High-temperature acidic corrosion inhibitor and preparation method thereof

A technology of acidizing corrosion inhibitor and high temperature, which is applied in the field of high temperature acidifying corrosion inhibitor and its preparation, can solve the problems of unstable dissolving and dispersing, formation damage, easy coking, etc., and achieves increasing comprehensive economic benefits, reducing corrosion, and preparing method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

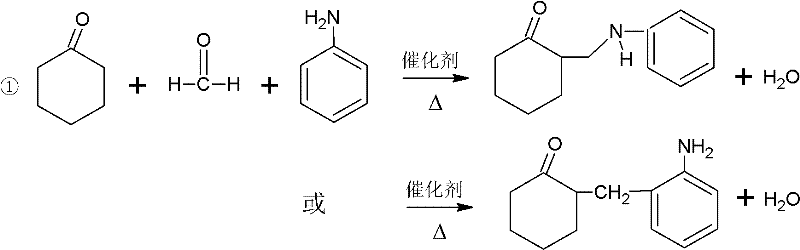

[0034] In the present invention, aniline is slowly added dropwise to cyclohexanone and paraformaldehyde, and the aldehyde, ketone, and amine condensate is synthesized in the following manner, and the reaction formula is as follows:

[0035]

[0036] details as follows:

[0037] Add 1989Kg of cyclohexanone into the reactor, start the stirrer, keep it at 100r / min, add 147Kg of 31% industrial hydrochloric acid under stirring, and stir for 10min. Slowly add 612Kg of paraformaldehyde, and slowly raise the temperature to control the temperature in the reactor between 60°C and 70°C; after adding the paraformaldehyde, raise the temperature to 85°C and 95°C, and react for 30 minutes. Turn on the circulating cold water, control the temperature of the reactor to 50°C-60°C, slowly add 869Kg of aniline, and then slowly add 83Kg of hydrochloric acid. Slowly raise the temperature of the reactor to 110°C. After the temperature in the reactor reaches 110°C, keep it at the temperature for 1...

Embodiment 2

[0050] The manufacturing process of the semi-finished product A is as described in Example 1. Add 100Kg of the semi-finished product A in the reactor, start the stirrer, stir at a speed of 100r / min, then add 12.0Kg of propynyl alcohol and 10.0Kg of formamide, stir well and then pour out to form a composite acidification corrosion inhibitor (named FHC for ease of description).

[0051] Corrosion inhibition performance evaluation test:

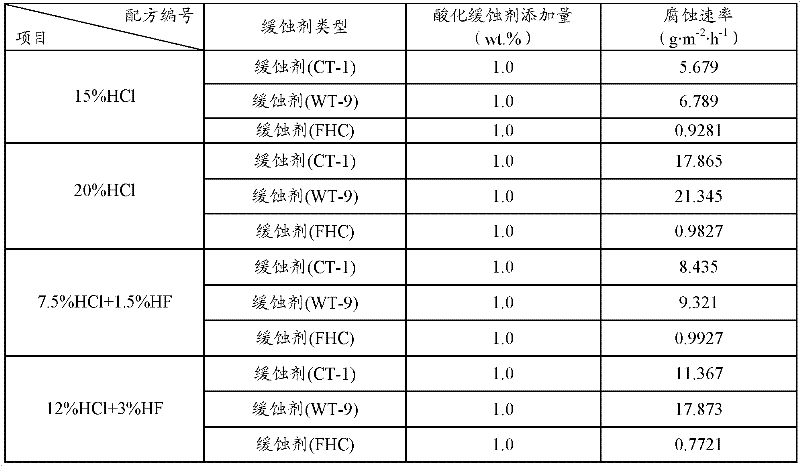

[0052] In different acid liquids, under the condition of the experimental temperature of 90°C, the corrosion inhibition performance of the corrosion inhibitor FHC was evaluated by referring to the People's Republic of China Petroleum and Natural Gas Industry Standard SY / T5405-1996 "Experimental Methods and Evaluation Indexes for Corrosion Inhibitors for Acidification" , the results are shown in Table 2.

[0053] Table 2 Evaluation of corrosion inhibition performance in different acid solutions (at 90°C)

[0054]

[0055] From the experiment...

Embodiment 3

[0057] The manufacturing process of semi-finished product A is as described in embodiment 1, in reactor, add 100.0Kg semi-finished product A, start agitator, stirring speed 100r / min, then add 10.0Kg propynyl alcohol, 10.0Kg potassium iodide, 6.7Kg trichloride respectively Antimony, stir well to form formula 1;

[0058] Or add 100.0Kg semi-finished product A in the reaction kettle, start the stirrer, stir at a speed of 100r / min, then add 10.0Kg propynyl alcohol, 10.0Kg potassium iodide, and 6.7Kg antimony trioxide respectively, and form formula 2 after stirring evenly;

[0059] Or add 100.0Kg semi-finished product A in the reaction kettle, start the agitator, and stir at a speed of 100r / min, then add 10.0Kg propynyl alcohol, 6.7Kg potassium iodide, and 10.0Kg antimony trichloride respectively, and form formula 3 after stirring evenly;

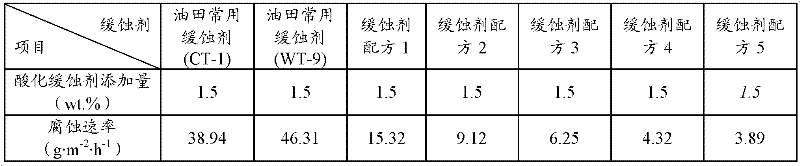

[0060] Or add 100.0Kg semi-finished product A to the reaction kettle, start the agitator, and stir at a speed of 100r / min, then add 10.0Kg prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com