Water-blocking damage blocking remover, using method thereof and water-blocking damage acidizing fluid

A technology of water-locking damage and plug-removing agent, which is applied in chemical instruments and methods, earthwork drilling, cleaning equipment, etc., can solve the problems of affecting the scope of use, taking up a long time in production, and the effect of increasing oil is not obvious, so as to avoid hydrogen Oxide precipitation, short operation time, and the effect of removing water lock damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

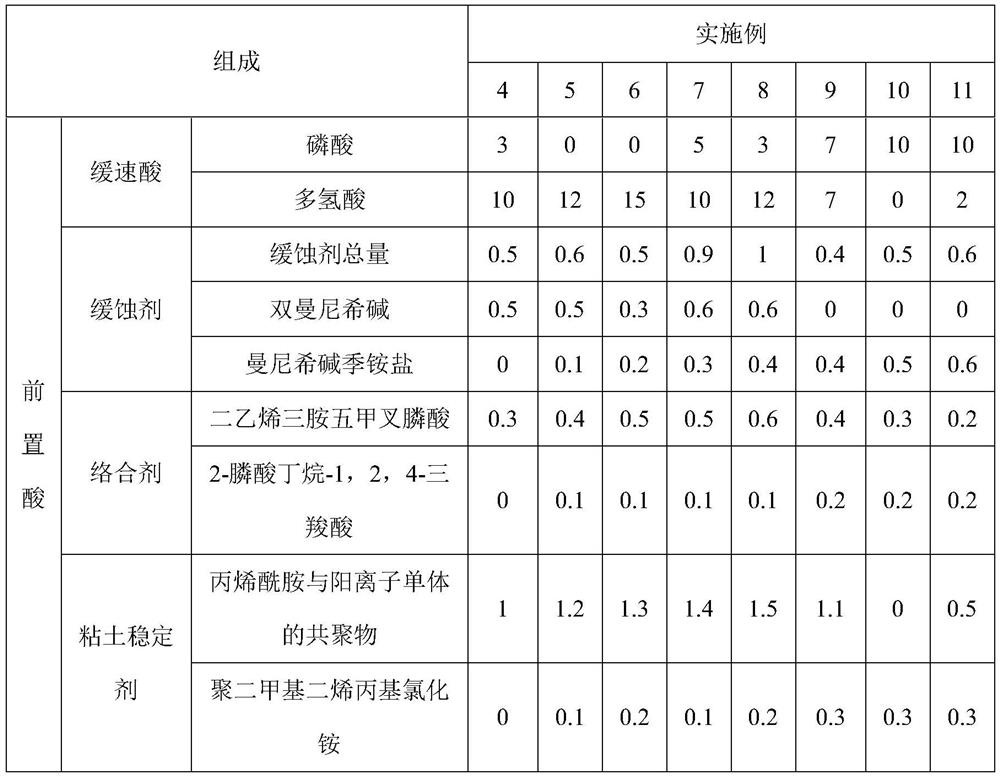

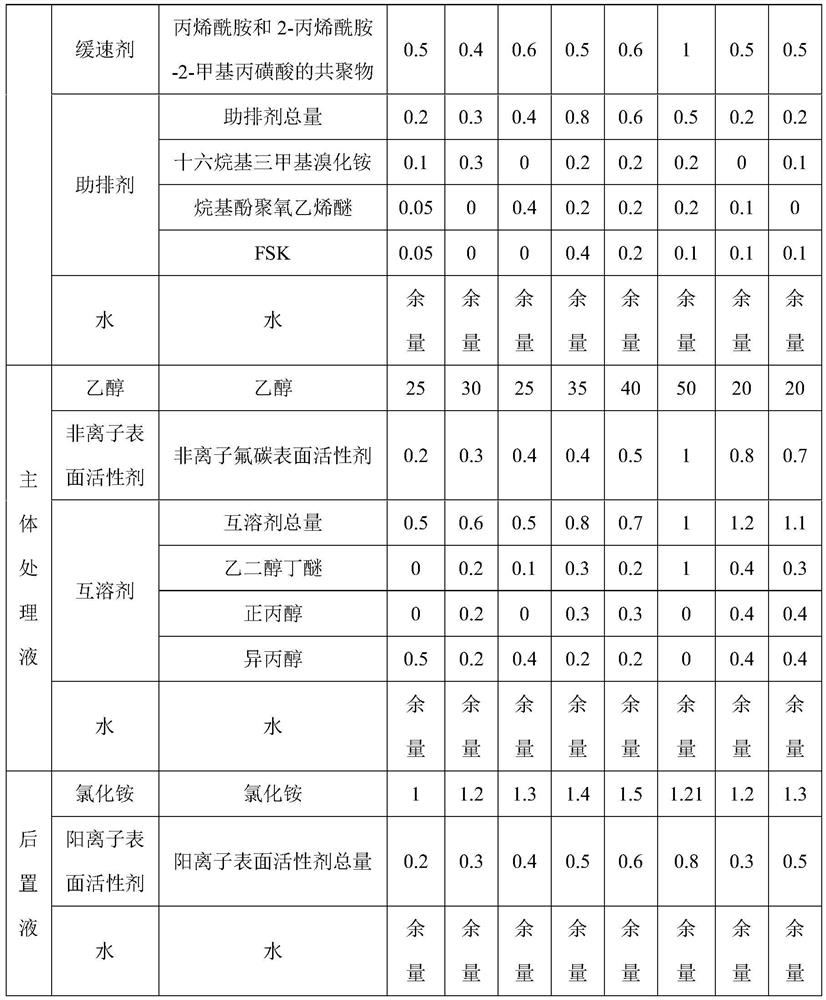

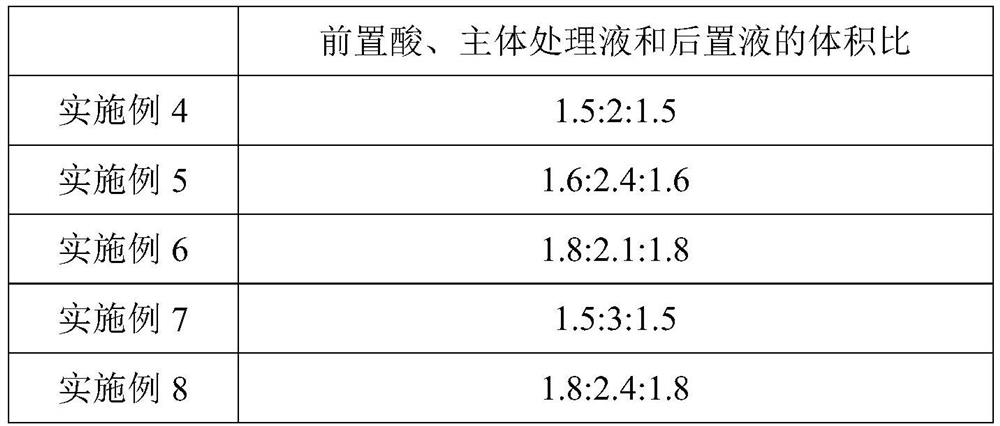

Examples

Embodiment 1

[0052] The water-locking damage acidification solution of the present embodiment is composed of the following components in mass percentage: 10% of retarding acid, 0.8% of corrosion inhibitor, 0.3% of complexing agent, 1% of clay stabilizer, 0.5% of retarder, The discharge agent is 0.7%, and the balance is water; the retarded acid used is phosphoric acid, the corrosion inhibitor is Mannich base quaternary ammonium salt, the complexing agent is diethylenetriaminepentamethylenephosphonic acid, and the clay stabilizer is propylene Copolymer of amides and cationic monomers, retarder is copolymer of acrylamide and 2-acrylamido-2-methylpropanesulfonic acid, drainage aid is composed of hexadecyltrimethylammonium bromide, alkyl Composed of phenol polyoxyethylene ether and FSK; the mass ratio of cetyltrimethylammonium bromide, alkylphenol polyoxyethylene ether and FSK is 2:1:1.

[0053] The water lock damage plugging remover of the present embodiment comprises pre-acid, main body treat...

Embodiment 2

