Patents

Literature

59results about How to "Convenient post-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sapphire mobile phone panel processing method

InactiveCN104088017AHigh hardnessHigh light transmittancePolycrystalline material growthAfter-treatment detailsStress concentrationWafer dicing

The invention discloses a sapphire mobile phone panel processing method. The process consists of material preparation, cutting, chamfering, rough grinding, annealing, DMP, CMP (chemical mechanical polishing), cleaning, coating, screen printing and finished product inspection, wherein in the step 1 of cutting, a crystal block is sliced to facilitate follow-up processing; in the step 2 of chamfering, the wafer edge is trimmed into an arc shape to improve the mechanical strength of the sheet edge and avoid stress concentration and consequent defect; in the step 3 of rough grinding, a wafer cutting damage layer caused by slicing is removed, and the flatness of the wafer is improved; in the step 4 of annealing, the stress concentration and large BOW caused by mechanical processing are improved; in the step 5 of DMP, the damage layer caused by rough grinding is improved, and the surface roughness of the wafer is reduced; in the step 6 of CMP, the wafer roughness is improved so that the surface reaches the nanoscale precision; in the step 7 of coating, the wafer is subjected to anti-fingerprint coating treatment; and in the step 8 of screen printing, the single side of the wafer is subjected to screen printing treatment to enhance light absorption. By adopting the method, a sapphire mobile phone panel without damage layer on surface and with nanoscale roughness can be obtained; moreover, the preparation period is greatly shortened, the production cost is saved, and the labor productivity is improved.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Technology for recovering nickel, cobalt and iron from nickel oxide ores through high-temperature chlorinating volatilization

The invention relates to a technology for recovering nickel, cobalt and iron from nickel oxide ores through high-temperature chlorinating volatilization. The technology comprises the following steps: A, respectively pulverizing and ball-milling the nickel oxide ores and coke powder; B, uniformly mixing the nickel oxide ores, the coke powder and a chlorinating agent to carry out high-temperature chlorinating volatilization roasting, converting chlorinated nickel, cobalt and iron into gas at a high temperature, filling smoke, and in a recovering device, washing with water, absorbing and dissolving a smoke chloride solution; C, producing an oxyhydrogen mixture product containing nickel, cobalt and iron. The nickel grade of the oxyhydrogen mixture product containing nickel, cobalt and iron, produced by the invention, is high and can be used for producing stainless steel. Compared with the traditional nickel oxide ore wet-process treatment technology, the method for recovering nickel, cobalt and iron from nickel oxide ores belongs to the technology having the advantages of high resource comprehensive utilization rate, low energy consumption, environment friendliness and easiness for implementation.

Owner:毛黎生 +2

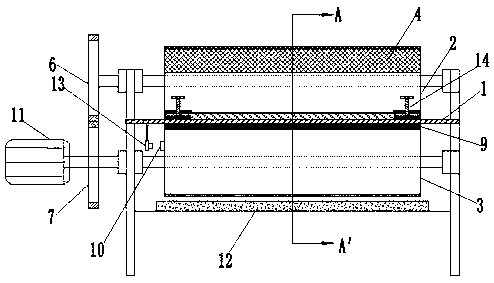

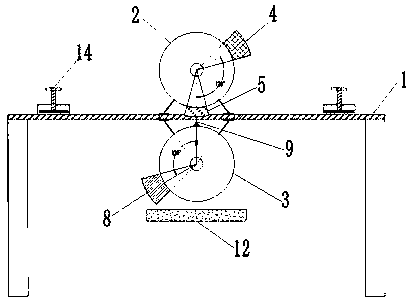

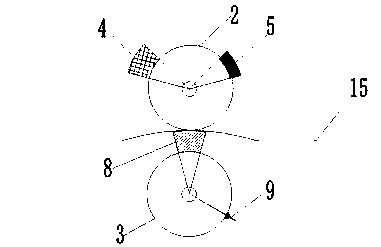

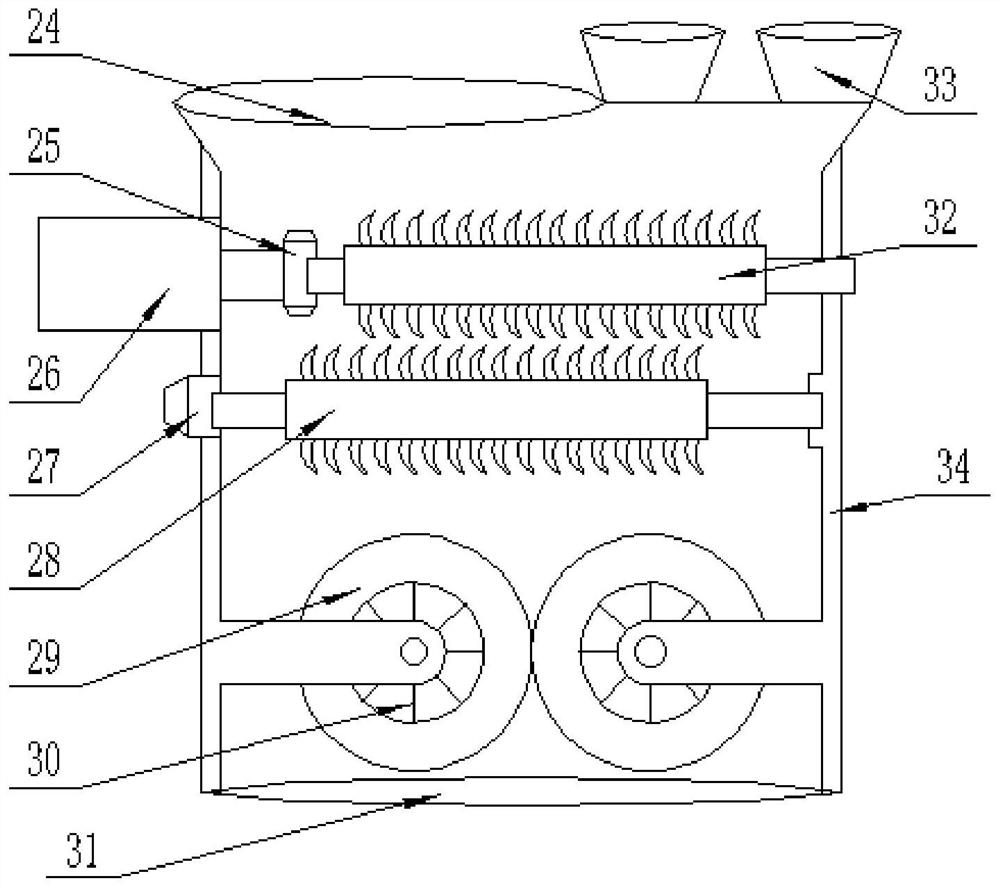

Preparation method of continuously-rolled biomass briquette

The invention relates to the technical field of biomass briquettes and provides a preparation method of a continuously-rolled biomass briquette. The preparation method comprises the following steps of raw material pretreatment; rolled slurry preparation; rolled slurry viscosity regulation; continuous rolling; and drying and rolling. The treatment steps such as roll compacting, secondary rolling and base material separation can also be carried out according to actual demands. The preparation method has the characteristics of high production efficiency, high universality and low cost, and is convenient and fast for posttreatment.

Owner:GUANGDONG TUOFENG IND CO LTD

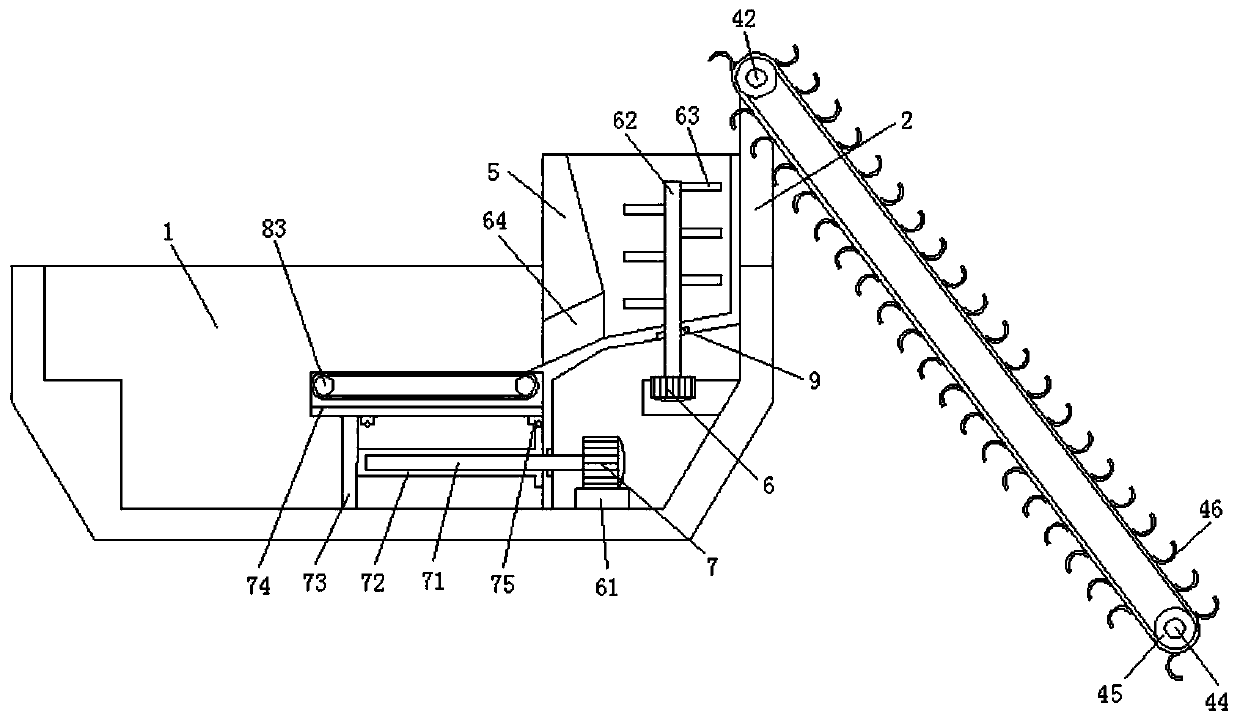

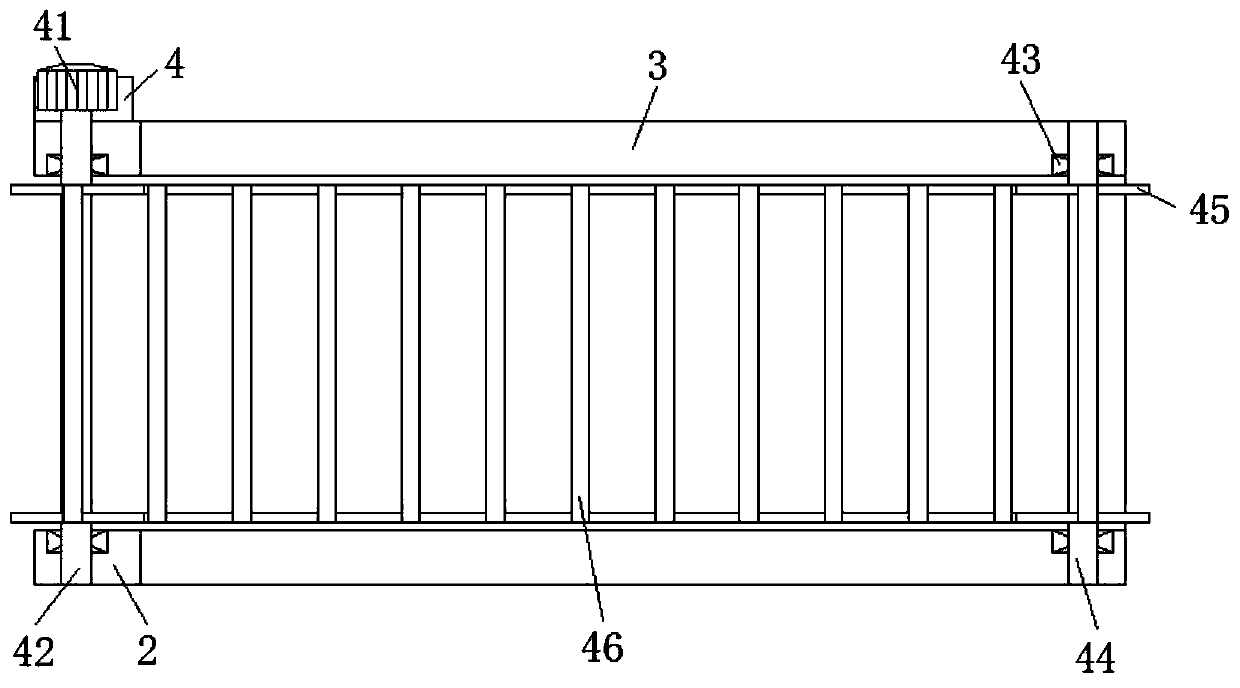

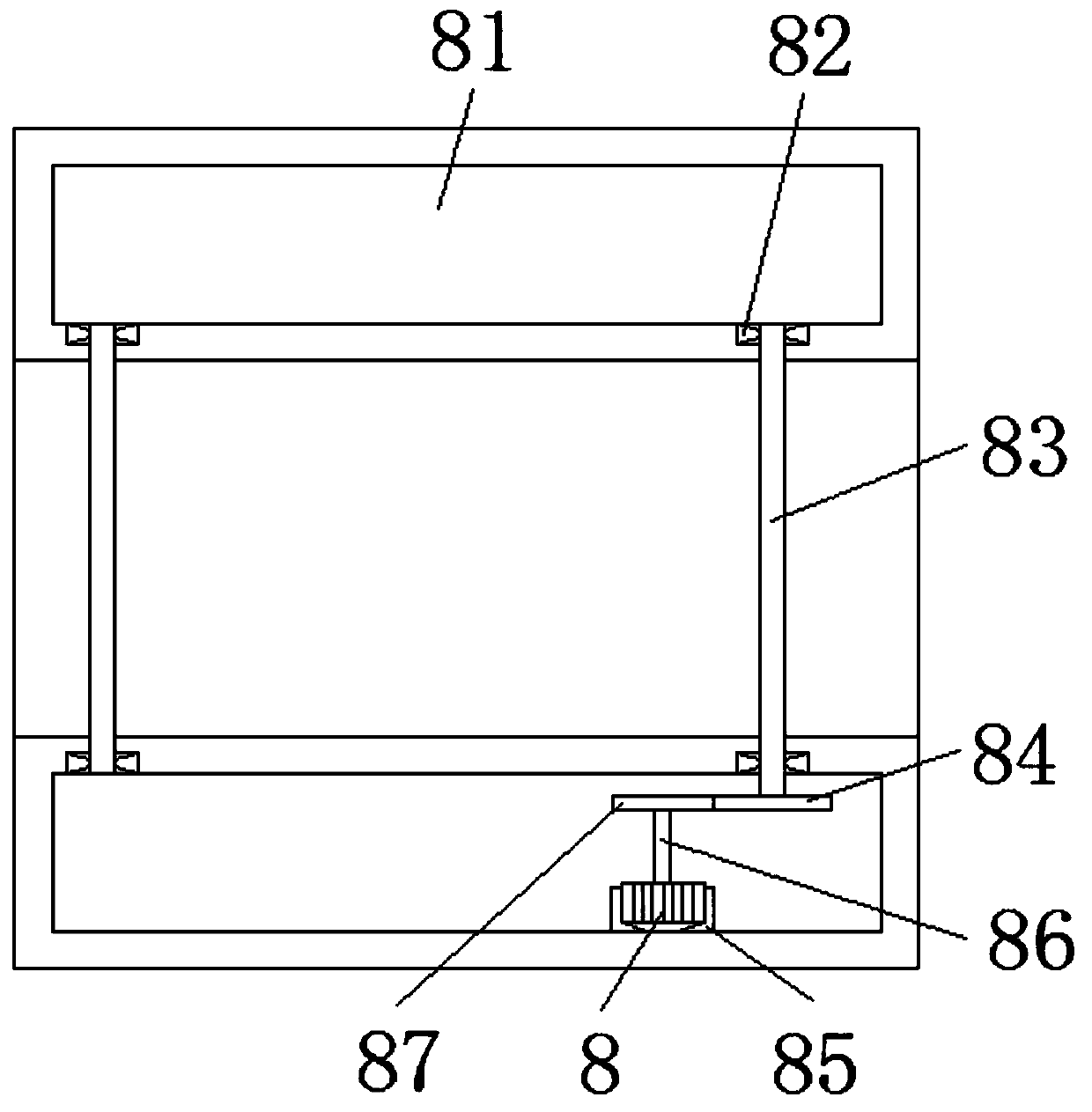

Riverway waterweed cleaning and collecting device and using method thereof

PendingCN111516814AImprove cleanlinessAvoid the effect of incomplete collectionWater cleaningWaterborne vesselsRiver routingElectric machinery

The invention belongs to the technical field of riverway equipment, and especially relates to a riverway waterweed cleaning and collecting device and a using method thereof. The device comprises a hull, mounting seats are fixedly connected to the upper surface of one end of the hull, connecting blocks are fixedly connected to the surfaces of one sides of the two mounting seats, waterseed collecting devices are arranged on the opposite surfaces of the two connecting blocks, and each waterseed collecting device comprises a collecting motor. The waterseed collecting devices are arranged on the opposite surfaces of the two connecting blocks, each waterseed collecting device comprises the collecting motor, so when the waterweeds in the riverway are collected, the waterweeds on the water surfaceare not only collected, but also are driven and collected together with the waterweeds in the deep water, the existing effect that the waterweeds are only crushed and collected on the water surface and grow out after a period of time is avoided, and the effect that the water surface can be kept clean without the waterweeds for a long time is achieved.

Owner:ANHUI JIAMING ENVIRONMENTAL PROTECTION TECHCO

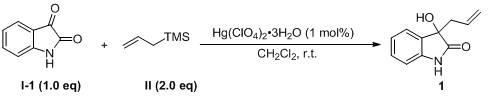

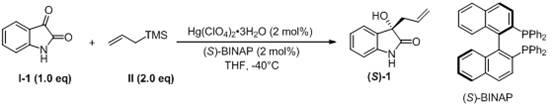

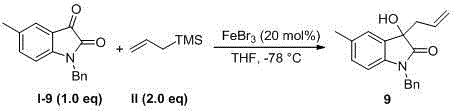

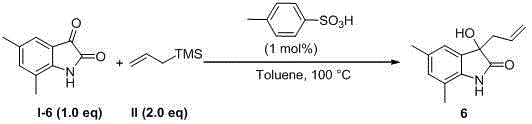

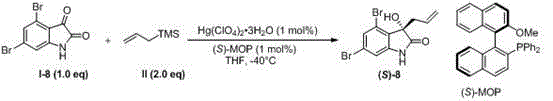

Method for preparing 3-allyl-3-hydroxy oxindole

InactiveCN102070509AWide variety of sourcesLow priceOrganic chemistryChromatographic separationPtru catalyst

The invention discloses a method for preparing 3-allyl-3-hydroxy oxindole, which comprises the following steps of: adding a catalyst, solvent, isatin and silicane in a reaction bulb, stirring at the specific temperature, performing thin layer chromatography (TLC) detection until the isatin disappears, adding ethyl acetate for diluting, dripping concentrated hydrochloric acid, stirring continuously at the room temperature for half an hour, washing once sequentially by using solution of saturated sodium hydrogen carbonate and saturated saline solution, drying an organic phase by using anhydrous magnesium sulfate, and performing column chromatographic separation to obtain the 3-allyl-3-hydroxy oxindole. Various reagents used in the method can be obtained commercially, and have wide sources of raw materials and low cost; the used catalyst has a good catalytic effect and helps to reduce cost and also helps to simplify a process, reduce cost, facilitate aftertreatment process and reduce pollution to the environment.

