Preparation method of gamma-FeOOH

A reaction and green rust technology, applied in the field of desulfurization, can solve the problem of poor purity of γ-FeOOH, and achieve the effect of improving purity and yield, increasing contact area and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

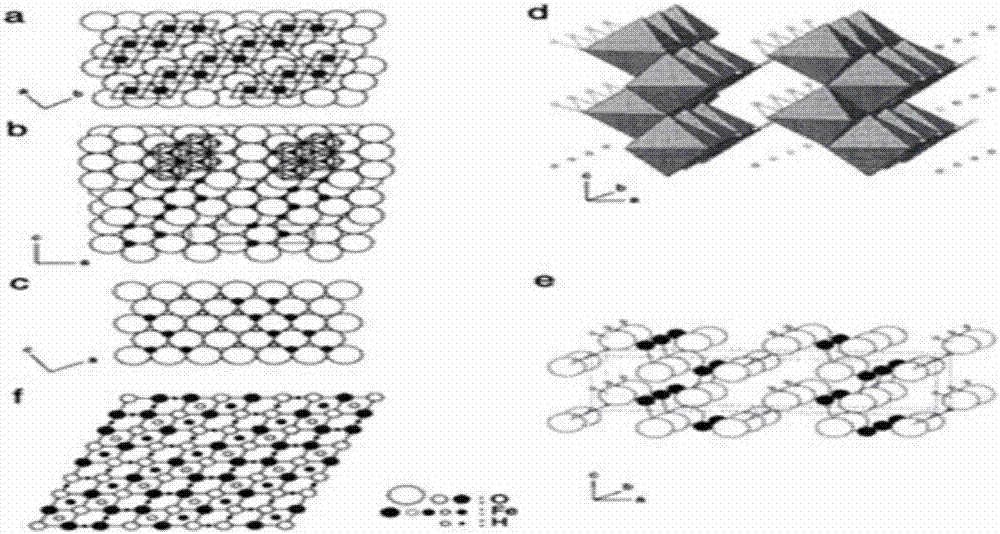

Method used

Image

Examples

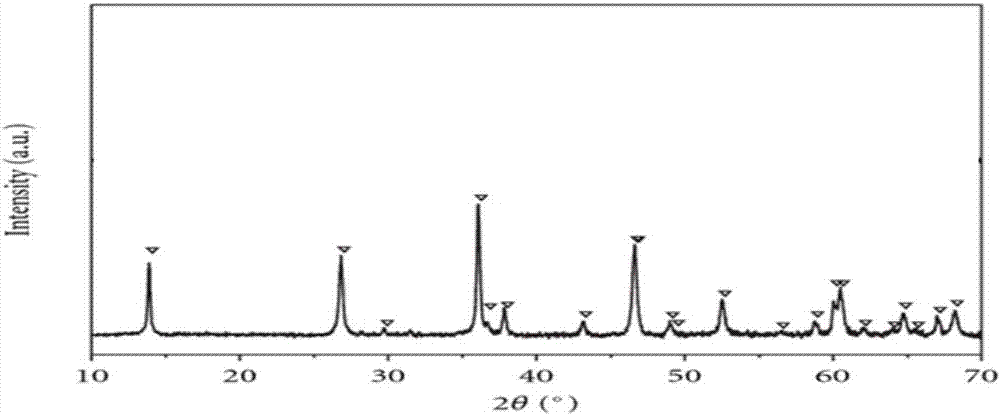

Embodiment 1

[0039] This embodiment provides a method for preparing γ-FeOOH, comprising the following steps:

[0040] (1) Add 400mL of 1.5mol / L ammonium carbonate solution to 200mL of 1.5mol / L ferrous sulfate solution, control the reaction temperature to 0-5°C, and control the pH value at the end of the reaction to 6.0-6.3;

[0041] (2) carry out solid-liquid separation to the slurry obtained after step (1) reaction finishes, collect solid phase and liquid phase respectively, described solid phase is Luxiu intermediate, and described liquid phase evaporates to dryness and obtains ammonium sulfate;

[0042] (3) After the solid phase is washed with water to remove impurities, it is made into a slurry with a concentration of 10wt%, and 30wt% hydrogen peroxide is added to the slurry to undergo an oxidation reaction at 0-5°C, and the concentration of hydrogen peroxide and ferrous sulfate is controlled. The molar ratio is 1:2. After the reaction is completed, filter and dry the filter cake at 70...

