Modularized integrated smoke purification system and method for removing plurality of pollutants

A flue gas purification system and pollutant technology, applied in the field of flue gas purification, can solve problems such as equipment corrosion, flue gas cannot be effectively lifted, diffused, and polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

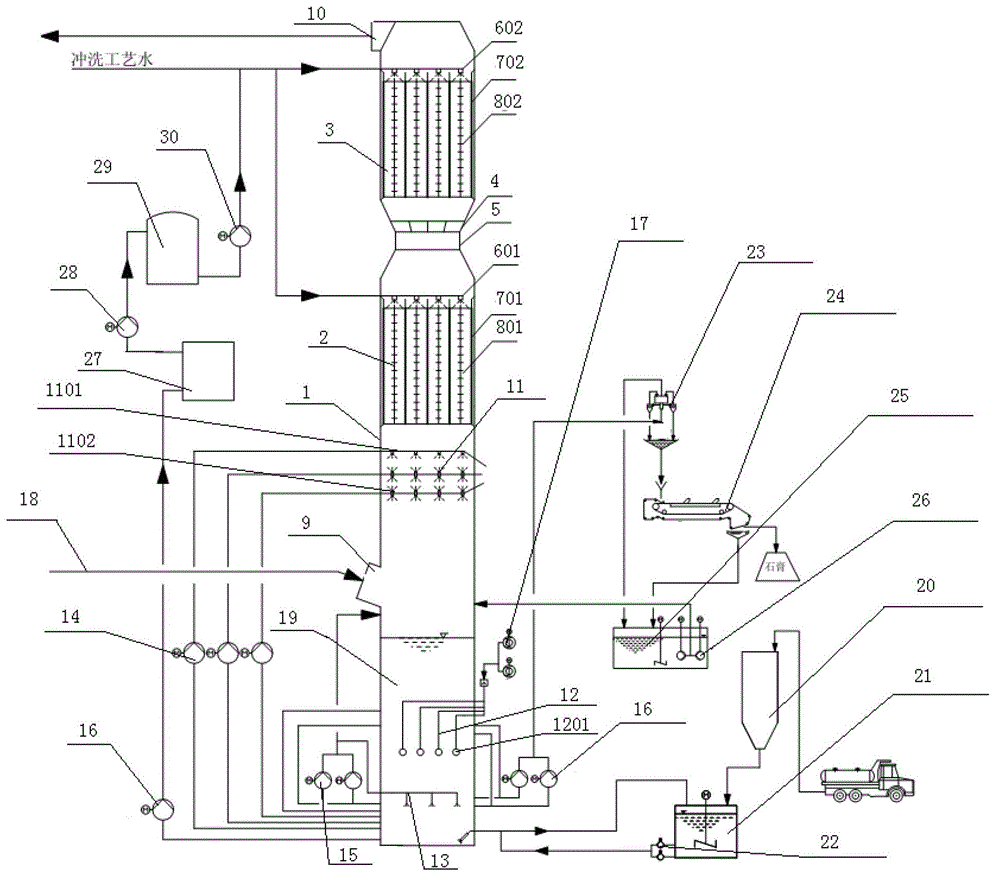

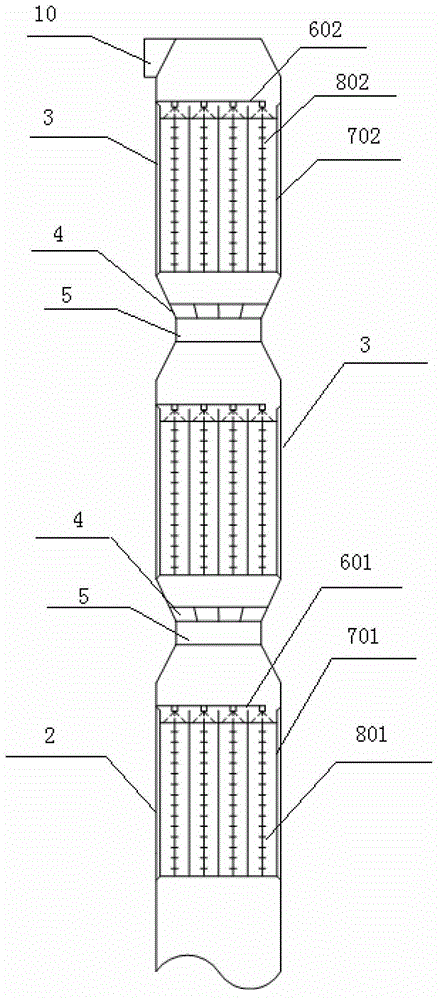

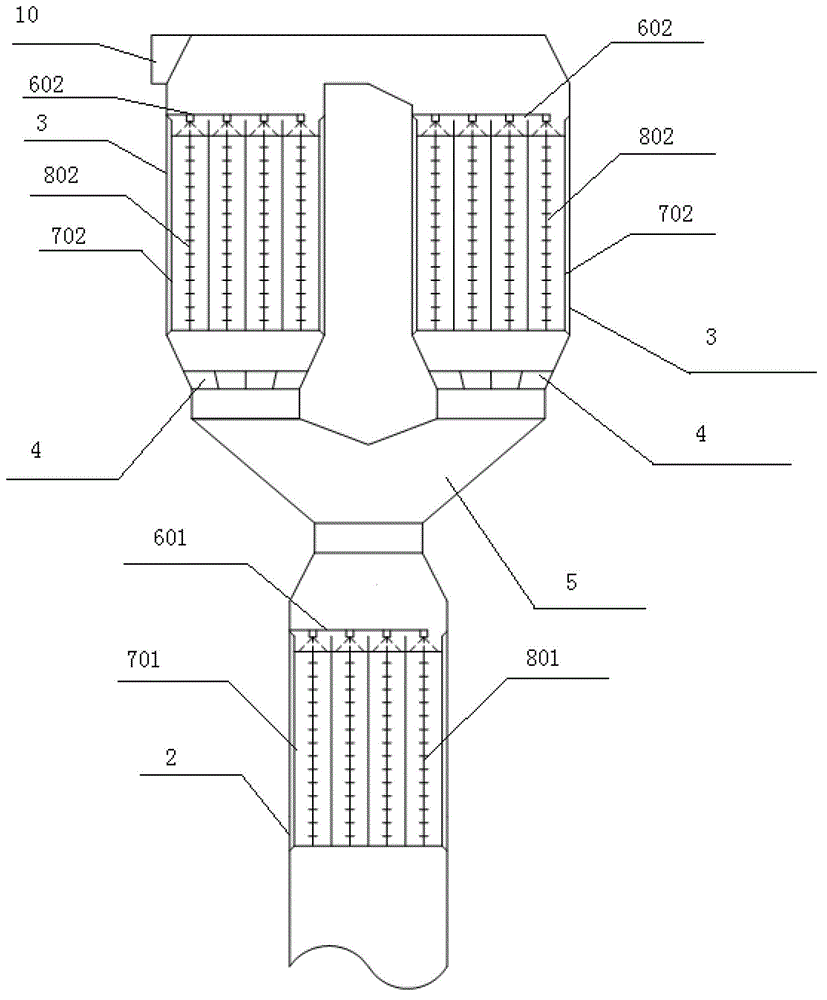

[0111] In a 300MW thermal power generation unit, the sulfur content of the coal fired is 2.4%~3.0%, and the amount of flue gas produced by the boiler is 1 million to 1.3 million Nm 3 / h,SO 2 Content 5100~6800mg / Nm 3 , the flue gas is firstly denitrated by the SCR device, and then dust is removed by the dry electrostatic precipitator ESP, bag filter or electrostatic bag filter. The flue gas enters the absorption tower 1 from the flue gas inlet 9 through the flue gas channel 18, and the inlet temperature It is 115°C~145°C. After the flue gas enters the absorption tower 1, it is sprayed and absorbed, and the spray device 11 sprays out the absorbent slurry to absorb the SO in the flue gas. 2 and few SO 3 Absorb dust, metal oxides (mercury, etc.), fine particulate matter (PM) in the flue gas 2.5 / PM 10 ) and so on for wet conditioning and preliminary absorption, the water vapor in the flue gas reaches saturation, and the flue gas conditioning and conditioning are carried out f...

Embodiment 2

[0113] In the 660MW thermal power generation unit, the sulfur content of coal combustion is 2.0%~2.4%, and the flue gas volume produced by the boiler is 1.90~2.2 million Nm 3 / h, SO 2 Content 10400~15500mg / Nm 3 , the flue gas is firstly denitrated by the SCR device, and then dust is removed by the dry electrostatic precipitator ESP, bag filter or electrostatic bag filter. The flue gas enters the absorption tower 1 from the flue gas inlet 9 through the flue gas channel 18, and the inlet temperature It is 120°C~155°C. After the flue gas enters the absorption tower 1, it is sprayed and absorbed, and the spray device 11 sprays out the absorbent slurry to absorb the SO in the flue gas. 2 and few SO 3 Absorb dust, metal oxides (mercury, etc.), fine particulate matter (PM) in the flue gas 2.5 / PM 10 ) and so on for wet conditioning and preliminary absorption, the water vapor in the flue gas reaches saturation, and the flue gas conditioning and conditioning are carried out for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com