Owner:EAST CHINA NORMAL UNIV

Film coating method for electronic circuit board

InactiveCN102686034ADoes not affect processabilityPerformance is not affectedVacuum evaporation coatingSputtering coatingHigh volume manufacturingOxidation resistant

The invention relates to a film coating method for an electronic circuit board. The film coating method comprises the steps of plating a film on the electronic circuit board under vacuum conditions and performing post-treatment, and specifically comprises the following steps: introducing a film-plating material which is vaporized and cracked by heating into a vacuum chamber placing the electronic circuit board, cooling the vacuum chamber, performing vacuum film plating operation on the surface of the electronic circuit board at normal temperature till the thickness of the plated film achieves the requirements, then taking out the electronic circuit board; then performing the post-treatment, that is, removing a film-plated layer at the part of the electronic circuit board, which is required to be exposed outside. Through the vacuum film-plating way, the film-plated layer is uniform and complete, the relatively complete waterproof, moisture-proof and anti-oxidation effects can be ensured, and even for all the small gaps and other dead points in the prior art, the effects are also good; and simultaneously, the processing cost is low, and the film coating method is suitable for mass production. The post-treatment process step can better treat the part to be exposed, and the follow-up processing and the use of the electronic circuit board can not be affected.

Owner:杨白

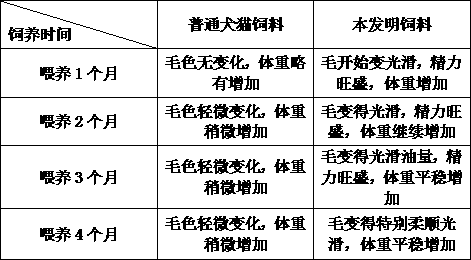

Dog-cat liquid wet food taking enzymolysis meat as main raw material and preparation method of food

InactiveCN108684967AIncrease concentrationMeet actual processing needsAnimal feeding stuffAccessory food factorsLocust bean gumHydrolysate

The invention relates to a dog-cat liquid wet food taking enzymolysis meat as a main raw material. The food is characterized by comprising the following components in percentage by weight: 40 to 50 percent of a fresh meat enzymolysis liquid, 5 to 8 percent of starch, 0.3 to 0.5 percent of locust bean gum, 0.8 percent of lysine, 0.2 percent of taurine, 0.3 to 0.5 percent of composite vitamin, 0.3 to 0.5 percent of composite mineral, 0.1 to 0.5 percent of beer yeast, 0.1 to 0.2 percent of salt and the balance of water. The product is a thick semi-liquid, is easy to lick and ea for pet dogs and catst, rich in nutrients, delicious in taste and easy to digest and absorb for pets. The method prolongs the reaction time of enzymolysis, improves the concentration of the hydrolysate while ensuring the ful enzymolysis of soup base, and improves the viscosity of the product without adding other raw materials.

Owner:青岛双安生物科技有限公司

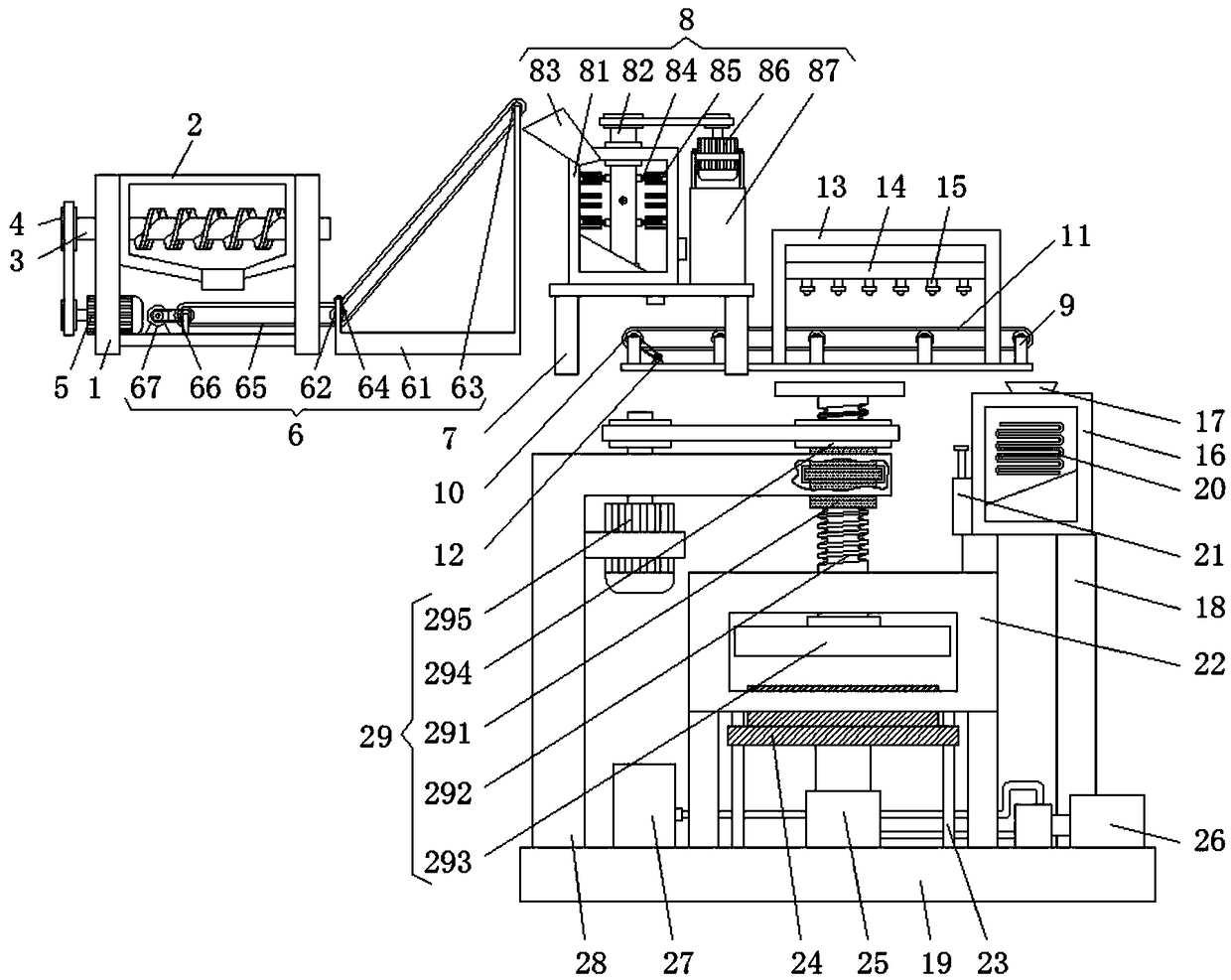

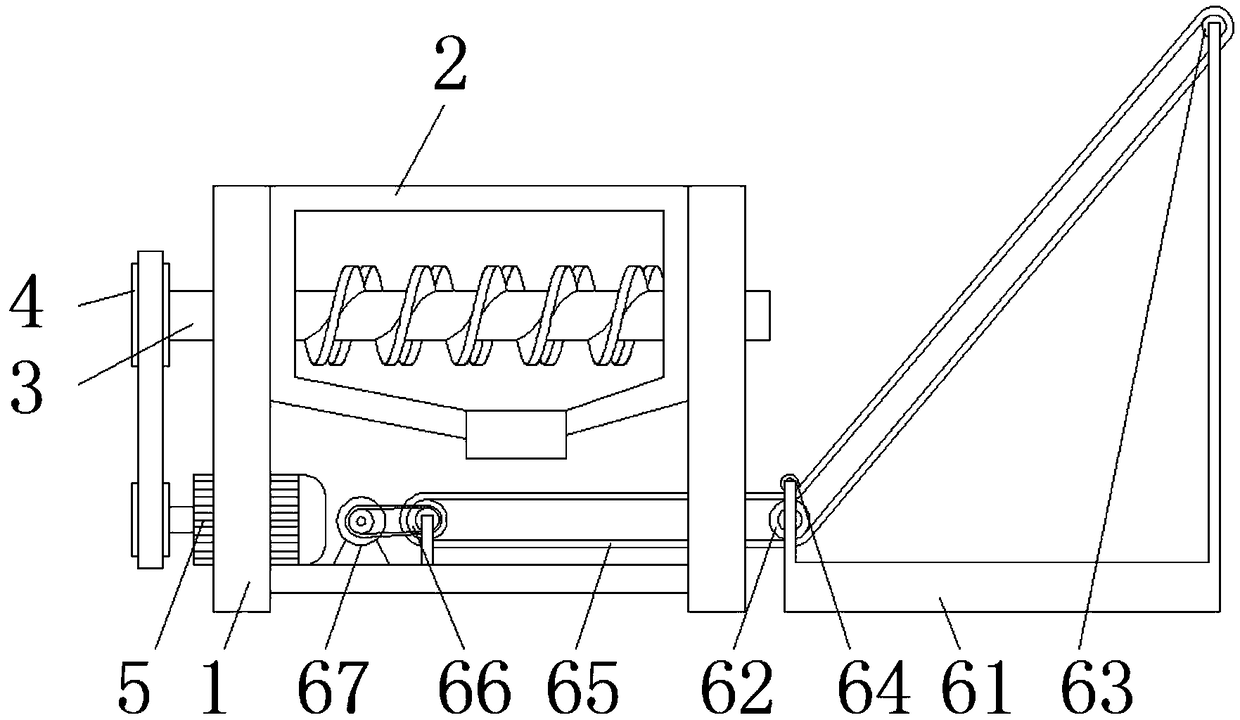

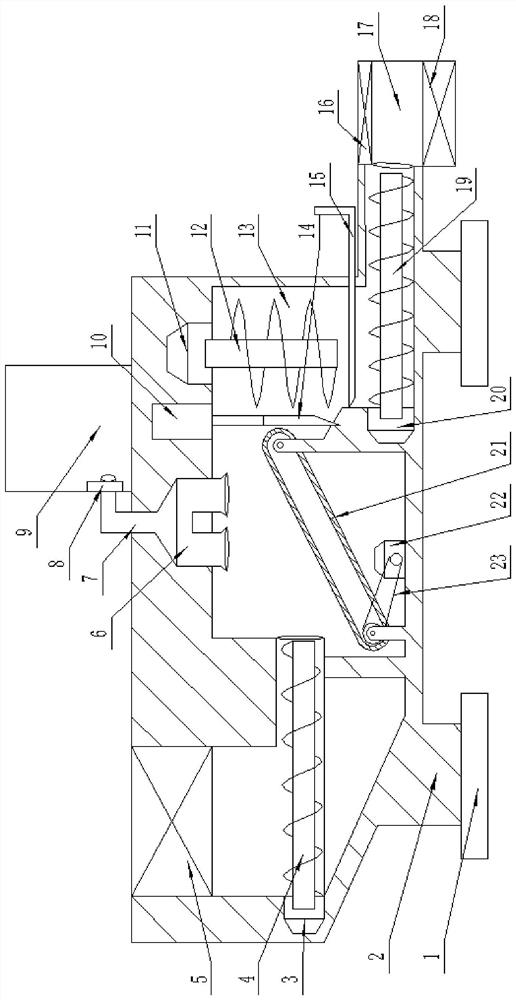

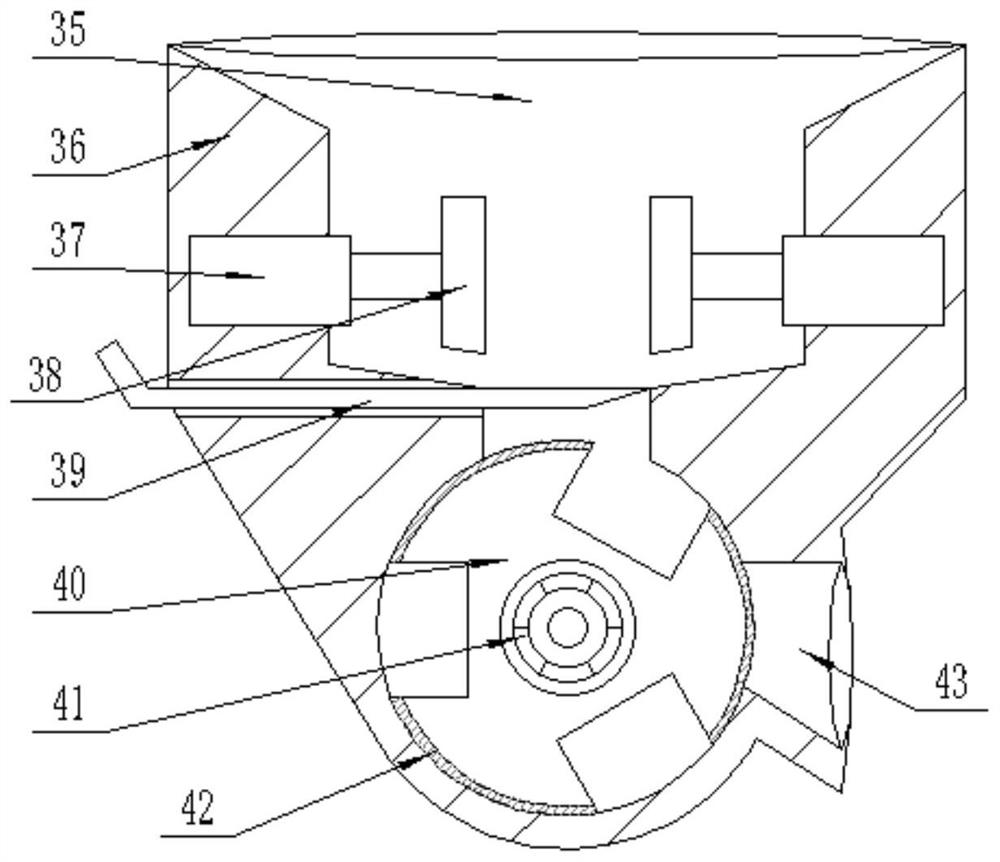

Device for recycling urban plastic garbage

ActiveCN108908792AComplete conversionConvenient post-processingPlastic recyclingCleaning using liquidsDrive wheelSpiral blade

The invention relates to the technical field of garbage recycling, and discloses a device for recycling urban plastic garbage. The device comprises a support; the left side and right side of the innerwall of the support are respectively and fixedly connected with the left side and right side of a crushing box; the inner wall of the crushing box is in movable sleeve connection with two packing augers, and the two packing augers are positioned in the same horizontal plane and are arranged in a staggered way together with spiral blades; the other ends of the packing augers extend out of one sideof the crushing box and are separately in fixed sleeve connection with a driving wheel; the exterior of one driving wheel is connected with an output shaft of the crushing shaft by means of a drivingbelt in a transmission way. According to the device for recycling the urban plastic garbage, the packing augers and a secondary crushing device are arranged, so that the plastic garbage is firstly broken by means of the packing augers, the crushed garbage is conveyed to the secondary crushing device by means of a crushed material conveying device after large plastic parts are broken into small plastic parts, and the secondary crushing device is used for performing high-speed secondary crushing; therefore, the various types of plastic product garbage can be more completely converted into smallbroken granules, and the post treatment process is facilitated.

Owner:ANHUI XINYU ENVIRONMENTAL SANITATION MACHINERY

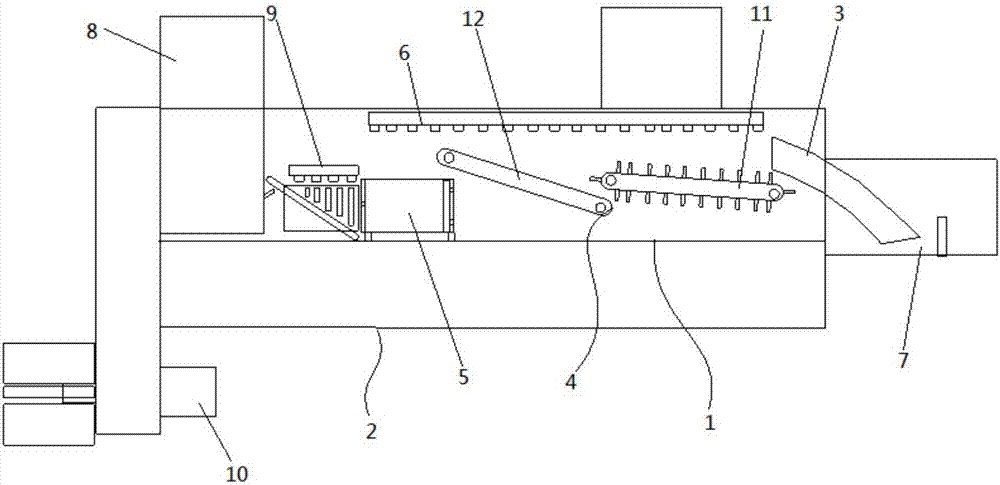

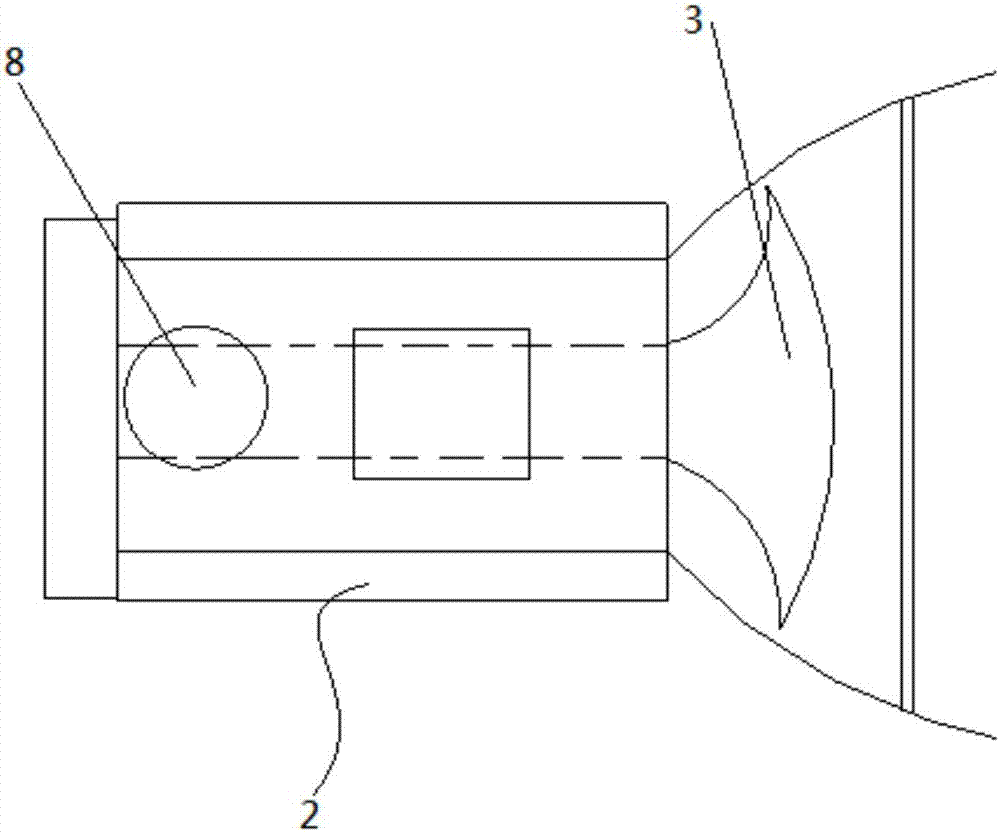

Blue-green algae collecting and processing storage chip for ecological maintenance

InactiveCN107313412AIncrease buoyancyReduce resistanceWater cleaningWaterborne vesselsFertilizerEngineering

The invention relates to a blue-green algae collecting and processing storage chip for ecological maintenance. The blue-green algae collecting and processing storage chip comprises a blue-green algae collecting device and a ship body. The blue-green algae collecting device comprises a collecting opening, a conveying mechanism and a compression mechanism. One end of the collecting opening is arranged at the front end of the ship body, and the other end of the collecting opening is arranged above the conveying mechanism. The conveying tail end of the conveying mechanism is arranged above the compression mechanism. The end, facing the front portion of the ship body, of the collecting opening is of an open type arc structure. A blow-drying device is arranged above the compression mechanism. The ship body is of a dual ship body structure. The blue-green algae collecting device is arranged at the vacation position in the middle of the dual ship body structure of the ship body. According to the blue-green algae collecting and processing storage chip for ecological maintenance, through the blue-green algae collecting ship, blue-green alga on the water surface can be automatically fished; the fishing speed is high; the cleaning effect is good; the movement speed on the water surface is high; cruising power is high; the fished blue-green alga can be collected after being processed to be utilized as feed or fertilizer; and ecological environmental protection is achieved.

