Patents

Literature

45results about How to "Increase the crushing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

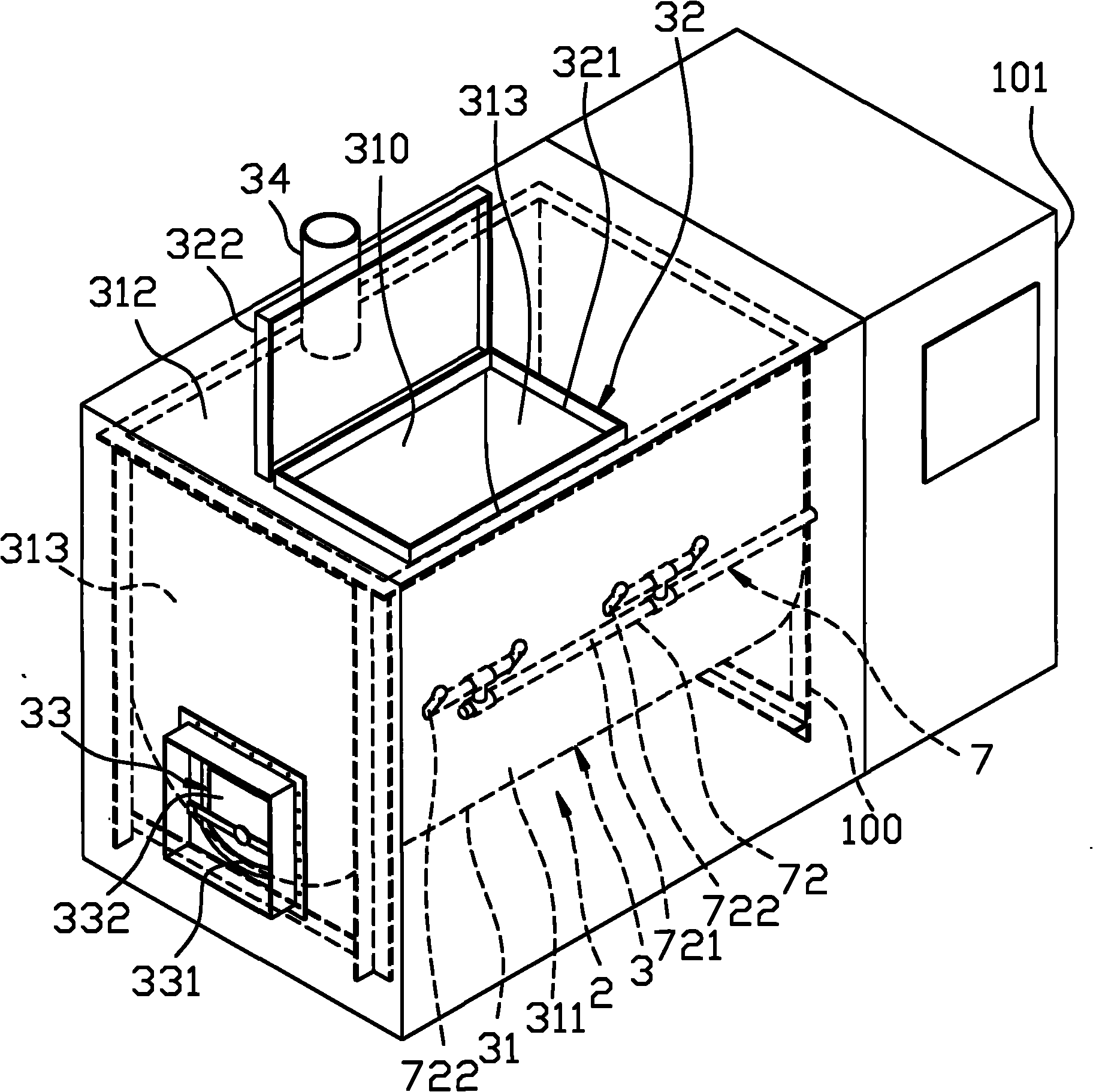

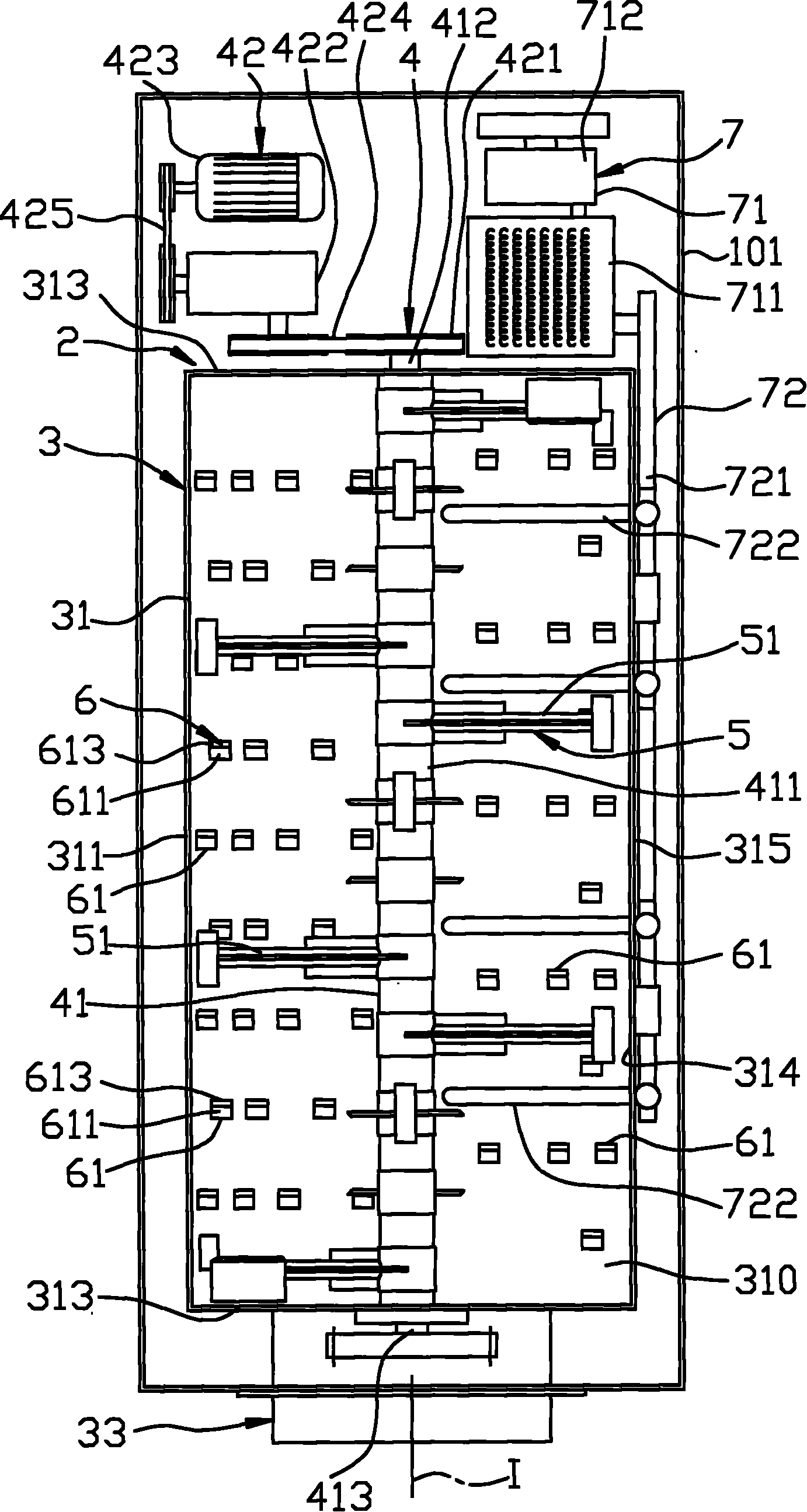

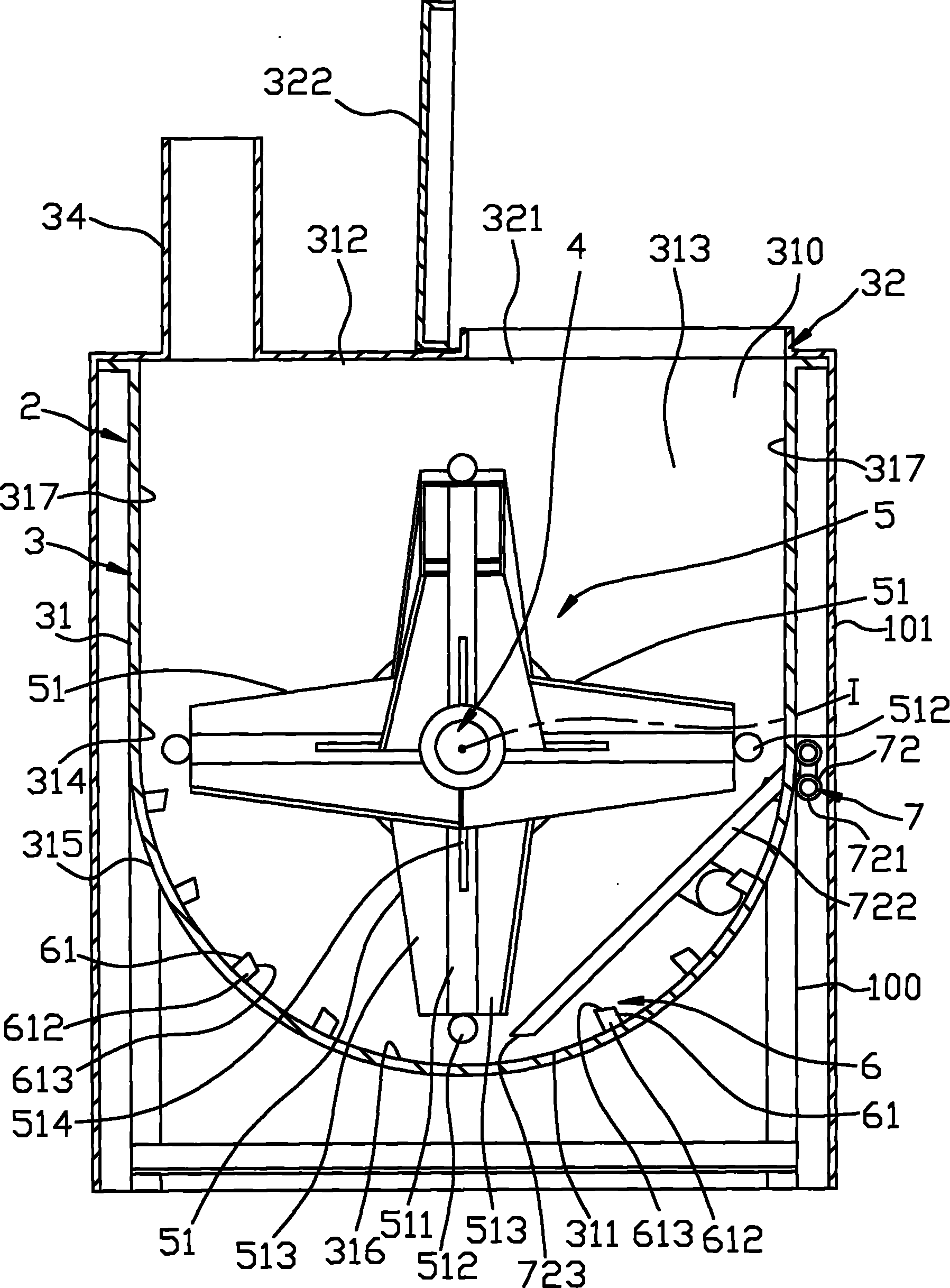

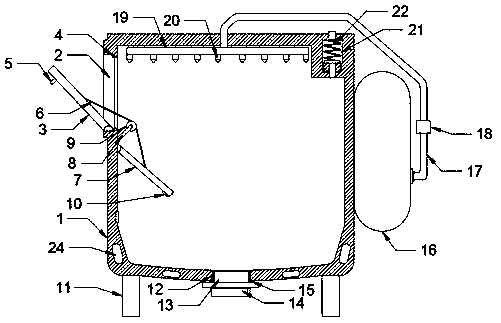

Treating device and treating method for organic wastes in farm

InactiveCN102039295AEffective dryingEfficient crushingDrying solid materials with heatFeeding-stuffWaste managementFertilizer

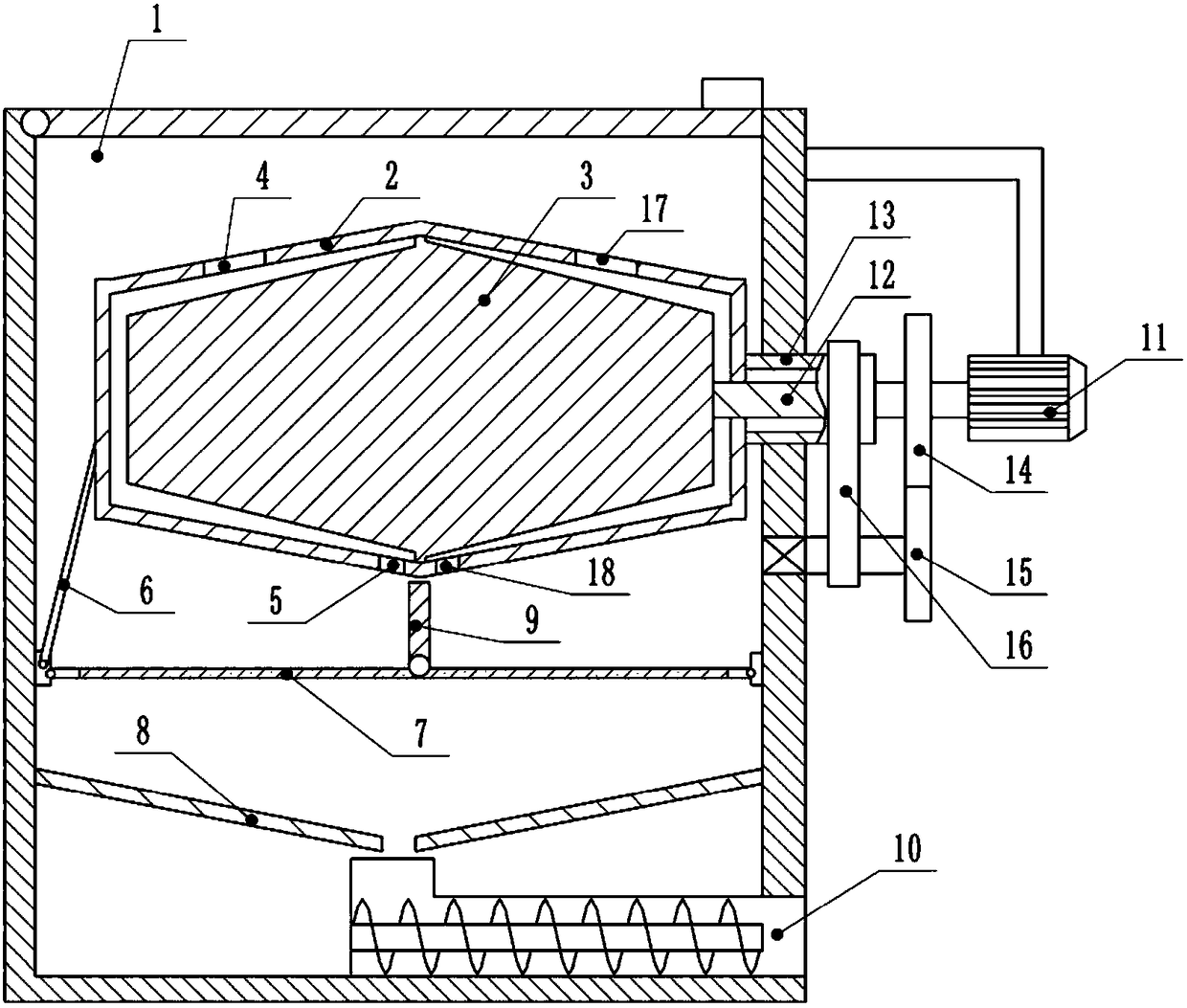

The invention relates to a treating device and treating method for organic wastes in a farm. The treating device comprises a treating tank unit, a rotating mechanism arranged in the treating tank unit, a first cutter unit connected to the rotating mechanism and a drying unit communicated with the treating tank unit, wherein the first cutter unit can be revolved in the treating tank unit through the linkage of the rotating mechanism to be used for stirring and cutting the organic wastes thrown into the treating tank unit, and the organic wastes are prepared into granular products which can not decay easily by matching the drying action of the drying unit. By the invention, the organic wastes can be effectively dried and crushed into fine fragments to be further prepared into organic reproduced products of feed or fertilizers with practical value.

Owner:LIUH TAY BIOTECH CORP

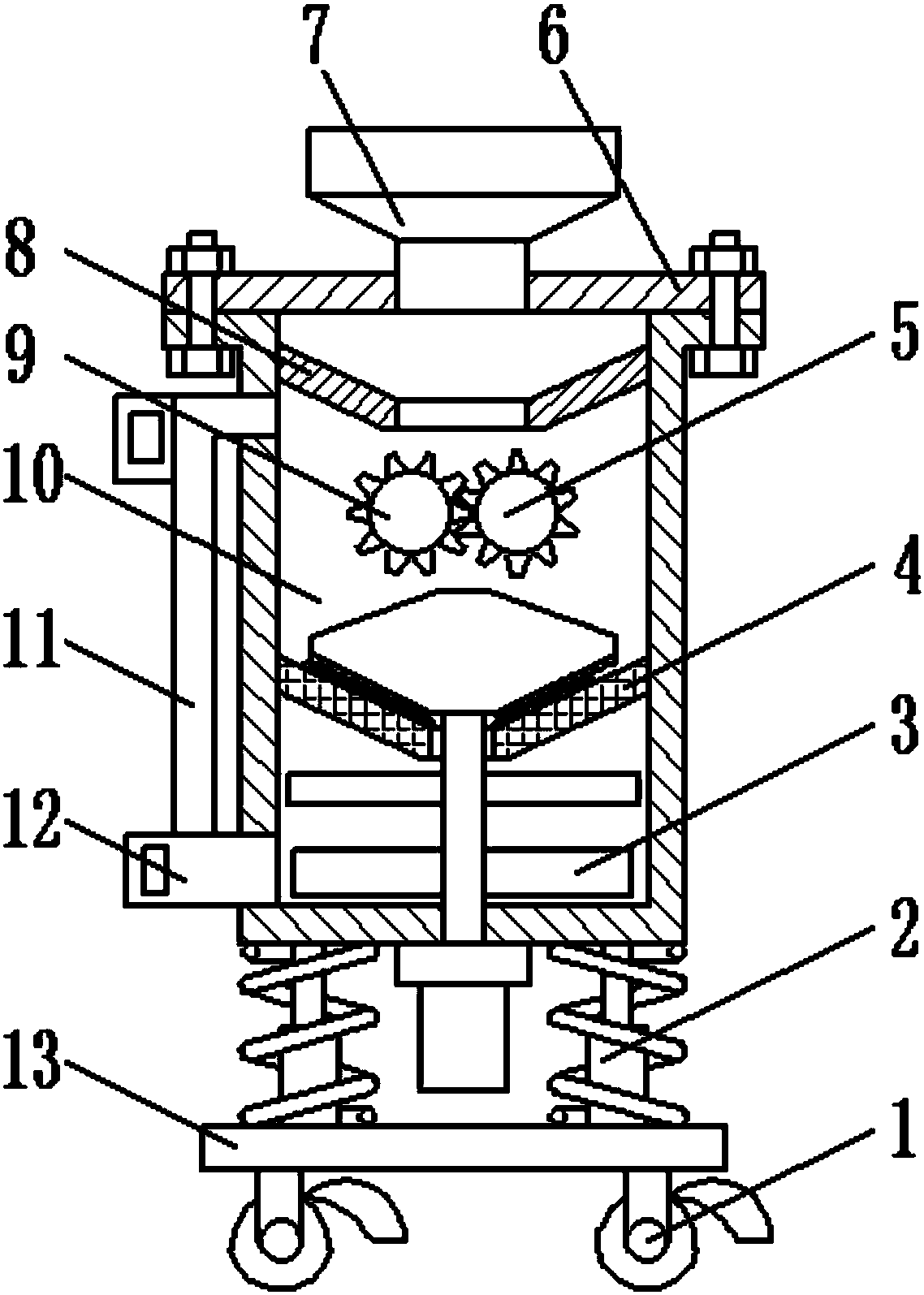

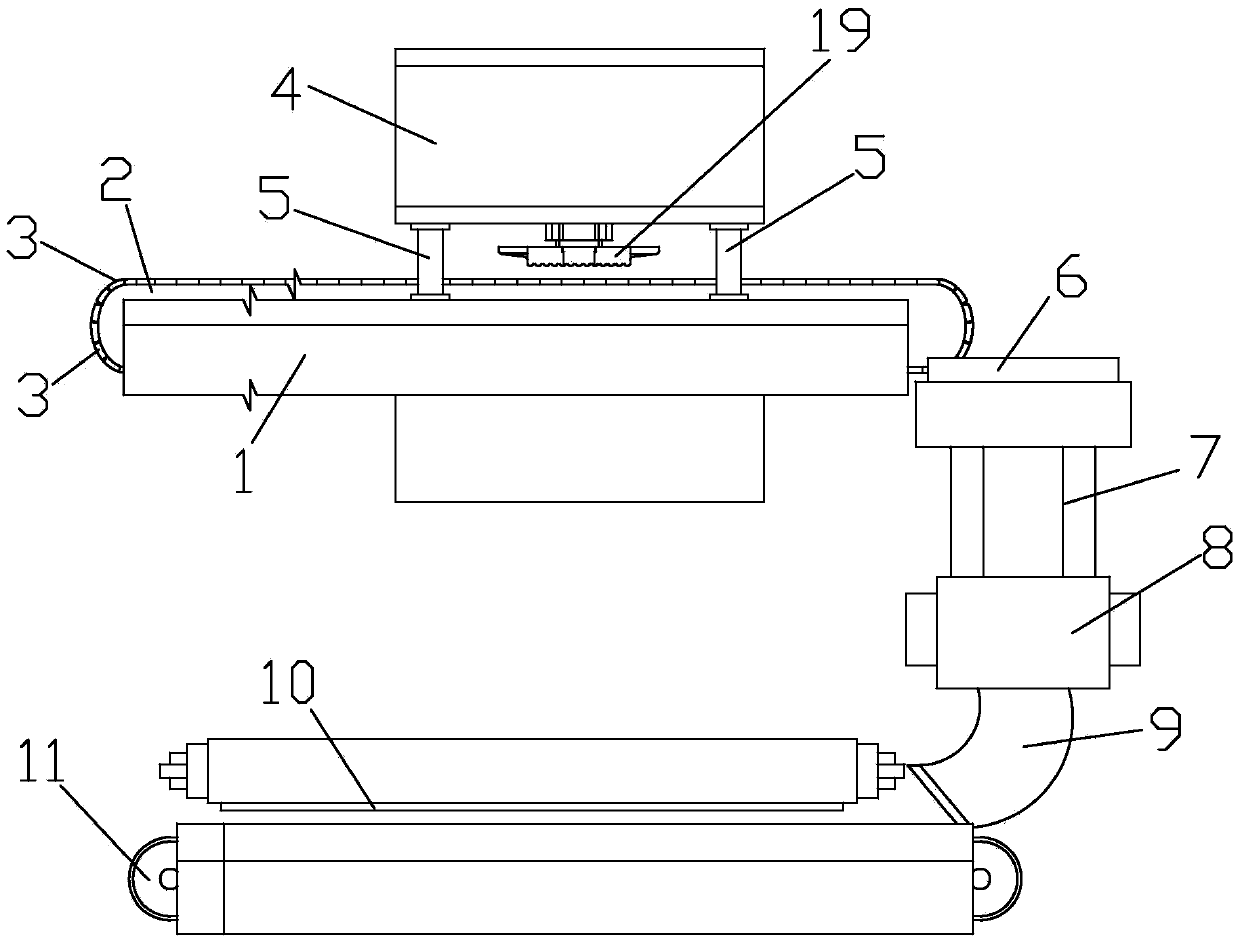

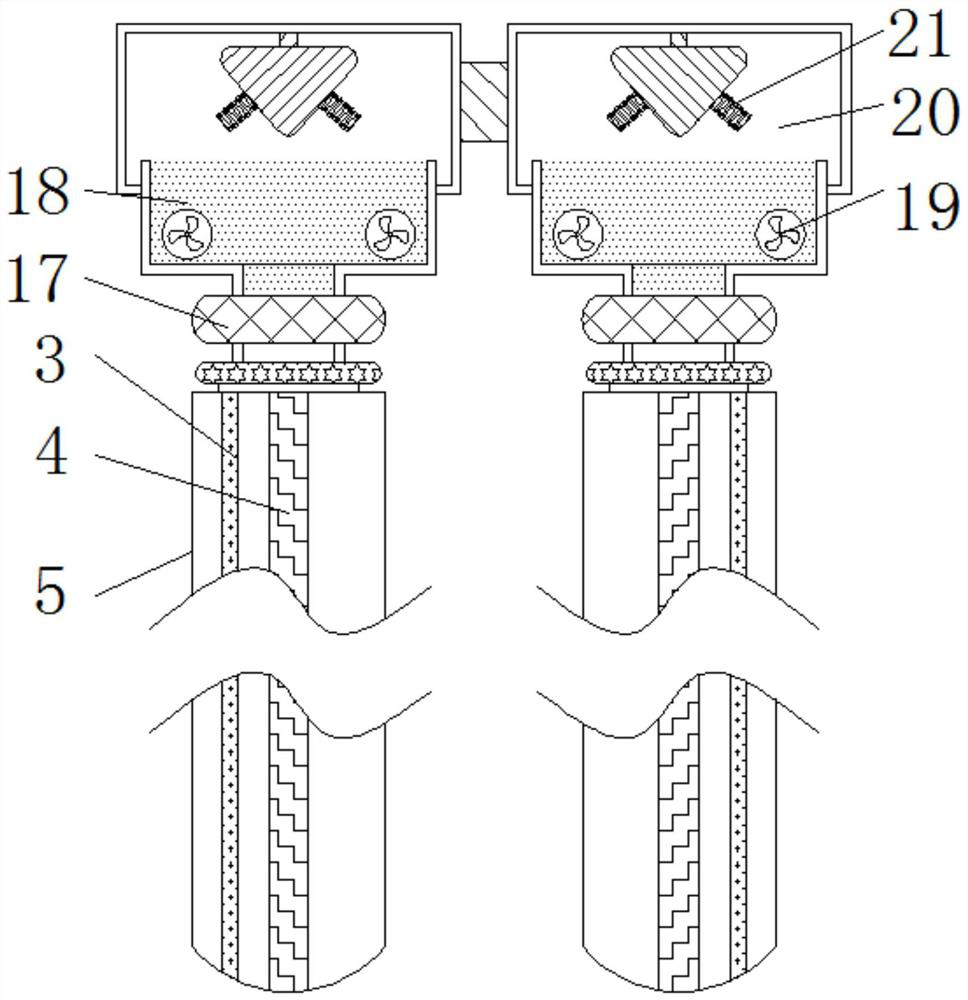

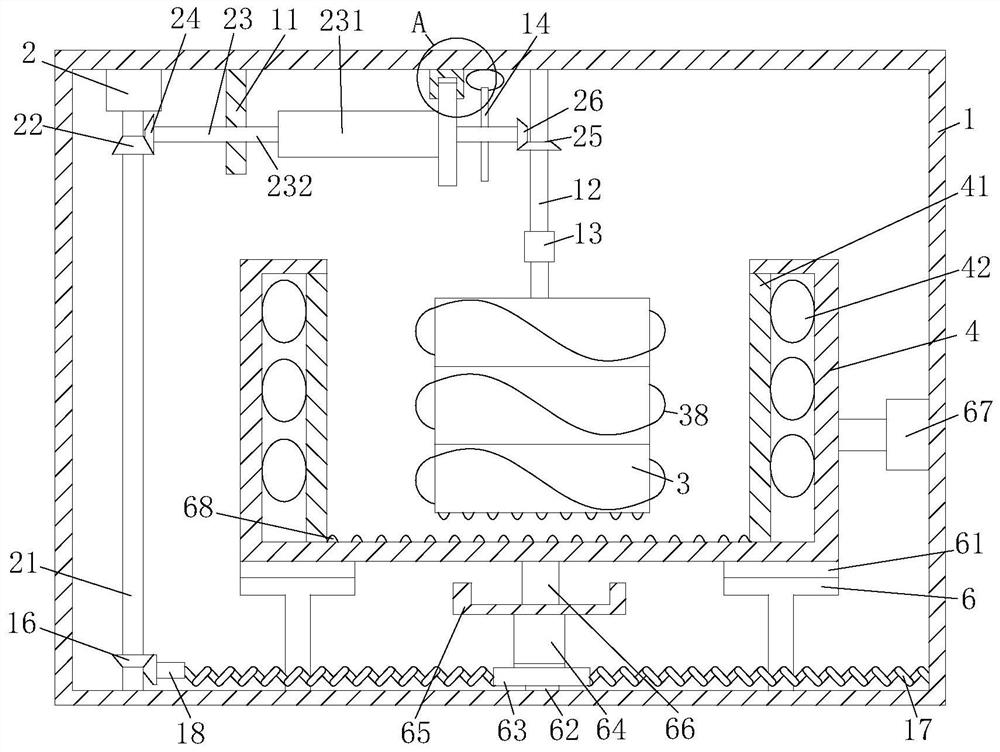

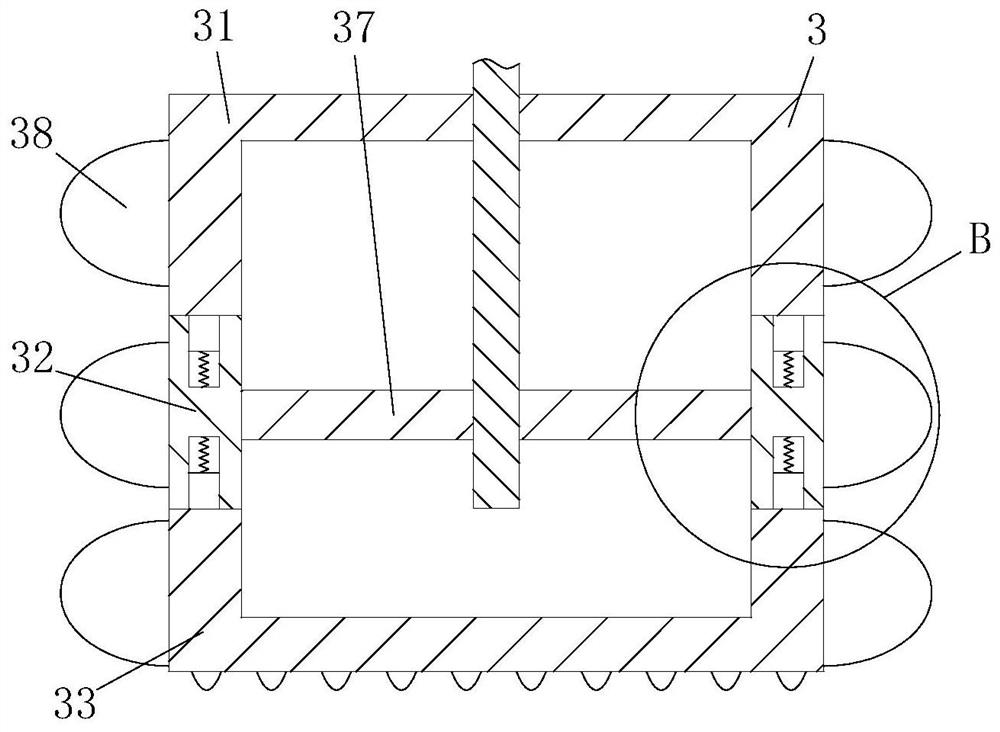

Vibration reduction type carbon block production wood powder breaking device convenient to move

InactiveCN108176448AImprove grinding and crushing qualityImprove crushing qualityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a vibration reduction type carbon block production wood powder breaking device convenient to move, and belongs to the technical field of material breaking. The device comprisesuniversal wheels, a bottom plate is arranged on the tops of the universal wheels, a vibration reduction base is arranged on the top of the bottom plate, a stirring device, a lower grinding block, a first breaking roller, a second breaking roller and a flow guide plate are arranged in the breaking chamber, and the device is simple in structure, reasonable in design and convenient to use; due to arrangement of the stirring device, under the action of a stirring motor, an upper grinding block is driven to move, in cooperation with the action of a lower grinding block, the material is subject to grinding and breaking, the material grinding and breaking quality is greatly improved, due to arrangement of the first breaking roller and the second breaking roller, a material can be primarily broken, the material breaking rate is improved, the material breaking quality is improved, due to arrangement of a dust suction pipe, dust generated in the grinding process is absorbed, and the dust is discharged along with the ground material, and the material use rate is greatly improved.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

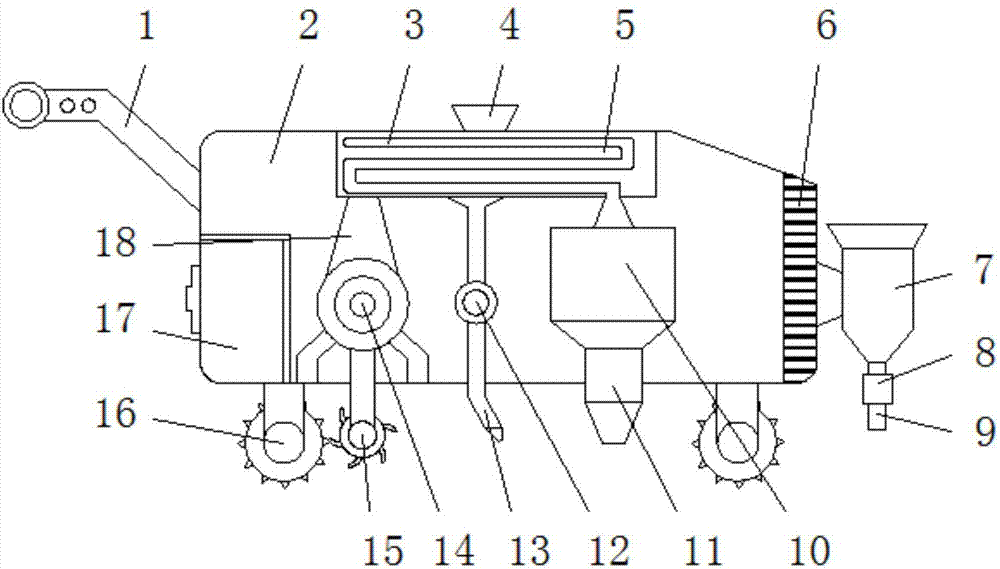

Road ice melting machine

InactiveCN107299616AIncrease the crushing rateImprove work efficiencySnow cleaningIce storageEngineering

The invention discloses a road ice melting machine, which comprises a main body of the ice melting machine, a handle is welded on one side of the ice melting machine body, a water storage tank is arranged on the inner top of the ice melting machine body, and an inlet Water outlet, the water storage tank is connected to the heater through a heating pipe, and a heat outlet pipe is welded at the bottom of the heater, a heat conduction pipe is welded on one side of the bottom of the water storage tank, and a motor is welded at the bottom of the heat conduction pipe, and the motor is connected to the ice breaker through a rotating shaft. The outer surface of the ice breaker is welded with an ice breaker, the motor is provided with a locker, the bottom of the salt storage tank is welded with a salt outlet pipe, and a flow meter is installed inside the salt outlet pipe. The bottom of the body is welded with a hub, and the outer surface of the hub is welded with sawtooth blocks. In the present invention, the overall structure design of the ice melting machine is simple and reasonable, the ice melting process is safe and simple, the heat utilization rate is high, and the ice melting work efficiency is strong.

