Biochemical treating system for kitchen garbage

A technology for biochemical treatment and kitchen waste, applied in the direction of biomass pretreatment, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as aggravating sewage pollution and sewer network blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

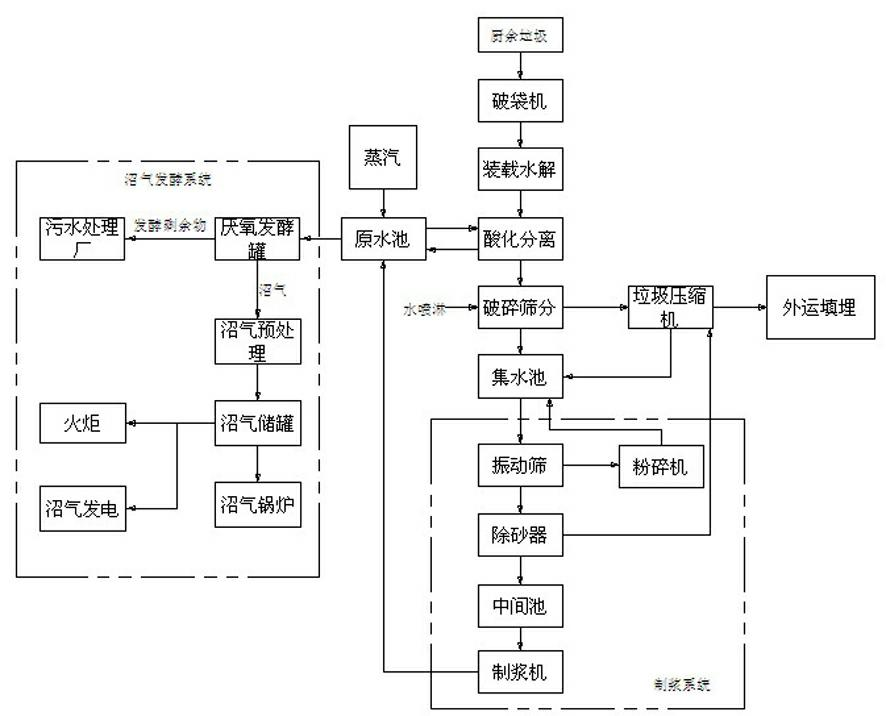

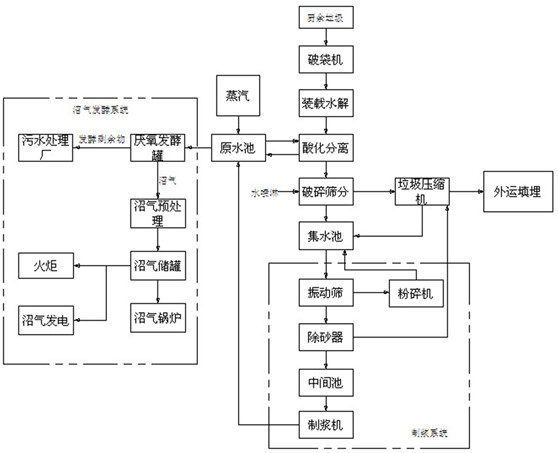

[0026] Such as figure 1 As shown, the embodiment of the present invention is a biochemical treatment system for kitchen waste. The biochemical treatment system includes an acidification loader, an acidification tank, a crushing and screening machine, a raw water pool, and a water collection tank; the biochemical treatment of kitchen waste includes the following steps:

[0027] Bag breaking step: a bag breaking device is provided above the feed port of the acidification loader, and food waste or fruit and vegetable waste to be treated is first dumped on the bag breaking device; start the bag breaking device, and the food waste or fruit and vegetable waste Garbage to be treated is broken into bags, which is good for material handling.

[0028] Loading hydrolysis step: The upper plane of the acidizing loader is equipped with a material inlet and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com