Owner:苏州尧智生态环保科技有限公司

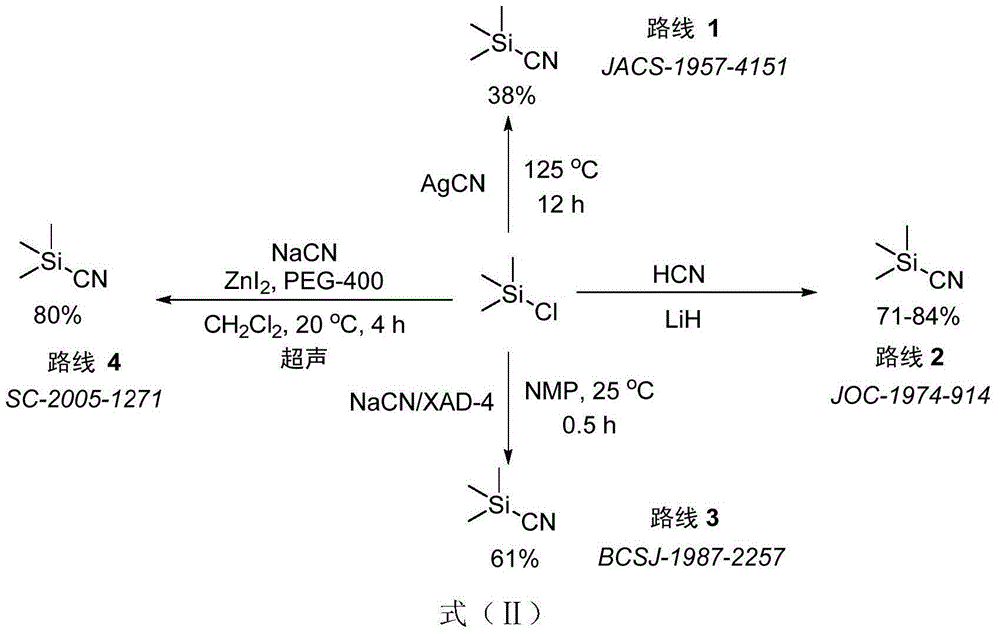

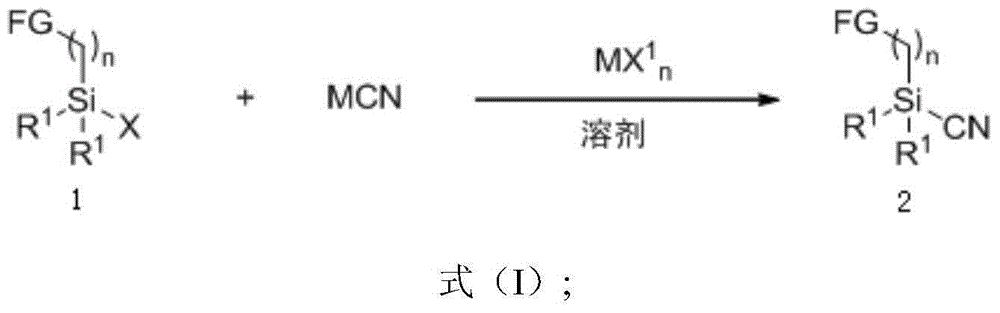

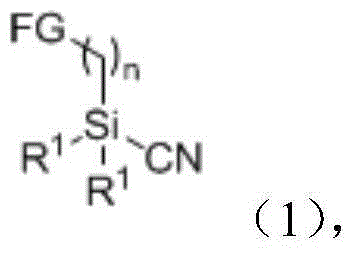

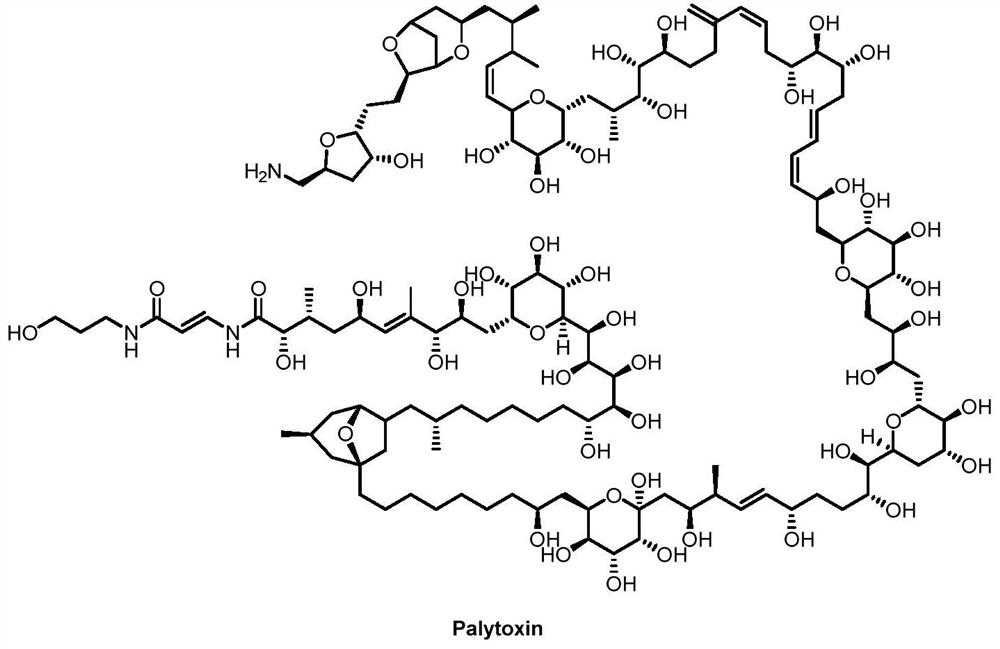

Functionalized cyanosilane, synthesis method and applications thereof

ActiveCN106366108AWide variety of sourcesLow priceGroup 4/14 element organic compoundsOrganic compound preparationCyanideOrganic solvent

The present invention discloses a functionalized cyanosilane and a synthesis method thereof. The method comprises: adding a raw material halogenated silane and a cyanogen source MCN into an organic solvent to synthesize the functionalized cyanosilane in the absence of a catalyst or by adopting a metal salt as a catalyst. According to the present invention, the functionalized cyanosilane can participate in the reactions capable of being participated by classic TMSCN to synthesize cyanhydrin, aminoalcohol, alpha-amino cyanide compounds and other important synthesis intermediates, and can further transfer the functional group carried by the silicon protecting group into the obtained addition product in the addition reaction through the appropriate conversion so as to substantially improve the synthesis efficiency and the atomic economy of the reaction, and synthesize a variety of products impossibly synthesized by the conventional TMSCN reagents.

Owner:EAST CHINA NORMAL UNIV

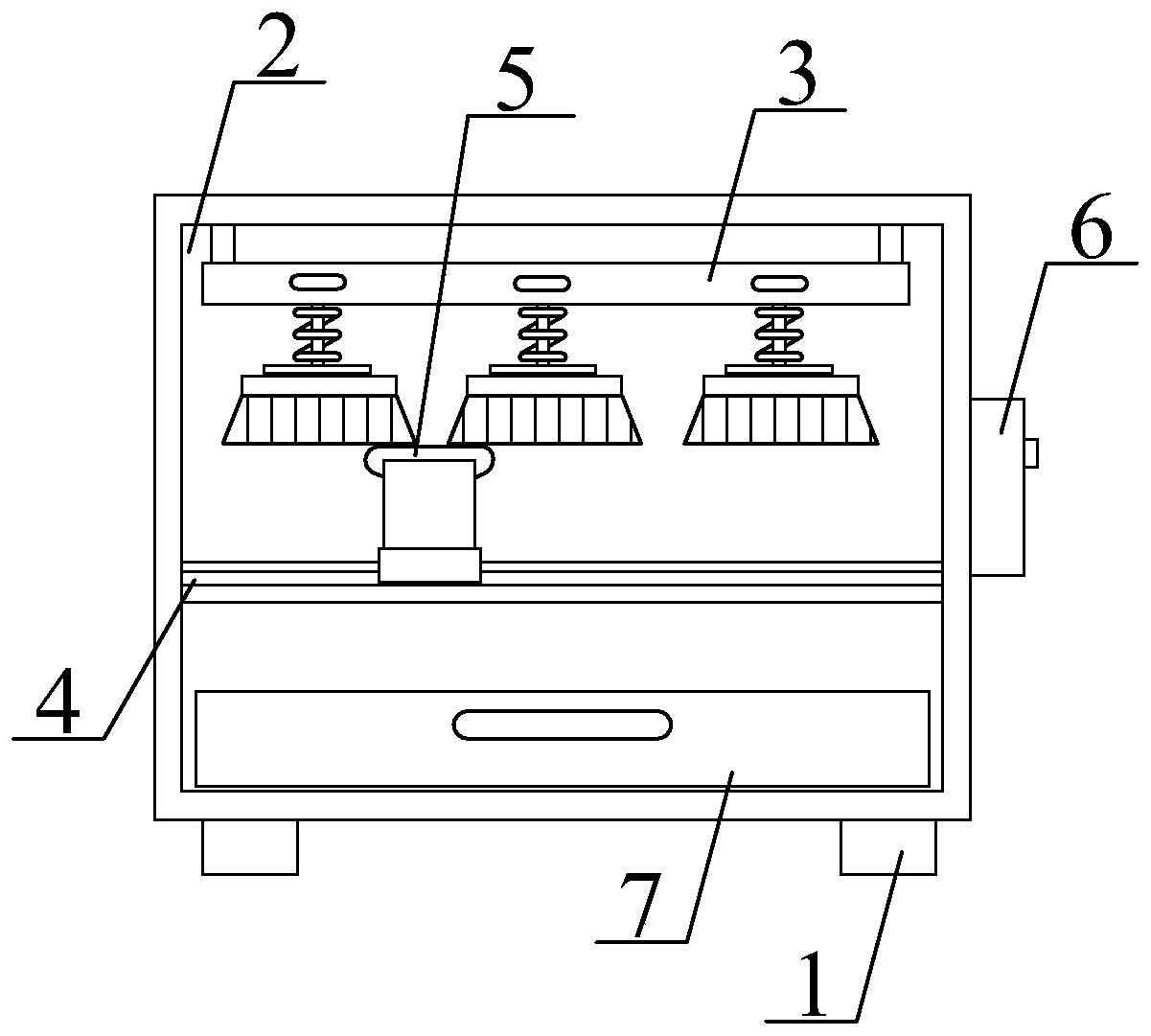

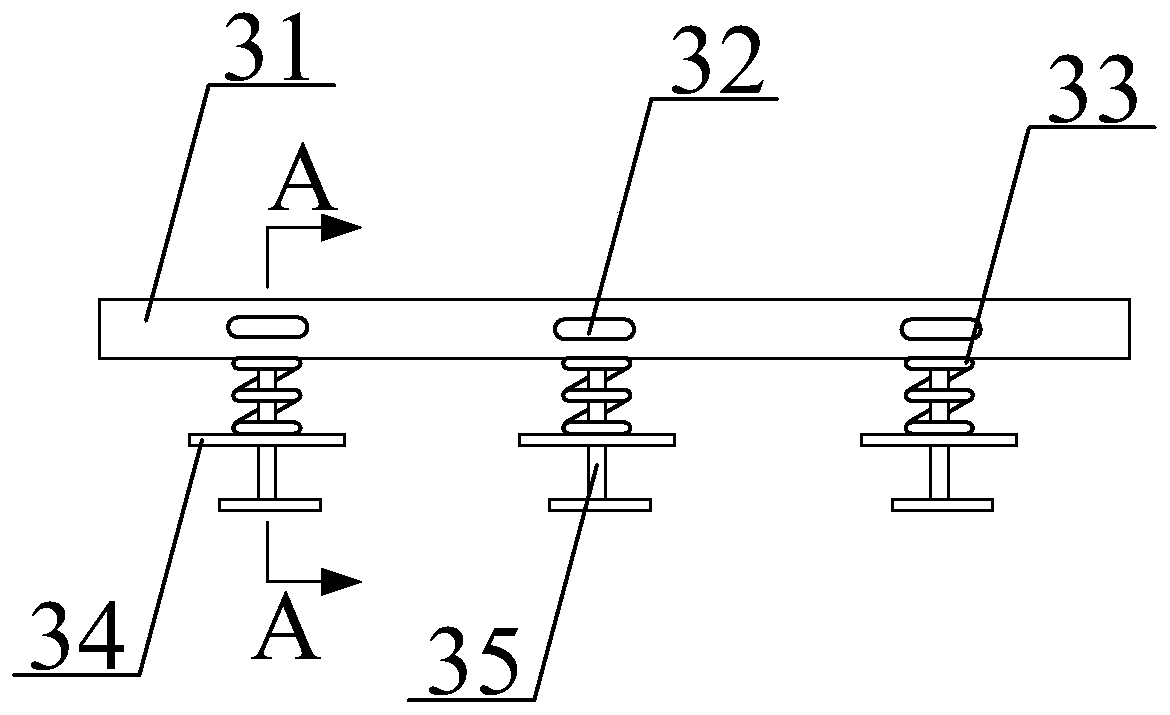

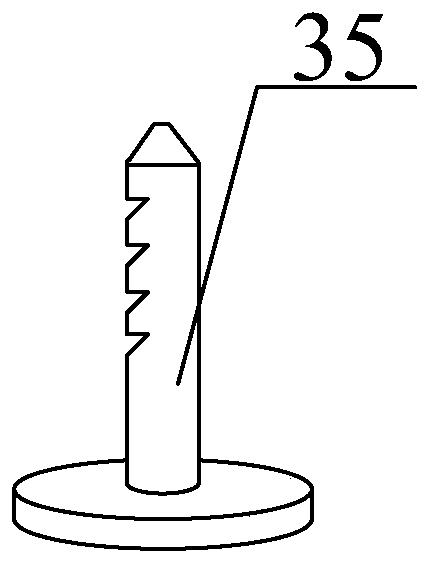

Brush bristle cutting device for processing of disc brush

The invention discloses a brush bristle cutting device for processing of a disc brush. The device comprises base foots, a case body, a brush disc fixing device, a linear motor, a brush bristle trimming mechanism, a power distribution cabinet and a slag collecting box, wherein the brush disc fixing device is arranged, a brush disc is clamped between a pressing plate and a brush disc fixing piece bya pressing spring through the pressing plate, and the situation that deflection or unreliable fixation during brush bristle trimming is effectively avoided; a clamping mechanism is arranged, so thatthe clamping connection is simple and convenient, and the working efficiency is effectively improved; the brush disc fixing piece is arranged, so that the relative position of the brush disc fixing piece can be adjusted according to processing requirements, and trimming of brush bristles in different length is realized; the linear motor is arranged, so that the linear motor drives the brush bristle trimming mechanism to move in a reciprocating manner, a plurality of brush discs can be trimmed at the same time, and the trimming efficiency is effectively improved; and the slag collecting box isarranged, so that the trimmed brush bristle slags can be collected, thereby facilitating later processing and guaranteeing the neatness of the working site.

Owner:安徽省潜山县志发机电配件有限公司

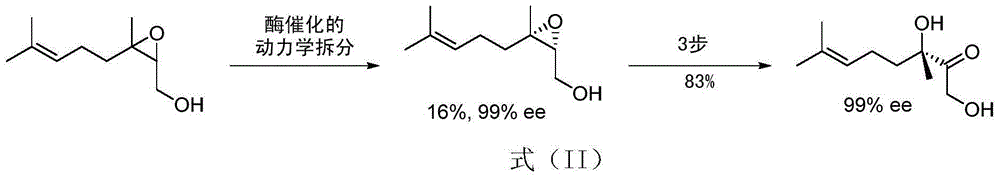

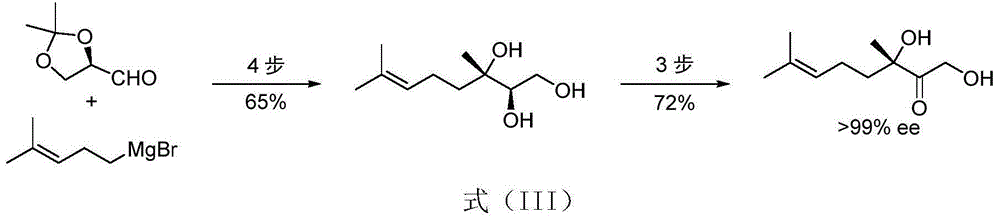

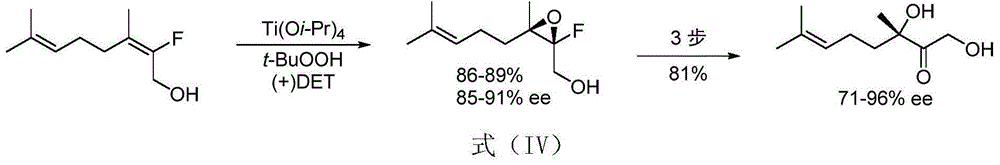

1,3-dihydroxy-3,7-dimethyl-6-octen-2-one synthesis method

ActiveCN106365962AWide variety of sourcesLow priceGroup 4/14 element organic compoundsCarbonyl compound preparation by hydrolysisSynthesis methodsCombinatorial chemistry

The present invention discloses new 1,3-dihydroxy-3,7-dimethyl-6-octen-2-one synthesis method, which comprises racemic synthesis and enantioselective synthesis. According to the present invention, commercially available 6-methyl-5-hepten-2-one (CAS:110-93-0) is adopted as a starting material, two one-pot series connection reaction systems are adopted, simple operations are performed, the separation purification of the intermediate is effectively avoided, the high-yield racemic synthesis of the 1,3-dihydroxy-3,7-dimethyl-6-octen-2-one is achieved, and the asymmetric synthesis method for enantioselective synthesis of (R)-1,3-dihydroxy-3,7-dimethyl-6-octen-2-one and (S)-1,3-dihydroxy-3,7-dimethyl-6-octen-2-one is developed. The present invention further discloses an intermediate compound.

