Method for preparing heavy metal adsorbent by sludge bioleaching-pyrolysis combined treatment

A technology of sludge and biochar, which is applied in the field of resource utilization of solid waste, can solve problems such as biochar, achieve high adsorption capacity, and improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

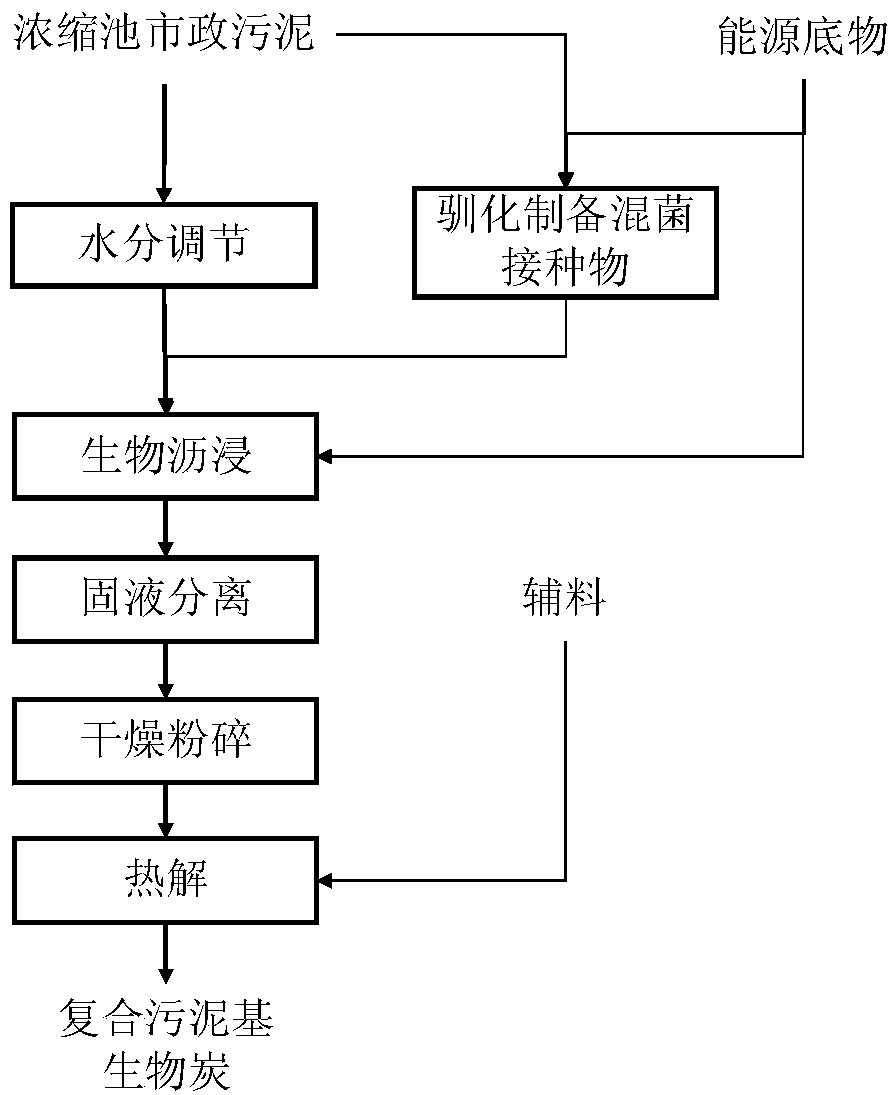

Method used

Image

Examples

Embodiment

[0028] (1) Take fresh sludge from the sludge concentration tank of a sewage treatment plant in Guangxi, add 500mL of fresh sludge to a 1000mL serum bottle, and add 5g of FeSO 4 ·7H 2 O is the substrate, and the culture is shaken at 25°C and 180 r / min until the pH value of the sludge drops and stabilizes to 2.0 to obtain the sludge bacterial solution.

[0029] (2) Take 50mL of the sludge bacterial solution obtained in step (1) and add it to 500mL of fresh sludge, add 5g of FeSO 4 ·7H 2 O, at 25°C, 180r / min shaking culture, until the pH value is stable to 2.0, repeat the above steps 5 times, to inoculate the sludge bacterial liquid; with the increase of the number of inoculations, each time the bacterial liquid is cultivated until the stable growth period Time gradually shortened to 5 days.

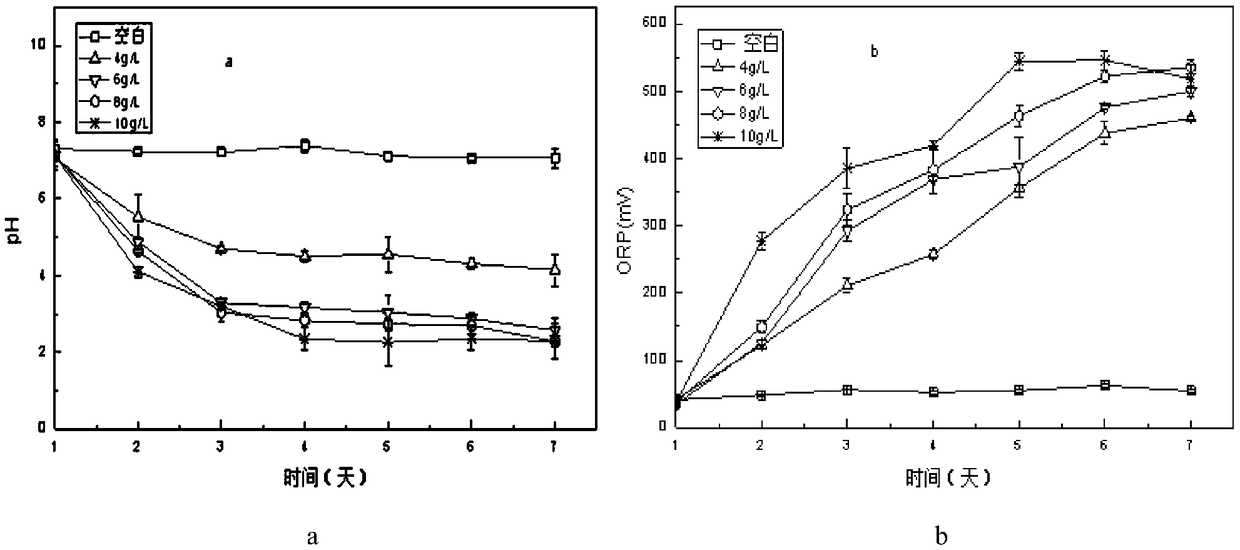

[0030] (3) Take the fresh sludge from the sludge thickening tank of a certain sewage treatment plant in Guangxi, adjust the sludge solid content to 2.2%; put 300mL of the above fresh slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com