Turning foamed acid for heterogeneous reservoir acidification

A technology of heterogeneous reservoir and foam acid, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of difficult flowback, difficulty in reasonable placement, and high acid consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Prepare a certain concentration of WT-60A to simulate the reaction process of the acid solution in the formation acid rock. As the concentration of the acid solution decreases, a large amount of calcium ions (or magnesium ions) are produced, and the system is cross-linked to increase the viscosity. The experimental results are shown in Table 1:

[0010] Table 1 Viscosity of Surfactant Acid with Different Concentrations of Residual Acid (30°C)

[0011] Surfactant formulations with different residual acid concentrations

Embodiment 2

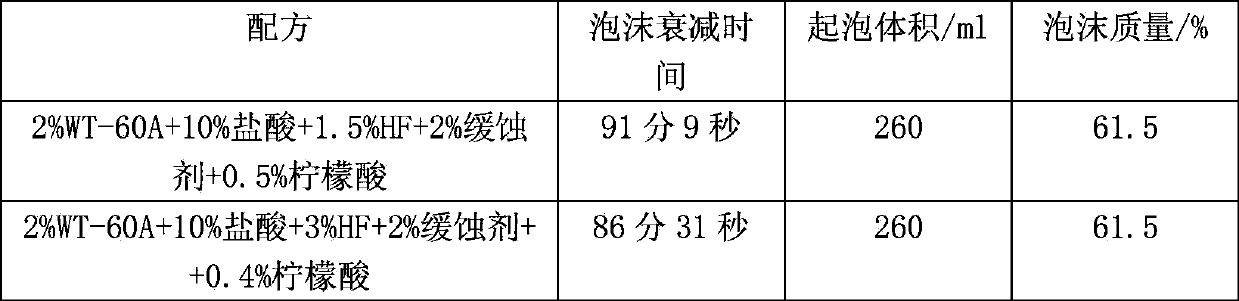

[0013] Prepare 100ml of this foam acid solution, stir it at a speed of 1000r / min for 1min, and see the following table for the foam half-life and foam quality measured at 30°C:

[0014] The performance measurement of table 2 foam acid

[0015]

Embodiment 3

[0017] Prepare foam acid 2% WT-60A+10% hydrochloric acid (stirring at 1000r / min for 1min) and 100ml of 10% hydrochloric acid respectively, put the weighed marbles into the two liquids respectively, and react at 30°C for 5min, experiment Data are as follows:

[0018] Table 3 foam acid retardation test data

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com