Owner:EAST CHINA NORMAL UNIVERSITY

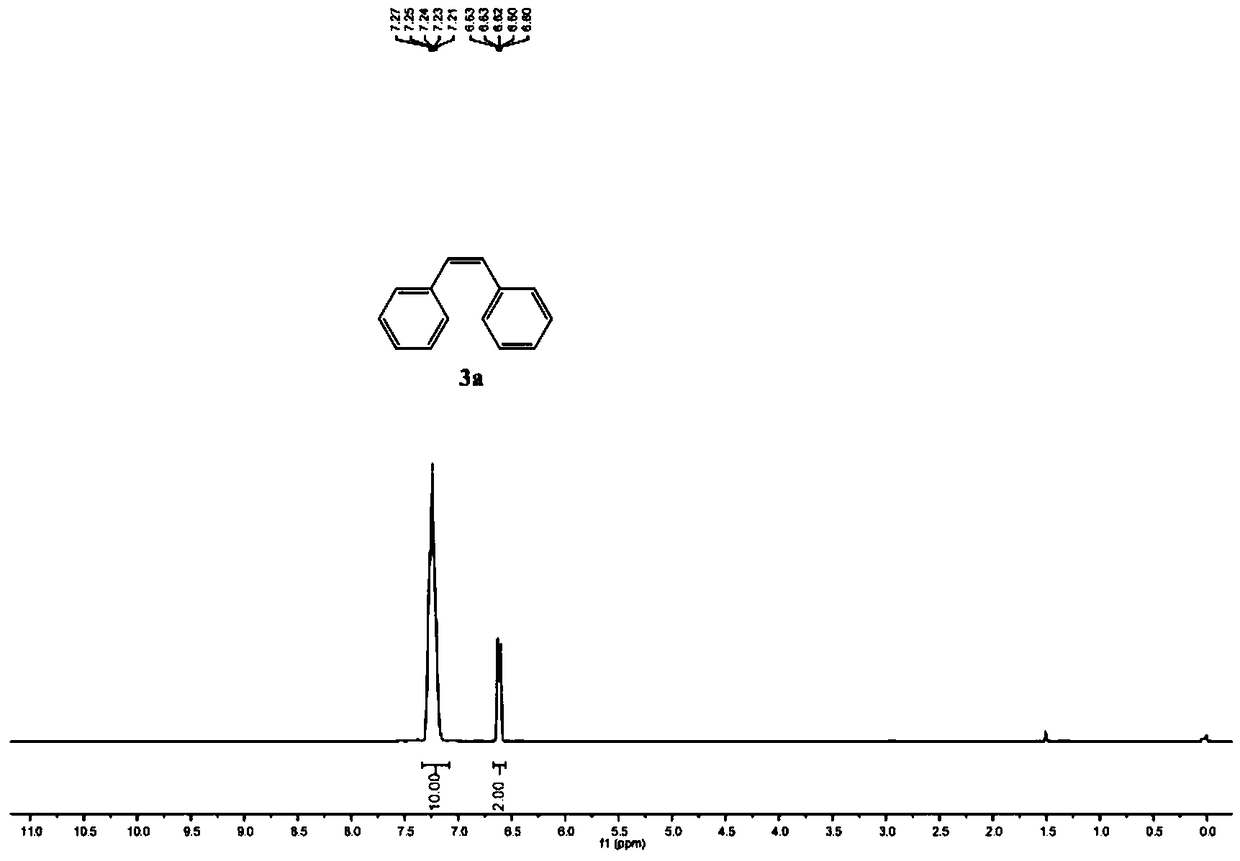

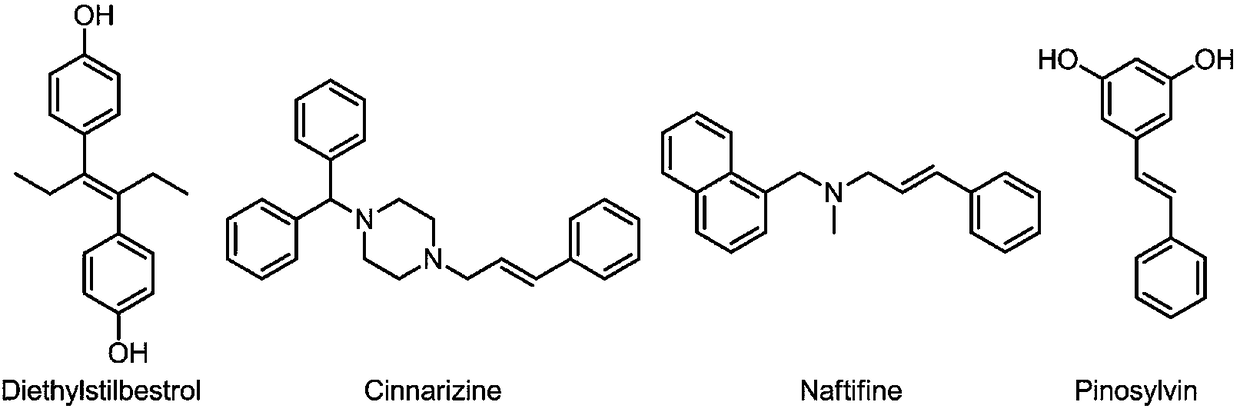

Method for catalytic-selectively synthesizing Z- and E-alkene through alcohol supply hydrogen iridium controlled by ligand

ActiveCN109134172AWide variety of sourcesLow priceOrganic reductionHydrocarbon by hydrogenationIridiumPhosphine

The invention discloses a method for catalytic-selectively synthesizing Z- and E-alkene through alcohol supply hydrogen iridium controlled by a ligand. The method comprises the following steps: usinga disubstituted acetylene compound as a starting raw material, using cheap alcohol as a hydrogen source, and using a metal iridium catalyst MmXn for catalyzing, under the control of a phosphine ligandand a diene ligand, to obtain cis-alkene and trans-alkene in high yield and high selectivity. The method is capable of using the cheap alcohol as the hydrogen source. Compared with a traditional hydrogenation strategy, economic cost is greatly reduced, and the process is simple. A metal iridium complex catalyst does not need to be prepared in advance. The operation is convenient, the product selectivity is good, the yield is high, and the method is suitable for industrial production.

Owner:NANTONG UNIVERSITY

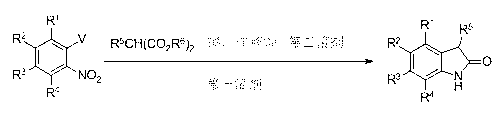

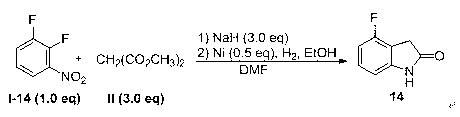

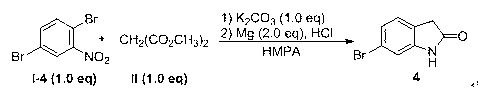

One-pot series synthetic method of oxoindole

InactiveCN103304468AImprove universalityImprove compatibilityOrganic chemistryMalonic acidBiochemical engineering

The invention discloses a one-pot series synthetic method of oxoindole, which comprises the following steps of: sequentially adding malonate, alkali, a first solvent, a reducing agent and a second solvent, carrying out aromatic nucleophilic substitution reaction, ester group removal reaction, reduction ring-closing reaction, and column chromatography separation on a raw material halogenated ortho-nitroaniline containing a substituent group in turn so as to obtain oxoindole, wherein a by-product metal salt of the aromatic nucleophilic substitution reaction is directly used as a promoter for the ester group removal reaction. The method disclosed by the invention has the advantages of good substrate universality, wide raw material sources, low cost, mild reaction conditions, is simple to operate, and is capable of avoiding environmental pollution, and is suitable for large-scale industrial production.

Owner:EAST CHINA NORMAL UNIV

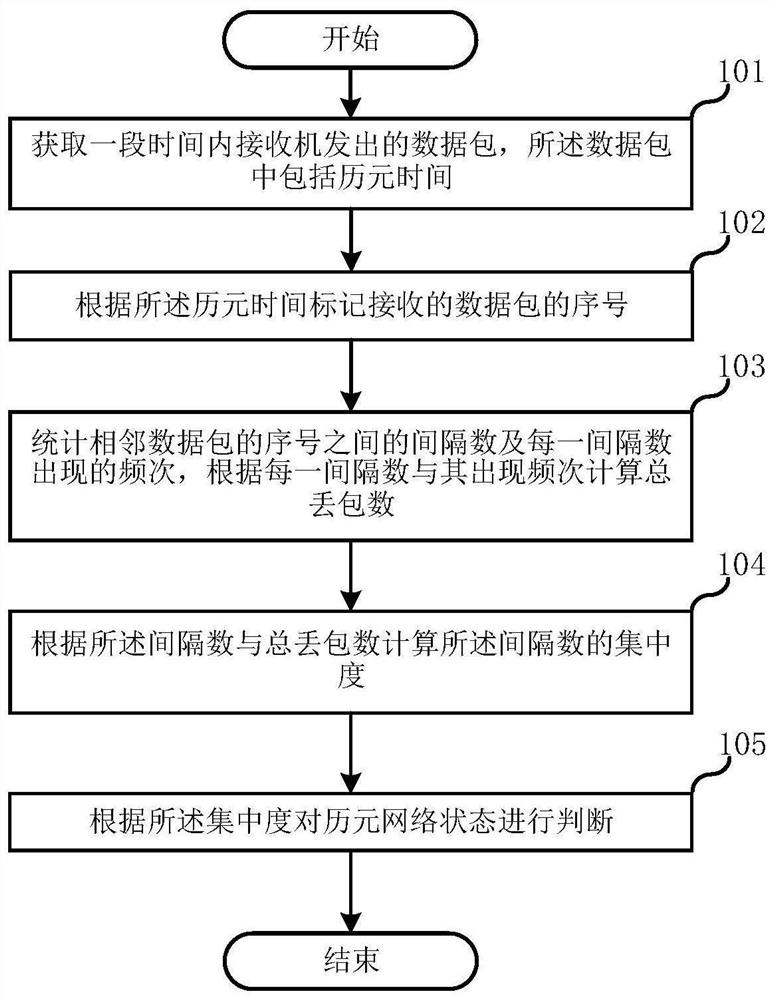

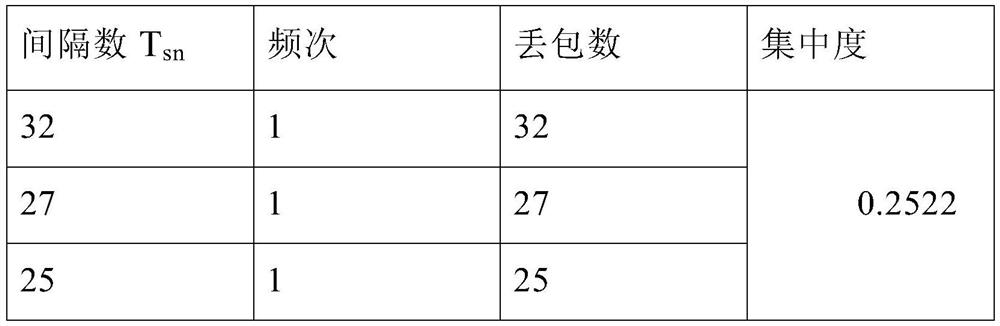

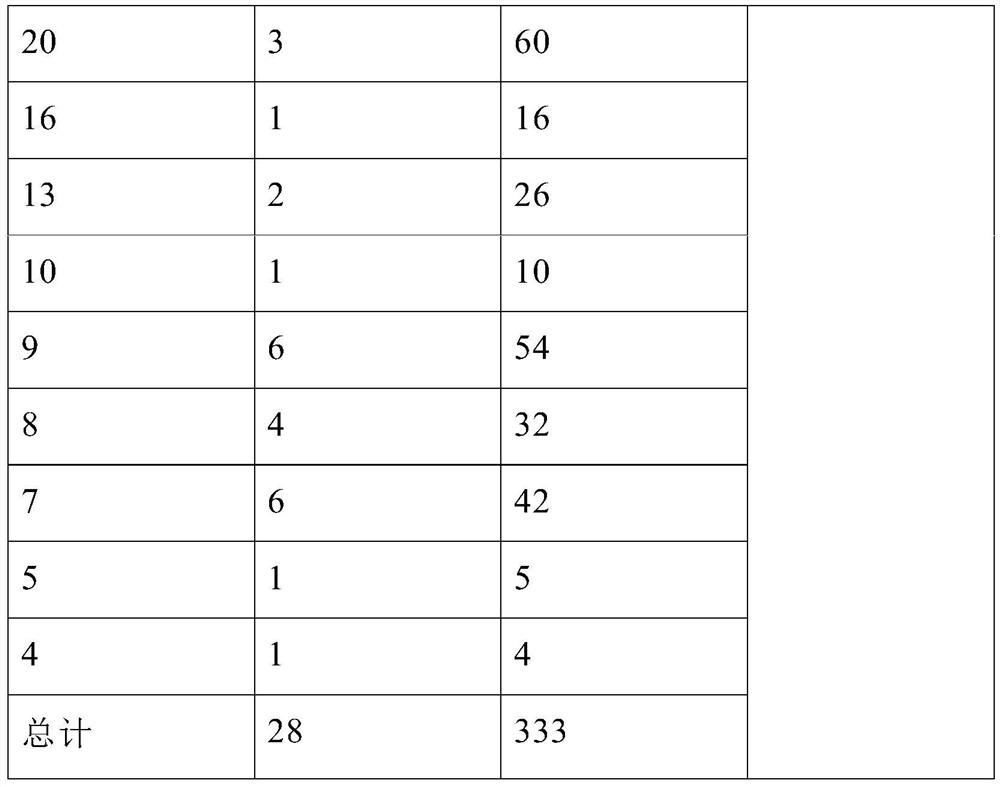

Epoch network state monitoring method

ActiveCN113726589AJudgment statusEasy to compare horizontallyData switching networksData packPacket loss

The invention provides an epoch network state monitoring method, and the method comprises the steps of obtaining a data package transmitted by a receiver in a period of time, and the data package comprises epoch time; marking the serial number of the received data packet according to the epoch time; counting the number of intervals between the serial numbers of the adjacent data packets and the occurrence frequency of each interval number, and calculating the total packet loss number according to each interval number and the occurrence frequency thereof; calculating the concentration ratio of the interval number according to the interval number and the total packet loss number; and judging the epoch network state according to the concentration degree.