Owner:CHENGDU YANXINGGUO TECH CO LTD

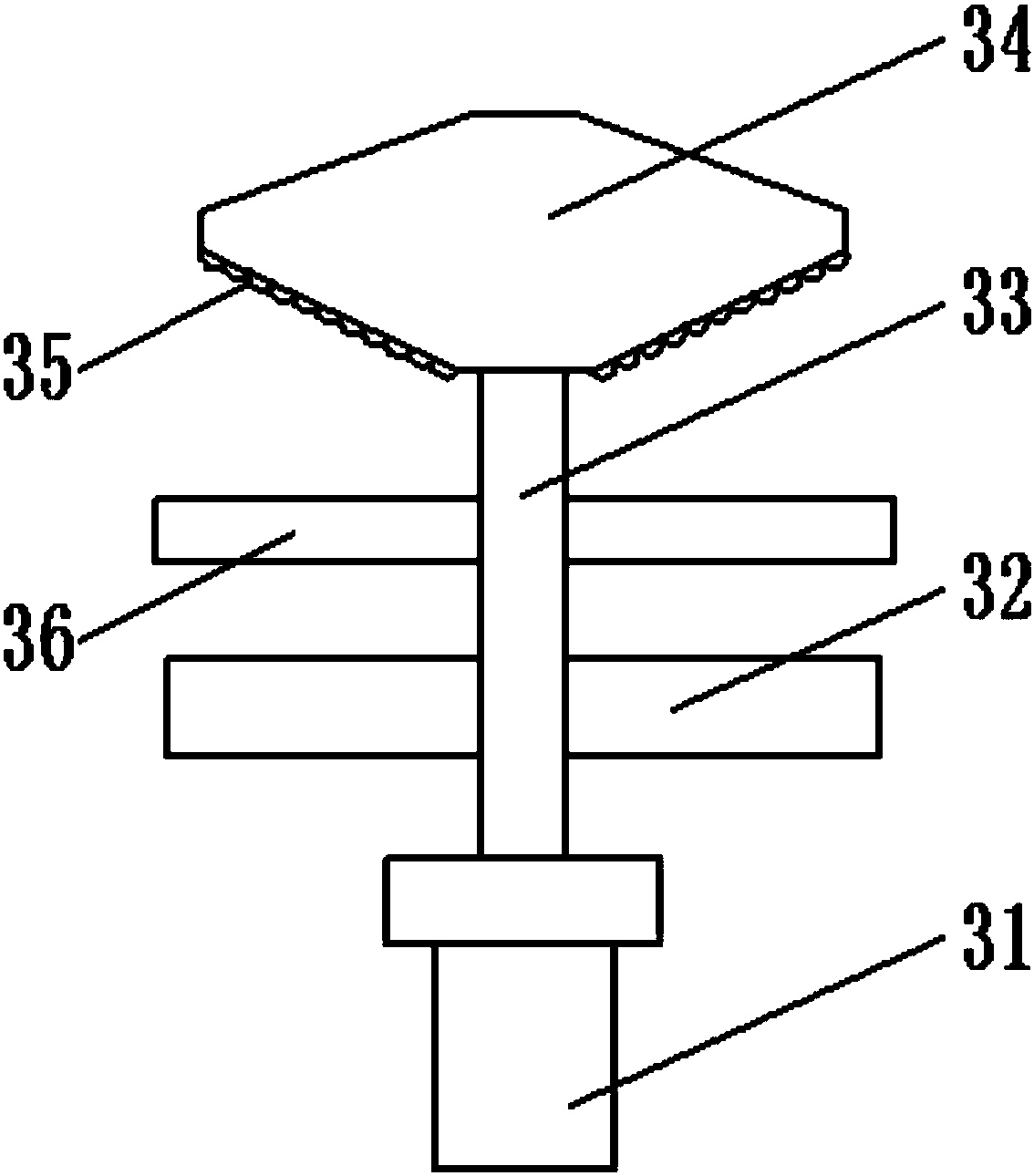

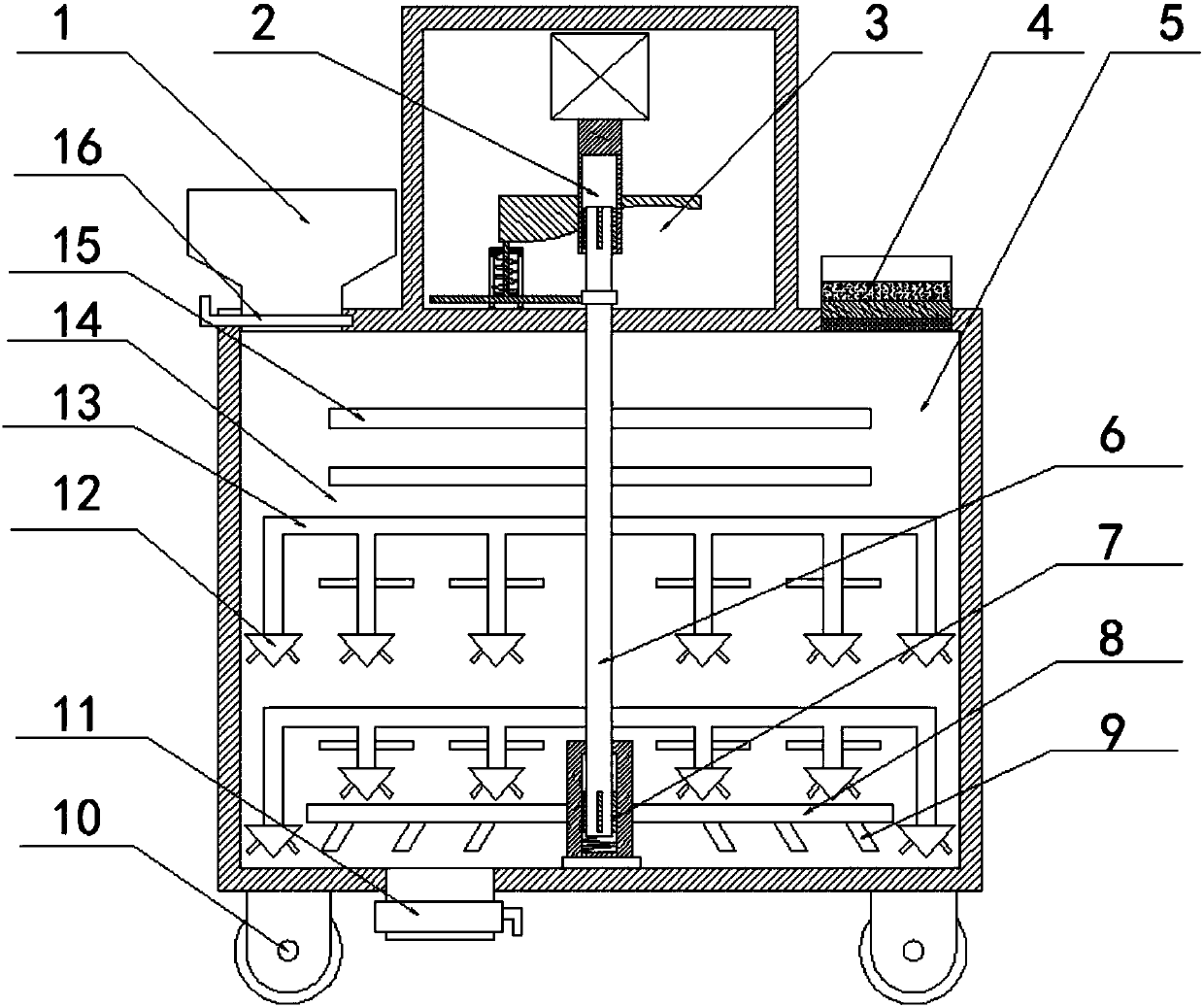

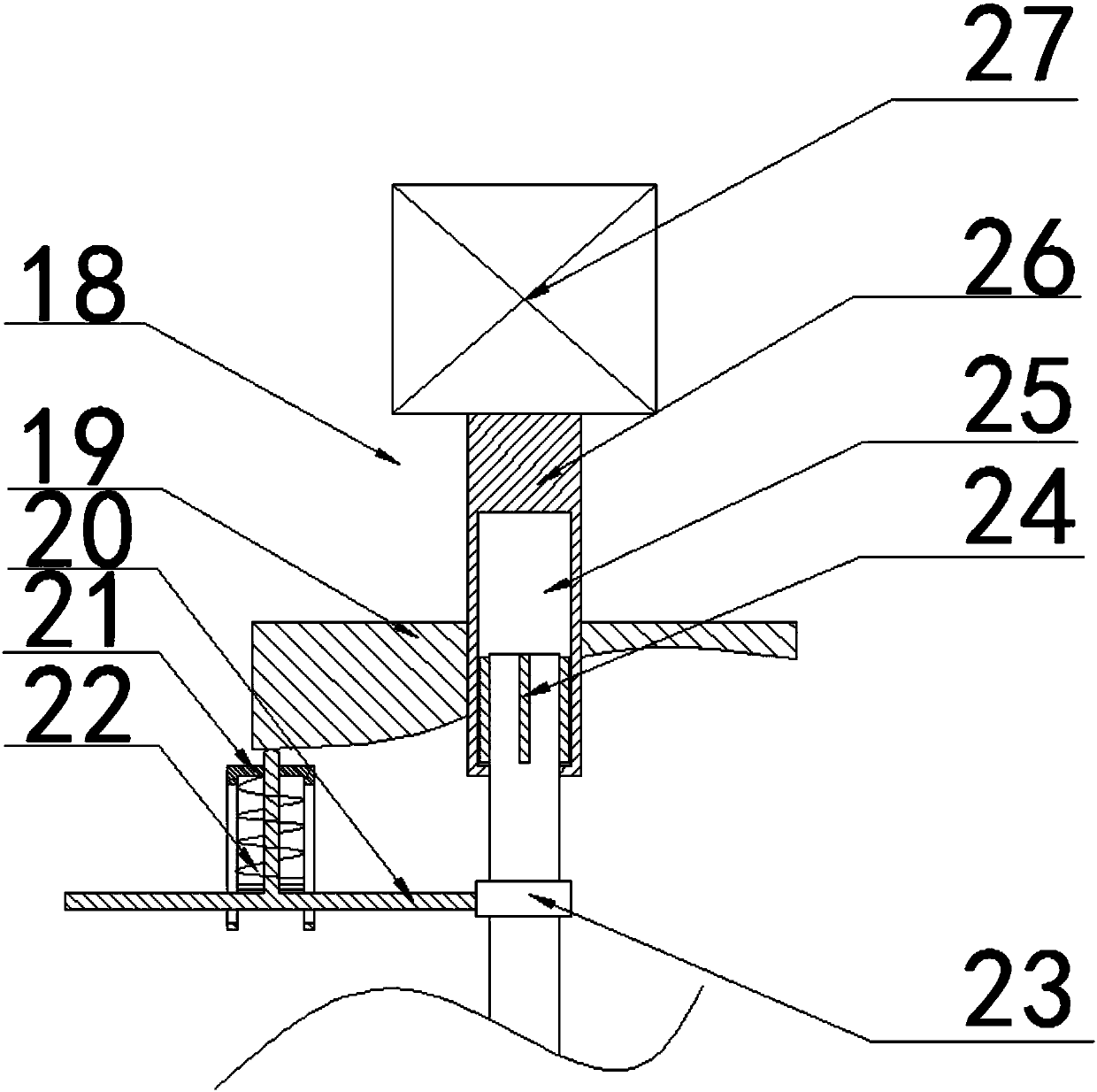

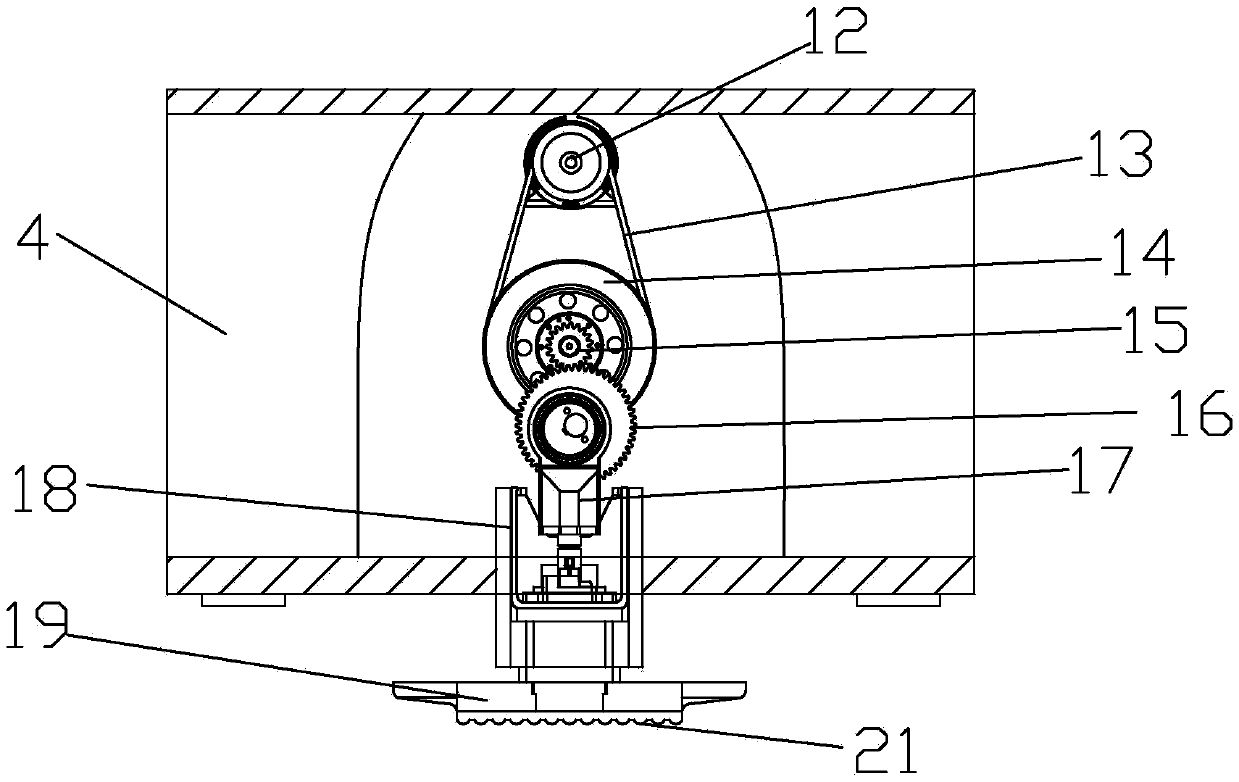

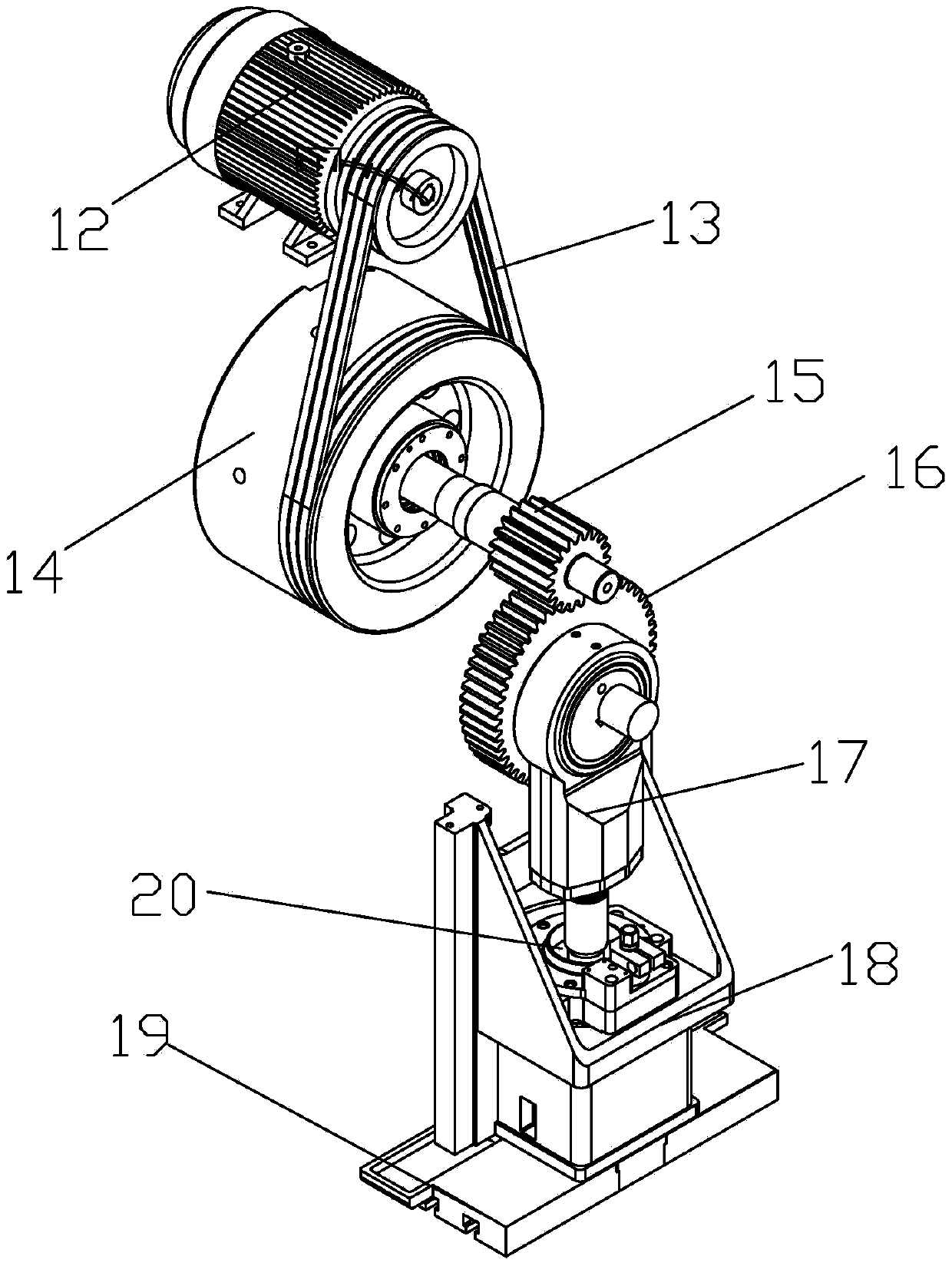

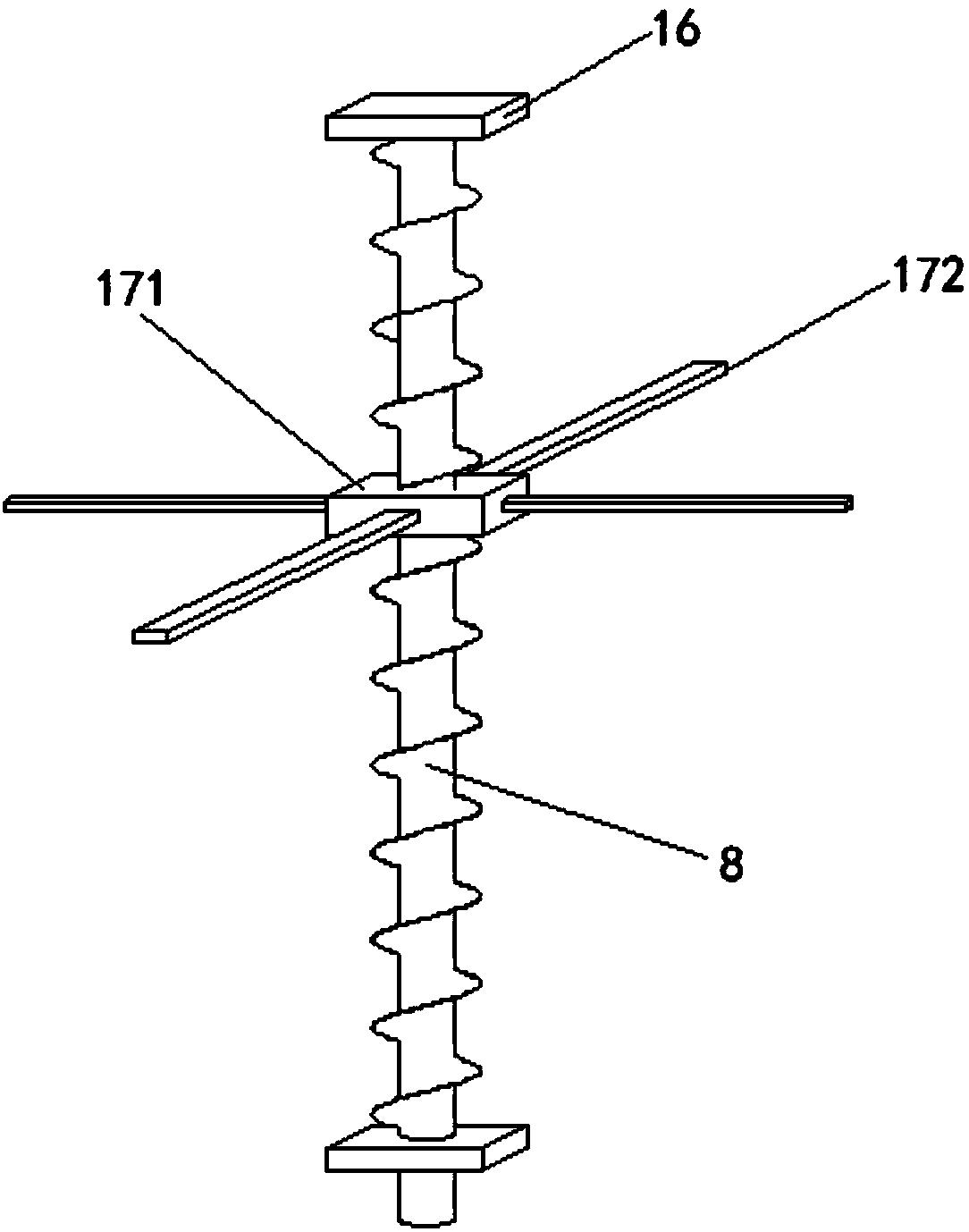

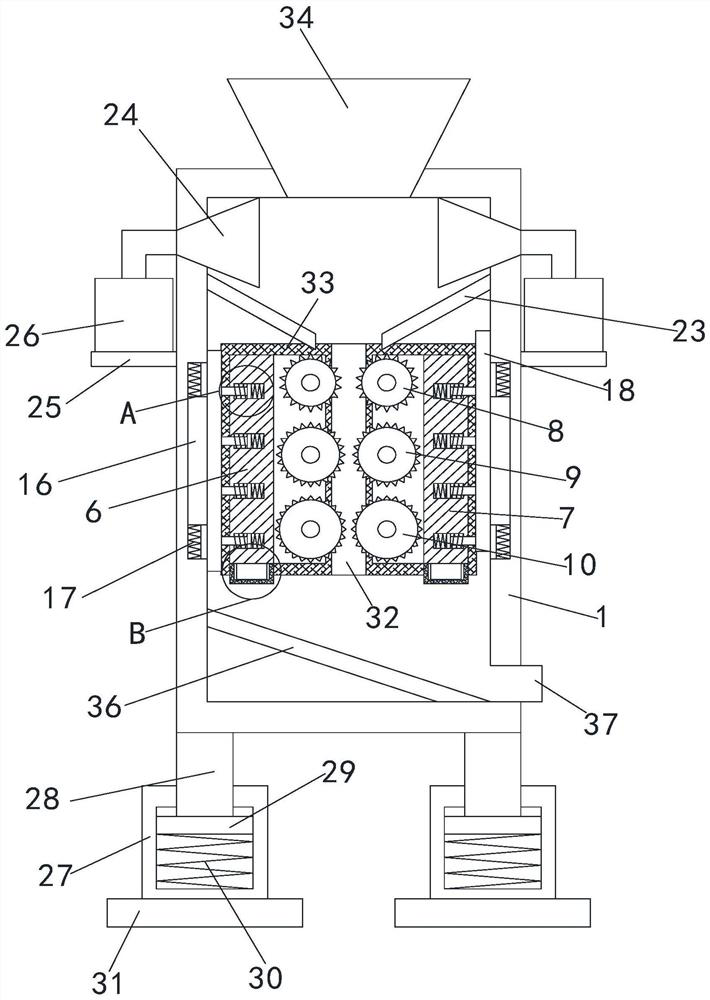

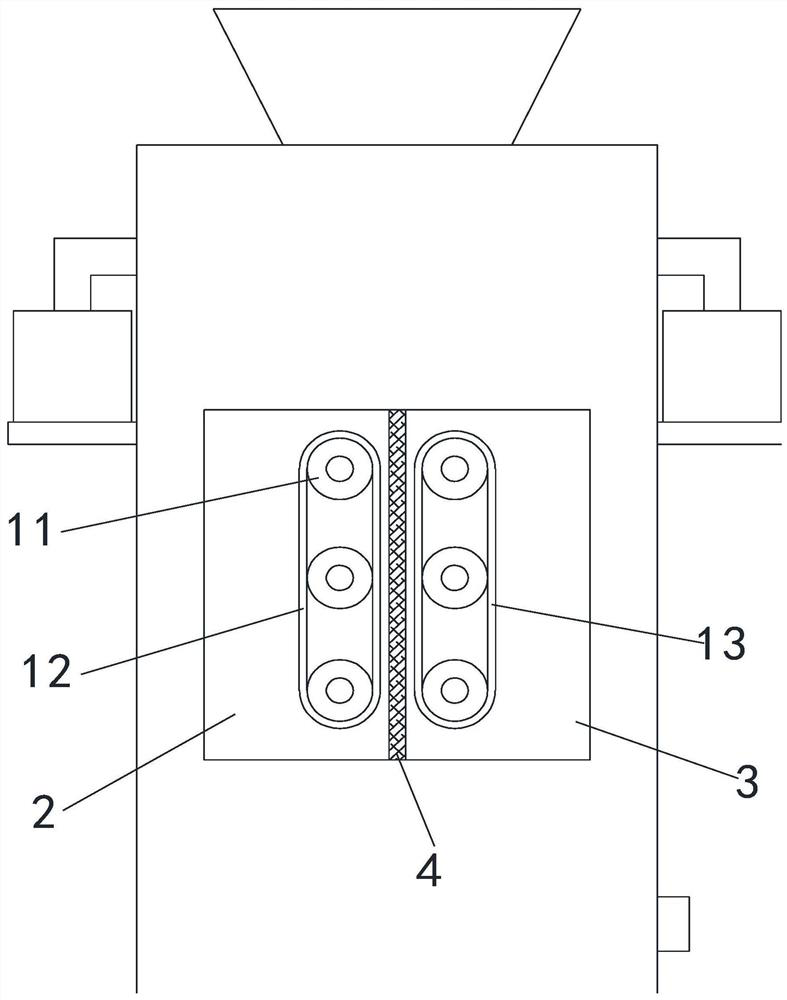

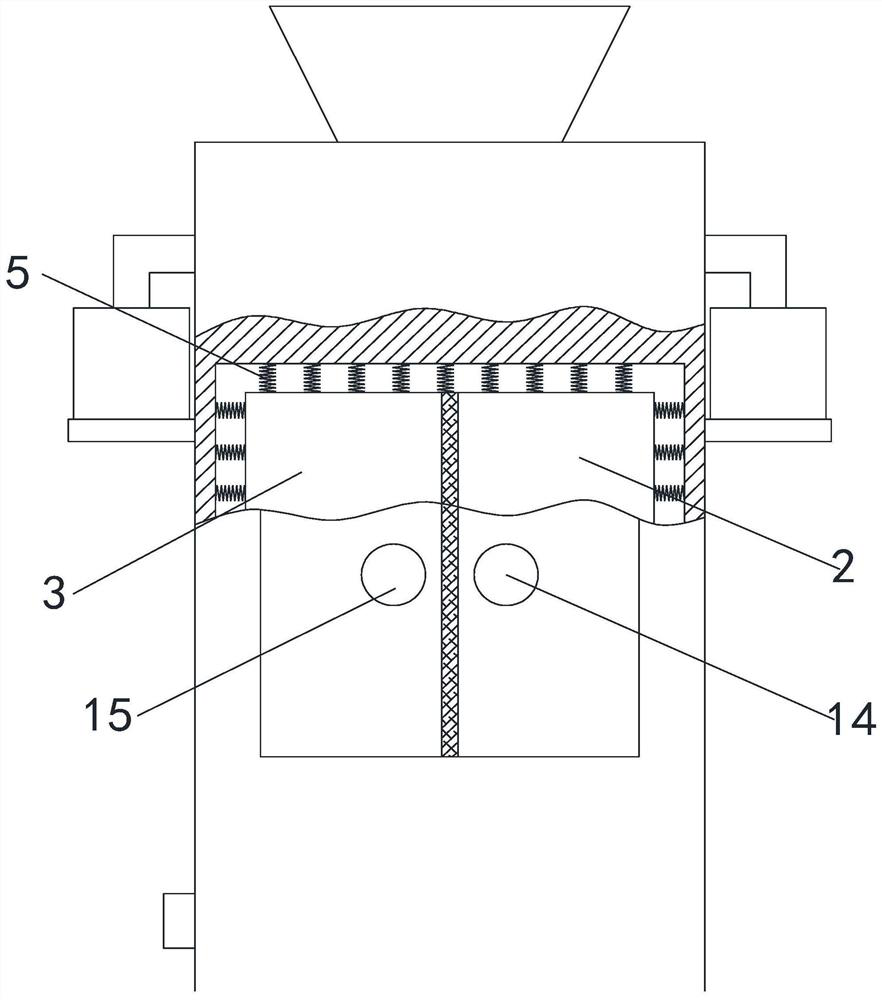

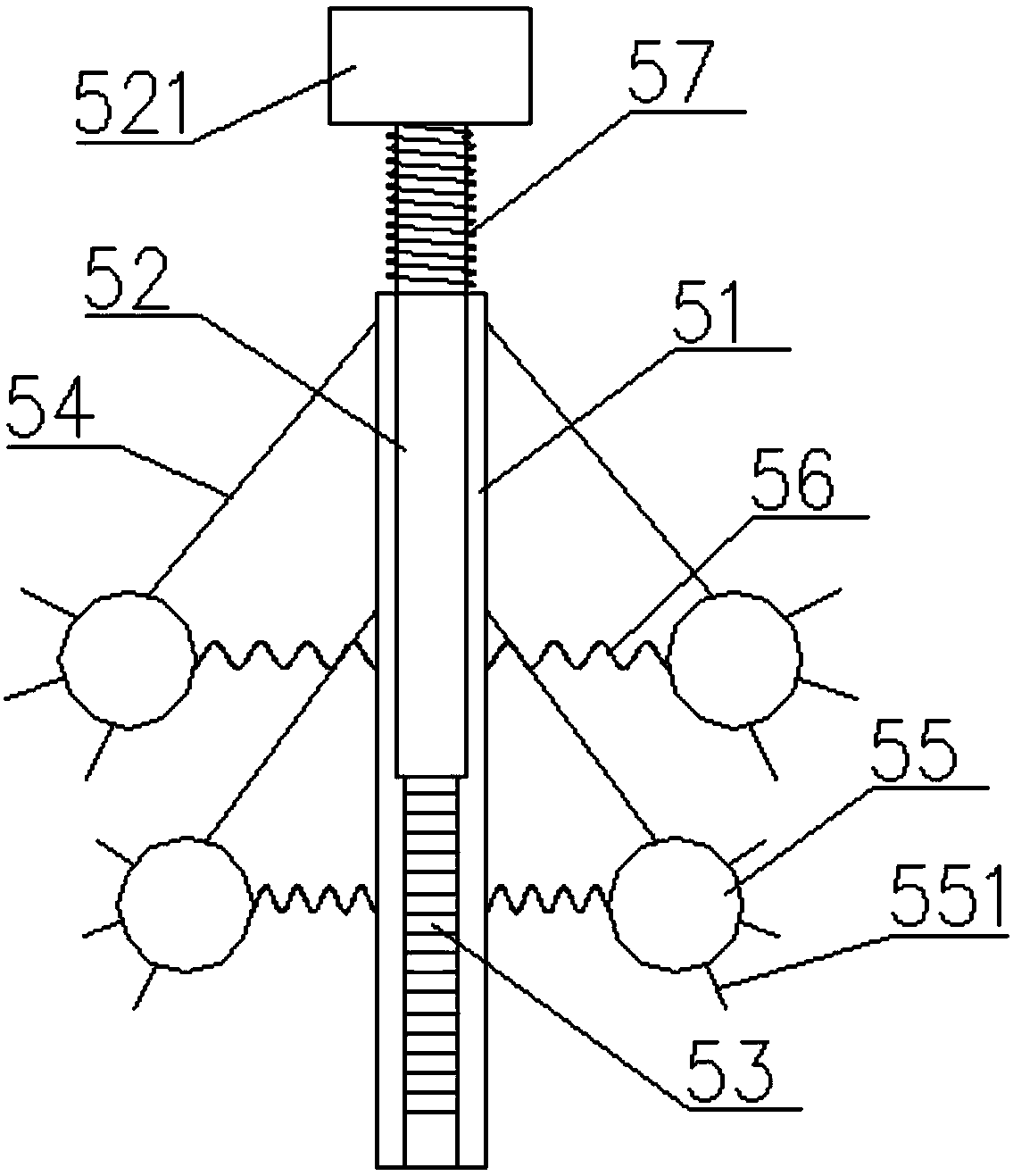

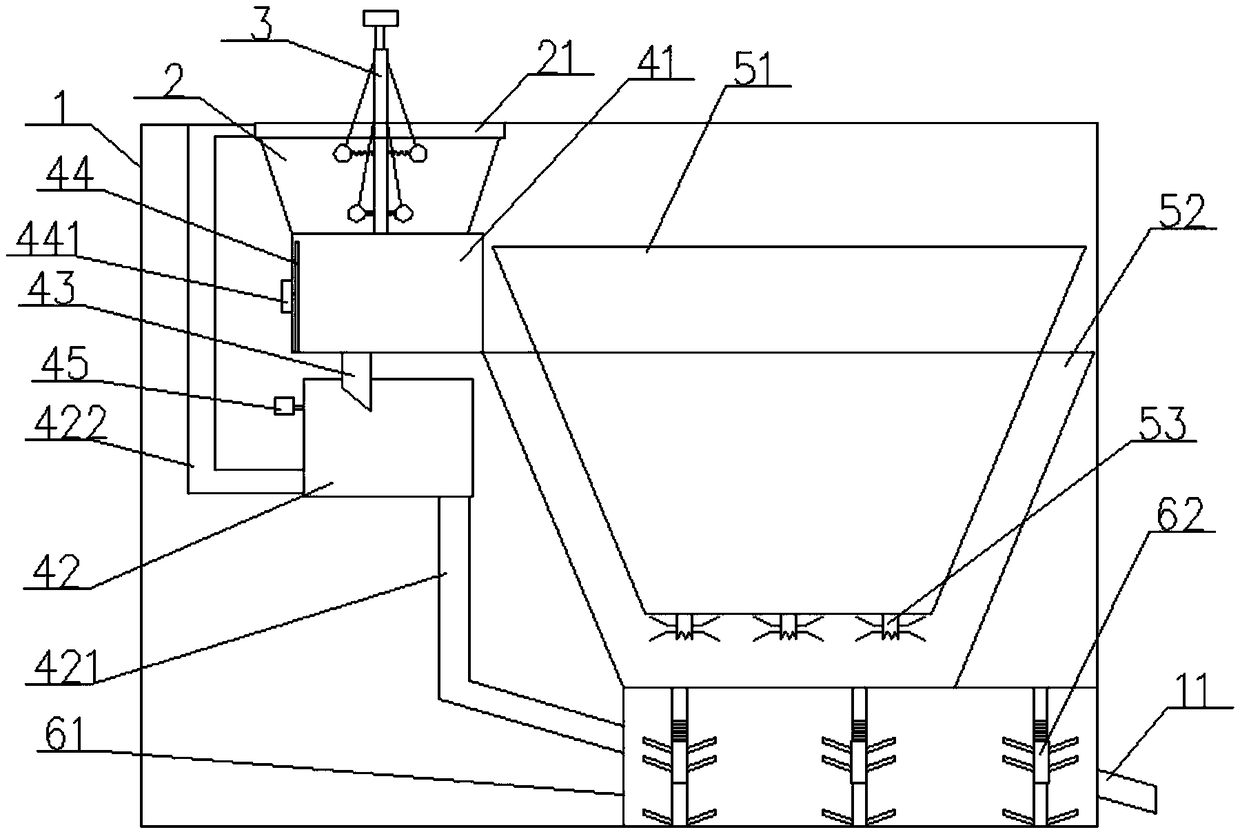

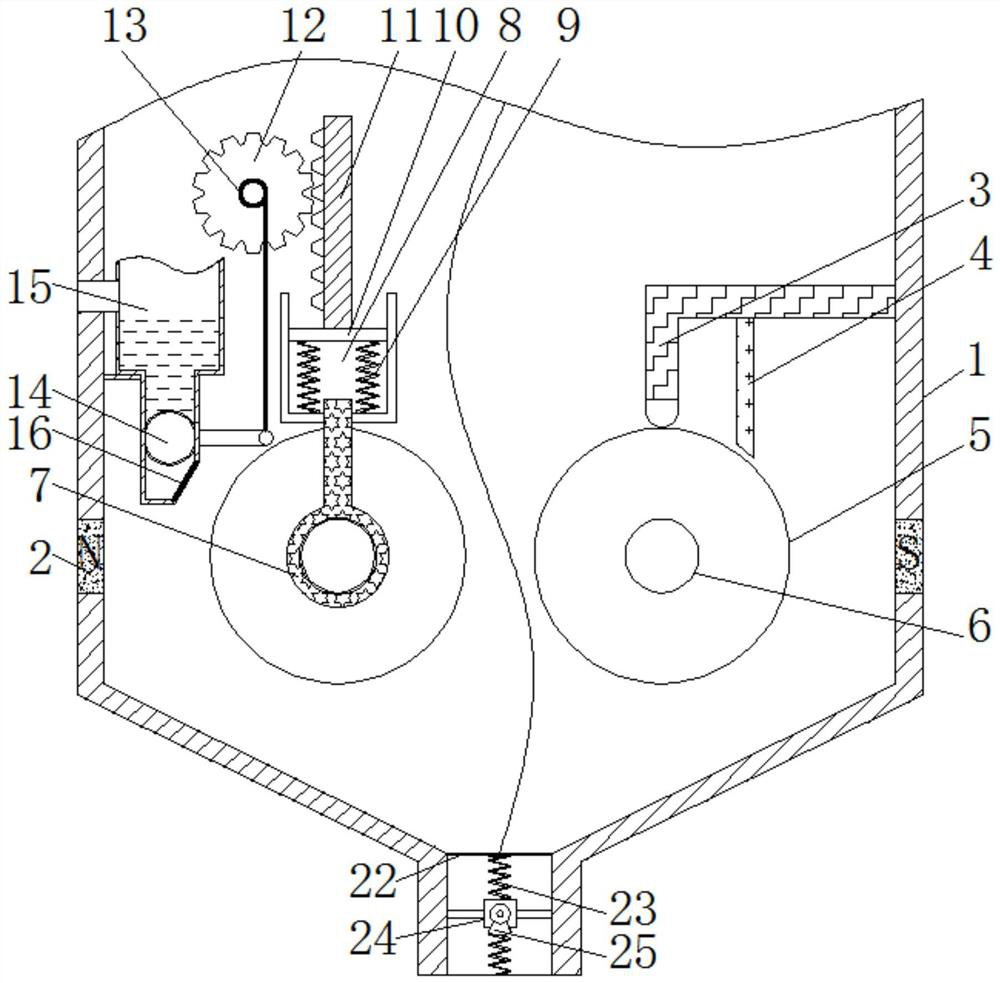

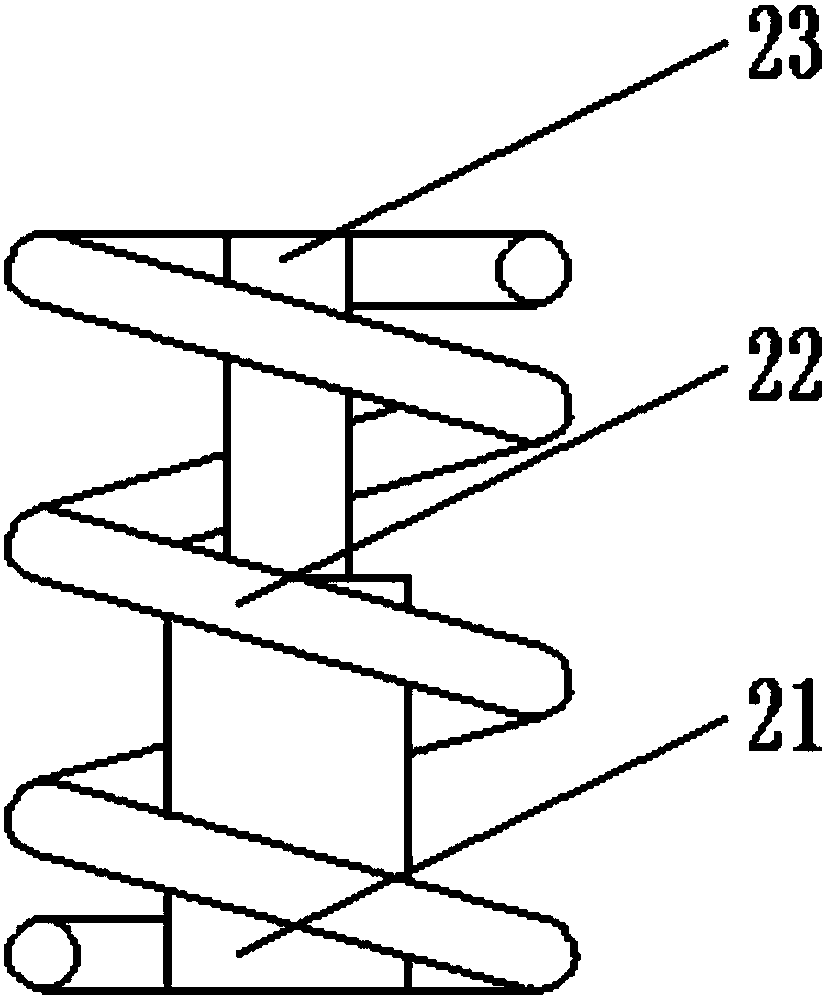

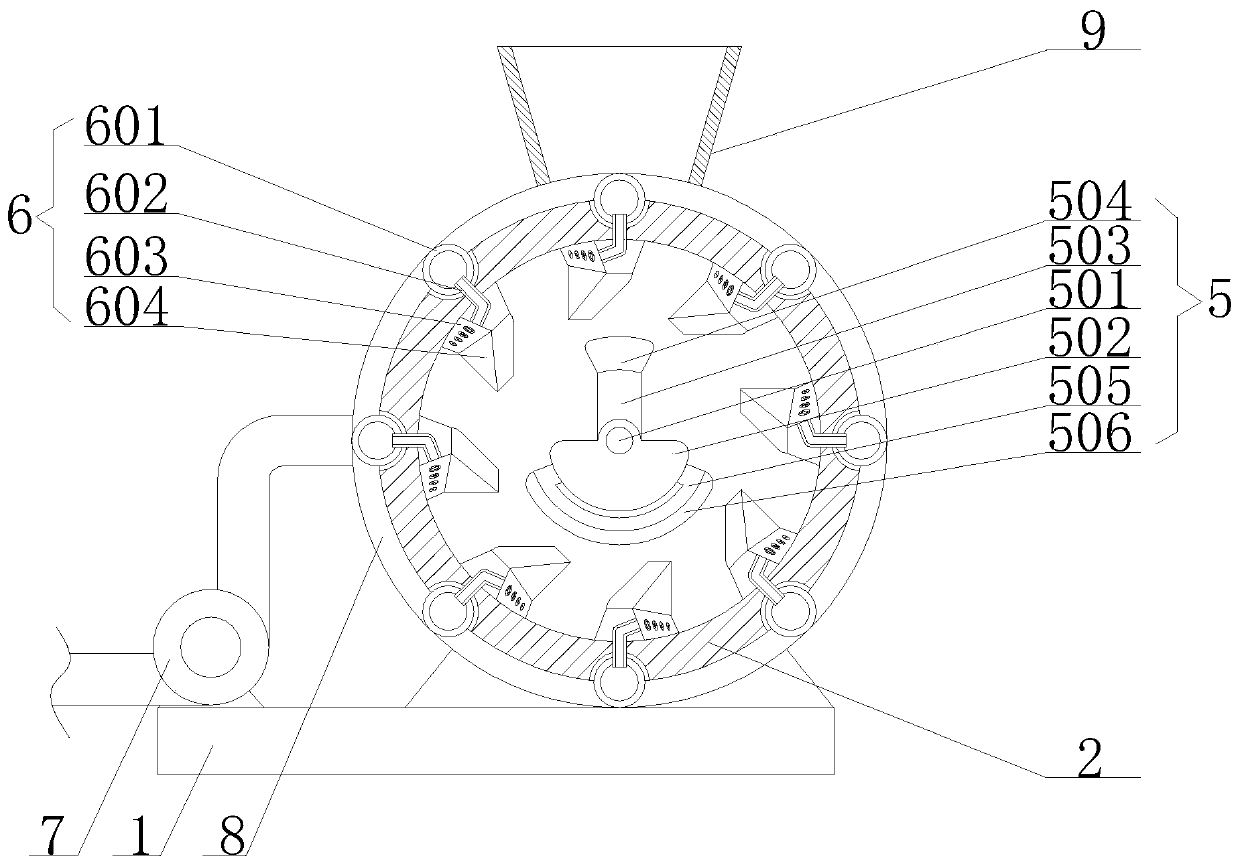

Novel caked feed crushing device

InactiveCN107649249AIncrease the crushing rateShaking/oscillating/vibrating mixersFeeding-stuffReciprocating motionEngineering

The invention provides a novel caked feed crushing device and belongs to the field of feed processing. The novel caked feed crushing device comprises a feeding device, a cam transmission device, a crushing and stirring device and an air exchange device. The cam transmission device is arranged inside a cam transmission device storing cavity. The crushing and stirring device is arranged inside a blocky feed crushing cavity. The air exchange device is arranged on the right side of the cam transmission device storing cavity and on the upper portion of the blocky feed crushing cavity, and a layer of filter cloth is arranged at the bottom of the air exchange device. By arranging the cam transmission device, a moving rotating shaft can rotate and make vertical reciprocating motion simultaneouslyand drives the crushing and stirring device on the lower portion to rotate and make vertical reciprocating motion together, accordingly blocky feed in the blocky feed crushing cavity is beat and extruded to be crushed into small particles and is stirred through rotating of the crushing and stirring device, thus the blocky feed can be beat and extruded uniformly, and accordingly the crushing rate of the blocky feed is increased.

Owner:惠安县飞联电子产品有限公司

Waste glass pretreatment system applied to glass production

InactiveCN105363538AGuaranteed uptimeRun orderlyMagnetic separationCleaning using gasesMetal particleEngineering

The invention discloses a waste glass pretreatment system applied to glass production. The waste glass pretreatment system comprises a primary smashing device, a secondary smashing device and a metal filter. The primary smashing device comprises an upper rack and a lower rack; the lower rack is provided with a primary guiding belt; a pressure device is disposed in the upper rack; the pressure device comprises an eccentric gear, a crank