Clastic sandstone gas reservoir acidizing fluid

A technology of clastic sandstone and acidizing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the active acid cannot reach the deep part of the formation, the effective distance of the acid solution is short, and the performance requirements of the corrosion inhibitor are high. Achieve the effects of preventing or reducing secondary precipitation, increasing wellhead test output, and reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

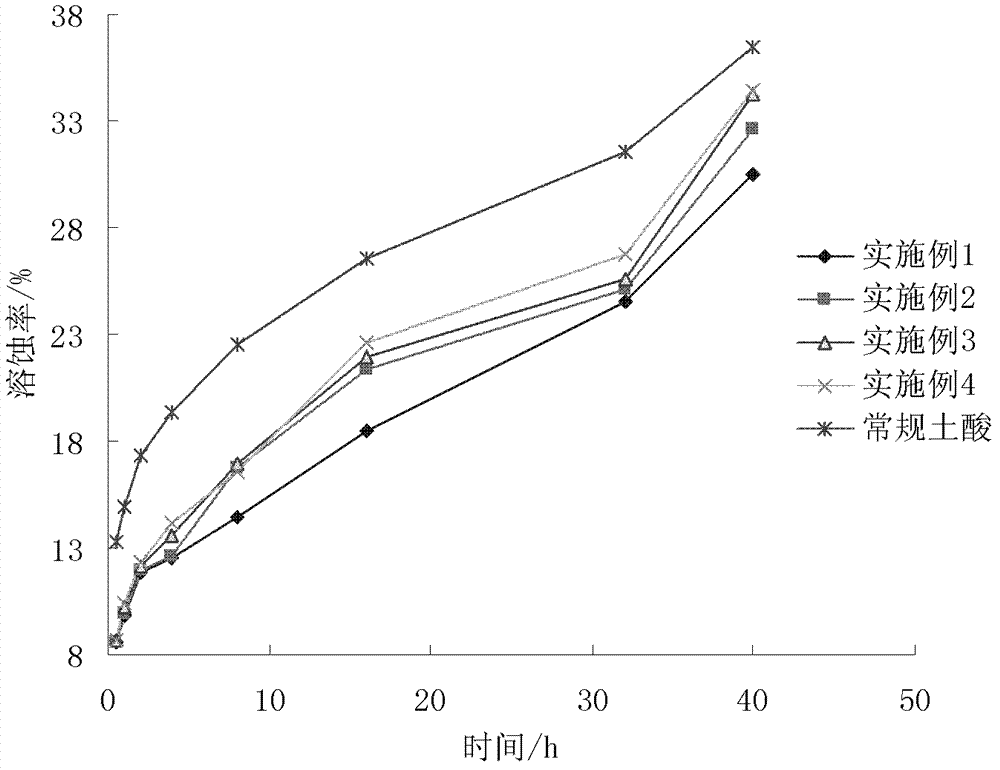

Examples

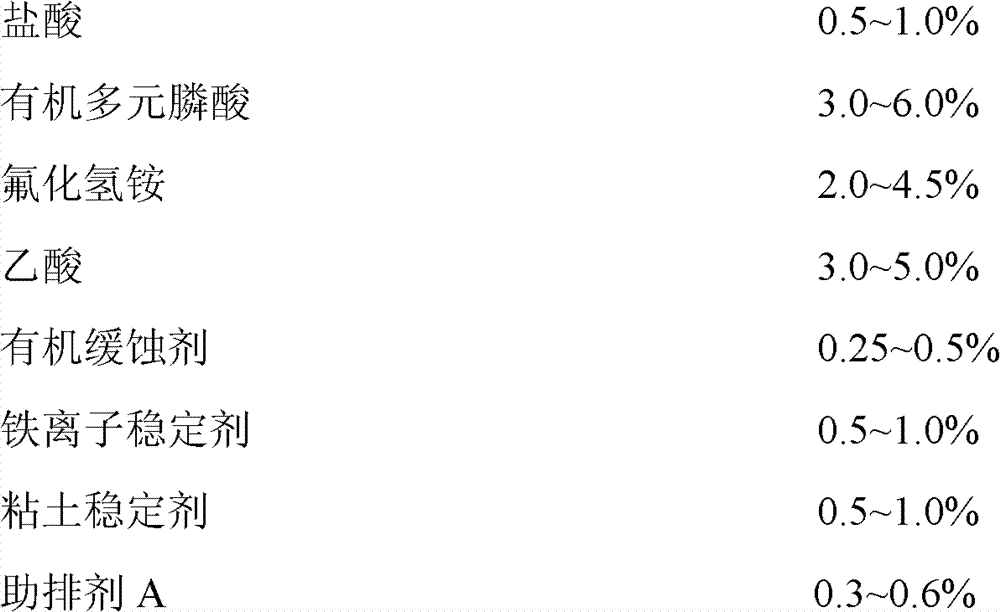

Embodiment 1

[0022] Add 2.4g36% analytically pure hydrochloric acid, 3.0g hydroxyethylene diphosphonic acid, 2.2g ammonium bifluoride, 3.0g acetic acid, 0.25g Lan-926, 0.5g nitrilotriacetic acid, 1.0g polyquaternary ammonium under stirring, Add 0.5g of drainage aid A flatly O-15, 0.5g of drainage aid B fluorocarbon chain surfactant FSO-100, and 86.65g of water, and mix evenly to obtain the sandstone acidizing solution of the present invention.

Embodiment 2

[0024] Add 2.4g36% analytically pure hydrochloric acid, 3.0g hydroxyethylene diphosphonic acid, 3.0g ammonium bifluoride, 5.0g acetic acid, 0.25g Lan-926, 0.5g nitrilotriacetic acid, 1.0g polyquaternary ammonium under stirring, Add 0.5g of drainage aid A Pingping O-15, 0.5g of drainage aid B fluorocarbon chain surfactant FSO-100, 83.85g of water, and mix evenly to obtain the sandstone acidizing solution of the present invention.

Embodiment 3

[0026] Add 2.4g36% analytically pure hydrochloric acid, 6.0g hydroxyethylene diphosphonic acid, 3.7g ammonium bifluoride, 3.0g acetic acid, 0.5g Lan-926, 0.5g nitrilotriacetic acid, 1.0g polyquaternary ammonium under stirring, Add O-15, 0.5g drainage aid B fluorocarbon chain surfactant FSO-100, and 81.9g water to 0.5g of drainage aid A, and mix evenly to obtain the sandstone acidizing solution of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com