Owner:QIANXUN SPATIAL INTELLIGENCE INC

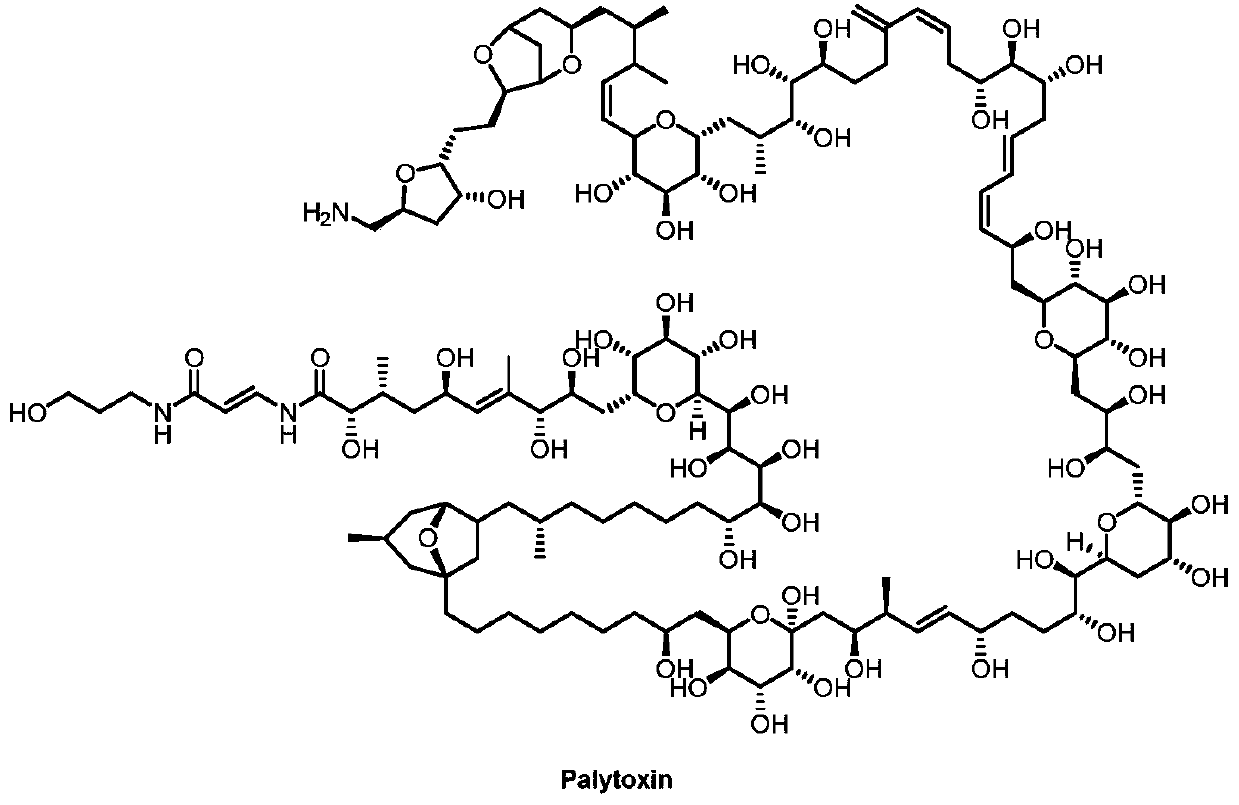

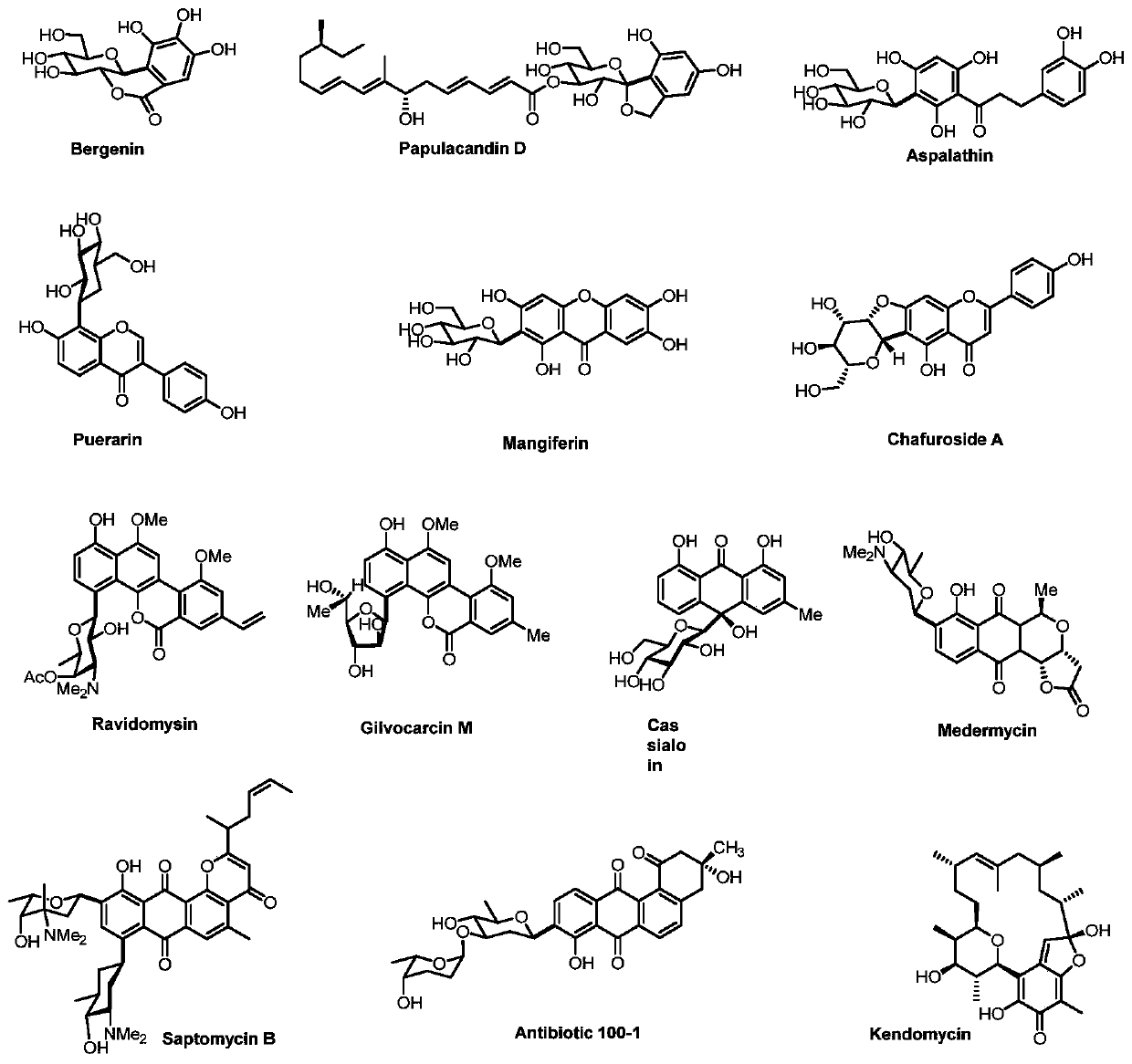

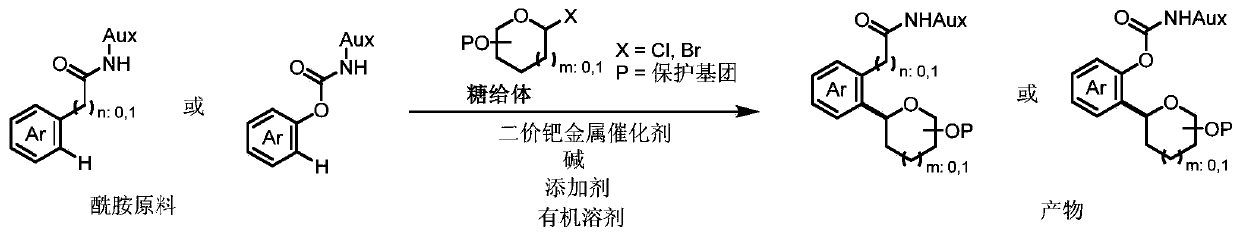

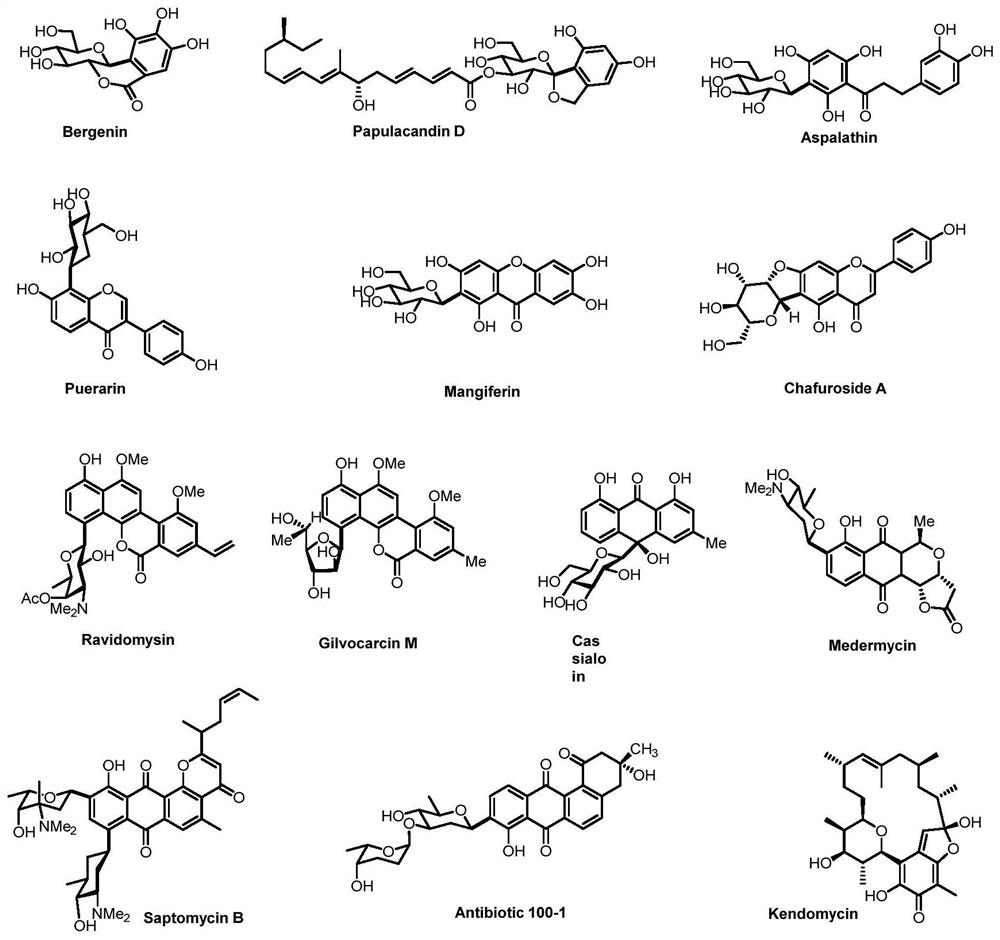

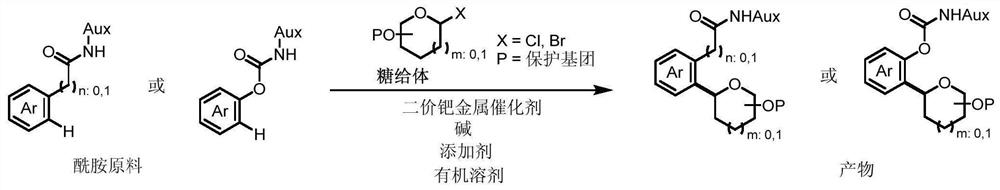

Synthesis method of aryl carbon glycoside compound

ActiveCN110054603AExtensive sources of raw materialsEasy to synthesizeOrganic chemistryBulk chemical productionChromatographic separationPhenols

The invention relates to a synthesis method of an aryl carbon glycoside compound. The preparation method includes: stirring amide raw material, sugar donor, divalent palladium metal catalyst, alkali and organic solvent for reaction while heating, cooling to room temperature, directly filtering, spin-drying filtrate, and performing column chromatographic separation to obtain the aryl carbon glycoside compound. Simple and efficient synthesis of the aryl carbon glycoside compound is realized by utilizing a method of Pd catalyzed aromatic hydrocarbon C (sp2)-H activation. The method has quite highuniversality and can be applied to a series of substrates like aryl formic acid, aryl acetic acid, benzylamine and phenol. The method utilizes halogenated sugar as the donor and is simple in synthesis step and suitable for large-scale production and application; guide groups which are used are not limited to 8-aminoquinoline, p-pyridine carboxylic acid and 2-aminopyridine nitrogen oxide and can be used for reaction. A new method and idea is provided for synthesizing a series of complex carbon glycoside drug and natural drug, and synthesis difficulty of carbon glycoside is lowered.

Owner:NANKAI UNIV

Welding rod packaging bag shaping device

InactiveCN104554906AReduce volumeEasy to foldPackagingWebs handlingUltimate tensile strengthLarge capacity

The invention provides a welding rod packaging bag shaping device. The welding rod packaging bag shaping device comprises a conveying mechanism, a vibrating mechanism and a smoothening mechanism, wherein the conveying mechanism comprises a thin film shaft, a shaping rod, a fixing rod and drums; the thin film shaft, the drums and a first motor are connected to one another; the drums are arranged between the thin film shaft and the shaping rod and are vertically arrayed alternately; the fixing rod clings to the shaping rod; the vibrating mechanism comprises a vibrating mechanism rack; parallel vibrating rolls are arranged on the vibrating mechanism rack; the smoothening mechanism comprises a conveying mechanism and a pressing mechanism; and each of the conveying mechanism and the pressing mechanism consists of a pair of clamping conveying bodies parallel to each other. By the welding rod packaging bag shaping device, welding rod packaging bags are easy and convenient to fold, and the problem that a manual smoothening mode is low in neatening efficiency and high in labor intensity is solved thoroughly. The welding rod packaging bag shaping device has the advantages of high packaging efficiency and high capacity.

Owner:TIANJIN MINGTANG ENVIRONMENTAL PROTECTION TECH

Cloth cutting device

ActiveCN110093773AReduce manual labor intensityQuality assuranceLiquid surface applicatorsTextile selvedgesEmulsionCushion

The invention discloses a cloth cutting device, and relates to the field of cutting devices. The cloth cutting device comprises a first cylinder above a workbench and a second cylinder below the workbench, wherein the first cylinder is provided with a heating device and a cushion block, the second cylinder is provided with a brush and a cutter, the first cylinder is connected with a first gear, the first gear is connected with a second gear, one side of the second gear is connected with the second cylinder, the other side of the second gear is connected with a stepping motor, a proximity switch is arranged below the workbench, and the two ends and two sides of the workbench are provided with clamping devices. The cloth cutting device has the advantages that the stepping motor and the gearsdrive the devices on the first cylinder and second cylinder to apply a white emulsion on a cutting line to bond a yarn, the white emulsion is heated and dried, then a knife is used for cutting to complete cutting, the occurrence of raw edges is avoided, the later processing and use are facilitated, the generation of fluffs, dust and the like is also prevented from polluting the working environment, a healthy working environment is created for workers, no dust removal device needs to be additionally arranged, the cutting process is integrated and automatic, the labor is saved, and the cuttingquality is ensured.

Owner:佛山市顺德区新飞腾纺织服装有限公司

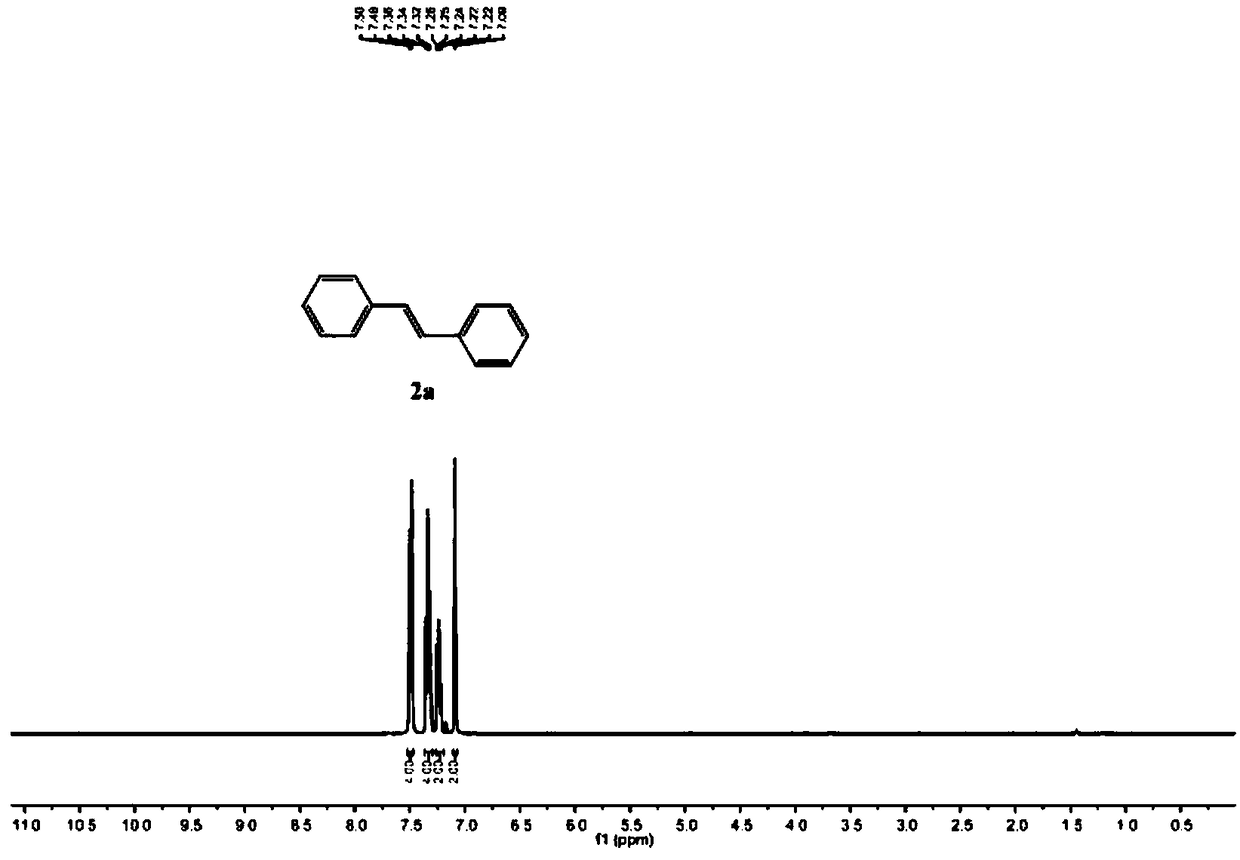

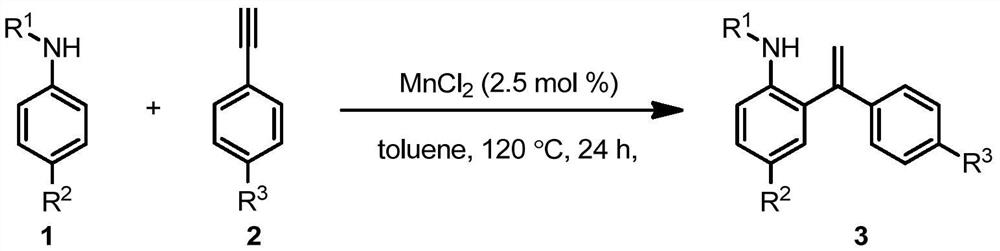

Bivalent manganese catalyzed arylamine ortho-enylation reaction method

ActiveCN112479898AWide variety of sourcesLow priceAmino preparation from aminesOrganic compound preparationPtru catalystOrtho position

The invention discloses a bivalent manganese catalyzed arylamine ortho-enylation reaction method, which comprises the following steps of: sequentially adding a weighed arylamine compound (1), substituted acetylene (2) and a metal catalyst MmXn into a reaction bottle, adding a corresponding solvent, performing stirring for 1h-48h in air under the reaction condition of 60-120DEG C, conducting cooling to room temperature, adding ethyl acetate for dilution, performing washing with saturated edible salt water, drying an organic phase with anhydrous magnesium sulfate, and carrying out column chromatography separation to obtain a target product (3). The method has the advantages that: arylamine and substituted acetylene are used as raw materials, the target product is obtained under the catalysisof divalent manganese, and compared with a traditional lewis acid catalytic synthesis strategy, the economic cost is greatly reduced, operation is convenient, product selectivity is good, safety andreliability are achieved, substrate universality is wider, the yield is high, and the method is suitable for industrial production.

Owner:杨锦飞

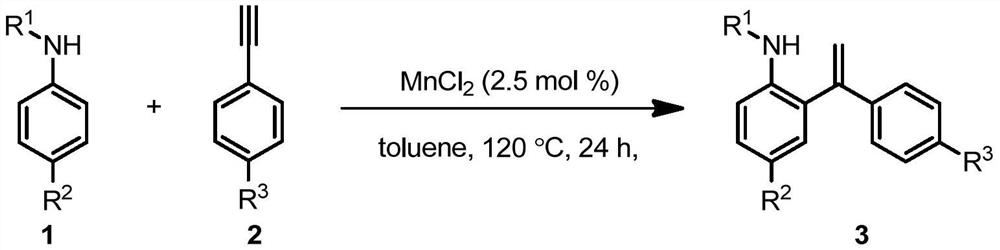

Stirring and conveying device of brick making machine

PendingCN112297214ADecrease productivityIncrease workloadDischarging arrangementDischarging apparatusHydraulic cylinderBrick

The invention discloses a stirring and conveying device of a brick making machine. The stirring and conveying device comprises a base, a device shell, a first motor, a first spiral conveying rod, an extrusion crusher, an atomizing nozzle, a first pipeline, a water pump, a water tank and the like. The stirring and conveying device is reasonable and simple in structure, low in production cost, convenient to install and complete in function, brick making raw materials are conveyed to a conveying belt through the arranged first motor and conveyed to a stirring chamber through the conveying belt, asecond motor in the stirring chamber drives a stirring rod to conduct sufficient stirring, and the raw materials flow into a bottom pre-forming device; water is pumped from the water tank through thearranged water pump and sprayed out from the atomizing nozzle to be evenly scattered on the surfaces of the brick making raw materials, and dust raising in the transportation process is prevented; and a second hydraulic cylinder in the pre-forming device drives an extrusion plate to extrude and form the brick making raw materials, then an eighth motor drives a rotary disc to rotate, formed bricksare conveyed to a discharging port through a groove in the rotary disc, primary forming of the raw materials is facilitated, subsequent procedure machining is facilitated, and time and labor are saved.