connecting rod and a pressing plate; the primary guiding belt is connected with the secondary smashing device; smashing rollers are disposed in the secondary smashing device and mutually matched; a guide pipe is disposed at the lower end of a dust remover; the guide pipe is connected with the metal filter; the metal filter comprises a secondary guiding belt and an electromagnet sucker; the electromagnet sucker is matched with the secondary guiding belt; the secondary guiding belt is connected with the guide pipe. According to the waste glass pretreatment system applied to glass production, the primary smashing device, the secondary smashing device and the metal filter are arranged respectively; waste glass is smashed by the aid of the primary smashing device and the secondary smashing device so as to form smashed glass of which the particle size is uniform; finally metal particle impurities in the smashed glass are gradually adsorbed through the metal filter.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

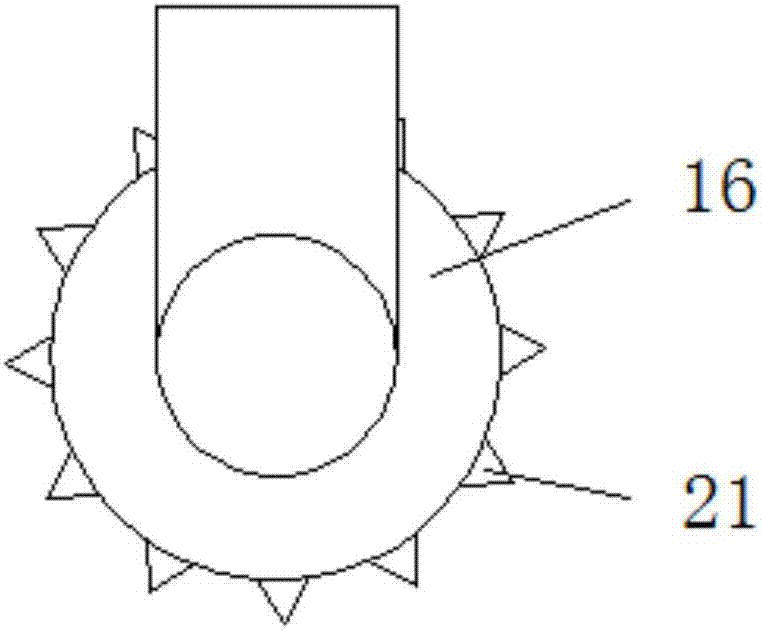

Garden fallen leaf and deadwood pulverizing equipment

InactiveCN108057504ASimple structureReasonable designPlant waste comminutingCuttersLeaf fallDrive motor

The invention provides garden fallen leaf and deadwood pulverizing equipment, and belongs to the technical field of garden pulverizing. The garden fallen leaf and deadwood pulverizing equipment comprises supporting legs. A bottom plate is arranged on the tops of the supporting legs. The top of the bottom plate is provided with a supporting vertical rod and a pulverizing cavity. The device is simple in structure, reasonable in design and convenient to use. Due to the arrangement of a feeding hopper, materials can be conveniently centralized and conveyed into a pulverizing chamber. Due to the arrangement of a pulverizing device, the materials can be subjected to primary pulverizing treatment, the material pulverizing rate is increased, and accordingly the pulverizing quality can be greatly improved. Due to the arrangement of a pulverizing block, a reset device and a drive device, a drive motor drives a rotation wheel to rotate under the action of the drive device, the pulverizing block is driven to move downwards, and the materials are subjected to pulverizing treatment; and under the action of the reset device, the pulverizing block is driven to move upwards and resets, then, the drive motor is used for driving the pulverizing block to move downwards, the motion is conducted repeatedly, and the continuous material pulverizing effect is achieved.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

