Submersible aerator and use method

An aerator and aeration technology, applied in water aeration, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems that the aeration efficiency cannot meet the demand, so as to improve the speed of sewage treatment, improve the efficiency, Effect of increasing the rate at which bubbles collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment I

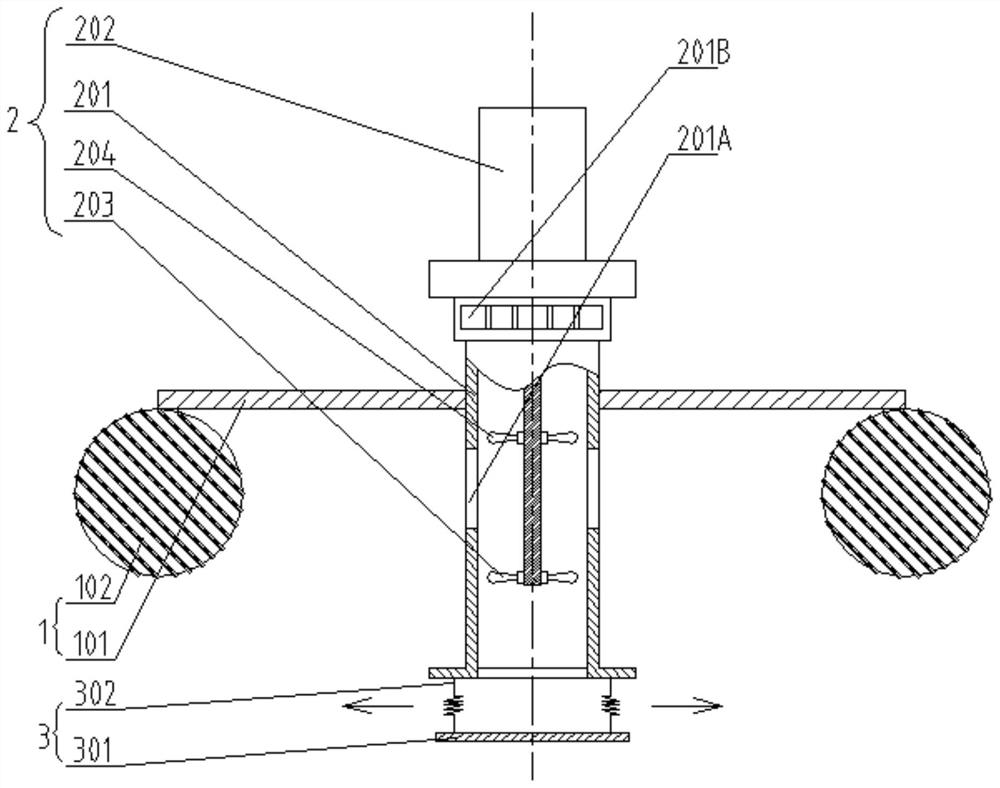

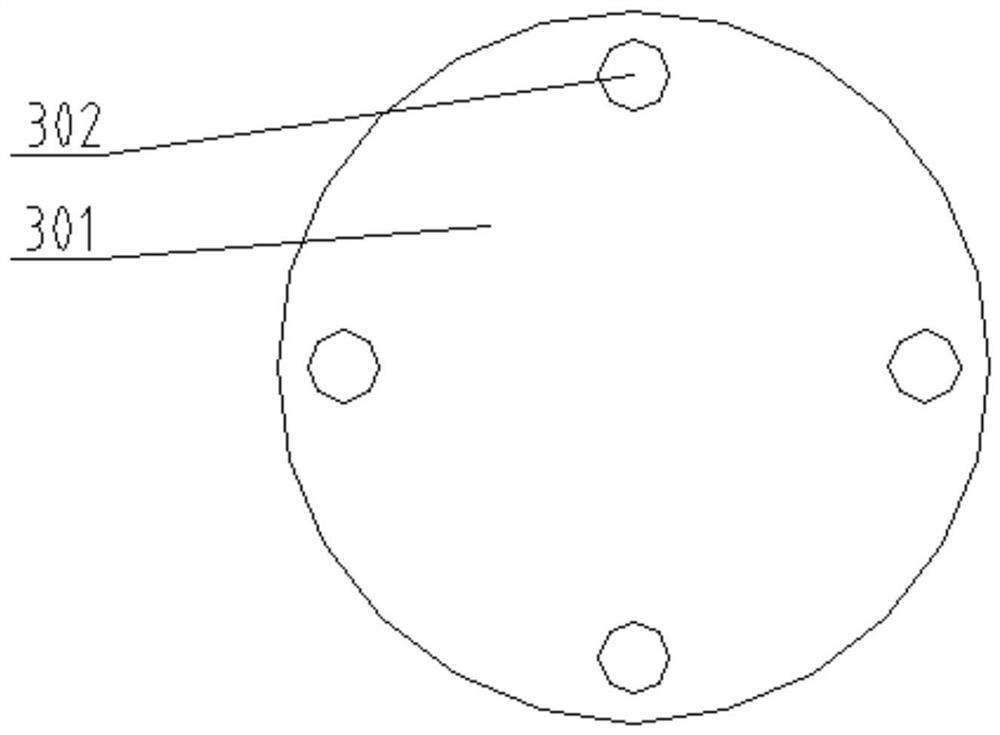

[0057] Such as Figure 1~2 , the oscillating assembly 3 includes: an oscillating plate 301 and more than two return springs 302; wherein, the oscillating plate 301 is closer to the bottom of the aeration tank than the output end of the aeration assembly 2; the return spring 302 is arranged on the Between the oscillating plate 301 and the output end of the aeration assembly 2, it is used to provide a vibrating restoring force for the oscillating plate 301; the oscillating plate 301 is flat or faces the bottom of the aeration tank.