Owner:临澧县梁冯新型墙体材料有限公司

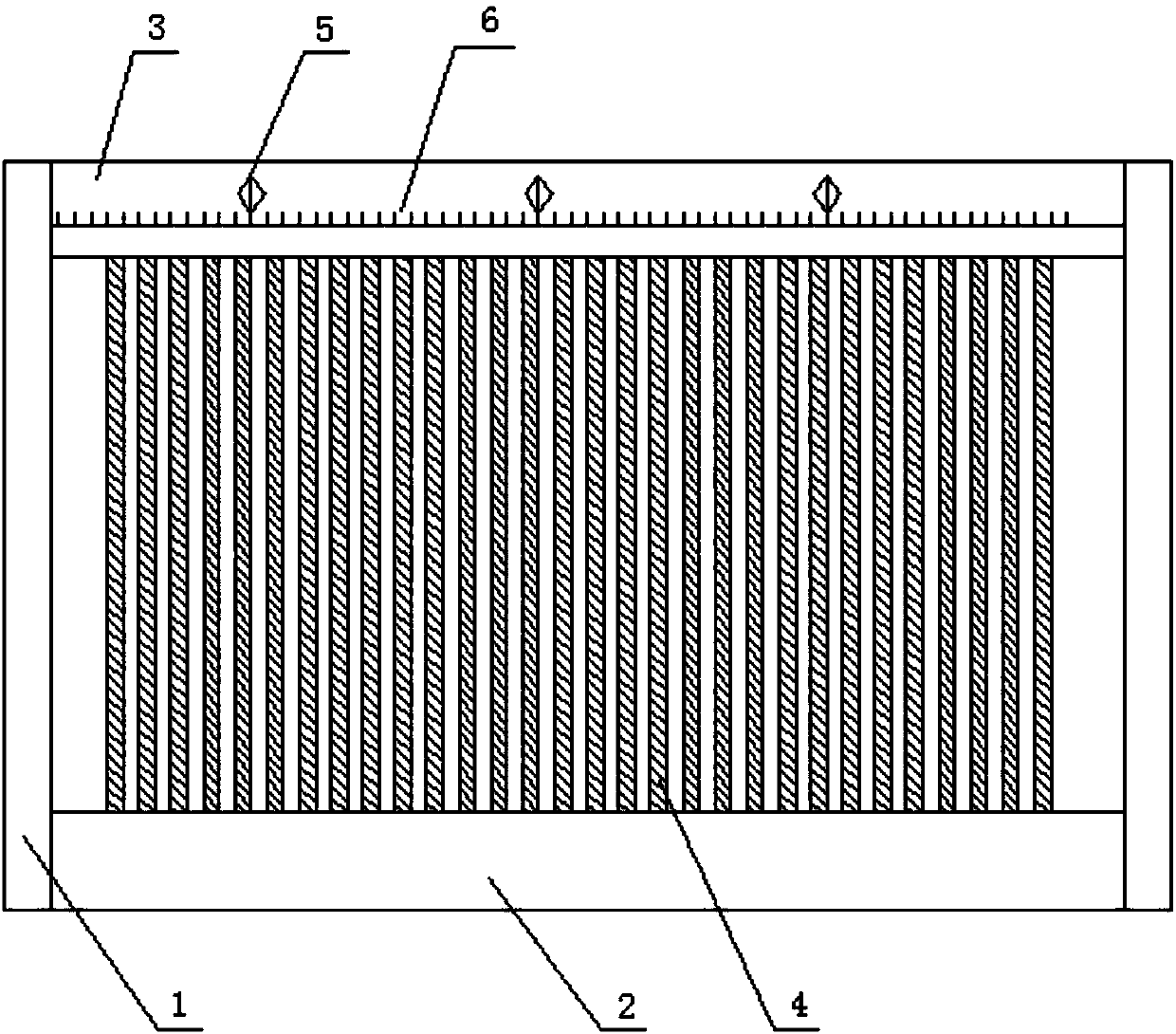

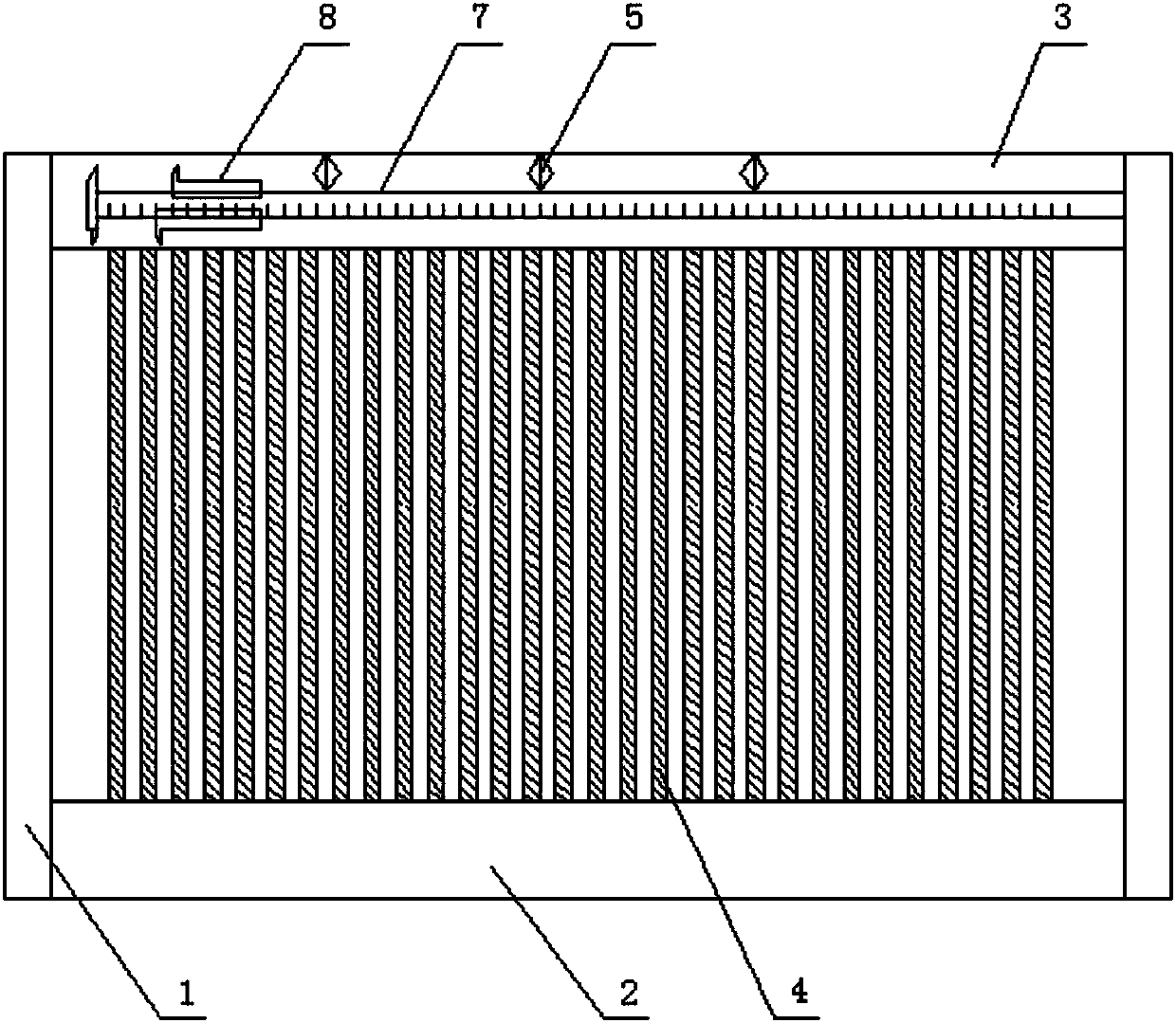

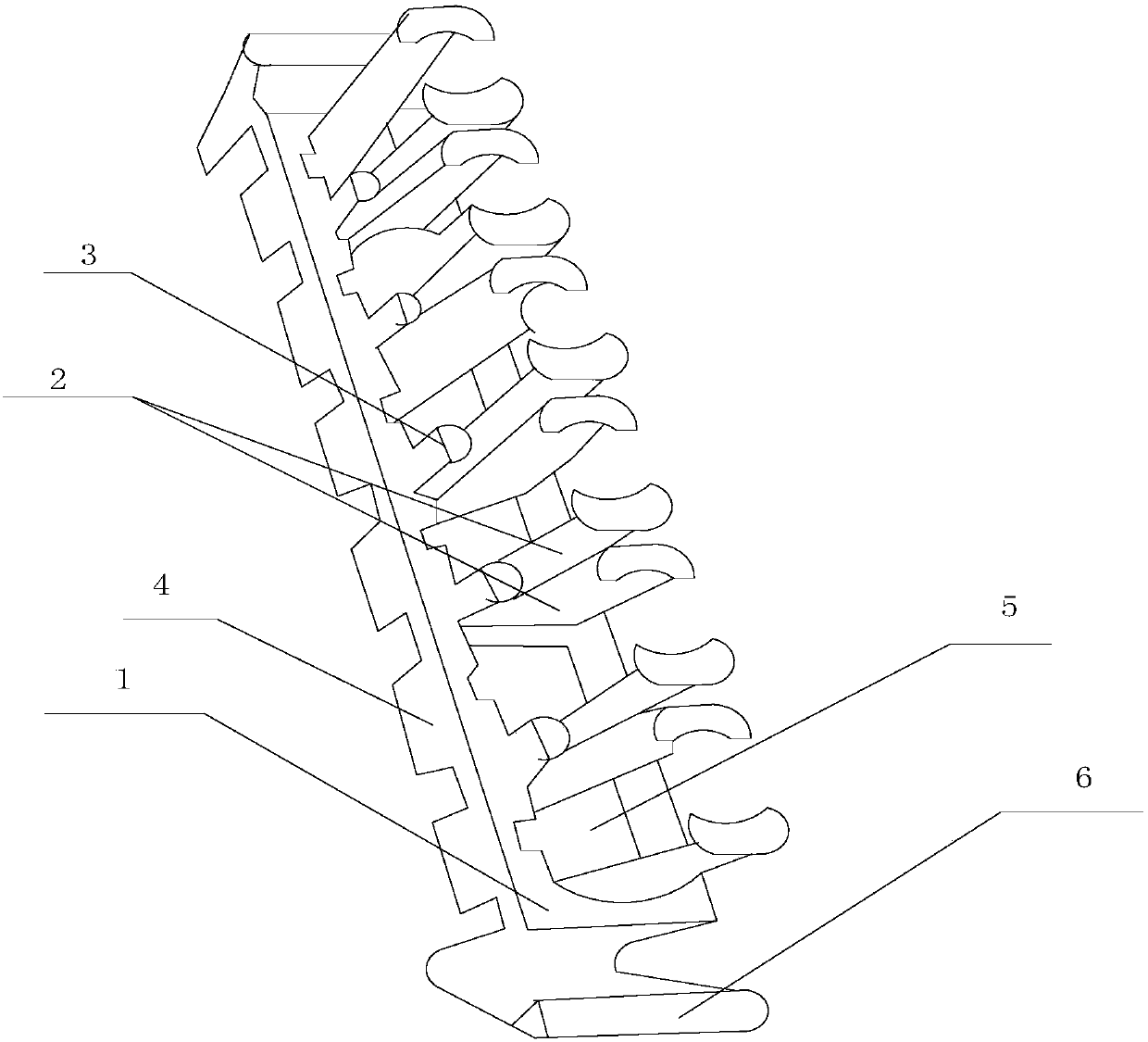

Reed with scale

InactiveCN110552105AHigh measurement accuracyAccurate measurementLoomsAuxillary apparatusYarnEngineering

The invention relates to a reed of a loom, in particular to a reed with a scale. The reed can accurately provide weft-direction coordinates, and facilitate the measurement of warp yarn distribution density and reed width in the weaving process; auxiliary spray position mark points are also set to ensure normal weft insertion of a weft-direction auxiliary spray device and accurately provide weft-direction coordinates of defect points when defects exist in warp-direction weaving to facilitate post-processing procedures. The reed comprises a square frame composed of reed beams and a transverse plate, wherein the reed beams comprise the upper reed beam and the lower reed beam, parallel reed-dents are installed between the upper reed beam and the lower reed beam, the reed beams are provided with ranging rods, and the ranging rods are provided with the auxiliary spray position mark points.

Owner:鲁丰织染有限公司

Method for preparing cerium-containing rare earth permanent magnet material by adding nano metal powder into magnet steel scrap

The invention discloses a method for preparing a cerium-containing rare earth permanent magnet material by adding nano metal powder into magnet steel scrap. The method comprises the following steps: according to the classifying standard that waste magnet steel with same batch, same model and same contained rare earth elements is classified as the same class, pre-classifying collected waste magnet steel into a pretreated magnet material; then, adding the obtained pretreated magnet material and prepared nano metal powder into a common electrolytic furnace to carry out smelting for enabling the pretreated magnet material and the prepared nano metal powder to form a molten alloy liquid; casting and cooling the molten alloy liquid to obtain alloy ingot, carrying out hydrogen-crushing and airflow milling and crushing on the alloy ingot to obtain fine powder, and carrying out static pressing, sintering and two-stage thermal treatment on the fine powder to obtain cerium-containing rare earth permanent magnet material blank; and finally, according to practical needs, carrying out mechanical processing, cutting and precision-grinding on the cerium-containing rare earth permanent magnet material blank, thereby obtaining the cerium-containing rare earth permanent magnet material. The fluorescent lifetime of the cerium-containing rare earth permanent magnet material is effectively prolonged by adding the nano metal powder; and the permanent magnet material has a relatively high activator critical concentration; and by virtue of pre-classifying, time of recycling waste magnet steel can be saved, and extraction process steps are reduced.