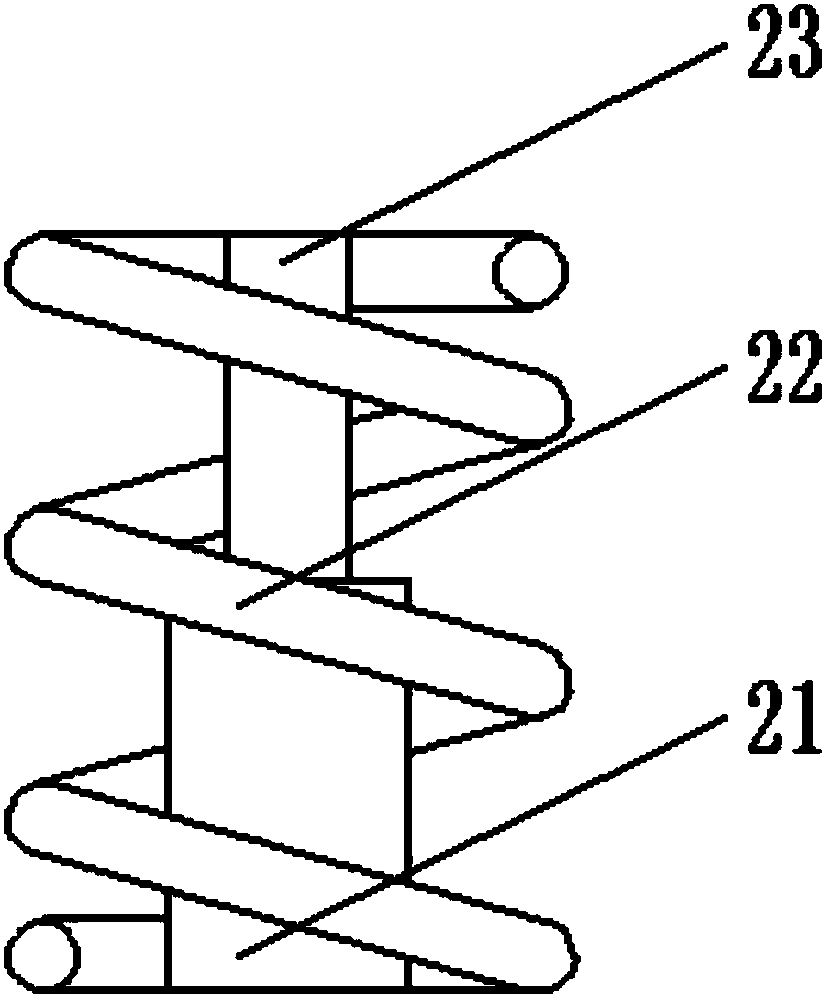

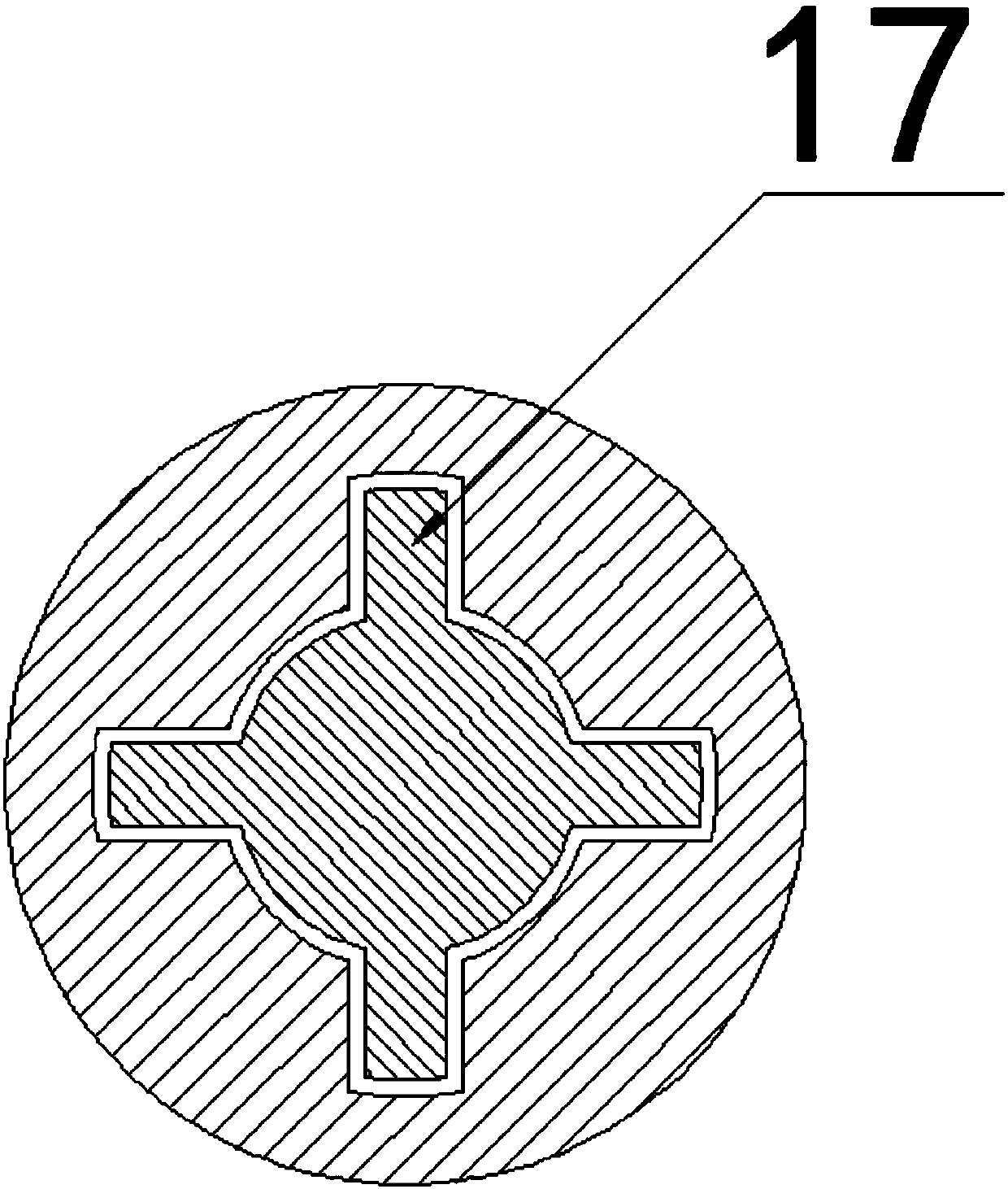

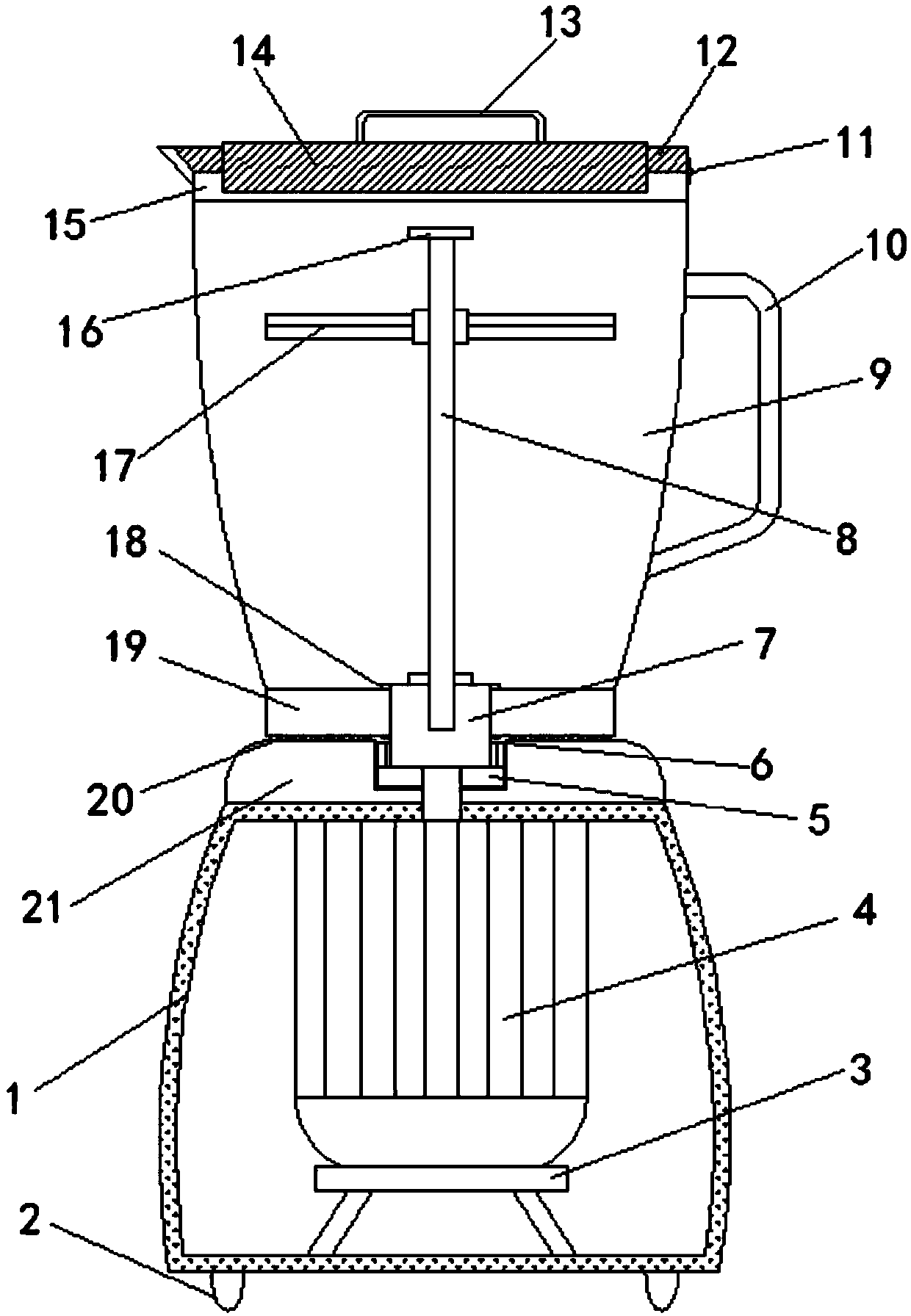

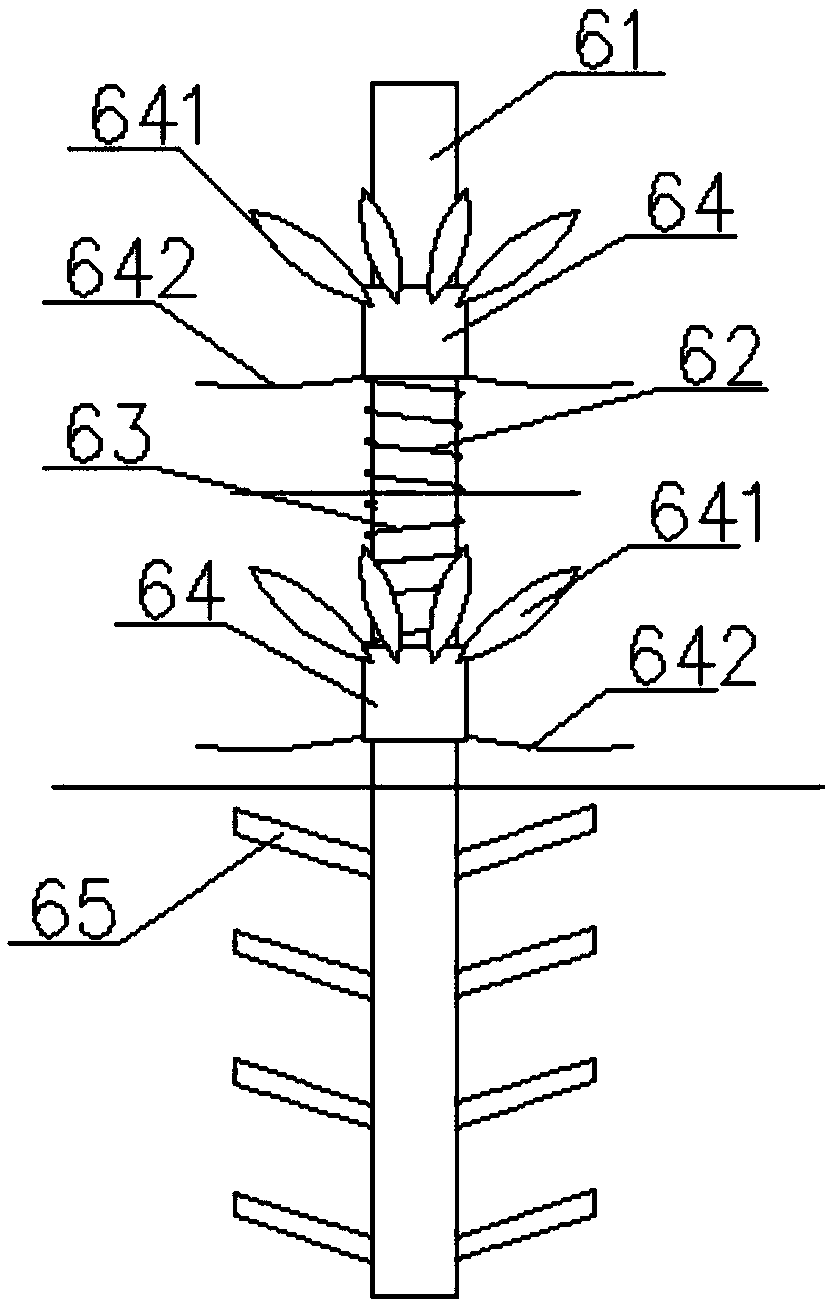

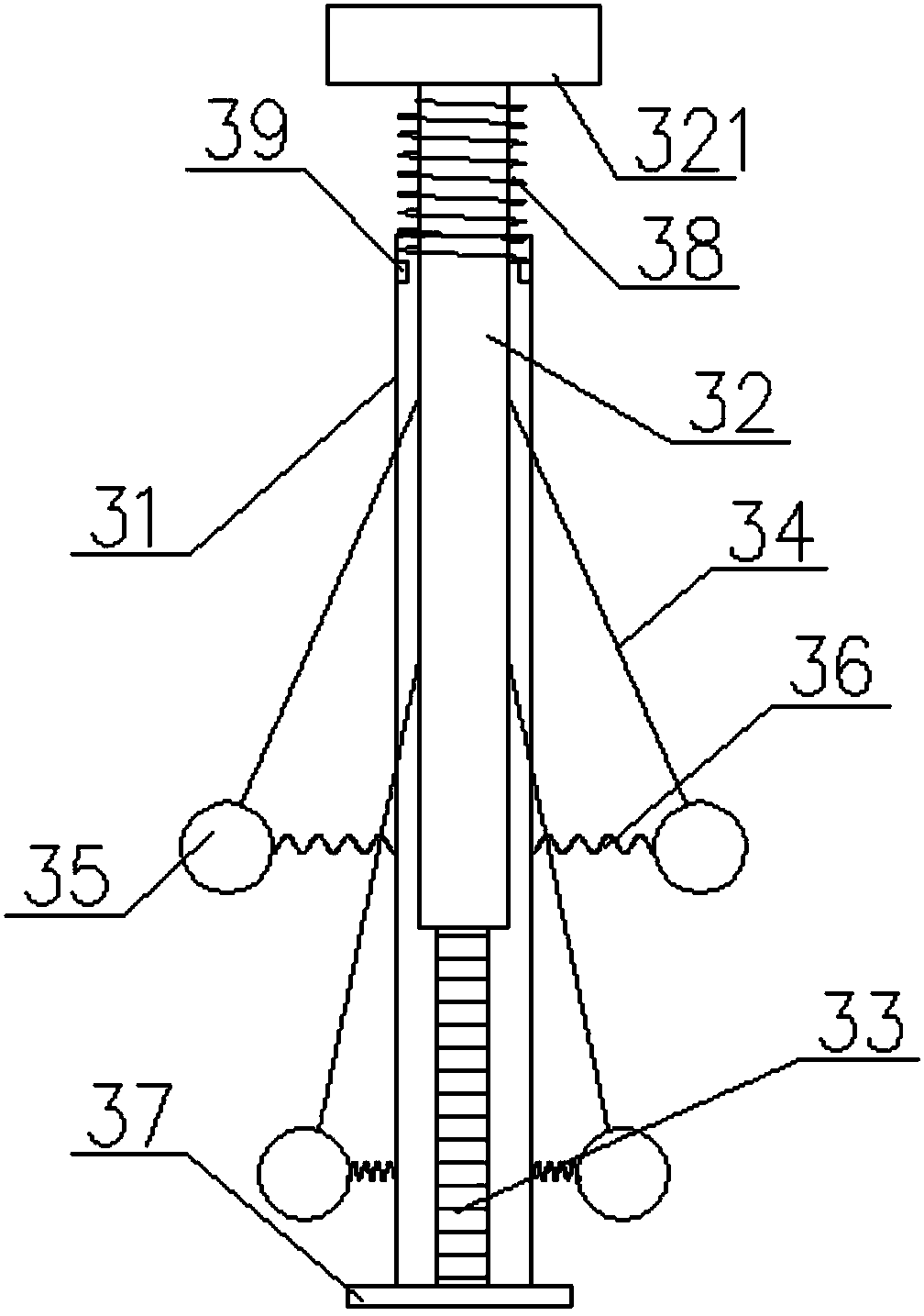

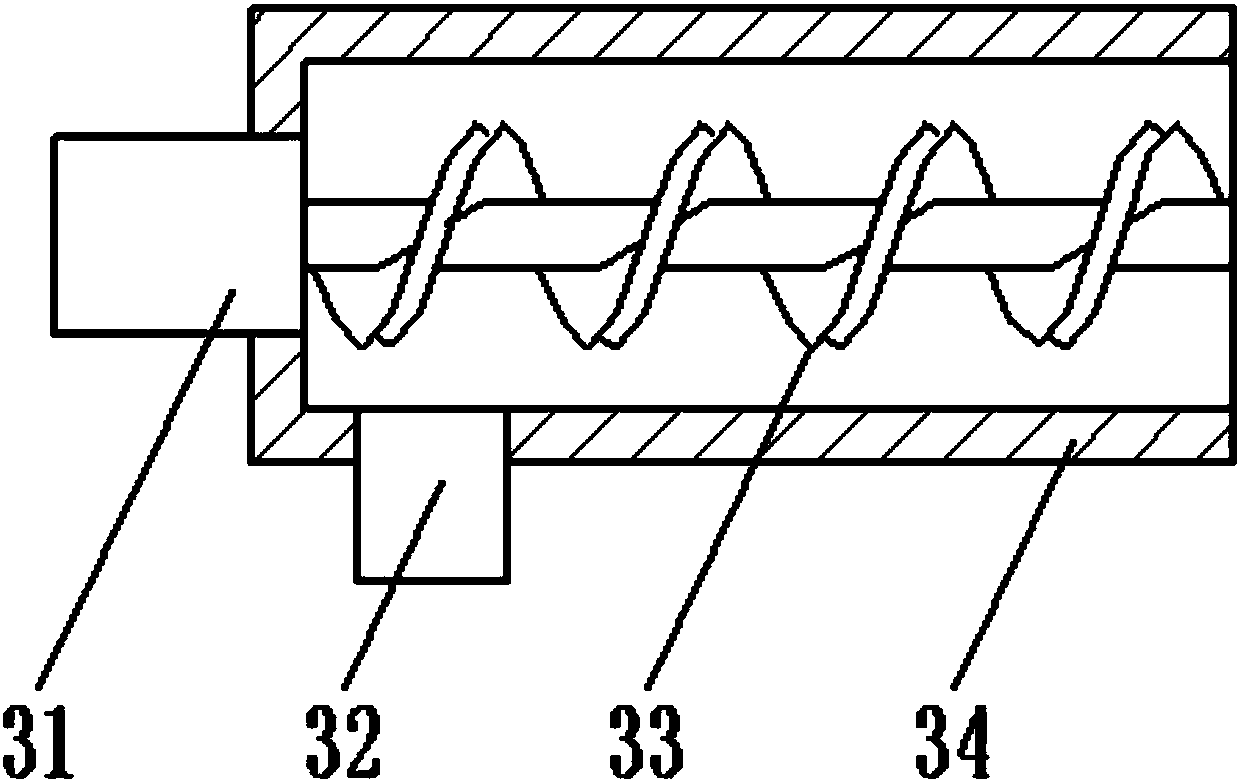

Small household food processer

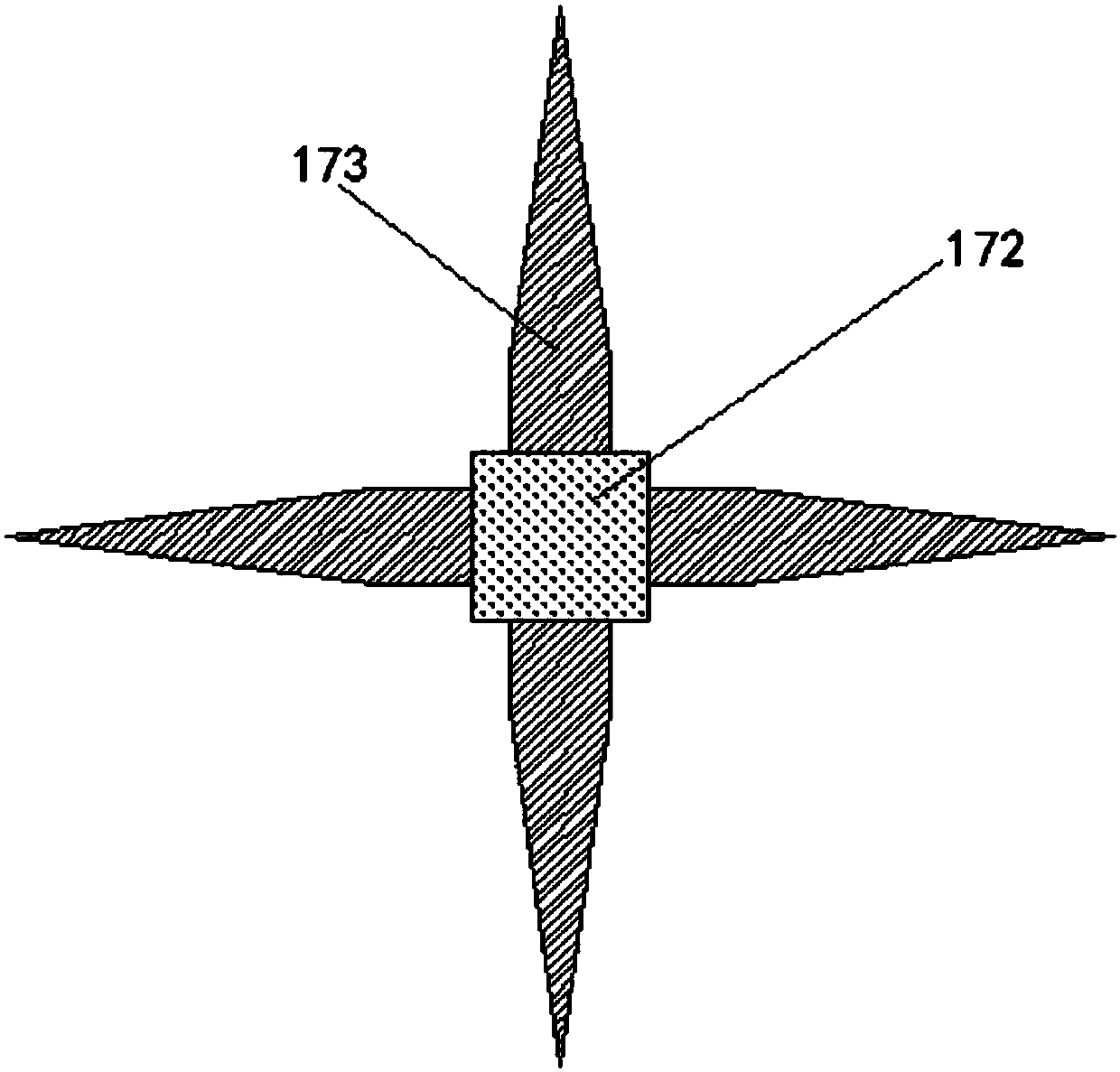

InactiveCN108042015AEffective cutting and crushingEfficient crushingKitchen equipmentEngineeringFood material

The invention relates to a small household food processer. The food processer includes a base, a stirring cup, a handle, an outer cover and an inner cover; multiple supporting legs are arranged on thelower surface of the base, a motor is arranged in the base, and a motor support is arranged below the motor; the motor is fixedly connected with the bottom surface of the interior of the base throughthe motor support, a placing table is arranged above the base, a groove is formed in the center of the placing table, and an output end of the motor penetrates through the placing table and stretchesinto the groove. By adopting a leading screw as a rotating rod and connecting a knife rest with the rotating rod, the rotating rod rotates in a reciprocating mode under the action of the servo motor;meanwhile, the knife rest rotates with the rotating rod and moves up and down in a reciprocating mode, and food materials within each horizontal plane can be effectively cut and smashed; meanwhile, the cross section of the blade point of a supporting rod on the knife rest is in a cross shape, not only is a horizontal cutting force provided during rotation, but also the food materials in the vertical direction can be cut when the knife rest moves up and down, the speed rate of smashing the food materials is further increased correspondingly, and the obtained food materials are fully smashed.

Owner:余国兰

Decorative material smashing and mixing device

ActiveCN108201942AHigh precisionImprove crushing qualitySievingScreeningMechanical engineeringMaterial technology

The invention belongs to the technical field of decorative materials and particularly discloses a decorative material smashing and mixing device. The decorative material smashing and mixing device comprises a box. A crushing mechanism is arranged in the box. The crushing mechanism comprises an inner roller and an outer roller. The outer roller comprises a coarse crushing outer roller body and a fine crushing outer roller body. The inner roller comprises a coarse crushing inner roller body and a fine crushing inner roller body. The outer roller is internally provided with a cavity. The coarse crushing inner roller body is shaped like a circular truncated cone and is located in the coarse crushing outer roller body. The conicity of the coarse crushing inner roller body is greater than that of the coarse crushing outer roller body. The fine crushing inner roller body is shaped like a circular truncated cone and is located in the fine crushing outer roller body. The conicity of the fine crushing inner roller body is greater than that of the coarse crushing inner roller body. The sidewall of the fine crushing outer roller body is provided with a first discharge port. The sidewall of thecoarse crushing outer roller body is provided with a second discharge port. A filter screen is arranged below the crushing mechanism. A partition board is arranged on the filter screen. Filter gaps of the filter screen on the two sides of the partition board are different. A material mixing plate is arranged below the filter screen. An outlet is formed in the center of the material mixing plate.Through the scheme, the decorative material smashing and mixing device achieves crushing and mixing of different decorative materials.

Owner:聊城泽润装饰工程有限公司

Junked tire liquid nitrogen cryogenic grinding box and using method

ActiveCN108638389AIncrease the crushing rateEasy to put inPlastic recyclingMechanical material recoveryBrickNitrogen

The invention discloses a junked tire liquid nitrogen cryogenic grinding box and a using method. The junked tire liquid nitrogen cryogenic grinding box comprises a box body, a feeding inlet, a sealingdoor, a connection rope, a sliding plate, two brackets, two rotation wheels, four stand bars, a discharging outlet, a sealing cover, a high-pressure liquid nitrogen cabin, a nitrogen pipe, an electromagnetic valve, a spray pipe, a spray head, a decompression cabin, a spring, a draught fan, a ring-shaped air duct, a jet head, an air exhaust slot, a sealing rubber rod and a bypass pipe, wherein thefour stand bars are uniformly mounted at the bottom of the box body; the feeding inlet is formed above the side wall of the box body; the bottom end of the feeding inlet is rotatably connected with the sealing door; the sliding plate is rotatably mounted on the inner wall of the box body and below the feeding inlet; the two brackets are symmetrically fixed on the inner wall of the box body and between the feeding inlet and the sliding plate; and the rotation wheels are rotatably mounted at the tops of the brackets. According to the junked tire liquid nitrogen cryogenic grinding box, rubber bricks are stirred through intermittently spraying liquid nitrogen and intermittently blowing air, so that the rubber brick grinding speed is improved, the liquid nitrogen is saved, and the putting andtaking of the rubber bricks are convenient, so that the junked tire liquid nitrogen cryogenic grinding box is simple in structure and safe to use.

Owner:WUHU INST OF TECH

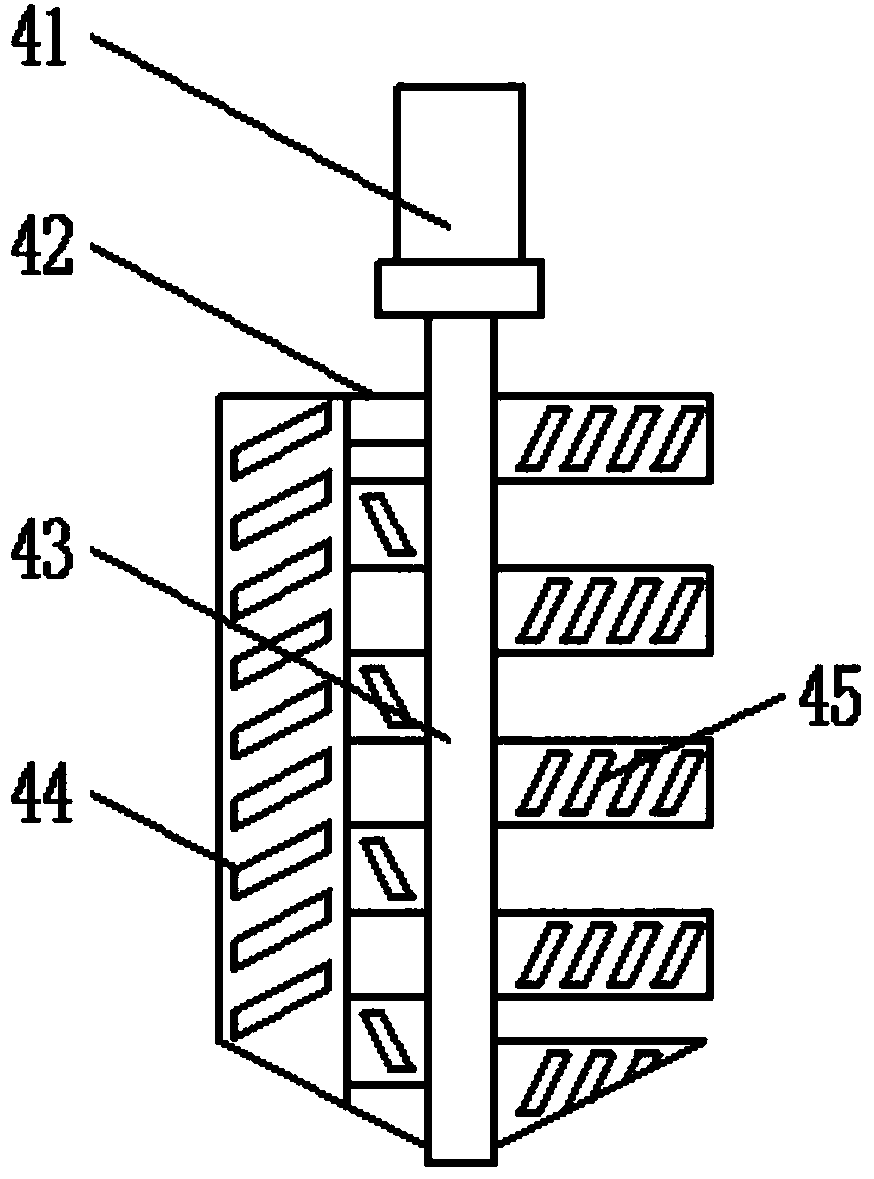

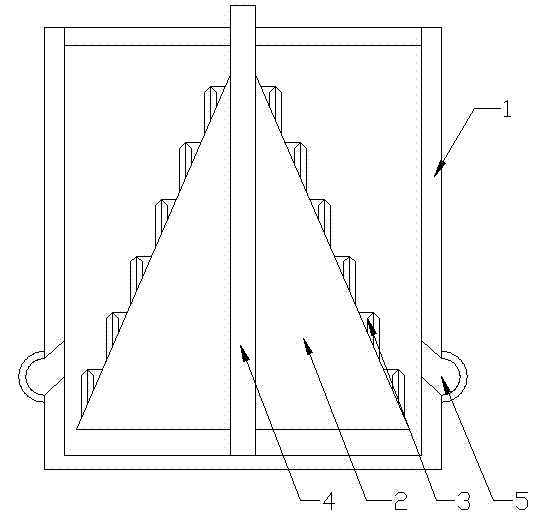

Array-type PCB photosensitive film crushing device

InactiveCN104492563AReduced sharpness requirementsSimple structureGrain treatmentsEngineeringMechanical engineering

The invention discloses an array-type PCB photosensitive film crushing device. The array-type PCB photosensitive film crushing device comprises a base barrel, a crushing mechanism and an air blast mechanism. The crushing mechanism comprises a conical rotation seat. A conical inclined plane of the conical rotation seat is provided with several annular smashing blades. The annular axis of the smashing blade and the axis of the rotation seat are the same. The air blast mechanism comprises a fan and an annular air duct. The annular air duct is arranged at the conical bottom of the base barrel corresponding to the rotation seat. The connection position of the annular air duct and the base barrel wall is provided with an annular air outlet. The annular air duct is connected to the fan by a connection pipe. The rotary-type conical crushing mechanism is used for crushing a photosensitive film raw material, when the photosensitive film raw material tumbles toward the conical bottom along the conical inclined plane, the raw material is cut and crushed by a cutter which is rotating at a high rate, and when the raw material falls on the conical ground, the raw material is blown by the fan to return to the conical top, then falls again and then is repeatedly cut and crushed. The array-type PCB photosensitive film crushing device has a simple structure.

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

Smashing device used for domperidone bulk drugs

InactiveCN108906240AIncrease the frequency of collisionsIncrease agitation rateGrain treatmentsSteel ballEngineering

The invention provides a smashing device used for domperidone bulk drugs. The device comprises a smashing body, a top cover is arranged at the top end of the smashing body, a rotation cylinder is arranged on the upper portion of an inner cavity, second steel balls are contained in the lower portion of the inner cavity, the lower end of the rotating cylinder is provided with a filter net plate, first steel balls are contained in the rotating cylinder, a lower rotating shaft is arranged below the filter net plate, a lower stirring paddle set is distributed on the lower segment of the lower rotating shaft, an upper rotating shaft is arranged below the top cover, and an upper stirring paddle set is distributed on the lower segment of the upper rotating shaft. The device has the beneficial effects that upper stirring paddles can stir the first steel balls in the rotating cylinder, the collision frequency of the first steel balls and the bulk drugs can be improved, the primary and rapid smashing is achieved, in addition, the rotating cylinder and the upper stirring paddles are controlled to be opposite in the rotating direction, the stirring rate of the upper stirring paddles for the first steel balls is improved, the smashing rate of the first steel balls for the bulk drugs is improved, the lower stirring paddles stir the second steel balls, secondary smashing of the bulk drugs is achieved, the smashing efficiency is effectively improved, and the smashing quality is ensured.

Owner:江苏又一城智能科技有限公司

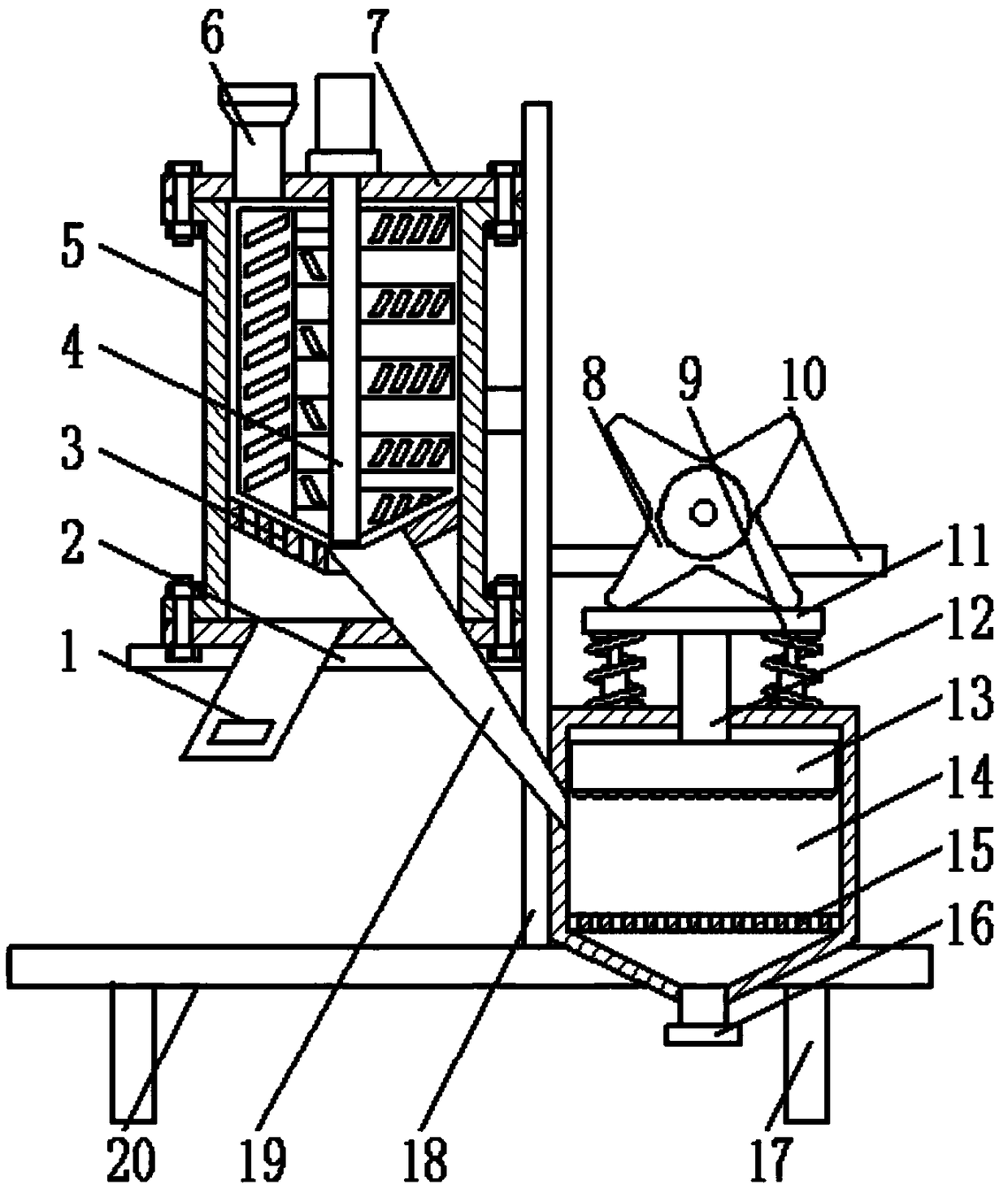

Feed crushing device with dust recycling function

InactiveCN107649279AImprove crushing effectReduce wasteFeeding-stuffGrain treatmentsFiltrationEngineering

The invention provides a feed crushing device with a dust recycling function and belongs to the field of crushing devices. The feed crushing device comprises a small-particle collection device, a funnel-shaped collection device, a vibration device, a secondary-crushing and screening device, a disc cutting device, a feeding device and transmission devices. The first transmission device and the second transmission device are arranged inside a transmission device storing cavity, and the secondary-crushing and screening device, a slope-type screen, the funnel-shaped collection device and the small-particle collection device are arranged inside a crushing and screening cavity. Compared with a common crusher, by arranging the multi-stage crushing device and an arc-shaped screen, the crushing speed can be increased, and meanwhile the feed crushing effect is improved; by arranging the slope-type screen and the vibration device, small particles and dust which are contained in crushed feed can be well filtered away; and through the arranged small-particle collection device on the lower portion, the dust feed in air is filtered and collected, and thus resource waste is reduced.

