A metal waste recycling process

A waste recycling and processing technology, which is applied in the field of hardware, can solve the problems of staff's health relying on manpower, reducing the service life of the device, and incomplete processing, so as to prevent damage, reduce the service life, and enhance the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

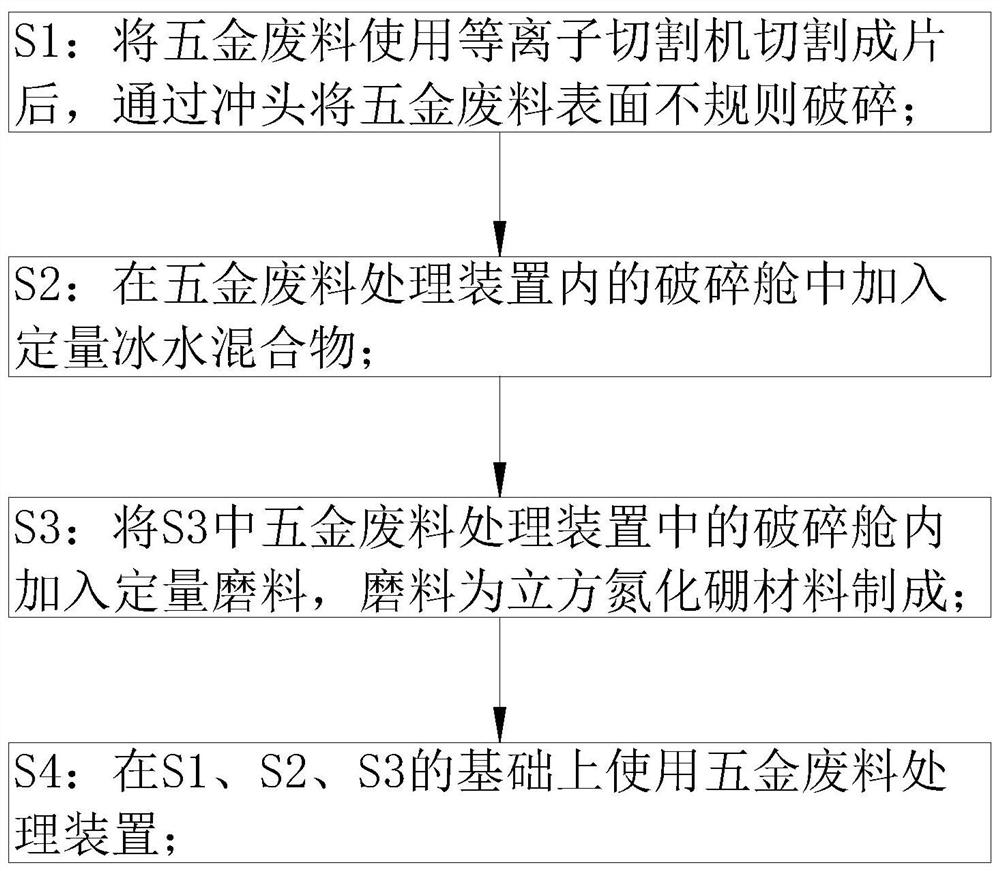

Method used

Image

Examples

Embodiment approach

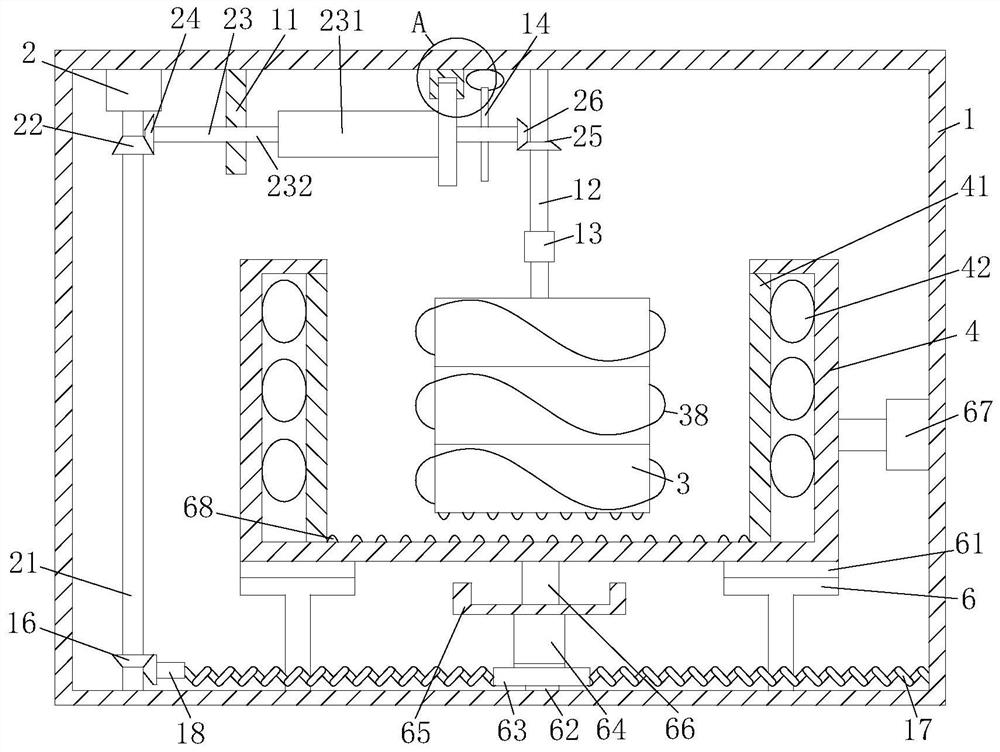

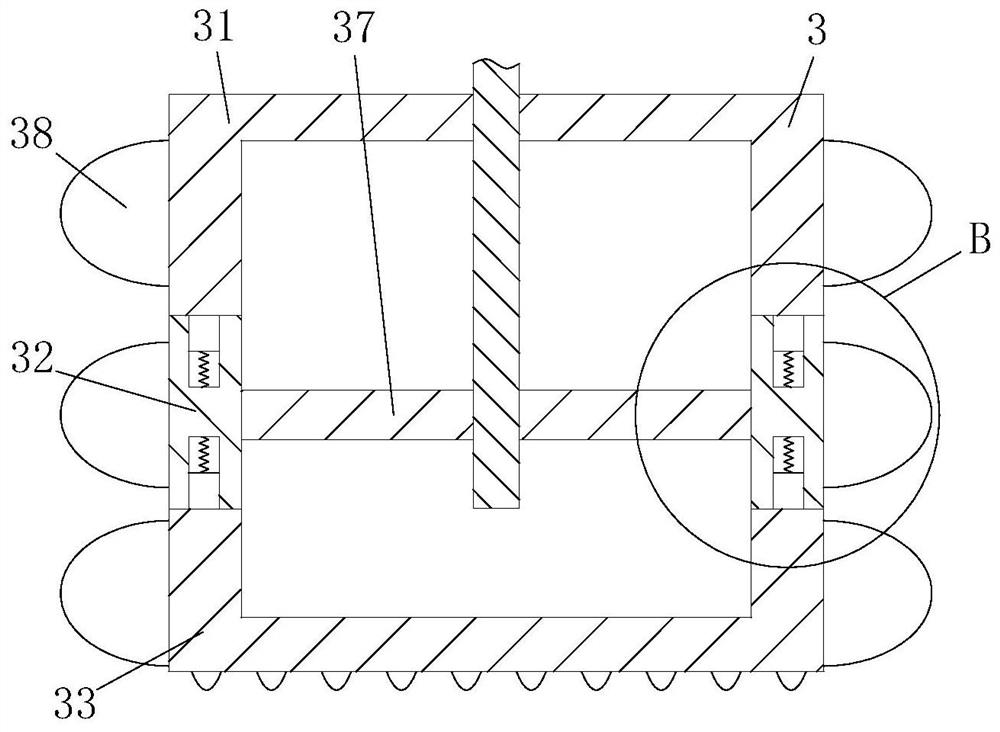

[0036] As an embodiment of the present invention, the transmission shaft 23 is composed of an elastic shaft 231 and a non-elastic shaft 232; the surface of the elastic shaft 231 is fixedly sleeved with a disc 5; block 51; the bottom of the friction block 51 is provided with a friction groove 52, and the disc 5 slides in the friction groove 52; during use, the motor 2 drives the transmission shaft 23 to rotate, and at the beginning, the friction between the disc 5 and the friction block 51 The force is greater than the torsion of the elastic shaft 231, and the disk 5 does not rotate. With the rotation of the motor 2, the torsion gradually increases. Under the action of torsion, the disc 5 will stop slowly, which acts as a buffer, effectively preventing the sudden stop of the crushing wheel 3 from causing damage to the crushing wheel 3, reducing the loss of parts, and at the same time enhancing the treatment effect of metal waste.

[0037] As an embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com