Owner:SUZHOU SABO IND DESIGN

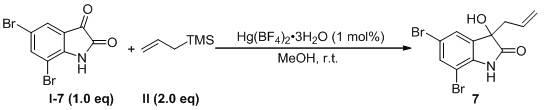

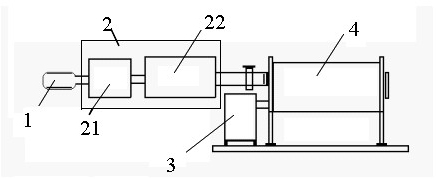

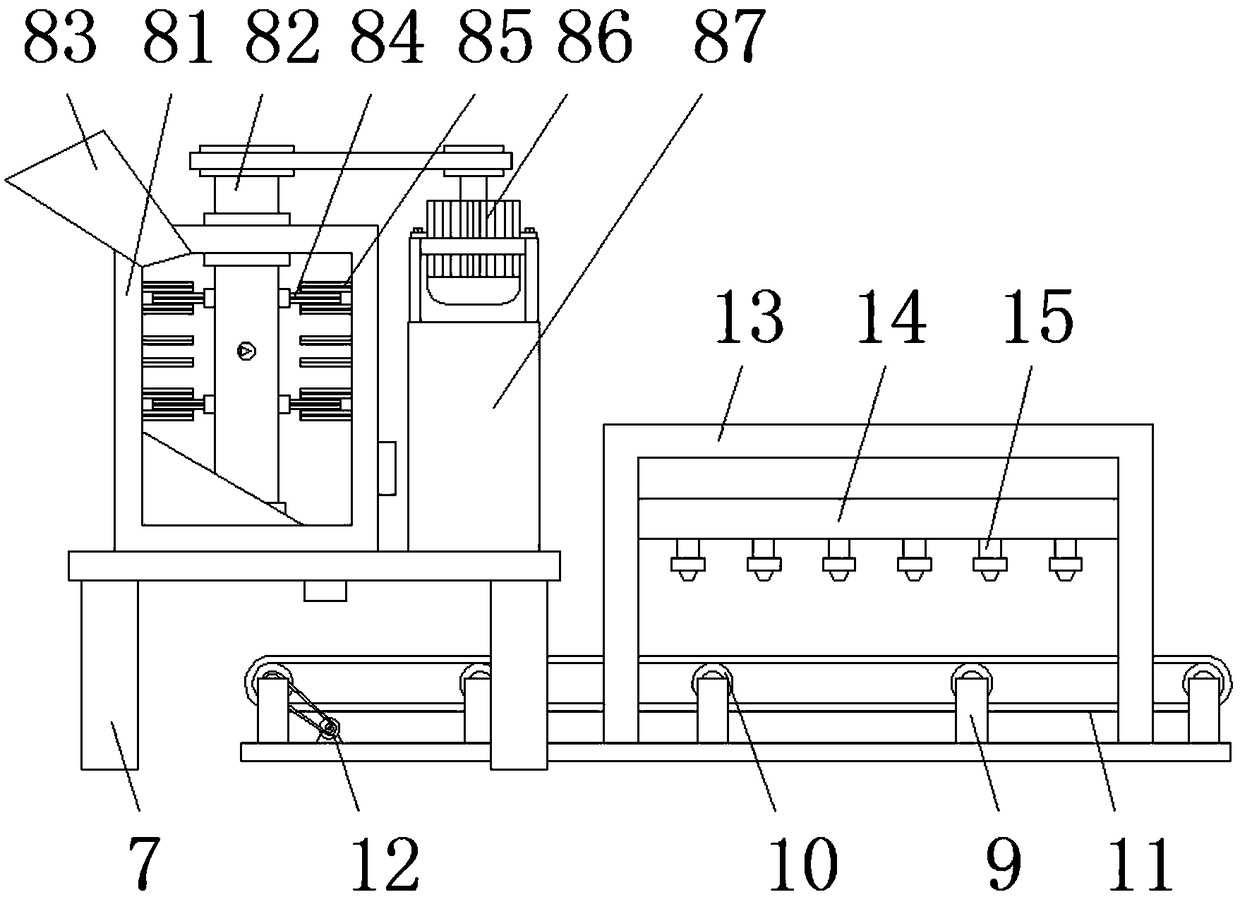

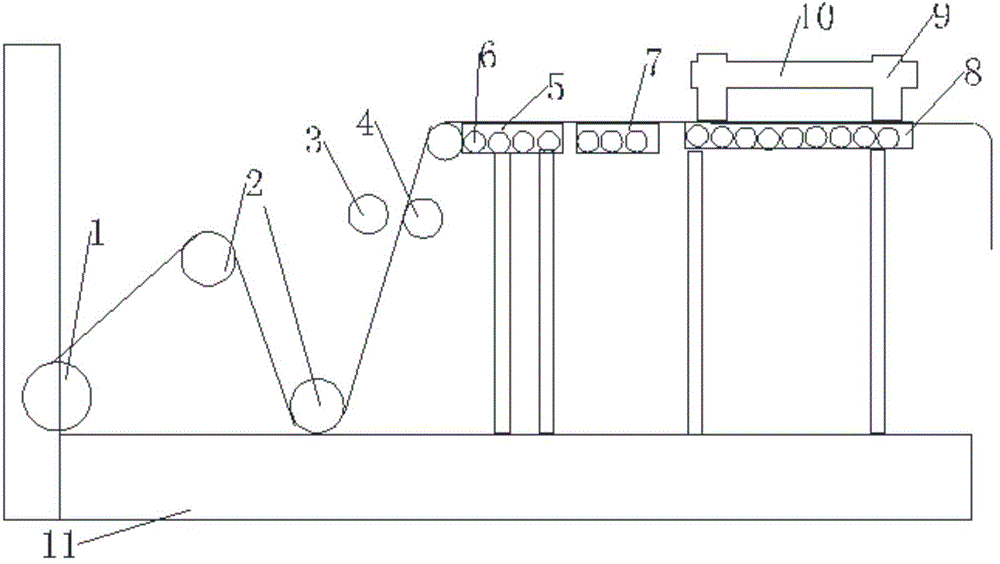

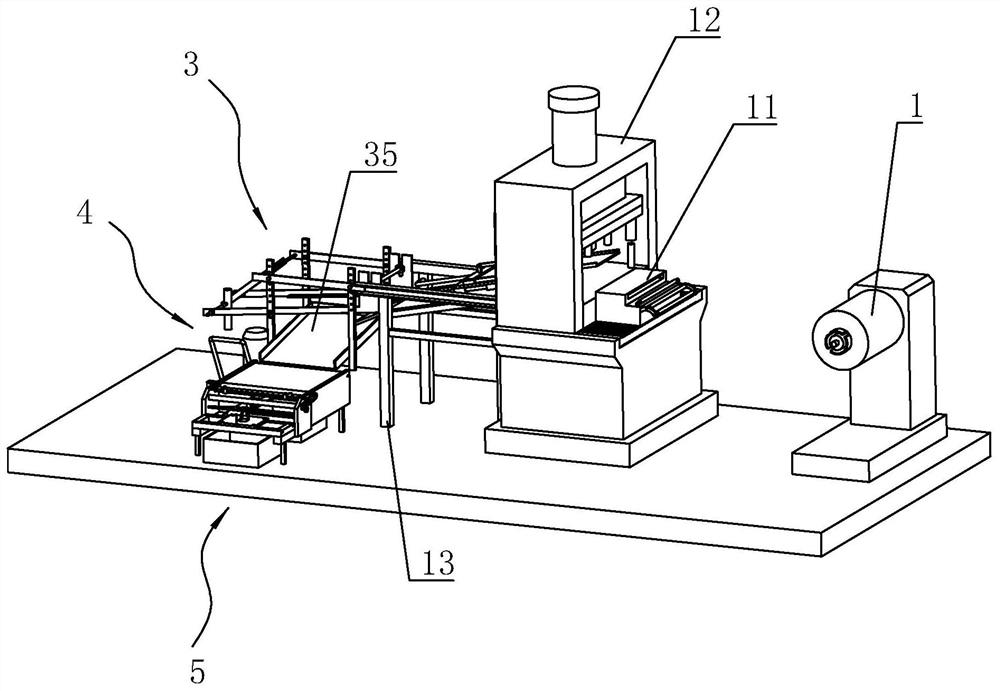

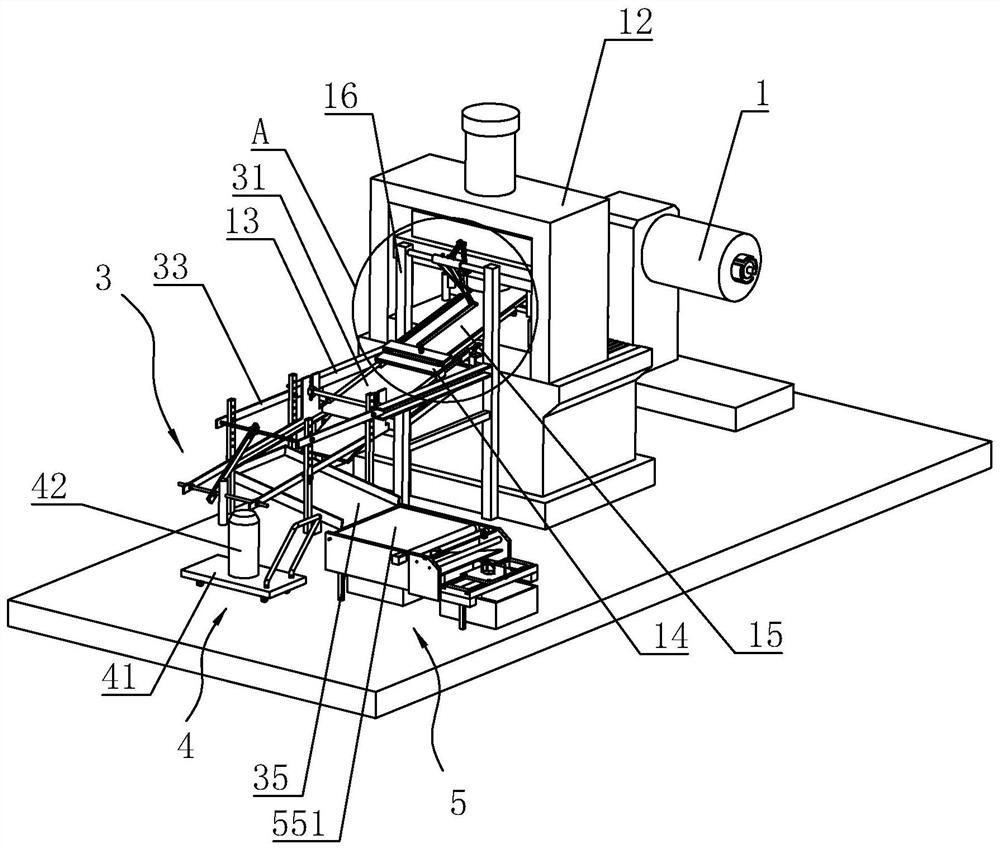

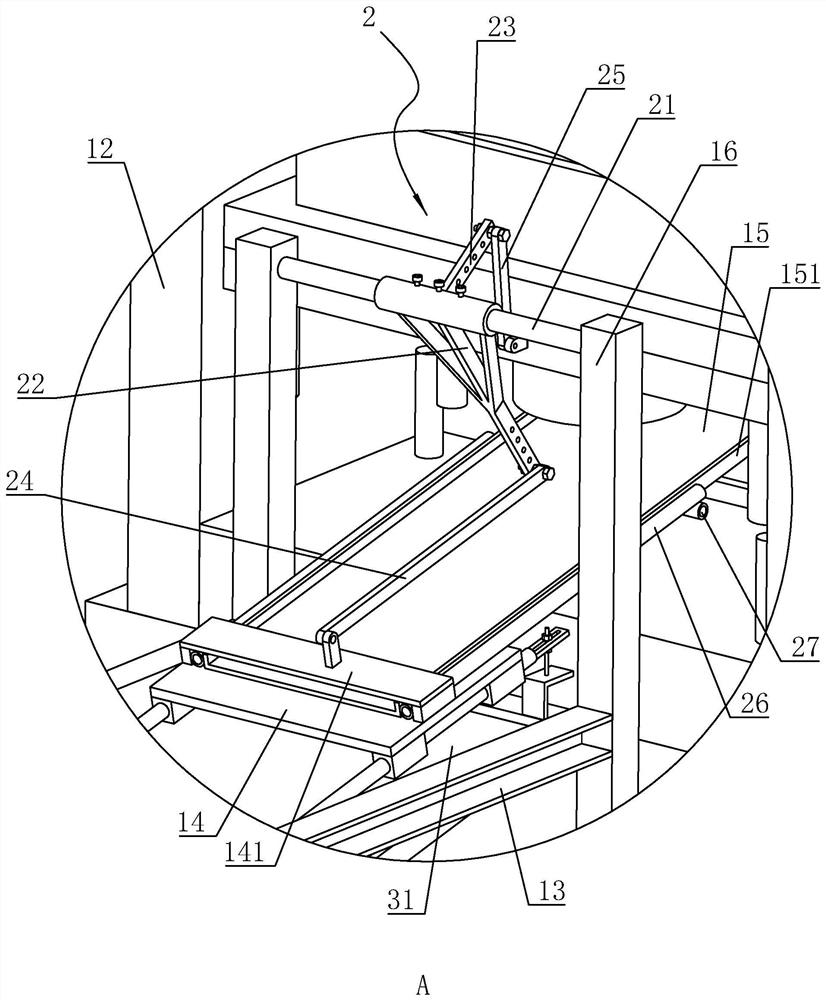

Stator and rotor punching production line

ActiveCN110556982BRealize automatic feeding processImprove production and processing efficiencyMetal-working feeding devicesManufacturing stator/rotor bodiesProduction linePunching

The invention relates to a production line for stator and rotor punching processing, which is applied in the field of processing equipment for stator and rotor punching. The first receiving device for collecting the stator punches and the second receiving device for collecting the rotor punches. The base frame is slidably connected with a sliding seat that moves upwards in the direction close to the stamping die on the punching machine. The sliding seat is equipped with an inclined The material receiving plate, the inclination direction of the material receiving plate is parallel to the moving direction of the sliding seat, the end of the base frame close to the punching machine is provided with a stand, and the connecting rod mechanism is arranged on the stand, and the sliding seat is connected with the punching machine through the connecting rod mechanism. When the first working table of the stamping machine is connected, when the first working table of the punching machine rises, the sliding seat moves upwards obliquely, and when the first working table of the punching machine moves back, the sliding seat moves downwards obliquely; The problem of low processing efficiency has the advantage of improving the processing efficiency of stator and rotor punching.

Owner:苏州艾尔拓机电有限公司

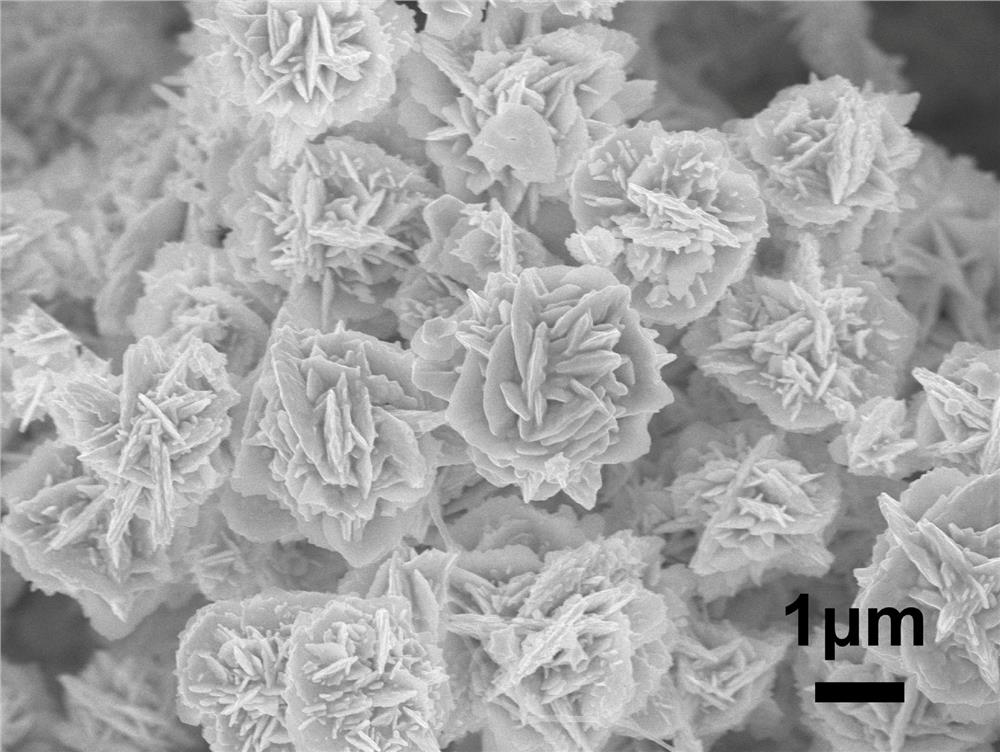

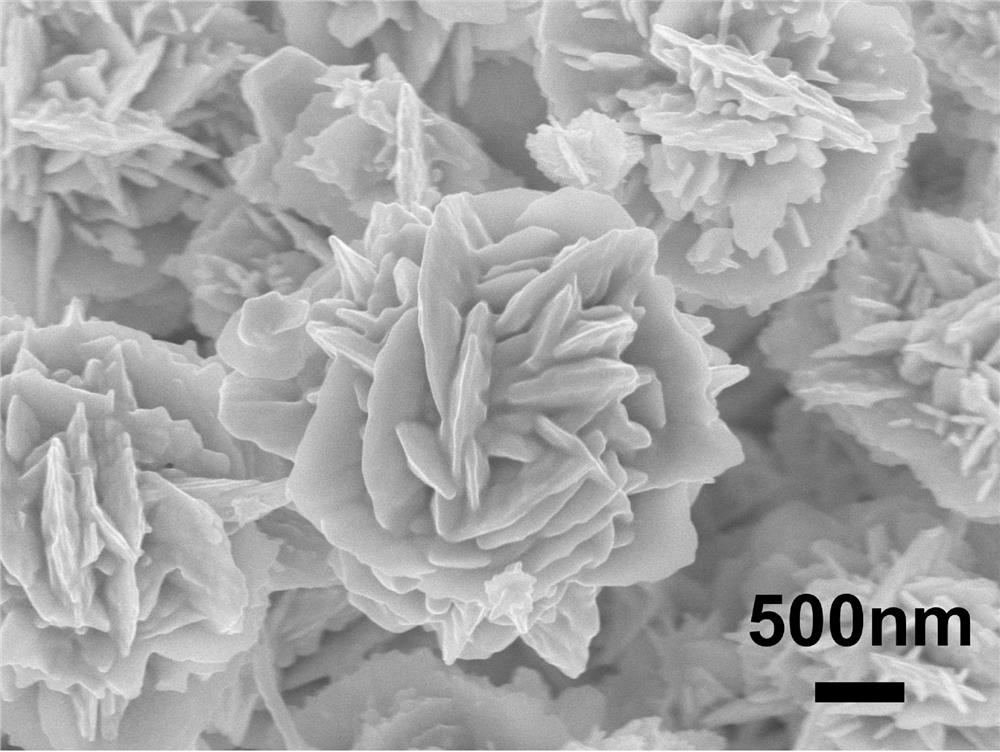

A kind of preparation method of gold nanoflowers in ionic liquid aqueous solution

ActiveCN108817414BThe preparation process steps are simpleSimple post-processingMaterial nanotechnologyTransportation and packagingVitamin CDistilled water

A method for preparing gold nanoflowers in an ionic liquid aqueous solution, comprising the following steps: mixing the ionic liquid aqueous solution, chloroauric acid solution, and distilled water to prepare a mixed solution, and then heating the mixed solution with vitamin C in a water bath to obtain a reaction After the mixture is centrifuged, the finished gold nanoflowers are obtained. The present invention adopts ionic liquid as the reaction medium, and through a unique and convenient preparation process, under the conditions of complex operations such as no need for gold seeds and no need to adjust the pH of the reaction solution, the particle composed of nanosheets is simply and quickly prepared in one step. Gold nanoflowers with uniform size, good shape, stable structure and excellent performance.