Owner:惠安县飞联电子产品有限公司

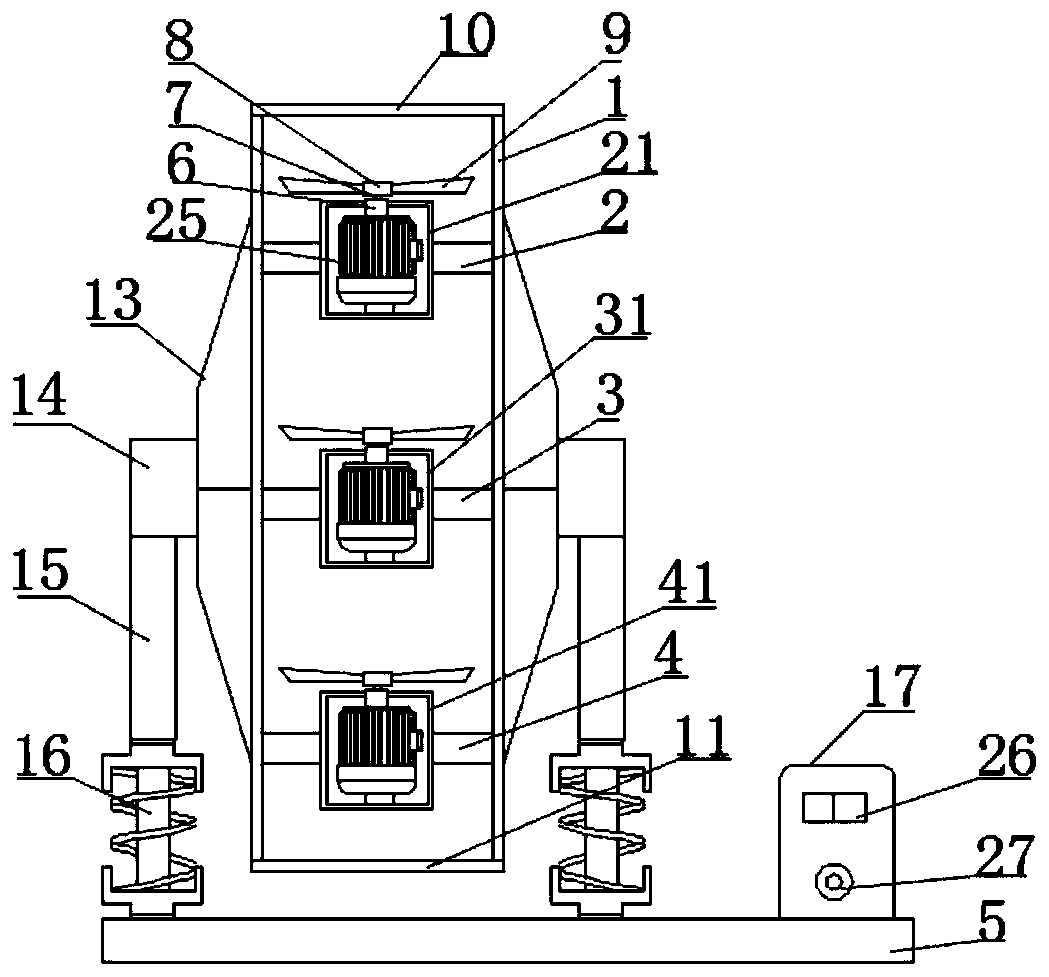

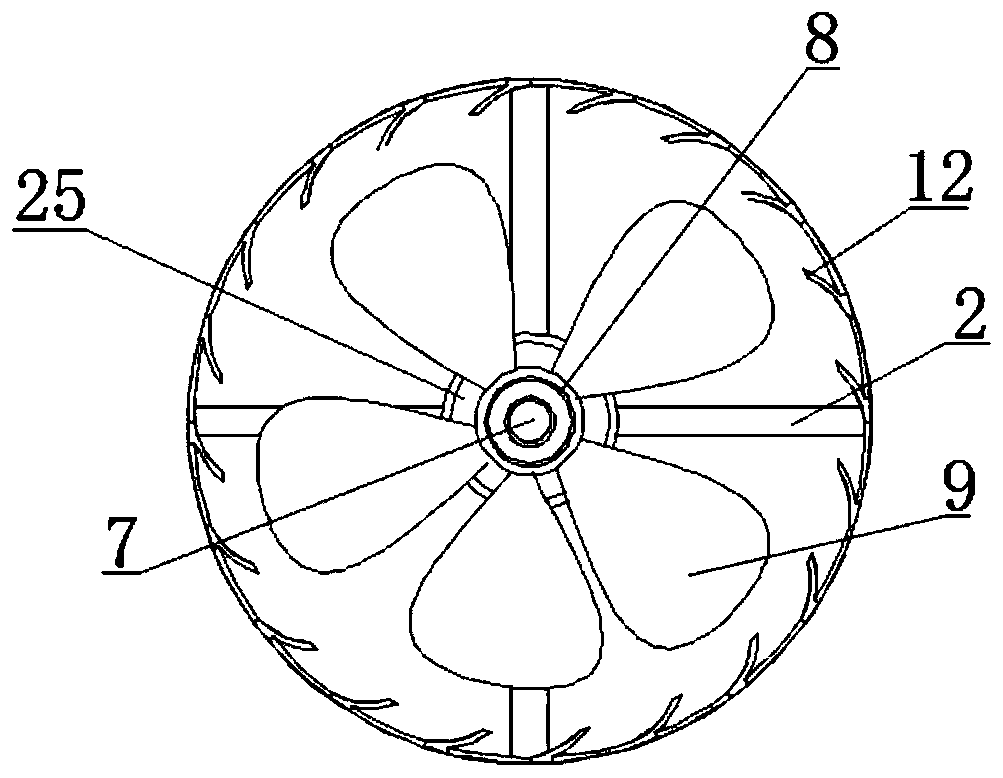

Clay mechanical crushing device for ceramic preparation

InactiveCN110639659APromote innovationEasy to useGrain treatmentsMechanical crushingElectric machinery

The invention relates to the technical field of mechanical crushing, in particular to a clay mechanical crushing device for ceramic preparation. The crushing device comprises a crushing machine shell,a primary positioning support, a secondary positioning support, a tertiary fixing frame and a device platform, wherein the primary positioning support, the secondary positioning support, the tertiaryfixing frame and the device platform are arranged in the crushing machine shell, and the two ends of the primary positioning support, the two ends of the secondary positioning support and the two ends of the tertiary fixing frame are vertically and fixedly connected to the inner wall of the crushing machine shell; and a primary crushing protection shell, a secondary crushing protection shell anda tertiary crushing protection shell are internally provided with crushing motors correspondingly, the top ends of the primary crushing protection shell, the secondary crushing protection shell and the tertiary crushing protection shell are provided with positioning bearings correspondingly, and the ends, away from the crushing motors, of main shafts are connected with the positioning bearings ina penetrating mode and are provided with crushing discs. According to the crushing device, through continuous crushing, from the primary stage to the tertiary stage, of the crushing process, the advantage of one-time crushing success is achieved, the rotating speed and forward and reverse rotation of the crushing motors can be controlled through a servo module, the crushing process of the crushingdevice is controlled in a customized mode, and the applicability is high.

Owner:CHANGCHUN UNIV OF SCI & TECH

Waste treatment device for civil engineering and treatment method thereof

ActiveCN112892706AImprove crushing efficiencyImprove uniformityConstruction waste recoveryDirt cleaningWaste treatmentStructural engineering

The invention relates to the technical field of waste treatment devices, in particular to a waste treatment device for civil engineering and a treatment method thereof. The waste treatment device comprises a smashing box, through grooves penetrating into the smashing box are formed in the front end and the rear end of the smashing box correspondingly, and first sliding grooves are formed in the outer sides of the through grooves. A first sealing plate and a second sealing plate are arranged on the left side and the right side in each through groove correspondingly and are in sliding fit with the corresponding first sliding groove, multiple first springs are fixedly connected to the outer sides of the first sealing plates and the second sealing plates correspondingly, and the ends, away from the first sealing plates and the second sealing plates, of the first springs are fixedly connected with the side walls of the first sliding grooves. A first smashing block is fixedly connected between the two first sealing plates, and a second smashing block is fixedly connected between the two second sealing plates. According to the waste treatment device for civil engineering and the treatment method thereof, waste can be smashed layer by layer, the smashing efficiency is improved, the uniformity after smashing is improved, the smashing quality is improved, the waste can be conveniently transported, and the waste can be conveniently recycled.

Owner:中建三局科创产业发展有限公司

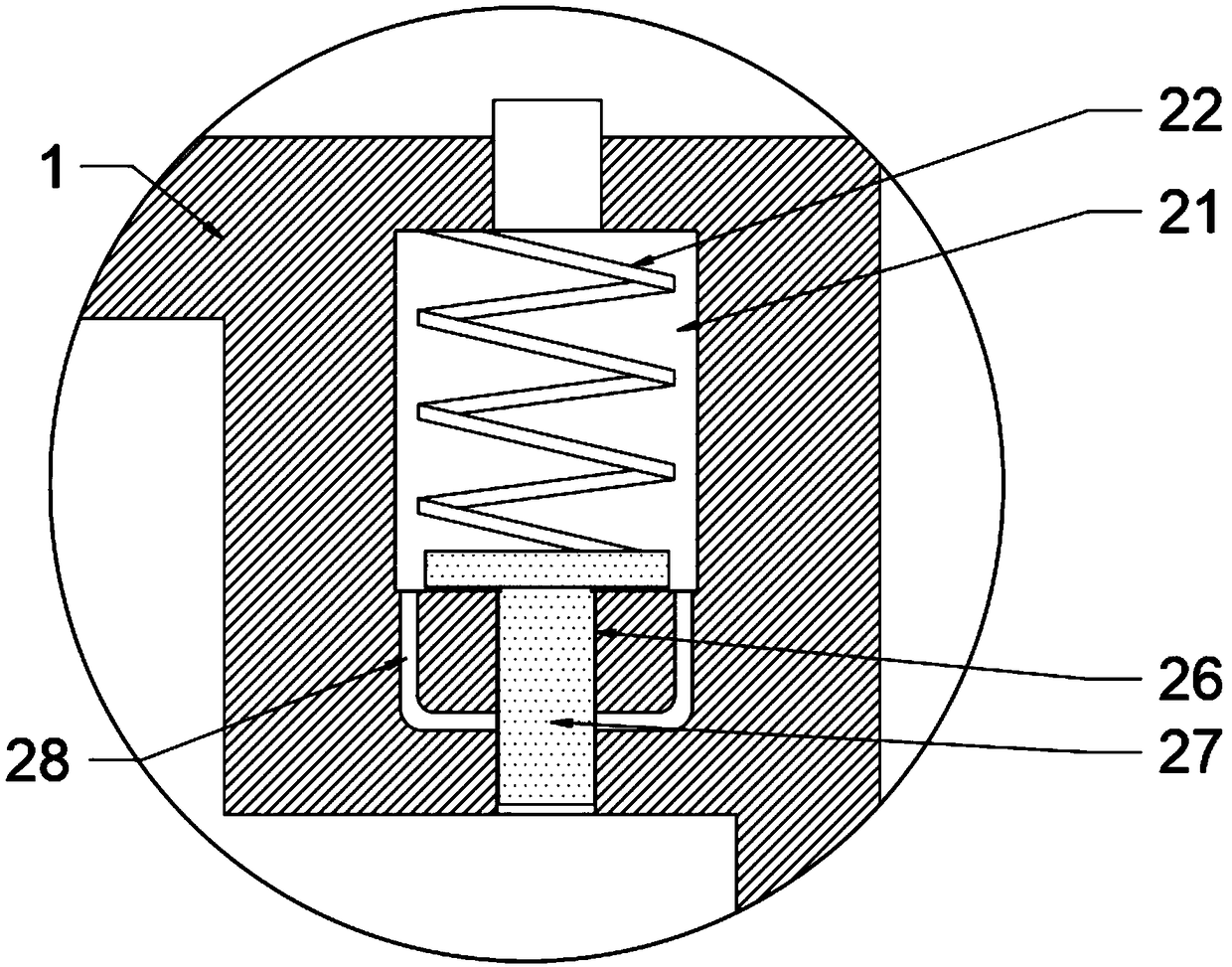

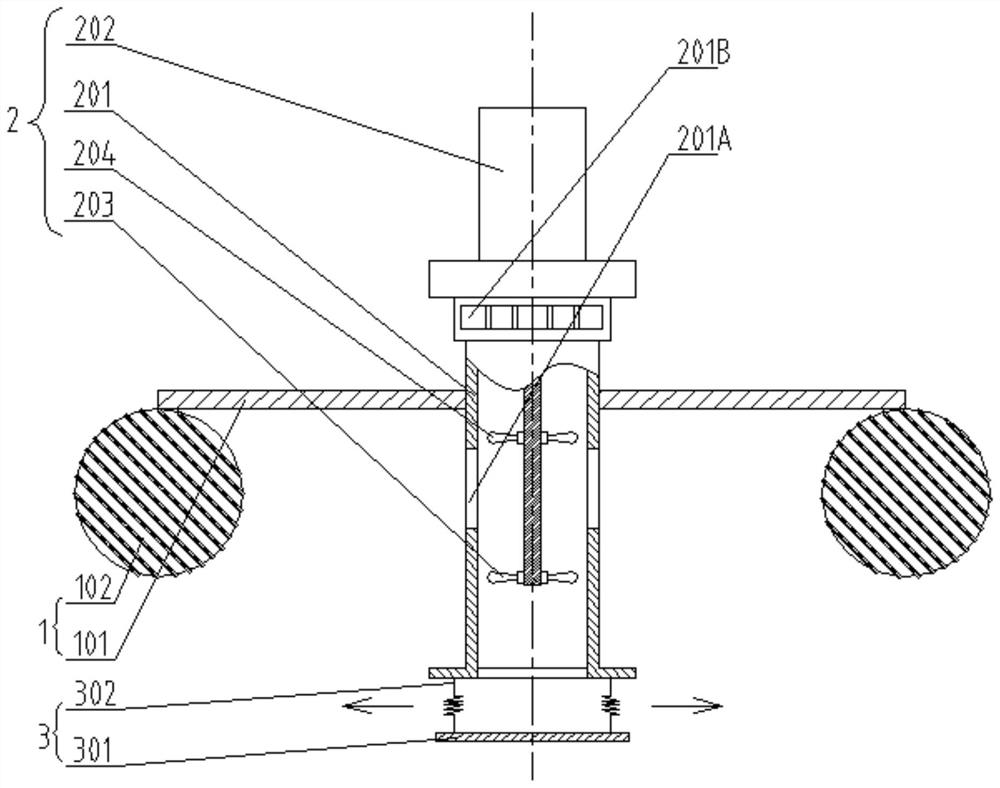

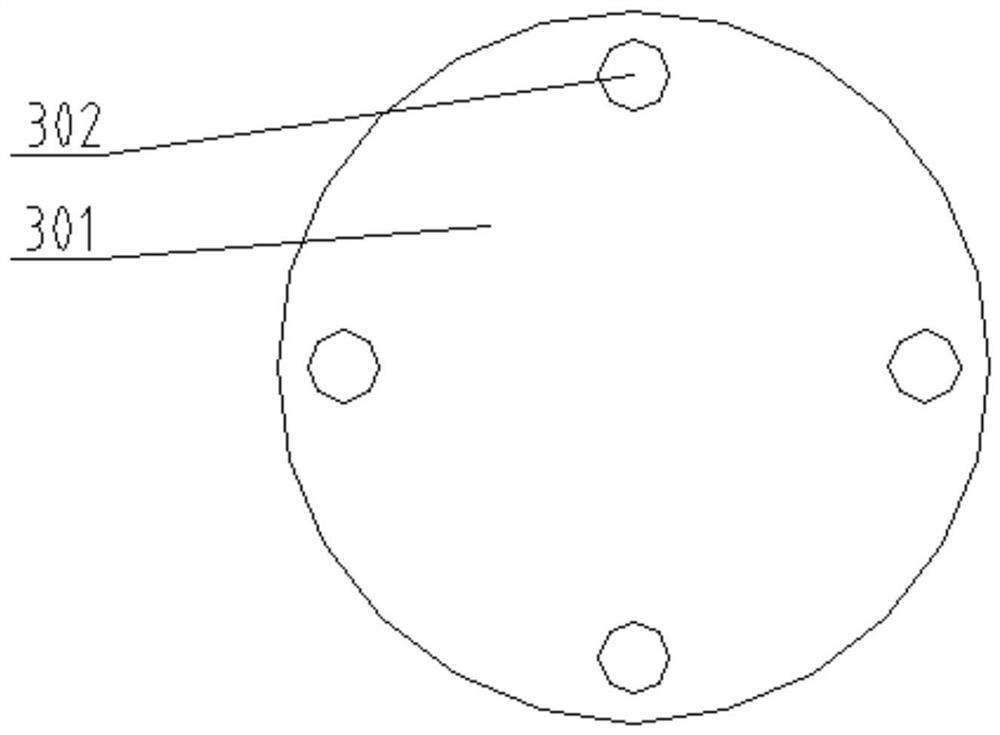

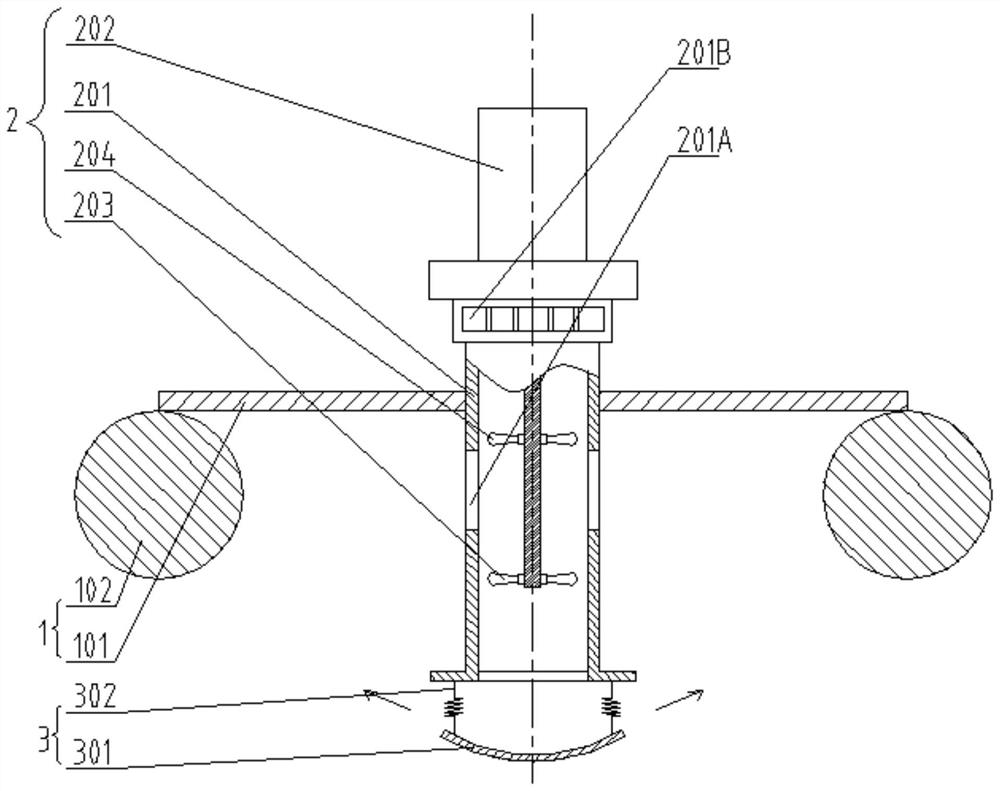

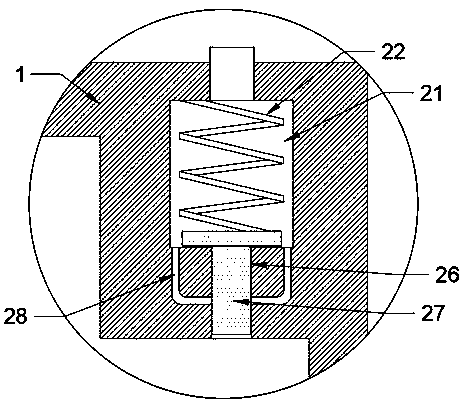

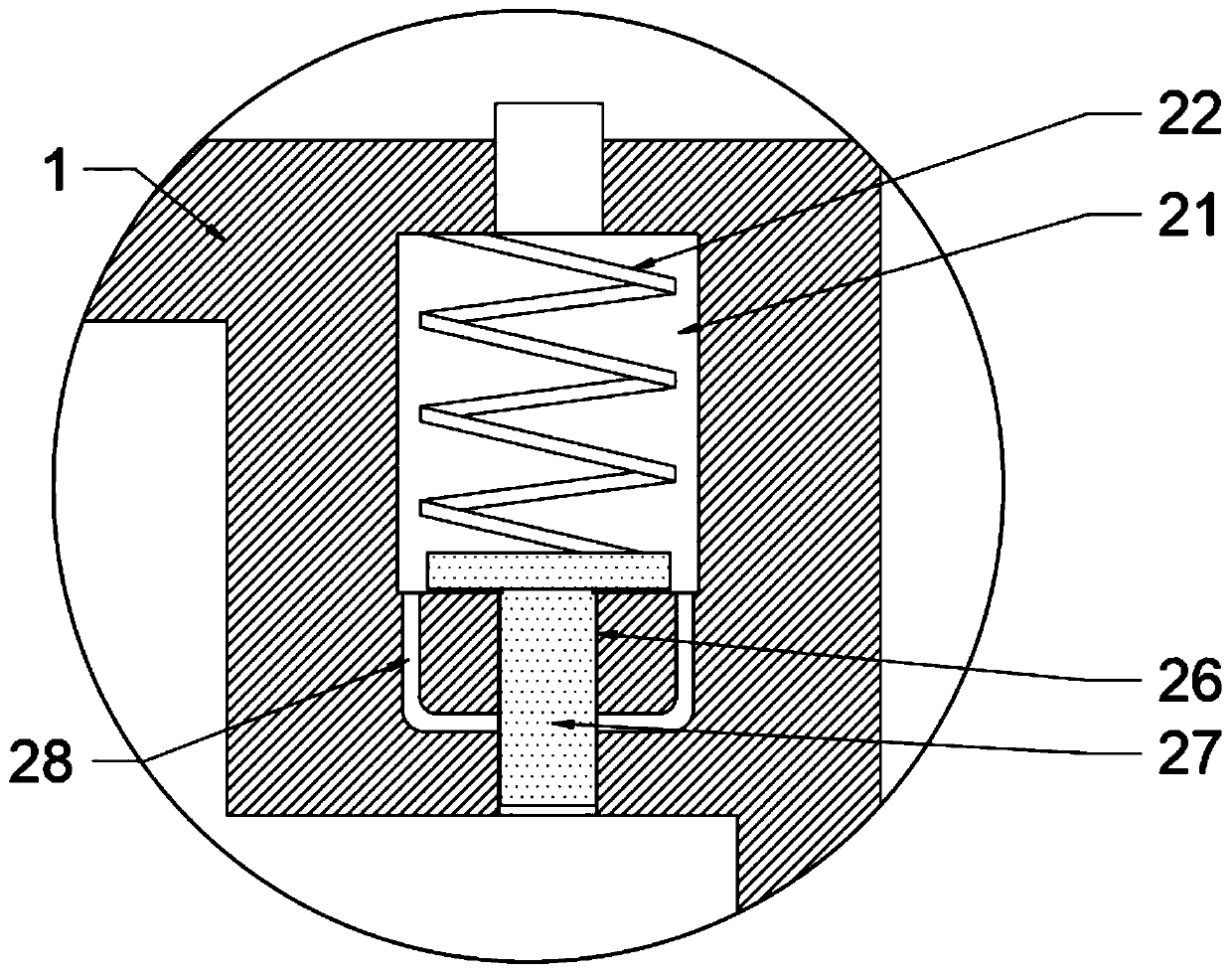

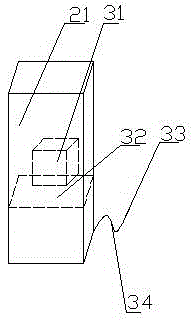

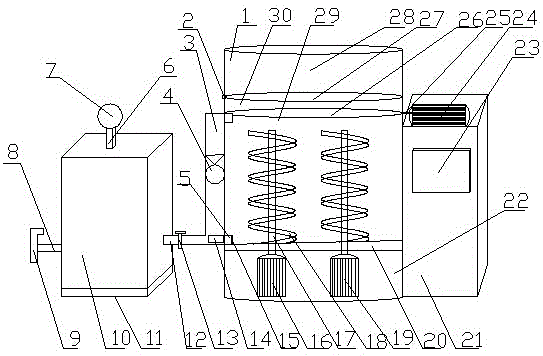

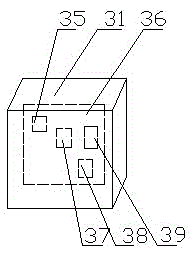

Submersible aerator and use method

PendingCN112079433AIncrease the crushing rateProcessing speedTreatment using aerobic processesWater aerationBiologyGas bubble

The invention aims to provide a submersible aerator and a use method thereof, and the submersible aerator comprises a support assembly, an aeration assembly and an oscillation assembly; wherein the support assembly floats on the water surface; the aeration assembly is arranged on the bracket assembly and is used for spraying liquid rich in bubbles from the output end of the aeration assembly underthe action of the aeration assembly; the oscillation assembly is arranged at the output end of the aeration assembly and is used for continuously adjusting the distance between the oscillation assembly and the output end of the aeration assembly according to the flow velocity of the liquid at the output end of the aeration assembly. The oscillating assembly is arranged at the output end of the aeration assembly, so that the oscillating assembly continuously adjusts the distance between the oscillating assembly and the output end of the aeration assembly according to the flow velocity of liquid at the output end of the aeration assembly, a vibration effect is generated, more fine bubbles are generated, and the basic area of liquid in the aeration tank is increased.