[0058]The return spring 302 can be selected according to needs. At the same time, in order to increase the impact force, the oscillation plate 301 adopts a flat plate shape. The water flow output by the aeration assembly 2 hits the plate-shaped oscillating plate 301 vertically. Since the aeration assembly 2 is generally output by an impeller, the water flow output from the output end of the aeration assembly 2 is not a constant flow rate, resulting...

specific Embodiment II

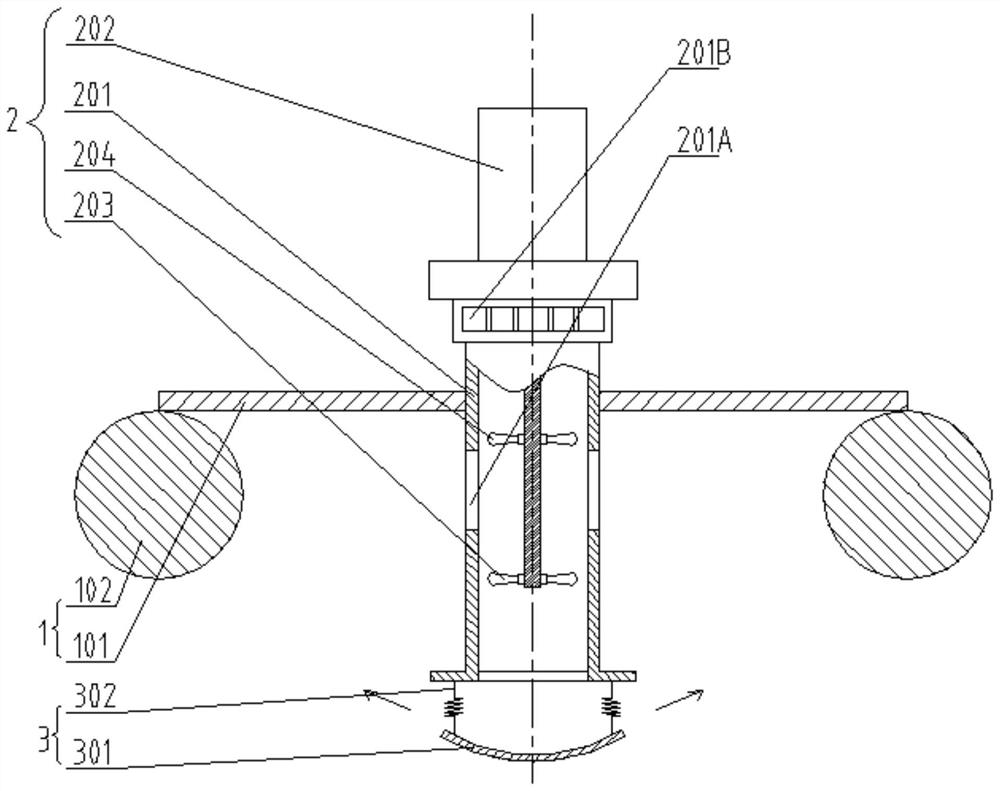

[0060] Such as image 3 Since the flat plate-shaped oscillating plate 301 is used in the specific embodiment 1, after the water flow containing large air bubbles hits the plate-shaped oscillating plate 301, too many fine air bubbles exist near the oscillating plate 301. During the movement, the oxygen is basically exhausted, and the aeration effect is not ideal.

[0061] In order to solve the above-mentioned problems, on the basis of the specific embodiment I, the oscillating plate 301 adopts an arc-shaped plate, and the arc-shaped plate protrudes toward the bottom of the aeration tank.

[0062] The water flow output by the aeration assembly 2 impinges on the arc-shaped oscillating plate 301. Since the aeration assembly 2 is generally output by an impeller, the water flow output from the output end of the aeration assembly 2 is not a constant flow rate, resulting in abnormal After the water flow at a constant velocity hits the oscillating plate 301, the oscillating plate 301 ...

specific Embodiment III

[0066] Such as Figure 4 , in order to increase the application reliability of the submersible aerator of the present invention, a submersible aerator also includes: a control unit 4, an air pump 5 and a counterweight 6; wherein the control unit 4 is arranged on the bracket assembly 1; the air pump 5 is arranged on the support assembly 1, and is used to forcefully inject air into the liquid in the aeration assembly 2; the counterweight 6 is used to balance the support assembly 1; the control unit 4 and the air pump 5 Electrically connected, used to control the air pump 5 to force ventilation according to the oxygen content in the aeration tank.

[0067] The oxygen content in the aeration tank is detected manually or electronically. If the oxygen content is too low, the control unit 4 controls the air pump 5 to work to perform forced ventilation and increase the oxygen in the aeration tank.

[0068] Preferably, the air pump 5 supplies air to the aeration tank through an air no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com