[0058] The water-locking damage acidification solution of the present embodiment is composed of the following components in mass percentage: 15% of retarding acid, 0.6% of corrosion inhibitor, 0.5% of complexing agent, 1% of clay stabilizer, 0.5% of retarder, The discharge agent is 0.6%, and the balance is water; the retarded acid used is phosphoric acid, the corrosion inhibitor is bis-Mannich base, the complexing agent is diethylenetriaminepentamethylenephosphonic acid, and the clay stabilizer is acrylamide and A copolymer of cationic monomers, the retarder is a copolymer of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, and the drainage aid is composed of cetyltrimethylammonium bromide, alkylphenol poly Oxyethylene ether and FSK; in the drainage aid, the mass ratio of cetyltrimethylammonium bromide, alkylphenol polyoxyethylene ether and FSK is 1:1:1.

[0059]The water lock damage plugging remover of the present embodiment comprises pre-acid, main body treatment li...

Embodiment 3

[0064] The water-locking damage acidification solution of the present embodiment is composed of the following components in mass percentage: 12% of retarding acid, 0.3% of corrosion inhibitor, 0.3% of complexing agent, 1% of clay stabilizer, 0.5% of retarder, The discharge agent is 0.2%, and the balance is water; the retarded acid used is composed of phosphoric acid and polyhydrogen acid, the mass ratio of phosphoric acid and polyhydrogen acid is 10:2, and the corrosion inhibitor is composed of double Mannich base and Mannich Alkali quaternary ammonium salt, the mass ratio of double Mannich base and Mannich base quaternary ammonium salt is 1:1, the complexing agent is diethylene triamine pentamethylene phosphonic acid, and the clay stabilizer is acrylamide and cationic mono The retarder is a copolymer of acrylamide and 2-acrylamide-2-methylpropanesulfonic acid, and the drainage aid is FSK.

[0065] The water lock damage plugging remover of the present embodiment comprises pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com