricating bush 16 to replace the traditional wear-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com