Owner:付康

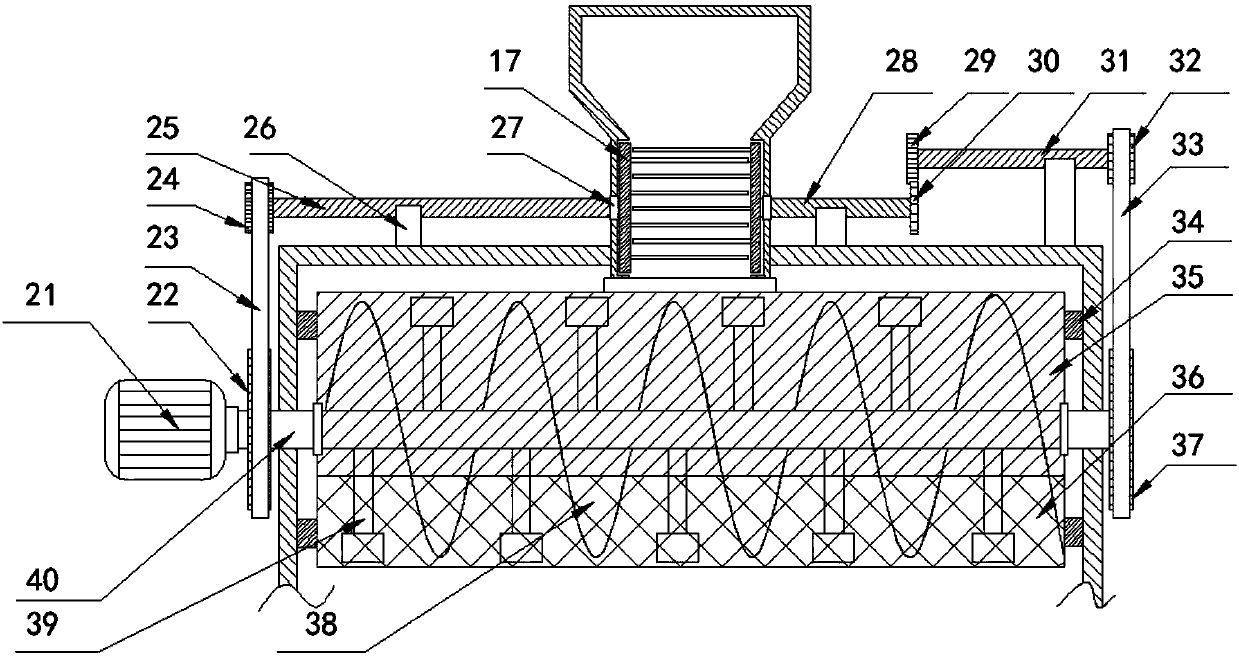

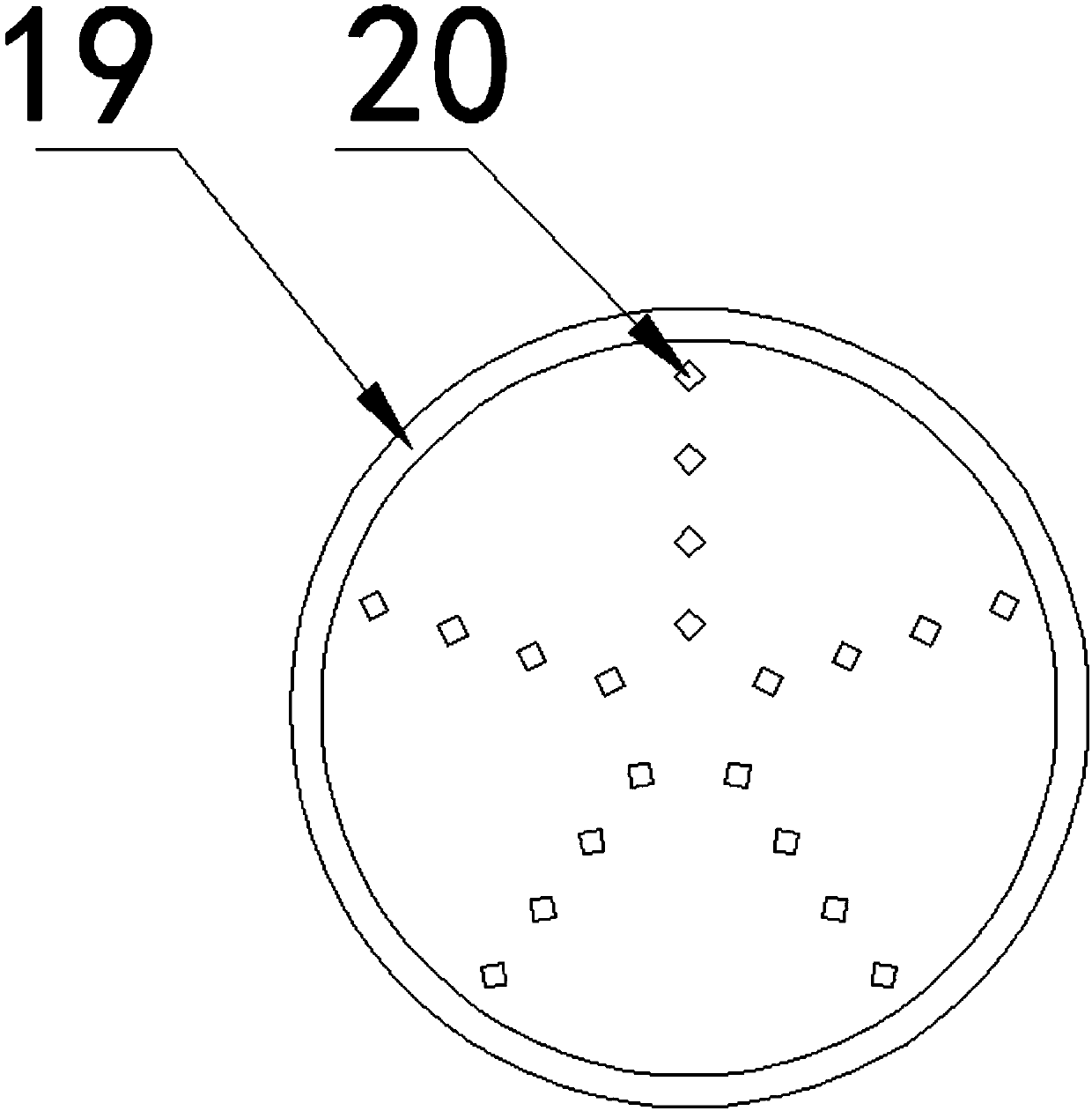

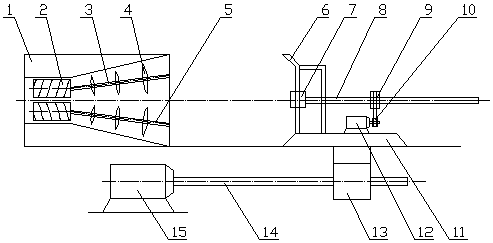

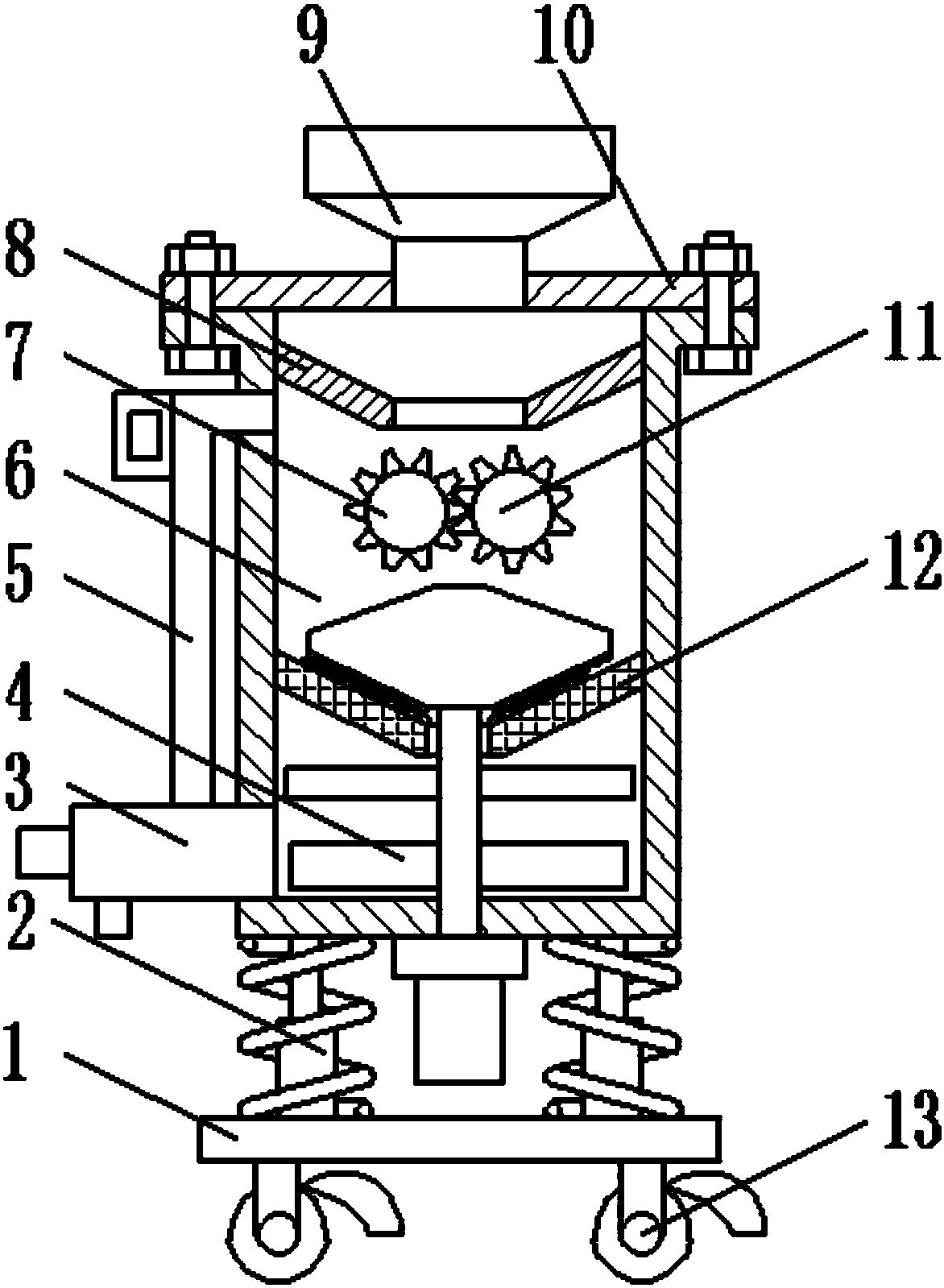

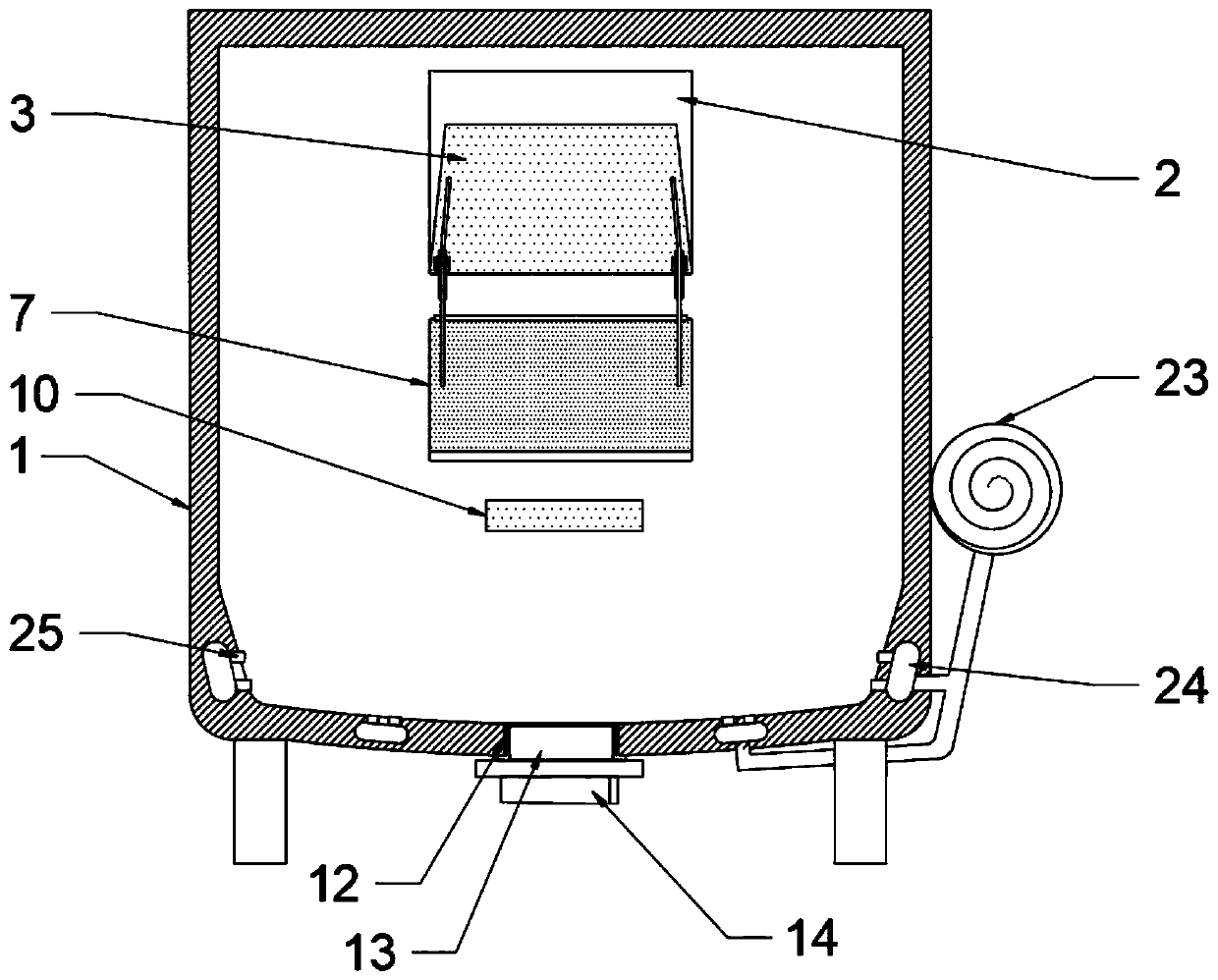

Efficient pulverizer

InactiveCN108236998AAvoid insecurityRealize automatic continuous feedingGrain treatmentsAgricultural engineeringPulverizer

The invention relates to an efficient pulverizer. The pulverizer comprises a propelling part and a pulverizing tank, wherein the propelling part comprises a big propelling device and a small propelling device; and the pulverizing tank comprises an inclined multi-disc pulverizing device, a spiral split pulverizing device and a tank body. The efficient pulverizer has the advantages of automatic feeding, double propelling, multi-stage pulverizing, high pulverizing speed and good pulverizing effect.

Owner:长沙仁之德自动化设备有限公司

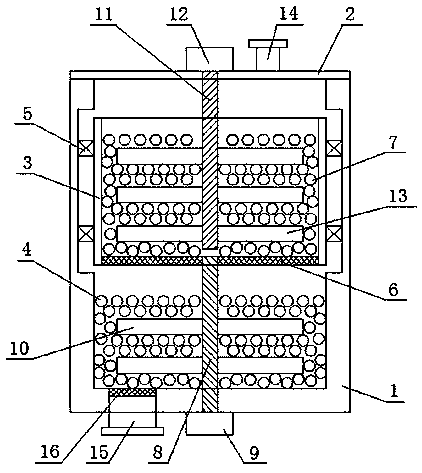

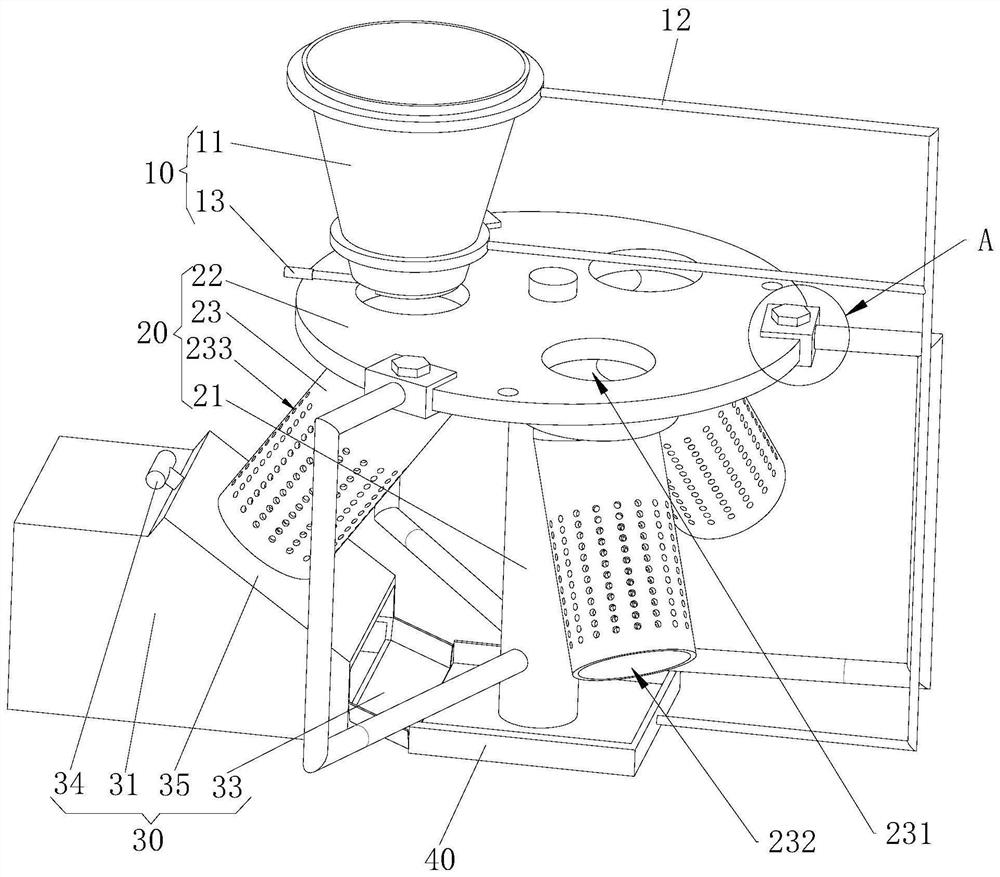

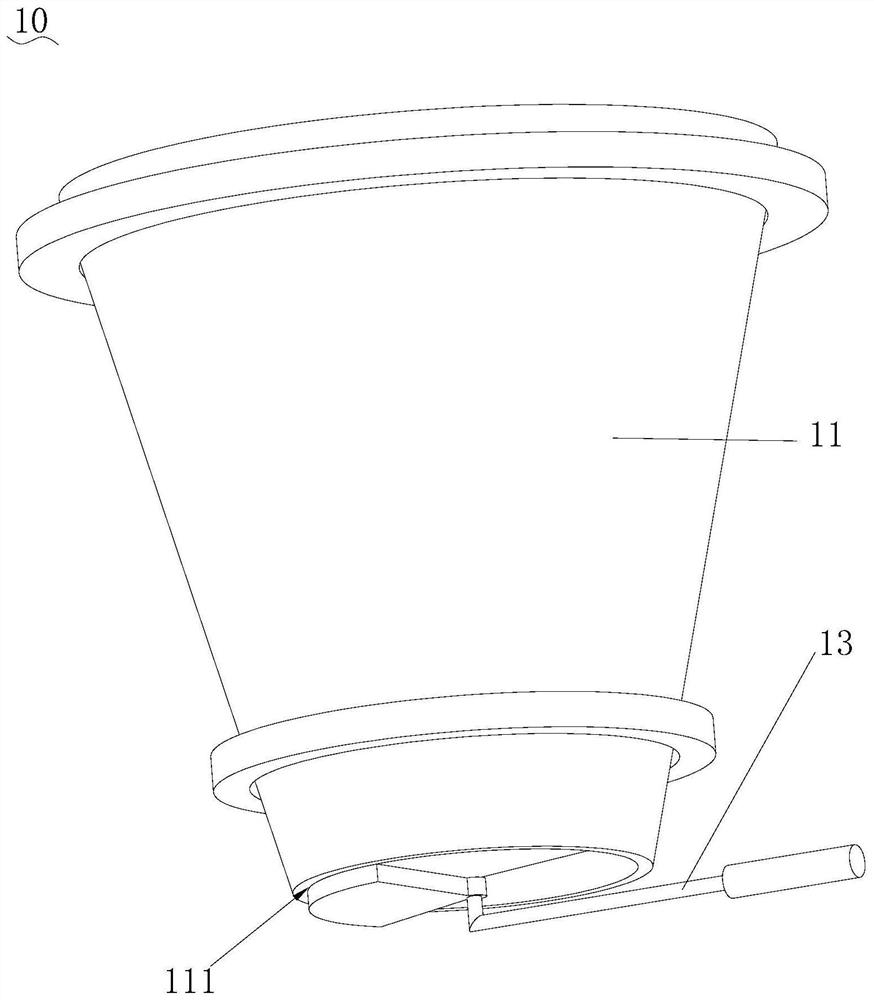

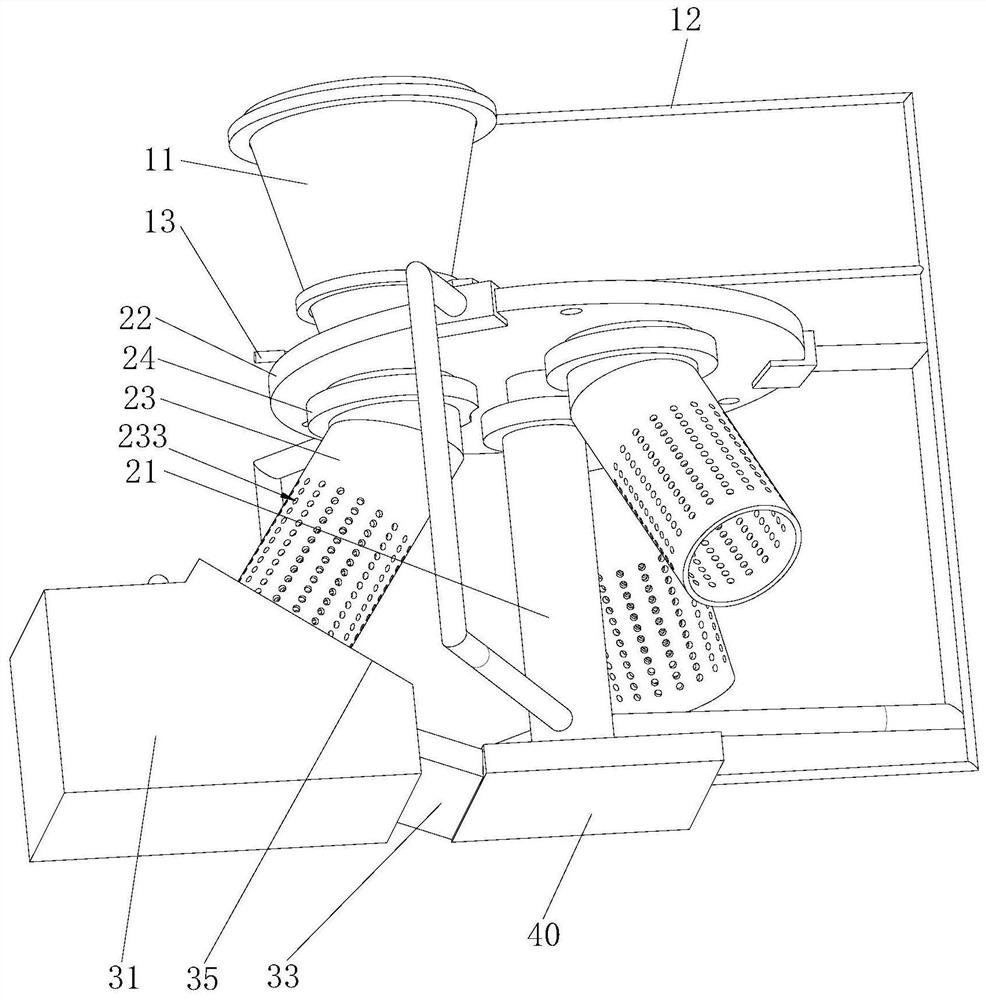

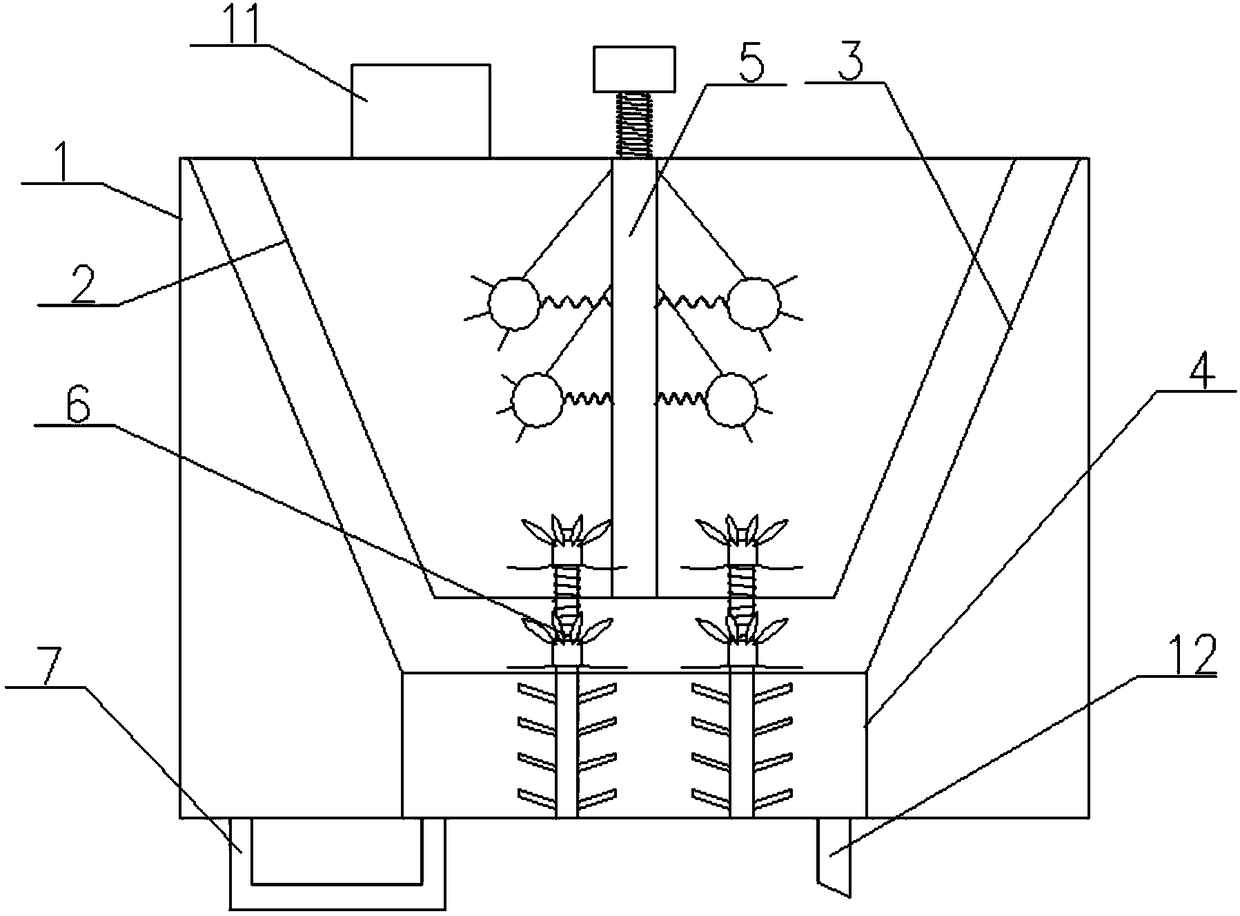

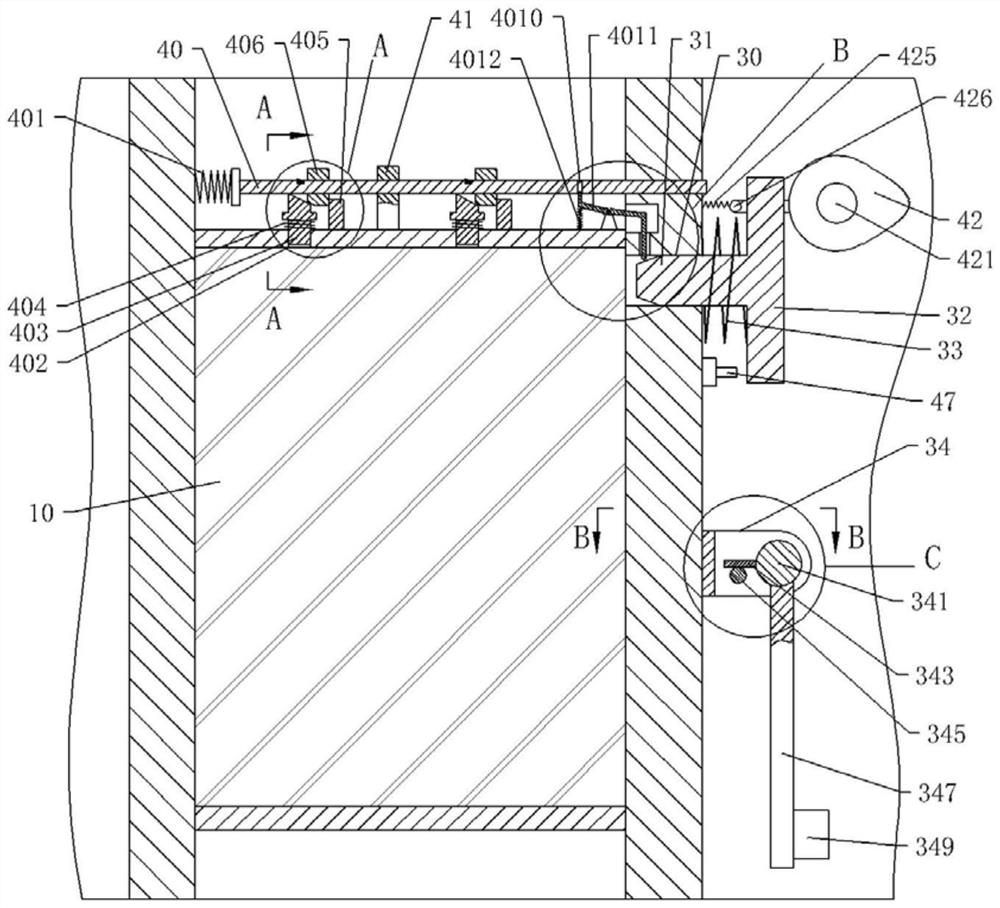

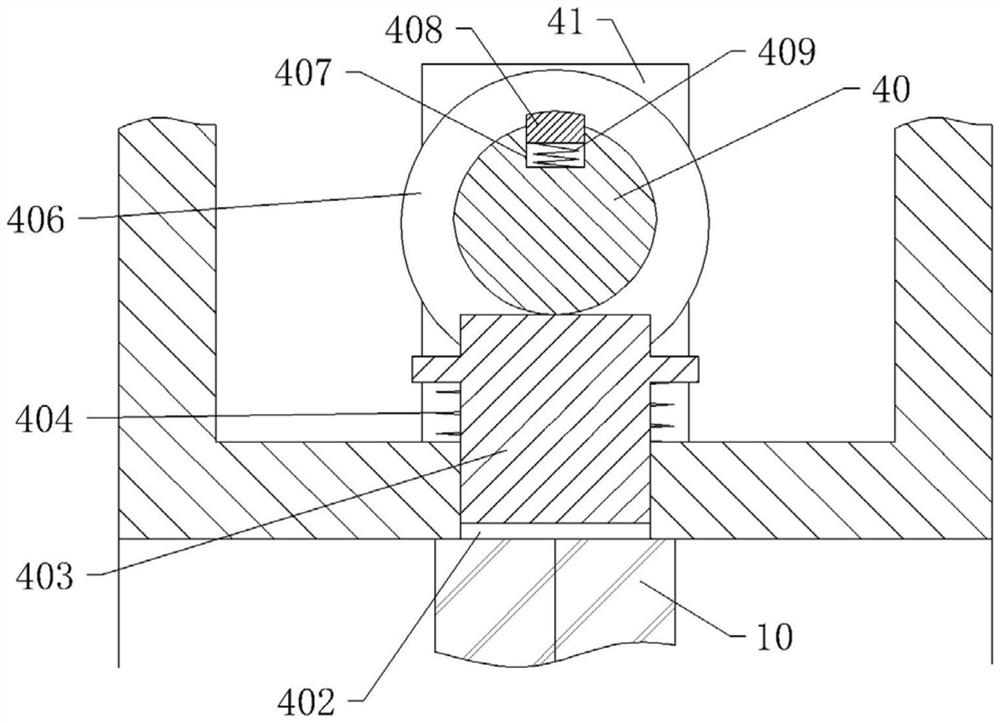

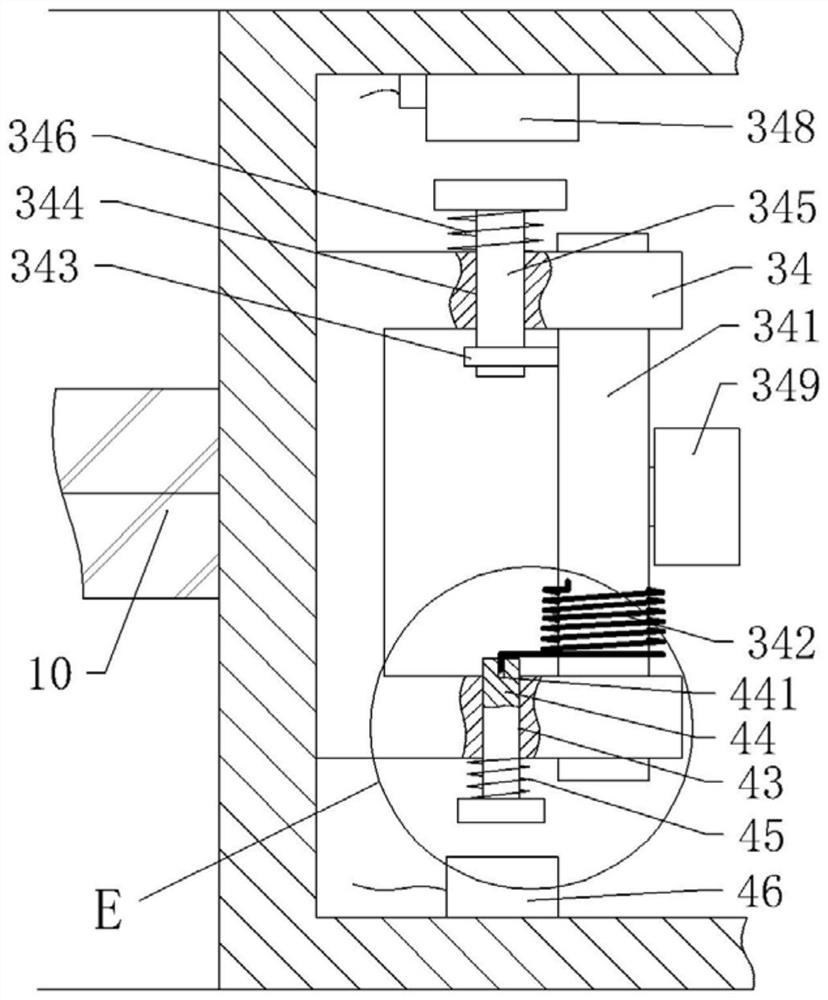

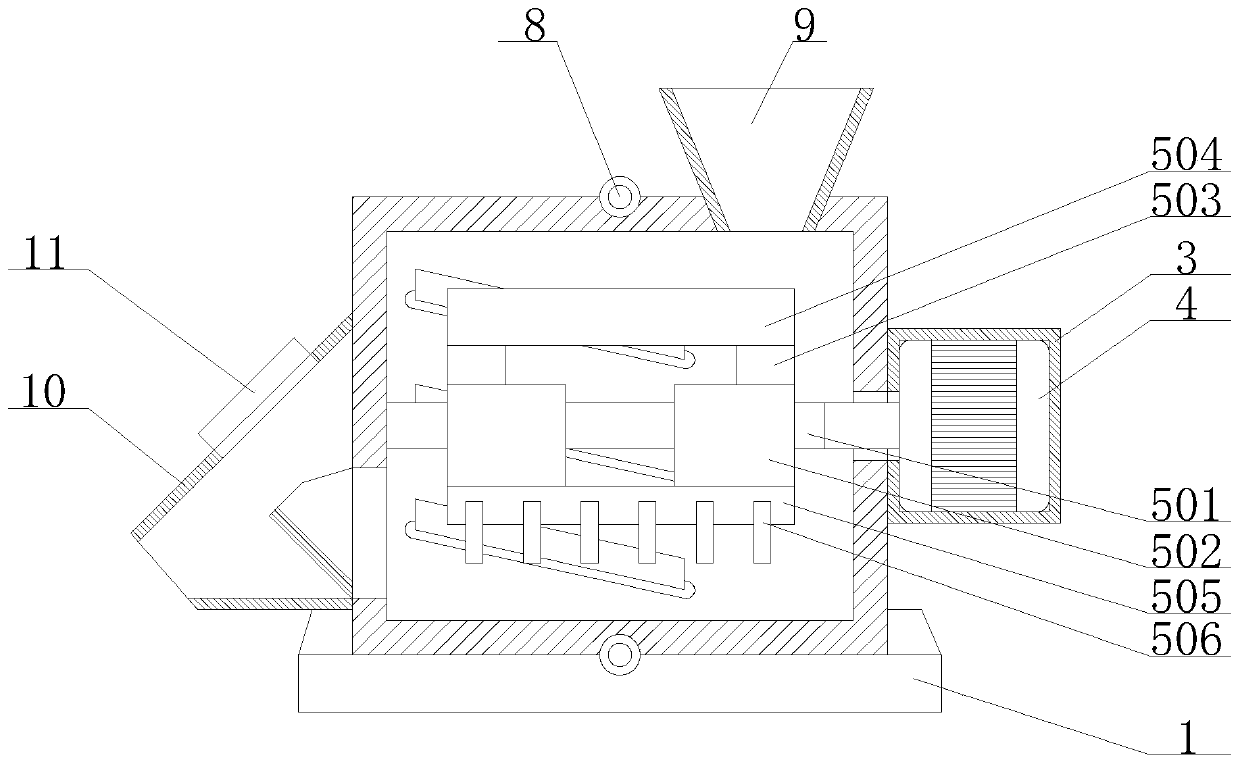

Coal sample preparing, sieving and crushing device

The invention belongs to the technical field of thermal power generation, and relates to a coal sample preparing, sieving and crushing device. The coal sample preparing, sieving and crushing device comprises a discharge mechanism, a sieving mechanism and a crushing mechanism, wherein the discharge mechanism, the sieving mechanism and the crushing mechanism are sequentially arranged from top to bottom; the discharge mechanism is used for collecting a coal sample to be sieved and placing the coal sample to be sieved into the sieving mechanism to sieve; the crushing mechanism is used for crushingthe coal sample sieved by the sieving mechanism; the sieving mechanism comprises a base, a rotary table which is rotatably arranged on the base and a plurality of sieving barrels arranged on the rotary table; the sieving barrels are used for sieving coal samples of different diameters; and each sieving barrel comprises a sieving charge hole, a sieving discharge hole and a sieving part for sievingthe coal sample. Multiple sieving barrels for the coal samples of different diameters are arranged on the rotary table for sieving and crushing the coal samples, so that manual operation is simplified, labor cost is reduced, and coal sample sieving crushing rate is greatly increased.