Owner:HENAN UNIV OF SCI & TECH

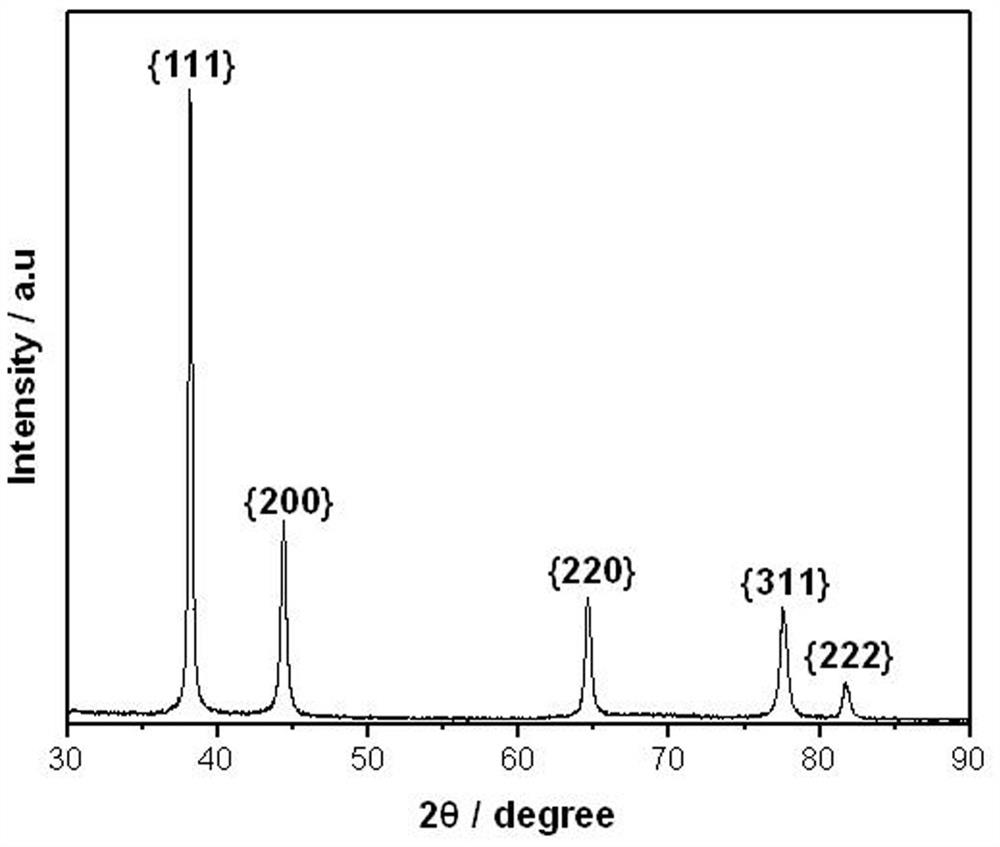

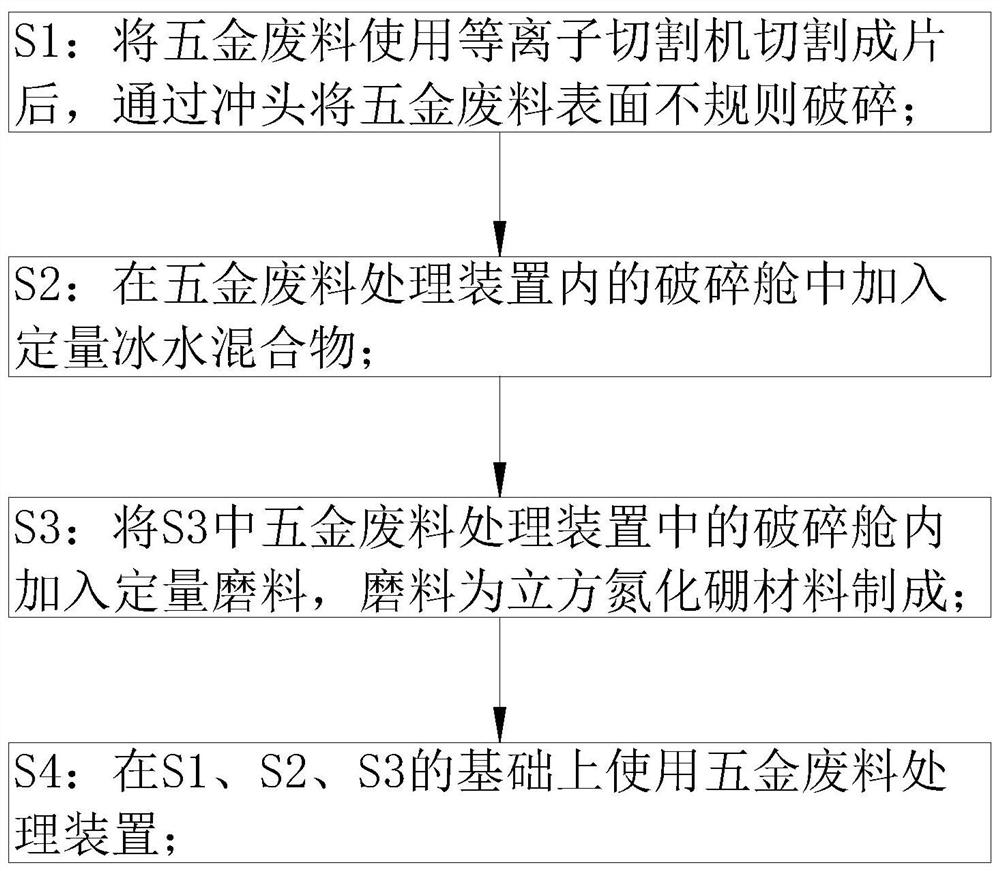

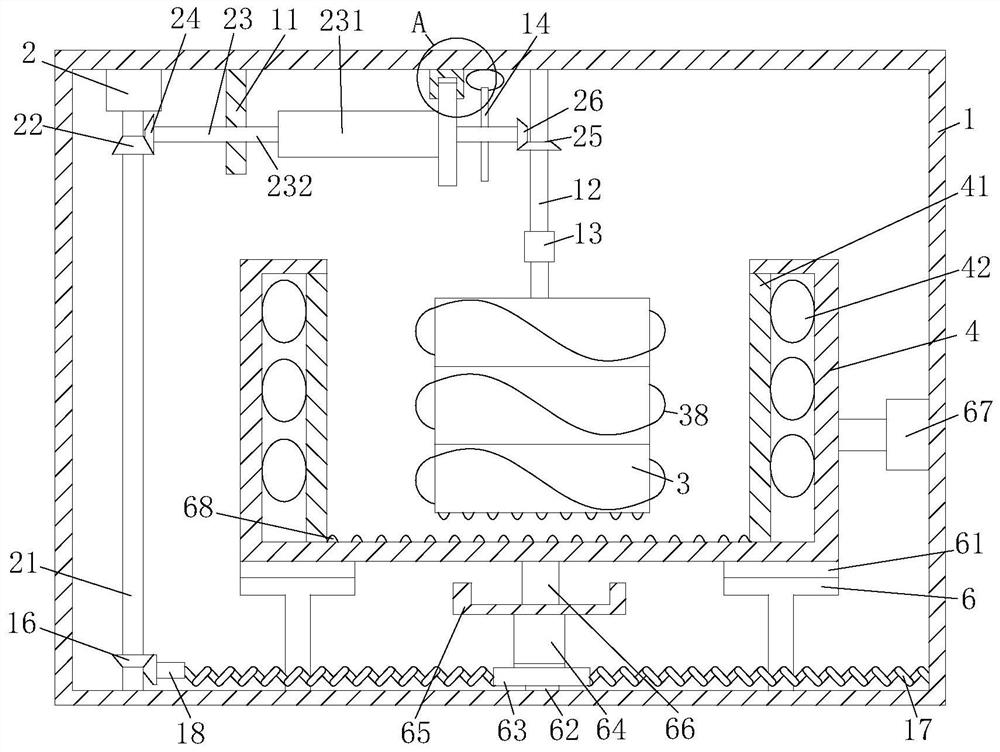

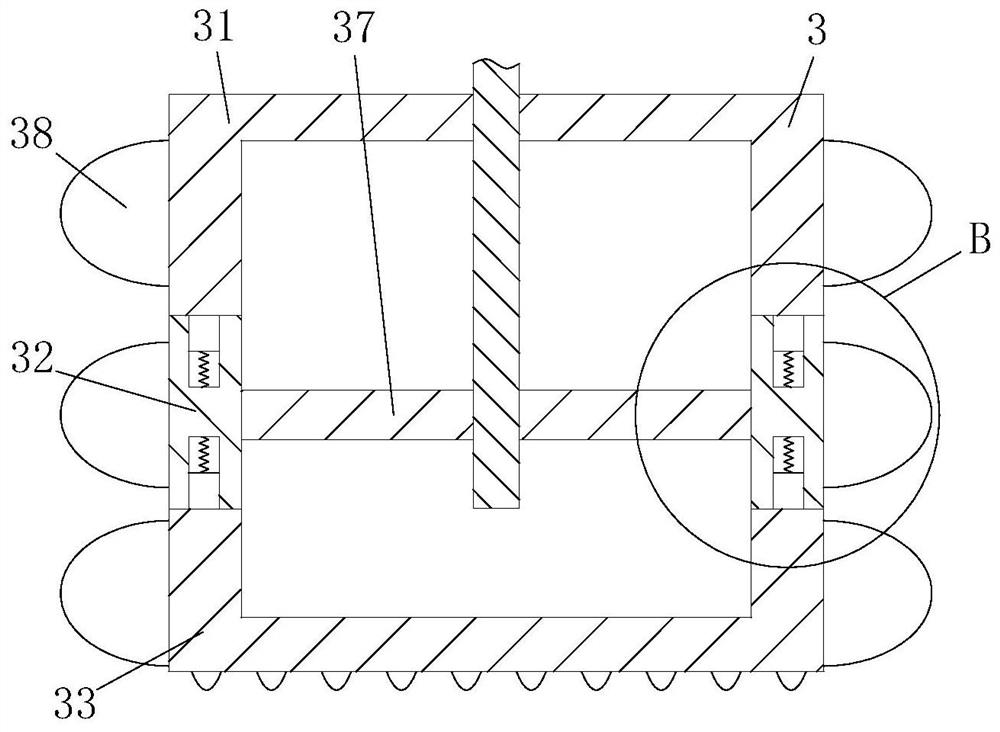

A metal waste recycling process

ActiveCN109225540BAvoid high temperatureConvenient post-processingGrain treatmentsIce waterProcess engineering

The invention belongs to the technical field of hardware, in particular to a hardware waste material recycling technology. The hardware waste material recycling technology has the advantages that after a hardware waste material is cut into sheets by a plasma cutting machine, the surface of the hardware waste material is irregularly crushed by a punch head, and the surface of the hardware waste material forms convex parts and broken openings, so as to conveniently crush the hardware waste material; by adding a quantitative amount of ice and water mixture and grinding material into a crushing bin of a hardware waste material treatment device, the ice and water mixture can effectively prevent the shortening of the service life of the device due to high temperature in the crushing process of the hardware waste material, and effectively reduce noise in the crushing process; the grinding material can assist the device to crush the hardware waste material, and the surface of the hardware waste material is ground into uneven parts by the grinding material, so as to accelerate the crushing rate; by utilizing the rotation and movement of a crushing wheel, the vibration of an upper wheel anda lower wheel and the vibration and movement of the crushing bin, the hardware waste material can be treated, so that while the labor intensity is decreased, the hardware waste material can be fully treated.

Owner:新沂市新南环保产业技术研究院有限公司

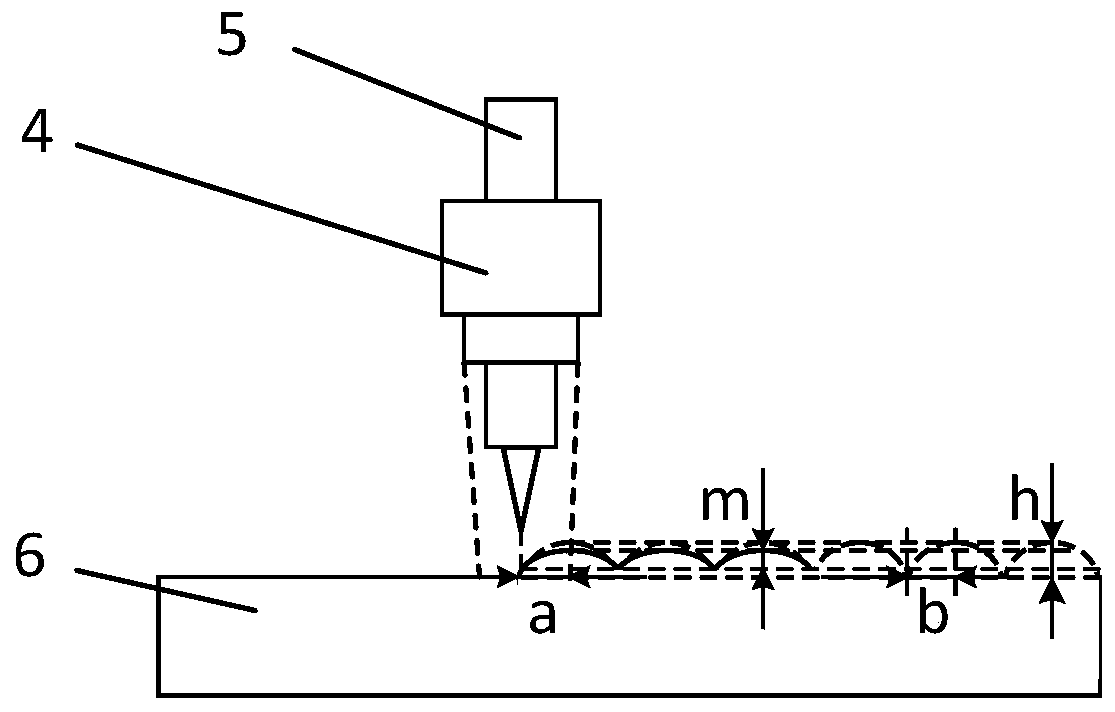

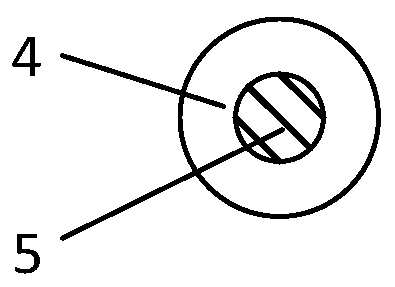

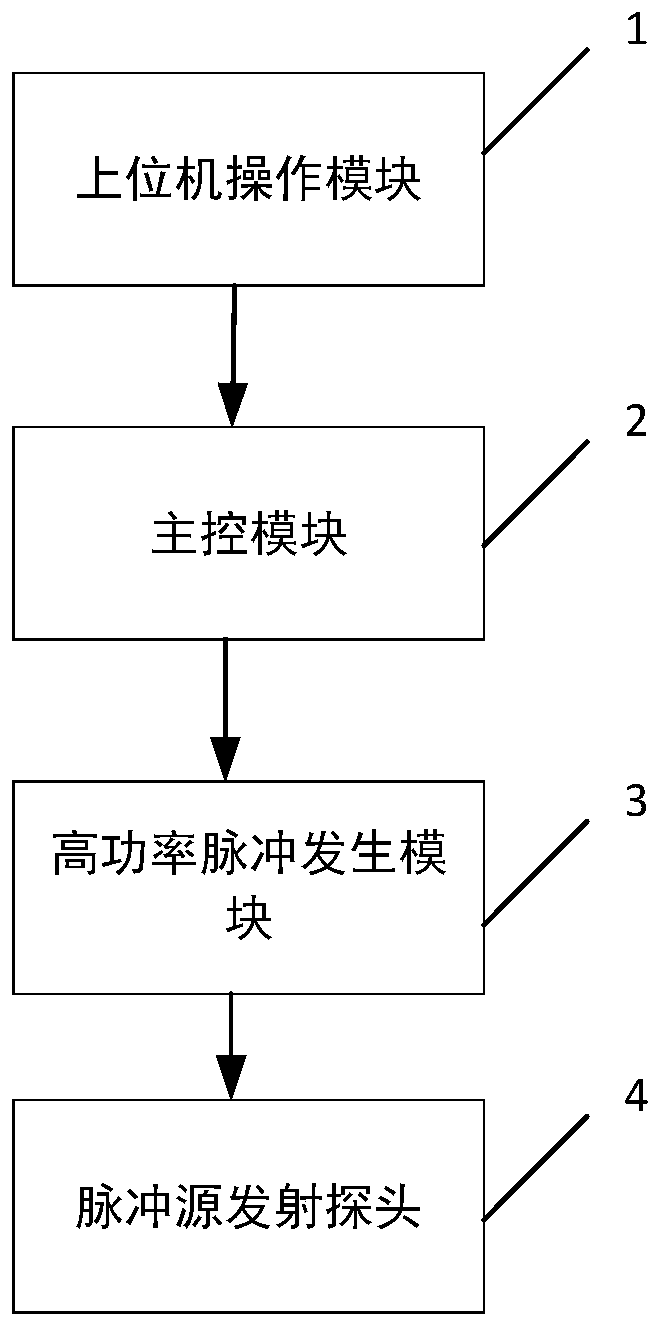

Electromagnetic ultrasonic method and system suitable for melting metal humping inhibition in additive manufacturing process

ActiveCN110369825ASmooth and uniform surfaceImprove surface qualityAdditive manufacturing apparatusIncreasing energy efficiencyMachine toolPulse load

The invention discloses an electromagnetic ultrasonic method and system suitable for melting metal humping inhibition in an additive manufacturing process, and belongs to the field of additive manufacturing. The method is suitable for wire feeding and powder feeding additive manufacturing and comprises the following steps of preparation before manufacturing, processing equipment adjusting, machinetool starting, synchronous high-power pulse loading and test piece forming, wherein a wire material or metal power is arranged, and the position of a welding gun or a powder feeding nozzle and a pulse source emitting probe is adjusted in the processing equipment adjusting step; and upper computer operating software, a main control system, a high-power pulse generating module and a pulse source emitting probe of an electromagnetic ultrasonic generating system enable molten metal to generate ultrasonic vibration in the synchronous high-power pulse loading step. The pulse source emitting probe follows up the welding gun or the powder feeding nozzle of the additive manufacturing machine tool, so that real-time irradiation on a molten pool is realized. According to the method, the ability forinhibiting humping of the additive manufacturing is obtained, the surface quality of the additive manufacturing test piece is improved, and convenience is provided for subsequent processing procedures.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of synthetic method of aryl carbon glycosides

ActiveCN110054603BWide variety of sourcesEasy to synthesizeOrganic chemistryBulk chemical productionChromatographic separationPtru catalyst

The invention relates to a synthesis method of an aryl carbon glycoside compound. The preparation method includes: stirring amide raw material, sugar donor, divalent palladium metal catalyst, alkali and organic solvent for reaction while heating, cooling to room temperature, directly filtering, spin-drying filtrate, and performing column chromatographic separation to obtain the aryl carbon glycoside compound. Simple and efficient synthesis of the aryl carbon glycoside compound is realized by utilizing a method of Pd catalyzed aromatic hydrocarbon C (sp2)-H activation. The method has quite highuniversality and can be applied to a series of substrates like aryl formic acid, aryl acetic acid, benzylamine and phenol. The method utilizes halogenated sugar as the donor and is simple in synthesis step and suitable for large-scale production and application; guide groups which are used are not limited to 8-aminoquinoline, p-pyridine carboxylic acid and 2-aminopyridine nitrogen oxide and can be used for reaction. A new method and idea is provided for synthesizing a series of complex carbon glycoside drug and natural drug, and synthesis difficulty of carbon glycoside is lowered.

Owner:NANKAI UNIV

Method for preparing 3-allyl-3-hydroxy oxindole

InactiveCN102070509BWide variety of sourcesLow priceOrganic chemistryChromatographic separationPtru catalyst

The invention discloses a method for preparing 3-allyl-3-hydroxy oxindole, which comprises the following steps of: adding a catalyst, solvent, isatin and silicane in a reaction bulb, stirring at the specific temperature, performing thin layer chromatography (TLC) detection until the isatin disappears, adding ethyl acetate for diluting, dripping concentrated hydrochloric acid, stirring continuously at the room temperature for half an hour, washing once sequentially by using solution of saturated sodium hydrogen carbonate and saturated saline solution, drying an organic phase by using anhydrousmagnesium sulfate, and performing column chromatographic separation to obtain the 3-allyl-3-hydroxy oxindole. Various reagents used in the method can be obtained commercially, and have wide sources of raw materials and low cost; the used catalyst has a good catalytic effect and helps to reduce cost and also helps to simplify a process, reduce cost, facilitate aftertreatment process and reduce pollution to the environment.

Owner:EAST CHINA NORMAL UNIV

Preparation method of free-of-immersion and quick-to-cook wild rice

PendingCN111820374AImprove featuresReduce cooking timeSeed preservation by freezing/coolingBiotechnologyStarch gelatinization

The invention discloses a preparation method of free-of-immersion and quick-to-cook wild rice. The wild rice is subjected to screening and impurity-removing treatments, properties of the wild rice areimproved by carrying out treatments with pressurizing and heating equipment to promote starch gelatinization and partial protein denaturation, so as to shorten cooking time of the wild rice, therebyobtaining ice crack-shaped wild rice without peculiar smell. The ice crack-shaped wild rice has strong aroma and good mouthfeel, nutrient substances are retained to the maximum extent, and the loss ofnutrient substances is reduced. After cooling and preserving treatment, heating treatment and drying treatment are carried out quickly to make the wild rice form the ice crack shape, thus facilitating later cooking, shortening cooking time and further improving the mouthfeel. The semi-finished wild rice is formed by using the preparation method of the invention, the semi-finished wild rice is notready to eat and not prone to producing harmful bacteria, and the low-temperature refrigeration treatment is carried out, thus eliminating some of the original harmful bacteria in the wild rice and prolonging the storage time of the wild rice.

Owner:乐世买(上海)实业发展有限公司

Wire clamping device

InactiveCN107769064ADamaged normal useEnsure safetyApparatus for overhead lines/cablesEngineeringMechanical engineering

Owner:MIANYANG XINYANG INTPROP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com