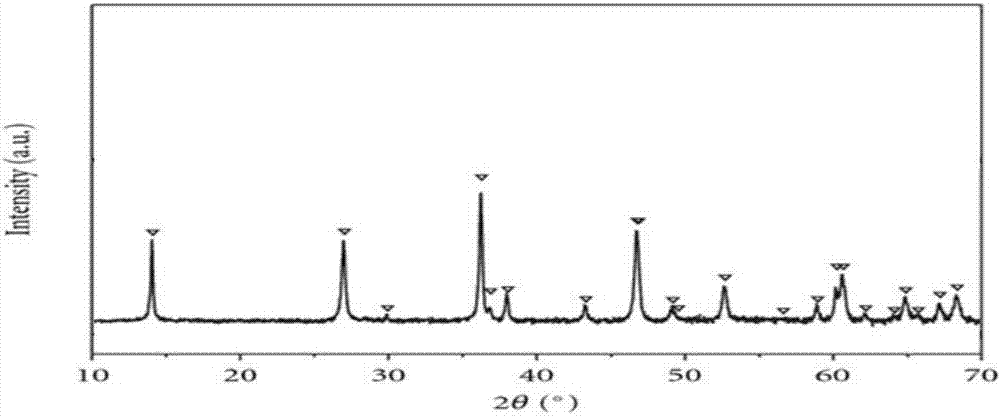

Embodiment 2

[0046] This embodiment provides a method for preparing γ-FeOOH, comprising the following steps:

[0047] (1) Add 800mL of 1.5mol / L ammonium carbonate solution to 200mL of 1.5mol / L ferrous sulfate solution, control the reaction temperature to 0-5°C, and control the pH value at the end of the reaction to 6.2-6.5;

[0048] (2) carry out solid-liquid separation to the slurry obtained after step (1) reaction finishes, collect solid phase and liquid phase respectively, described solid phase is Luxiu intermediate, and described liquid phase evaporates to dryness and obtains ammonium sulfate;

[0049] (3) After the solid phase is washed with water to remove impurities, it is made into a slurry with a concentration of 20wt%, and 50wt% hydrogen peroxide is added to the slurry to undergo an oxidation reaction at 0 to 5°C, and the concentration of hydrogen peroxide and ferrous sulfate is controlled. The molar ratio is 1:2. After the reaction is completed, filter and dry the filter cake at 6...

Embodiment 3

[0052] This embodiment provides a method for preparing γ-FeOOH, comprising the following steps:

[0053] (1) Add 600mL of 1.5mol / L ammonium bicarbonate solution to 200mL of 1.5mol / L ferrous sulfate solution, control the reaction temperature to 0-5°C, and control the pH value at the end of the reaction to 6.2-6.5;

[0054] (2) carry out solid-liquid separation to the slurry obtained after step (1) reaction finishes, collect solid phase and liquid phase respectively, described solid phase is Luxiu intermediate, and described liquid phase evaporates to dryness and obtains ammonium sulfate;

[0055] (3) After the solid phase is washed with water to remove impurities, it is made into a slurry with a concentration of 15wt%, and 40wt% hydrogen peroxide is added to the slurry to undergo an oxidation reaction at 0 to 5°C, and the concentration of hydrogen peroxide and ferrous sulfate is controlled. The molar ratio is 1.1:2. After the reaction is completed, filter and dry the filter cak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com