Owner:贵州华电桐梓发电有限公司

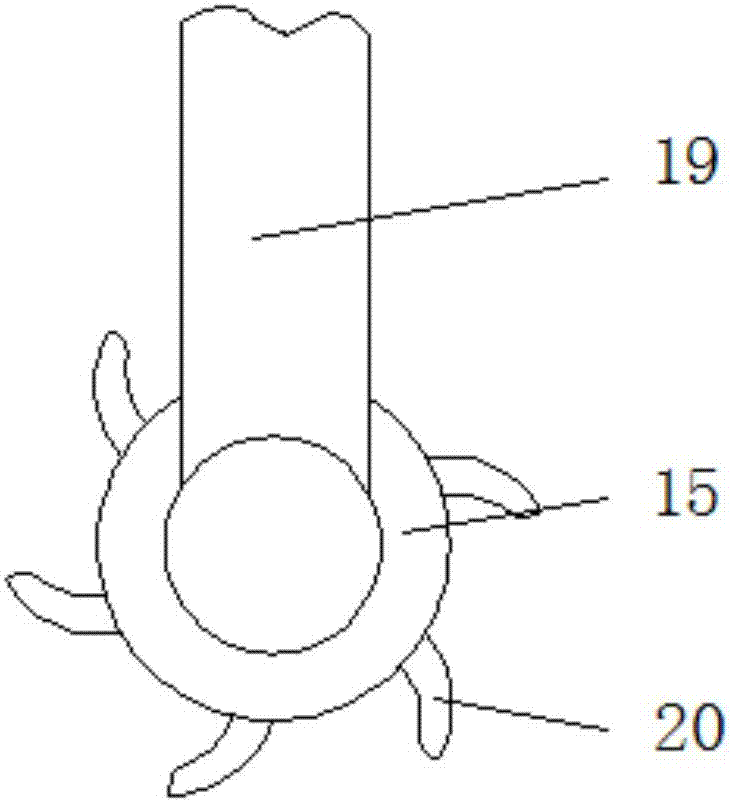

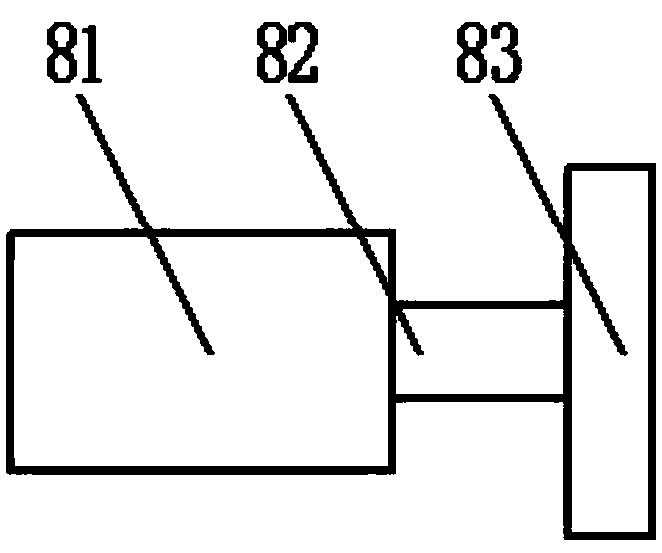

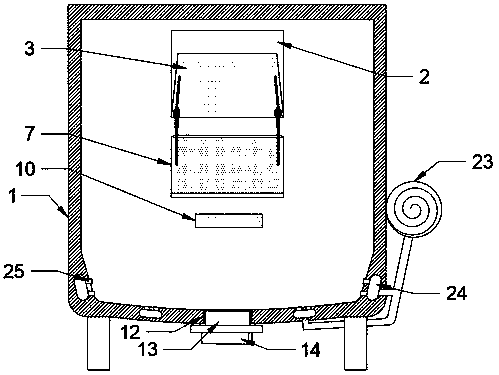

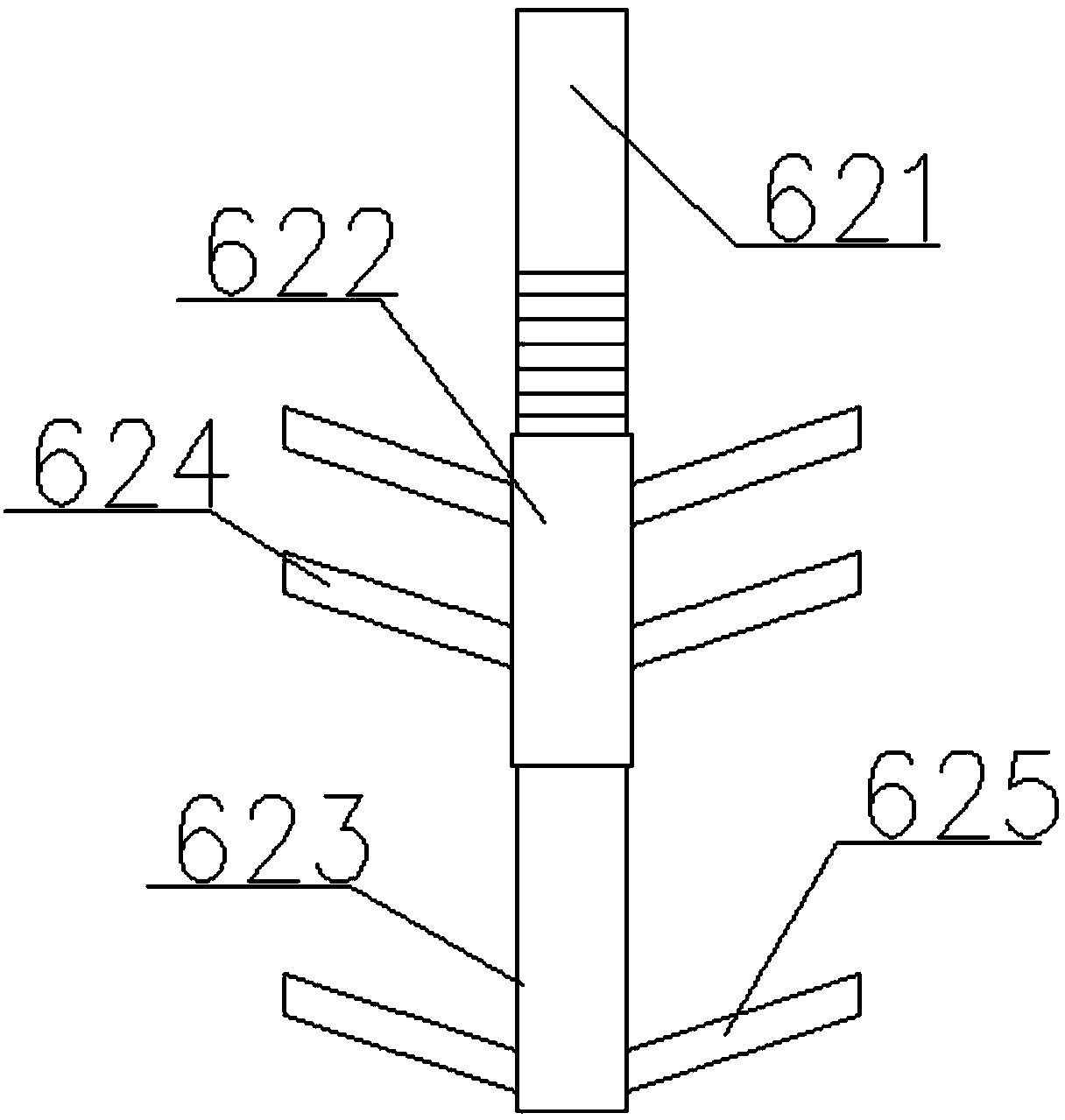

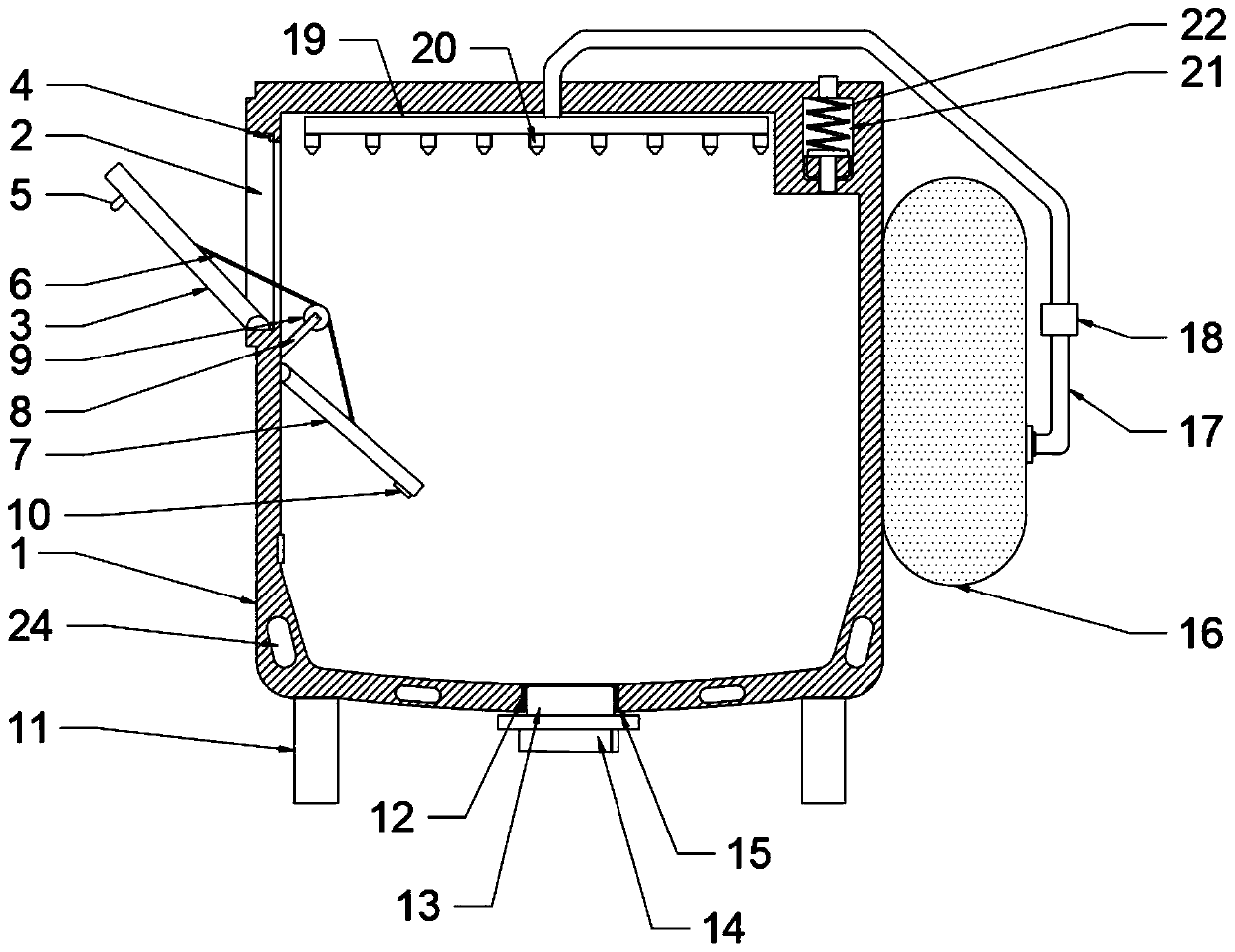

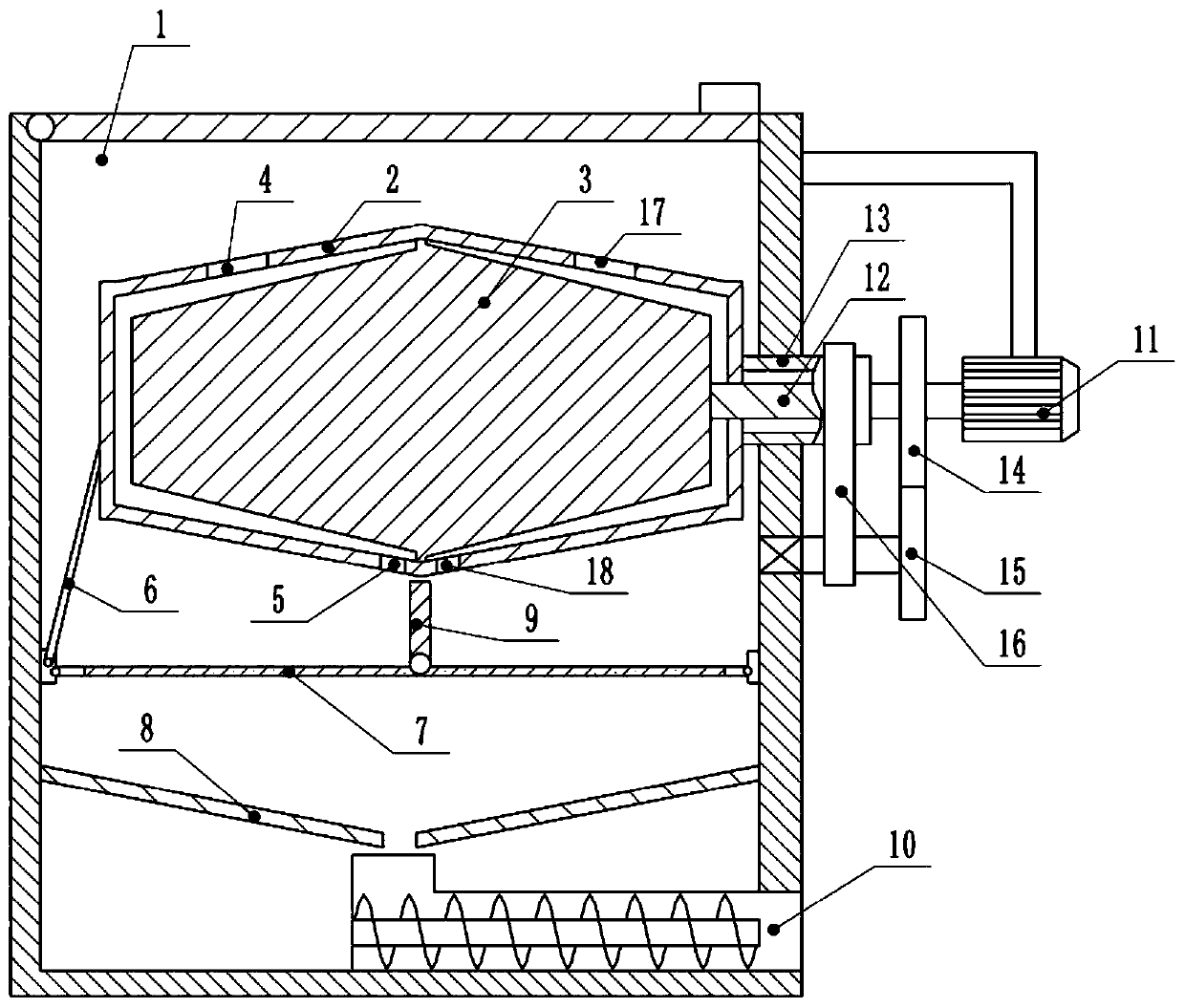

Household kitchen garbage treatment equipment

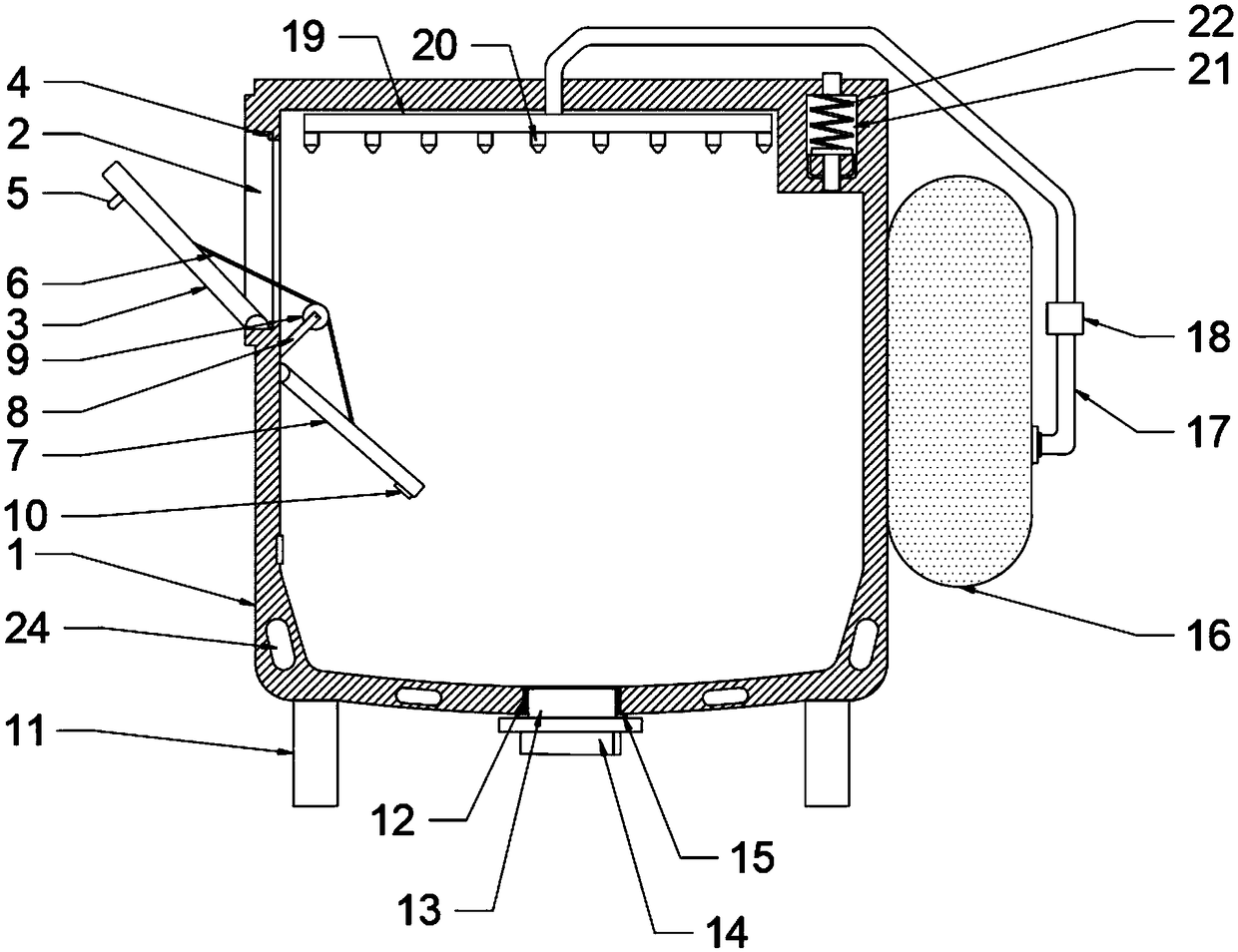

InactiveCN109290001AEfficient tearingImprove family living environmentDomestic plumbingGrain treatmentsSewerageGarbage disposal

The invention discloses household kitchen garbage treatment equipment. The household kitchen garbage treatment equipment comprises a box body, a first frame body, a second frame body, a storage box, afirst stirring mechanism, and multiple second stirring mechanisms, wherein the first stirring mechanism comprises a first cylinder, a second cylinder, a first screw rod and multiple sets of stirringmodules. The household kitchen garbage treatment equipment can thoroughly crush household kitchen garbage in time and smoothly discharge the household kitchen garbage into a sewer, and is simple in structure, easy to operate and higher in economical practicability.

Owner:李玉娟

Discarded tire liquid nitrogen frozen grinding box

The invention discloses a discarded tire liquid nitrogen frozen grinding box. The discarded tire liquid nitrogen frozen grinding box comprises a box body, a feed port, a sealing door, a connecting rope, a sliding plate, supports, turning wheels, support legs, a discharge port, a sealing cover, a high-pressure liquid nitrogen bin, a nitrogen delivery pipe, a solenoid valve, a spray pipe, spray nozzles, a pressure reduction bin, a spring, a draught fan, an annular gas pipe, gas spray heads, an gas discharge duct, a sealing rubber rod and a bypass pipe. The four support legs are uniformly mountedat the bottom of the box body. The feed port is formed in the upper portion of the sidewall of the box body, The sealing door is rotatably connected to the bottom end of the feed port. The sliding plate is rotatably mounted in the position, located under the feed port, of the inner wall of the box body. The two supports are symmetrically fixed to the inner wall of the box body and located betweenthe feed port and the sliding plate. The discarded tire liquid nitrogen frozen grinding box intermittently sprays liquid nitrogen and intermittently blows gas to stir rubber blocks; the crushing rateof the rubber blocks is increased; the liquid nitrogen is saved; the rubber blocks are put in and taken out conveniently. The discarded tire liquid nitrogen frozen grinding box is simple in structureand safe in use.

Owner:毛伟军

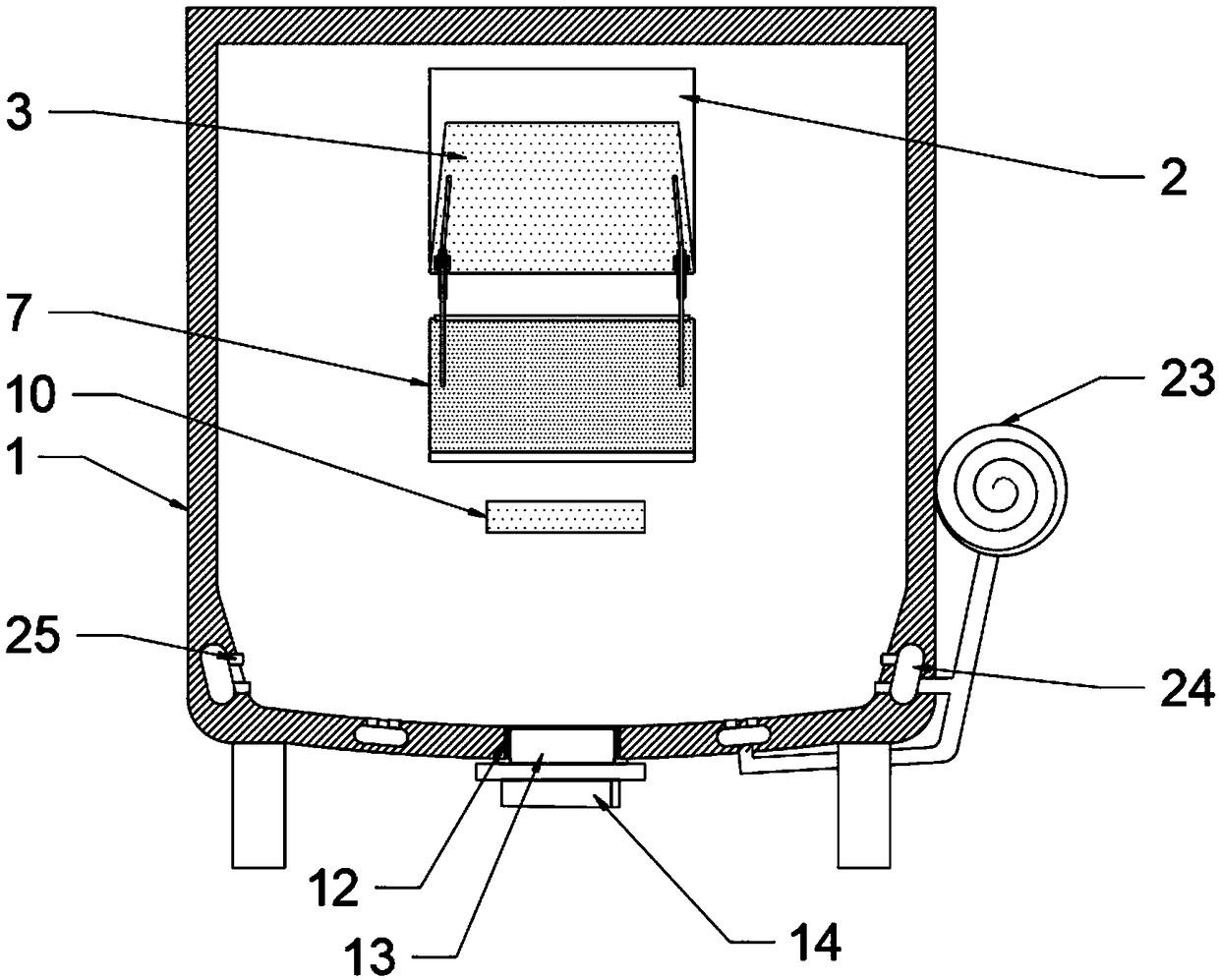

Kitchen waste treatment system

The invention discloses a kitchen waste treatment system. The kitchen waste treatment system comprises a box body, a material charge hopper, a material charge mechanism, a suction filtration mechanism, a crushing mechanism and a material discharge mechanism, wherein the material charge mechanism comprises a first cylinder body, a second cylinder body, a first screw rod and a plurality of groups ofmaterial discharge assemblies; the suction filtration mechanism comprises a material storage box, a liquid storage box and a first pipe body; the crushing mechanism comprises a first rotary body anda second rotary body; the material discharge mechanism comprises a material discharge box and a plurality of stirring assemblies. The kitchen waste treatment system has the advantages that the kitchenwaste can be timely and thoroughly crushed, and be smoothly discharged via a sewer, and the blockage accident of the sewer is prohibited; the structure is simple, the manufacturing cost is lower, theconsumption level of more users can be met, and the economy and practicality are higher.

Owner:李玉娟

Automatic cooling ceramic raw material crusher

InactiveCN112138757AIncrease productivityIncrease air pressureDirt cleaningMagnetic separationCrusherBrush

The invention relates to the technical field of material crushing, and discloses an automatic cooling ceramic raw material crusher. The automatic cooling ceramic raw material crusher comprises a shell, wherein magnetic blocks are fixedly mounted on the left side and the right side of the shell, brushes are fixedly mounted on the left side and the right side of the shell, scrapers are fixedly mounted on the sides, close to the shell, of the brushes on the left side and the right side of the shell, crushing rollers are fixedly mounted on the left side and the right side in the shell, rotating shafts are fixedly mounted on the front sides and the rear sides of the crushing rollers, heat conduction pieces are rotatably mounted on the surfaces of the rotating shafts, heat conduction cavities are fixedly connected to the top ends of the heat conduction pieces, and first springs are fixedly mounted in the heat conduction cavities. According to the automatic cooling ceramic raw material crusher, when the temperature of equipment rises, a cooling liquid is sprayed automatically to reduce the temperature of the equipment, dust generated during crushing is absorbed to protect the health of workers, and iron impurities in the equipment are adsorbed to improve the processing quality, so that a filter screen can vibrate to prevent a condition of low work efficiency as the filter screen is blocked.

