Preparation method of sucralose

A technology for sucralose and sucralose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low yield of sucralose, etc. short time effect

Active Publication Date: 2010-08-25

南通宏信化工有限公司

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the above-mentioned single-group protection method is: the acetylation reagent selected in the acylation reaction is usually trimethyl orthoacetate or acetic anhydride, and this type of acetylation reagent leads to a low yield of the final sucralose

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Login to View More

Abstract

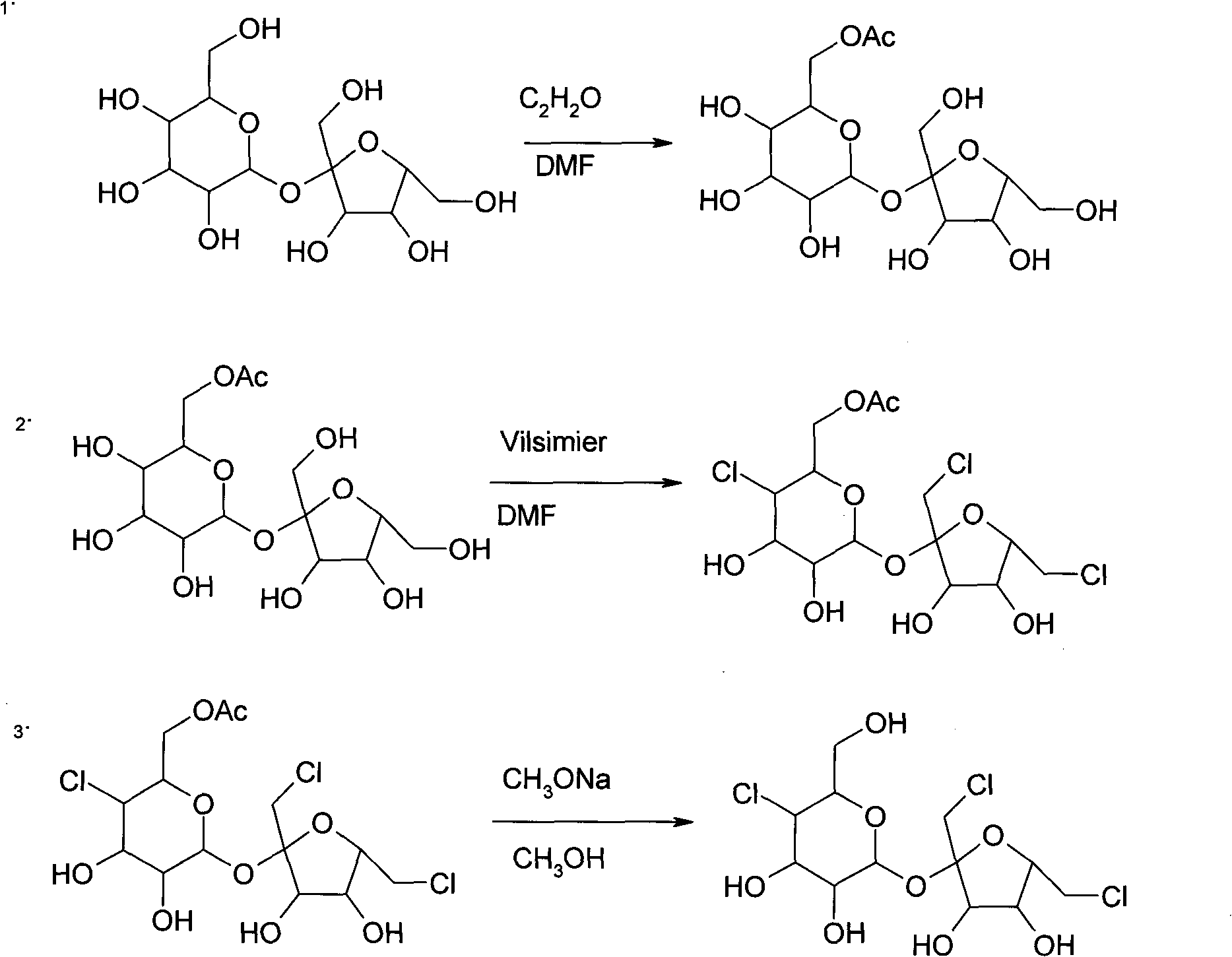

The invention discloses a method for preparing sucralose by using a new acetylation reagent, which comprises the following steps: (1) acylation reaction: reacting sucrose with acetylation reagent to produce sucrose-6-acetate; (2) chlorination reaction: carrying out chlorination reaction on the sucrose-6-acetate obtained in the step (1) to obtain sucralose-6-acetate; (3) and deacetylation reaction: carrying out deacetylation reaction on the sucralose-6-acetate obtained in the step (2) to obtain sucralose. The ketene gas used in the acylation reaction is used as the acetylation reagent. The method can effectively increase the sucralose yield, and has the advantages of short reaction time, easy control of reaction temperature, and easy realization of industrial production.

Description

technical field The invention relates to a method for synthesizing sweetener sucralose, and further relates to a method for preparing sucralose by using sucrose and organic reagents as raw materials and adopting a single-group protection method. Background technique Sucralose, chemical name 4,1',6'-trichloro-4,1'6'trideoxygalactose, its sweetness is 600 times that of sucrose, widely used in beverages, chewing gum, bread, jelly and other foods In addition, its application in the field of medicine is also expanding. Using sucrose and organic reagents as raw materials, the method for preparing sucralose by the single-group protection method includes the following three process steps: (1) acylation reaction, first dissolving sucrose in an organic solvent, then adding acetylating reagents for reaction, and reacting After finishing, remove solvent and filter and dry to obtain sucrose-6-acetate; (two) chlorination reaction, the sucrose-6-acetate that first step reaction is obtaine...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07H5/02C07H1/00

Inventor 陈小萍陈颖刘纪才

Owner 南通宏信化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com