Actual-condition tolerance modeling method based on Jacobian spinors

A technology of actual working conditions and modeling methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as digital model differences

- Summary

- Abstract

- Description

- Claims

- Application Information

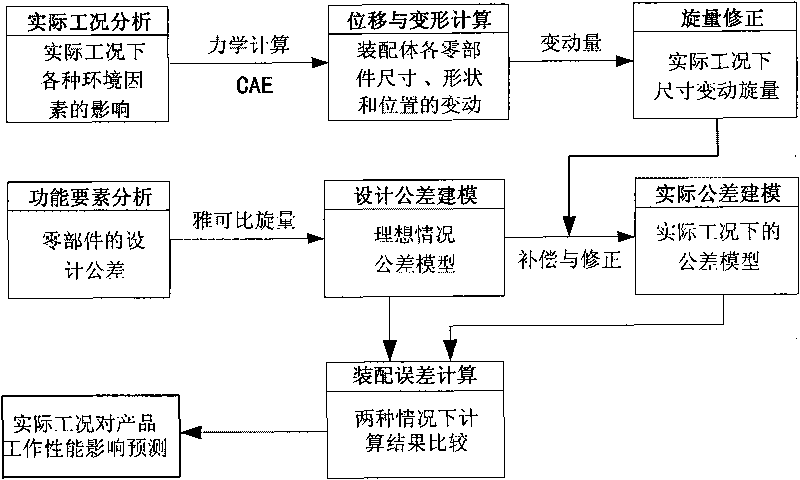

AI Technical Summary

Problems solved by technology

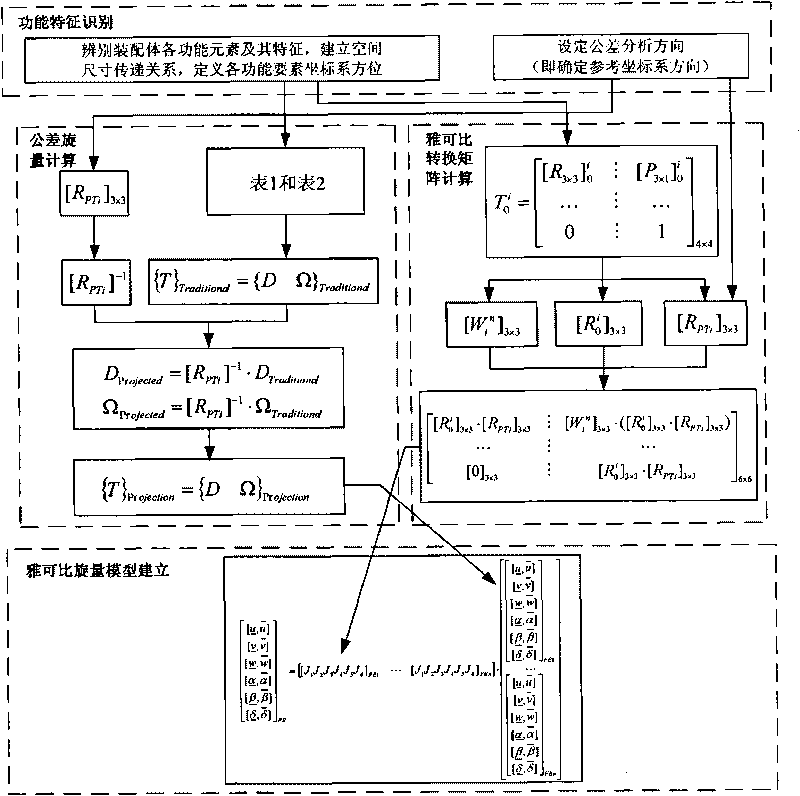

Method used

Image

Examples

Embodiment 1

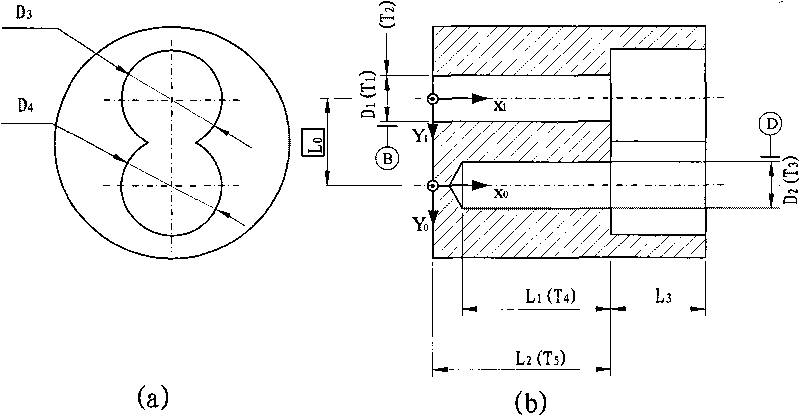

[0107] Embodiment 1: Take a certain gear pump as an example to carry out case analysis. Number of teeth z=10, modulus m=1.5, tooth width 16mm, rated pressure 25MPa, rated speed 1450r / min. The gear pump assembly consists of three parts: pump body P1 (see image 3 ), driving gear P2 (see Figure 4 ), driven gear P3 (see Figure 5 ), the assembly requirement that needs to be guaranteed and controlled among the three is the meshing gap between the two gears. A, B, C, D in the figure are reference codes, T i is the tolerance code, and the corresponding tolerance values are shown in Table 3, D i with L i is the part size, and the corresponding size values are shown in Table 4.

[0108] Tolerance code and corresponding tolerance value in the embodiment of table 3

[0109]

[0110] Dimension codes and corresponding dimension values in the embodiment of Table 4

[0111]

[0112] The first step is to establish an assembly model under ideal conditions and calculate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com