Owner:广州胡丽娟科技有限公司

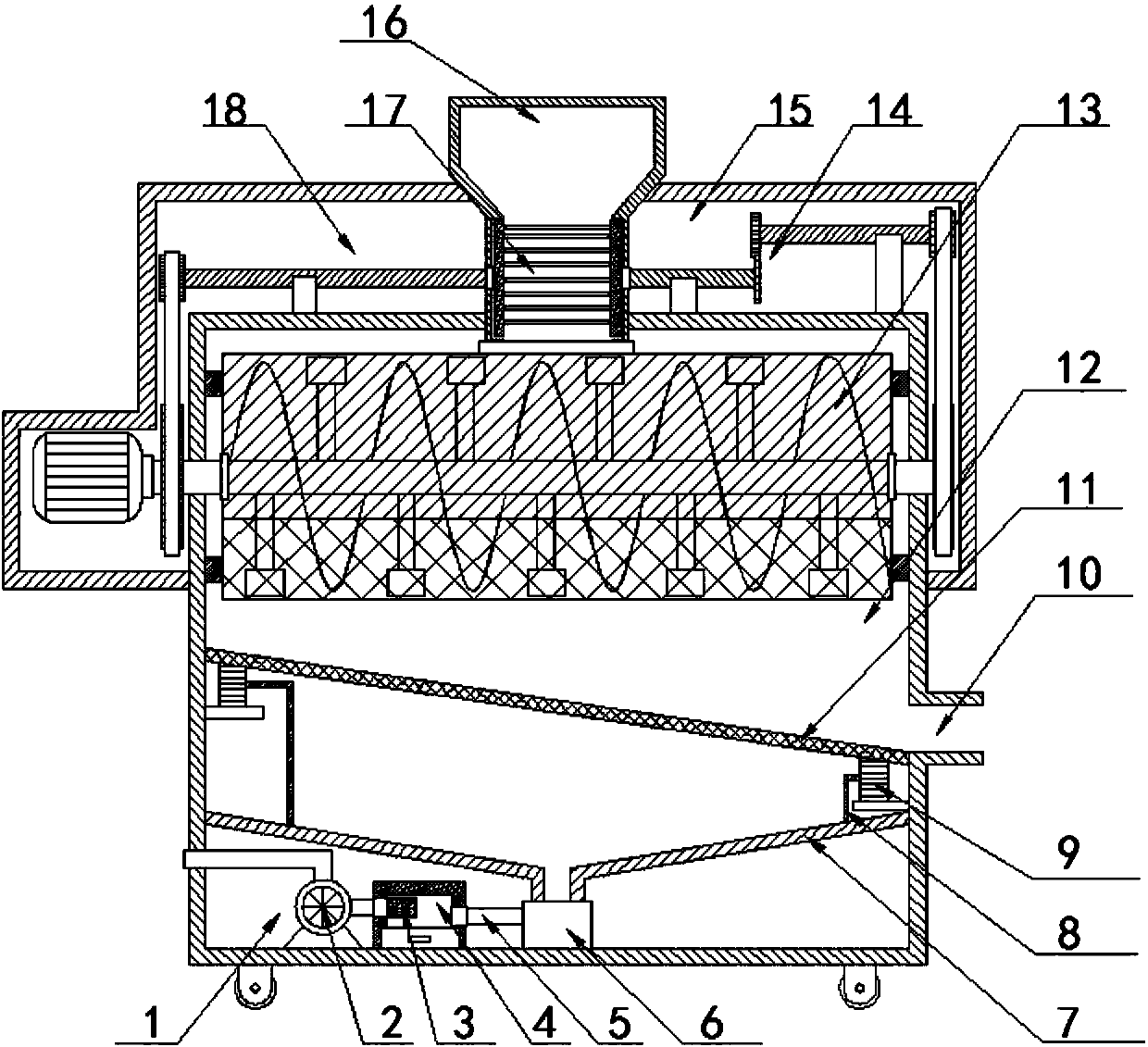

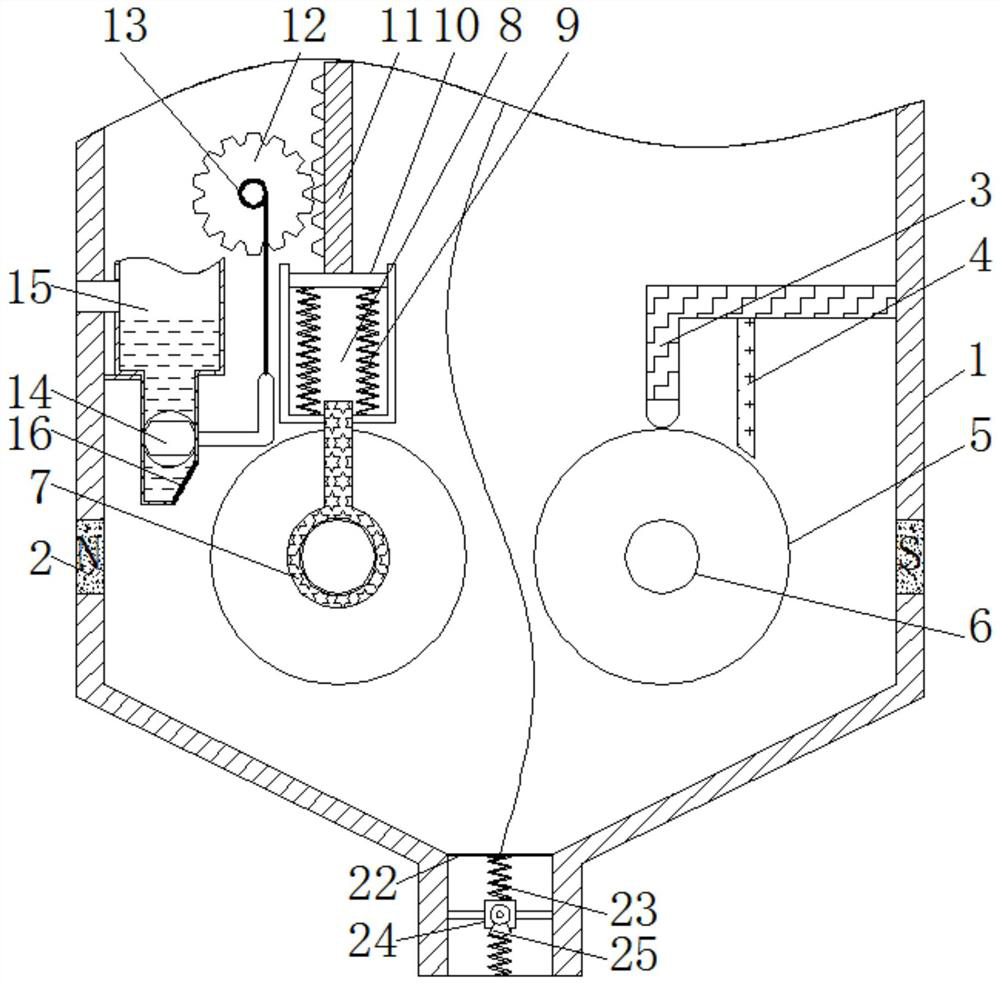

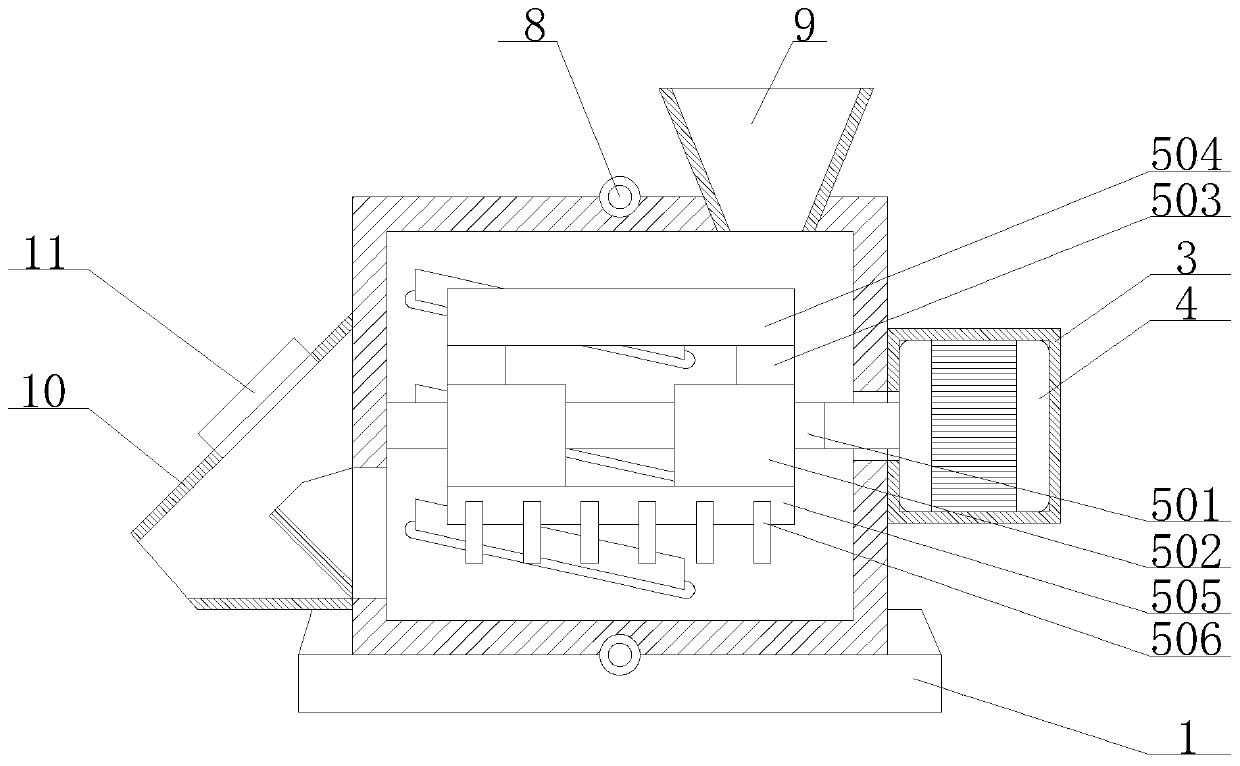

High-efficient wood powder smashing device for discharging materials

InactiveCN108214793AImprove grinding and crushing qualityImprove crushing qualityBark-zones/chip/dust/waste removalElectric machineryGrinding process

The invention provides a high-efficient wood powder smashing device for discharging materials, and belongs to the technical field of material smashing. The high-efficient wood powder smashing device comprises a universal wheel; the top part of the universal wheel is provided with a bottom plate, and the top part of the bottom plate is provided with a damping base; the inner part of a smashing roomis provided with a mixing device, a lower grinding block, a first smashing roller, a second smashing roller and a guide flow plate. The device is simple in structure, reasonable in design and convenient to use; the mixing device can drive the upper grinding block to move under the effect of the mixing motor, and grind and smash the materials under the effect of matching with the lower grinding block; thus the material grinding and smashing quality is greatly improved; through the first smashing roller and the second smashing roller, the materials can be preliminarily smashed, the material smashing rate is accelerated, the material smashing quality is improved; a dust collecting pipe can absorb powder dust in the grinding process, and discharge the dust along with the grinded materials; thus the utilization rate of the material is greatly improved.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

A liquid nitrogen freezing crushing box for waste tires

ActiveCN108638389BIncrease the crushing rateEasy to put inPlastic recyclingMechanical material recoveryEnvironmental engineeringSlide plate

The invention discloses a junked tire liquid nitrogen cryogenic grinding box and a using method. The junked tire liquid nitrogen cryogenic grinding box comprises a box body, a feeding inlet, a sealingdoor, a connection rope, a sliding plate, two brackets, two rotation wheels, four stand bars, a discharging outlet, a sealing cover, a high-pressure liquid nitrogen cabin, a nitrogen pipe, an electromagnetic valve, a spray pipe, a spray head, a decompression cabin, a spring, a draught fan, a ring-shaped air duct, a jet head, an air exhaust slot, a sealing rubber rod and a bypass pipe, wherein thefour stand bars are uniformly mounted at the bottom of the box body; the feeding inlet is formed above the side wall of the box body; the bottom end of the feeding inlet is rotatably connected with the sealing door; the sliding plate is rotatably mounted on the inner wall of the box body and below the feeding inlet; the two brackets are symmetrically fixed on the inner wall of the box body and between the feeding inlet and the sliding plate; and the rotation wheels are rotatably mounted at the tops of the brackets. According to the junked tire liquid nitrogen cryogenic grinding box, rubber bricks are stirred through intermittently spraying liquid nitrogen and intermittently blowing air, so that the rubber brick grinding speed is improved, the liquid nitrogen is saved, and the putting andtaking of the rubber bricks are convenient, so that the junked tire liquid nitrogen cryogenic grinding box is simple in structure and safe to use.

Owner:WUHU INST OF TECH

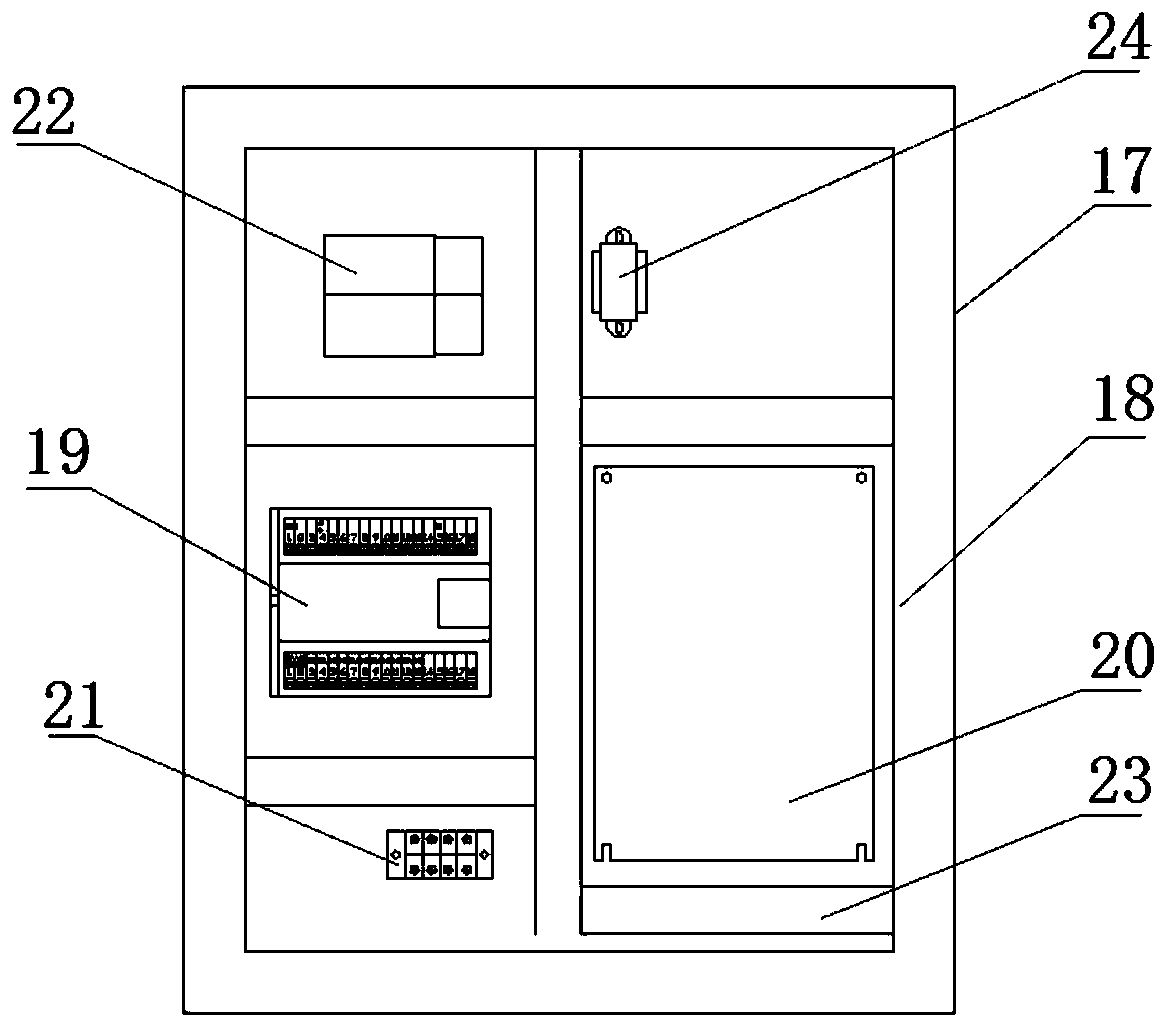

Chemical raw material pulverizing equipment

InactiveCN105413820ASpeed up crush sizeIncrease the crushing rateGrain treatmentsDrive shaftEngineering

The invention discloses chemical raw material pulverizing equipment. The chemical raw material pulverizing equipment comprises a pulverizer. The pulverizer comprises a storage box, a pulverizing box and a console. The pulverizing box is connected with the storage box through a guide pipe. The console is installed at one side of the pulverizing box. The pulverizing box is divided into a pulverizing chamber and a control chamber by an oblique plate. A rotary shaft is installed on one side of the upper end of the pulverizing box. The pulverizing box is connected with a cover body through the rotary shaft. A feed inlet is formed in the upper end of the pulverizing box. A vibrating screen is arranged at the lower end of the feed inlet. A vibrating motor is installed at the upper end of the console. An operation screen is arranged on the outer side of the console. The vibrating screen is connected with the vibrating motor through a transmission shaft. An electromagnetic valve is installed on the guide pipe. A material flow sensor is arranged in the guide pipe. A discharge outlet is formed in one side of the guide pipe. A filter screen is arranged in the discharge outlet. According to the chemical raw material pulverizing equipment, due to the fact that the vibrating screen can vibrate through the vibrating motor, materials can enter the pulverizing chamber at an accelerated speed.

Owner:郑臣钏

Lime grinding and slaking all-in-one machine

PendingCN112892748AIncrease the crushing rateIncrease digestion rateGrain treatmentsMetallurgyPhysical chemistry

The invention discloses a lime grinding and slaking all-in-one machine. The machine comprises a slaker body, a slaking cavity is formed in the slaker body, a quick lime smashing device is arranged on one side of the slaker body and comprises a crushing and grinding cylinder installed on the slaker body, a crushing and grinding area is distributed in the crushing and grinding cylinder, a grinding body is movably arranged in the crushing and grinding area, the crushing and grinding area is communicated with the slaking cavity, and a grinding body blocking assembly is mounted between the discharging end of the crushing and grinding area and the slaking cavity. Quick lime blocks are preliminarily ground and crushed through the crushing and grinding cylinder, so that large quick lime blocks are crushed into small quick lime, furthermore, the crushing rate of the quick lime is improved, the later slaking rate of the quick lime is improved, the lime can be subjected to zoning treatment through a reaction mixing zone, a homogenizing zone and a slurry-slag separation zone, so that lime blocks react to generate lime milk, the speed of generating the lime milk through the reaction of the lime blocks is further increased, and the production efficiency is improved.

Owner:潍坊市和成工程机械制造有限公司

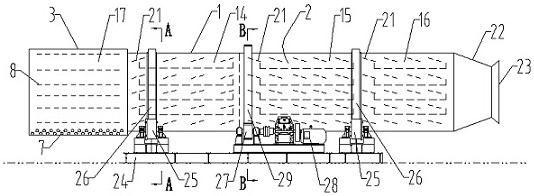

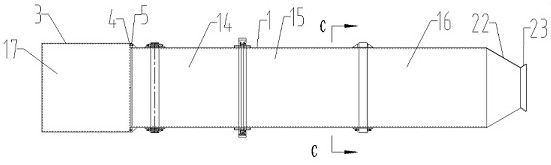

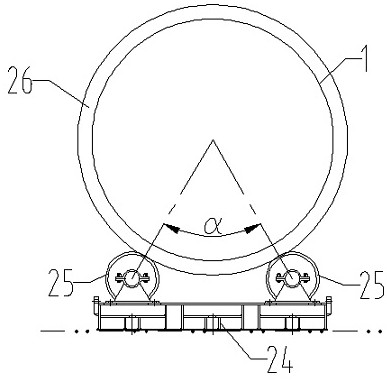

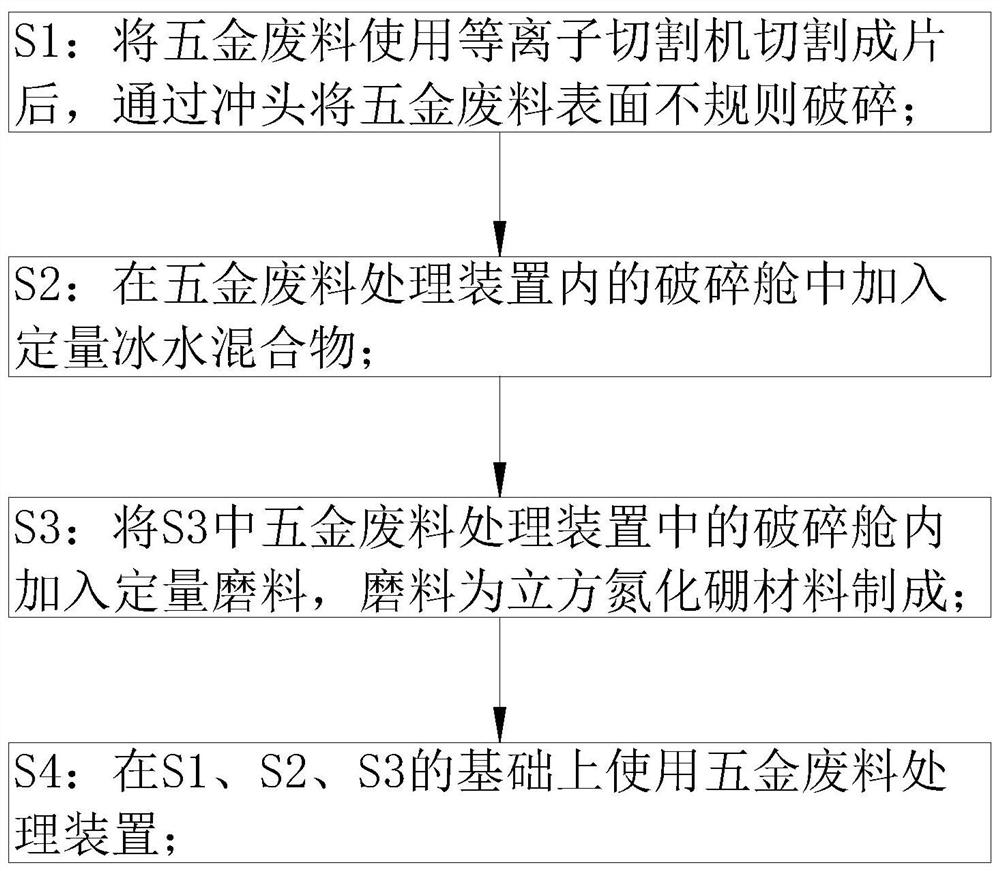

A metal waste recycling process

ActiveCN109225540BAvoid high temperatureConvenient post-processingGrain treatmentsIce waterProcess engineering

The invention belongs to the technical field of hardware, in particular to a hardware waste material recycling technology. The hardware waste material recycling technology has the advantages that after a hardware waste material is cut into sheets by a plasma cutting machine, the surface of the hardware waste material is irregularly crushed by a punch head, and the surface of the hardware waste material forms convex parts and broken openings, so as to conveniently crush the hardware waste material; by adding a quantitative amount of ice and water mixture and grinding material into a crushing bin of a hardware waste material treatment device, the ice and water mixture can effectively prevent the shortening of the service life of the device due to high temperature in the crushing process of the hardware waste material, and effectively reduce noise in the crushing process; the grinding material can assist the device to crush the hardware waste material, and the surface of the hardware waste material is ground into uneven parts by the grinding material, so as to accelerate the crushing rate; by utilizing the rotation and movement of a crushing wheel, the vibration of an upper wheel anda lower wheel and the vibration and movement of the crushing bin, the hardware waste material can be treated, so that while the labor intensity is decreased, the hardware waste material can be fully treated.

Owner:新沂市新南环保产业技术研究院有限公司

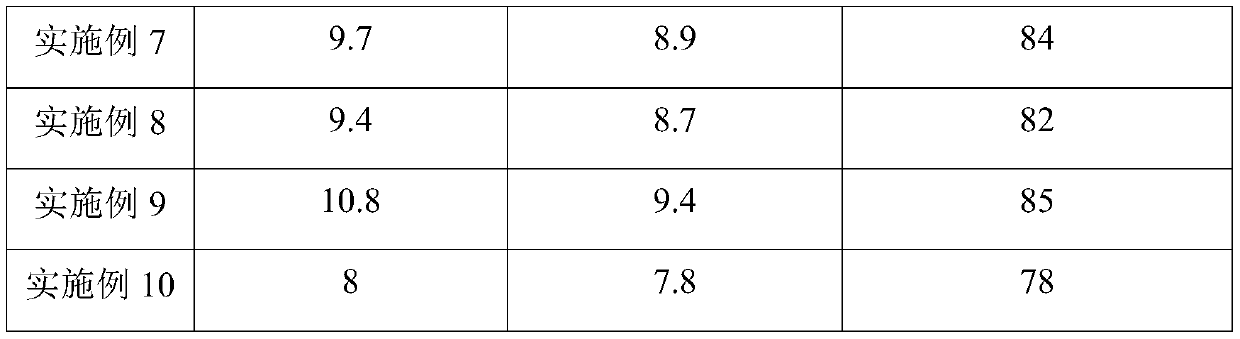

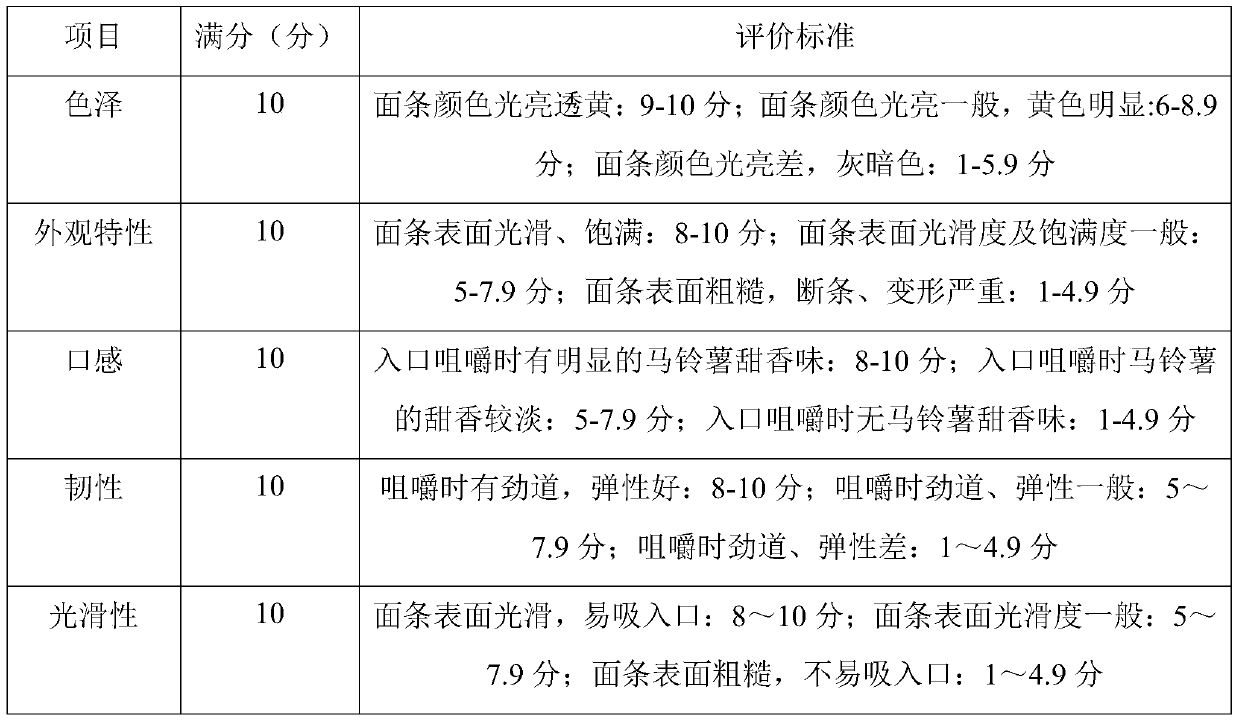

Preparation method of mashed potatoes

The invention discloses a preparation method of mashed potatoes. The preparation method includes the following steps that first, potatoes are washed, the outer parts of the potatoes are coated with mixed liquor, the potatoes are wrapped with silver paper, and a potato material package is obtained; second, the potato material package is put in an oven for baking, the silver paper is teared off after baking, and peel-removed potatoes are obtained; third, the peel-removed potatoes are frozen and dried, and dried potatoes are obtained; and fourth, the dried potatoes are crushed in a crusher, and the mashed potatoes are obtained. According to the preparation method of the mashed potatoes, by reserving the potato peels before potato ripening, the potatoes can be prevented from browning with airduring processing, the color uniformity of the mashed potatoes is improved, meanwhile, the loss of the nutrient content of the potatoes can further be reduced, original flavor and taste of the potatoes are preserved as much as possible, and the quality of the mashed potatoes is improved.

Owner:西藏天虹科技股份有限责任公司

Rail transit escape device

The invention relates to the technical field of rail transit equipment, and particularly relates to a rail transit escape device. The rail transit escape device comprises glass embedded in the side wall of a carriage, a safety hammer and an impact mechanism, the safety hammer comprises a hammerhead and a handle, a conical head is slidably connected in the hammerhead, a wireless switch button end is arranged in the hammerhead, the impact mechanism comprises an impact rod, a mounting seat, a first electromagnet and an impact block, one end of the impact rod penetrates through the side wall of the carriage and is close to the side end of the window glass, the mounting seat is rotatably connected with a first rotating shaft, the first rotating shaft is sleeved with a first torsional spring, the impact block is fixedly connected with the first rotating shaft through a connecting rod, and a metal stop lever for preventing the first rotating shaft from rotating is arranged on the mounting seat. According to the scheme, when the safety hammer is used for hitting the glass from the side of the glass while hitting the glass from the front, so that the glass can be broken more easily, the glass breaking speed is increased, more escape time is won for safe escape of passengers, and the safe escape efficiency is improved.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

Livestock breeding forage crushing device

ActiveCN111149524AHigh speedImprove chopping effectHollow article cleaningCuttersAgricultural scienceCrop livestock

The invention discloses a livestock breeding forage crushing device, and relates to the field of farming and grazing feed processing equipment. The livestock breeding forage crushing device comprisesa baseboard, wherein a crushing bin is fixedly connected with the top of the baseboard, a rack is fixedly connected with the right end of the crushing bin through bolts, a driving motor is fixedly connected with the middle portion of the rack, and an output end of the driving motor penetrates through the right side of the crushing bin, and extends into the crushing bin. According to the livestockbreeding forage crushing device, through eddy current devices, a rotating direction of forage with wind in the crushing bin is opposite to a running direction of blades, by means of an eddy current effect of air, the relative speed of the forage and the blades is improved, the cutting effect is enhanced, a crushing rate is improved, by means of adsorption force of eddy current, attachment of the forage to an inner wall of the crushing bin and the blades in a cutting process can be effectively avoided, the cutting and running effects are improved, and blocking of the crushing bin and deadlocking of the blades are avoided. By means of the livestock breeding forage crushing device, the problem that the crushing effect of a crushing device is not ideal is solved.

Owner:湖南超群农业科技股份有限公司

Decorative material crushing and mixing device

ActiveCN108201942BHigh precisionImprove crushing qualitySievingScreeningMechanical engineeringMaterial technology

The invention belongs to the technical field of decorative materials and particularly discloses a decorative material smashing and mixing device. The decorative material smashing and mixing device comprises a box. A crushing mechanism is arranged in the box. The crushing mechanism comprises an inner roller and an outer roller. The outer roller comprises a coarse crushing outer roller body and a fine crushing outer roller body. The inner roller comprises a coarse crushing inner roller body and a fine crushing inner roller body. The outer roller is internally provided with a cavity. The coarse crushing inner roller body is shaped like a circular truncated cone and is located in the coarse crushing outer roller body. The conicity of the coarse crushing inner roller body is greater than that of the coarse crushing outer roller body. The fine crushing inner roller body is shaped like a circular truncated cone and is located in the fine crushing outer roller body. The conicity of the fine crushing inner roller body is greater than that of the coarse crushing inner roller body. The sidewall of the fine crushing outer roller body is provided with a first discharge port. The sidewall of thecoarse crushing outer roller body is provided with a second discharge port. A filter screen is arranged below the crushing mechanism. A partition board is arranged on the filter screen. Filter gaps of the filter screen on the two sides of the partition board are different. A material mixing plate is arranged below the filter screen. An outlet is formed in the center of the material mixing plate.Through the scheme, the decorative material smashing and mixing device achieves crushing and mixing of different decorative materials.

Owner:聊城泽润装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com