Gelatinizing emulsified acid and preparation method thereof

A technology of emulsifying acid and gelling acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of stability and viscosity that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

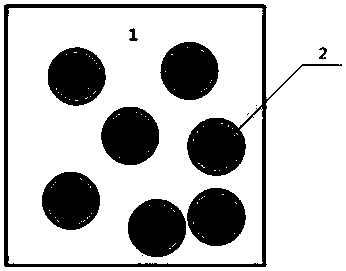

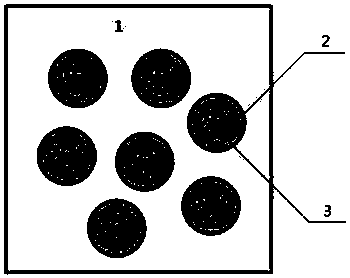

Image

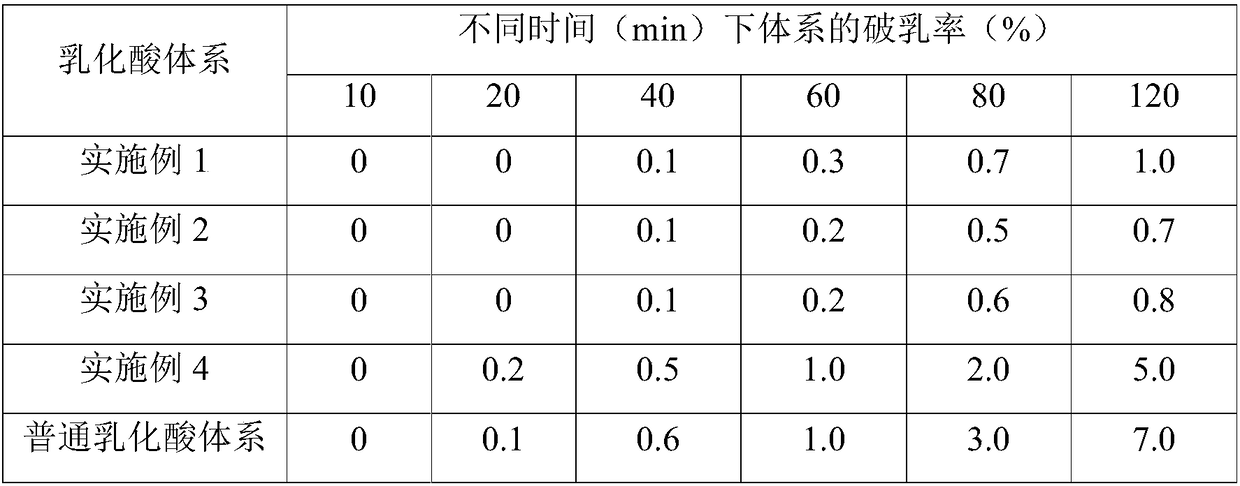

Examples

Embodiment 1

[0032] 1) Prepare low-viscosity gelling acid according to the following components by weight: take 96.8 parts of hydrochloric acid solution (concentration: 15% wt), slowly add 0.3 parts of polyacrylamide thickener SRAP for acid at a speed of 500r / min -1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, then added 1.2 parts of iron ion stabilizer (ethylenediaminetetraacetic acid, Tianjin Guangfu Chemical Reagent Factory) and 1.7 One part of corrosion inhibitor Miramine TO-I (Solvay Company), stirred evenly, sealed at room temperature and stood still for 1 hour;

[0033] 2) The oil phase was prepared according to the following components by weight: 3 parts of span80 and 0.5 part of dodecylamine were heated and dissolved in 96.5 parts of diesel oil, stirred evenly, cooled to room temperature, and set aside;

[0034] 3) Prepare the gelled emulsified acid according to the following components by v...

Embodiment 2

[0036] 1) Prepare low-viscosity gelling acid according to the following components by weight: take 96.7 parts of hydrochloric acid solution with a concentration of 15% wt, and slowly add 0.4 parts of polyacrylamide thickener SRAP- 1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, then added 1.2 parts of iron ion stabilizer (ethylenediaminetetraacetic acid, Tianjin Guangfu Chemical Reagent Factory) and 1.7 parts The corrosion inhibitor Miramine TO-I (Solvay Company), stir well, seal room temperature and stand still for 1 hour;

[0037] 2) The oil phase was prepared according to the following components by weight: 3 parts of span80 and 0.5 part of dodecylamine were heated and dissolved in 96.5 parts of diesel oil, stirred evenly, cooled to room temperature, and set aside;

[0038] 3) Prepare the gelled emulsified acid according to the following components by volume: Slowly add the prepared lo...

Embodiment 3

[0040] 1) Prepare low-viscosity gelling acid according to the following components by weight: Take 96.6 parts of hydrochloric acid solution with a concentration of 15% wt, slowly add 0.5 parts of polyacrylamide thickener SRAP- 1 (produced by Sinopec Petroleum Engineering Technology Research Institute, SRAP-1), stirred for half an hour to form a uniform solution, and then added 1.2 parts of iron ion stabilizer (ethylenediaminetetraacetic acid, produced by Tianjin Guangfu Chemical Reagent Factory) and 1.7 parts One part of corrosion inhibitor Miramine TO-I (Solvay Company), stirred evenly, sealed at room temperature and stood still for 1 hour;

[0041] 2) The oil phase was prepared according to the following components by weight: 3 parts of span80 and 0.5 part of dodecylamine were heated and dissolved in 96.5 parts of diesel oil, stirred evenly, cooled to room temperature, and set aside;

[0042]3) Prepare the gelled emulsified acid system according to the following components b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com