Stirring and conveying device of brick making machine

A conveying device and brick making machine technology, which is applied to clay preparation devices, mixing operation control devices, mixing plants, etc., can solve the problems of low work efficiency, heavy workload of operators, and low degree of automation, so as to facilitate subsequent processing , Reasonable and simple structure, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

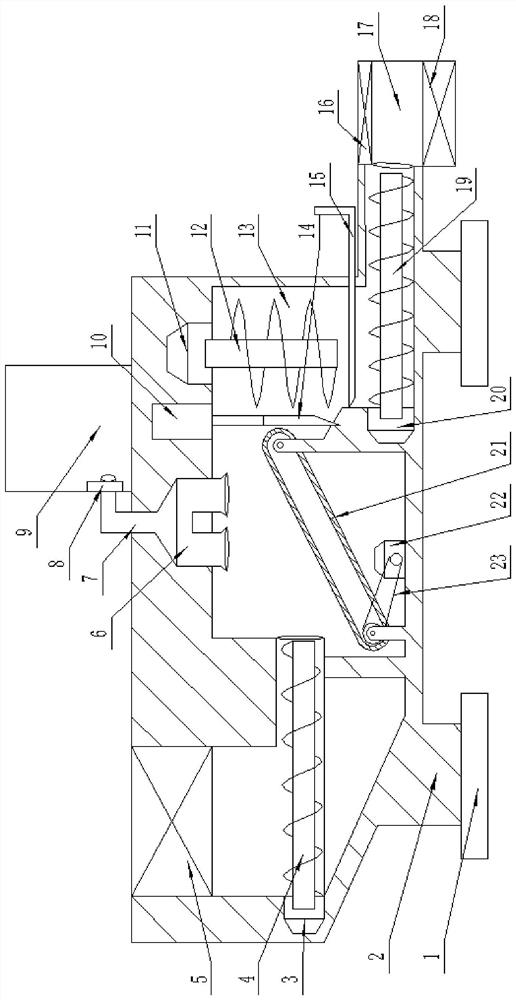

[0020] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a brick making machine mixing and conveying device, including a base 1, a device shell 2, a first motor 3, a first screw transmission rod 4, an extrusion breaker 5, and an atomizing nozzle 6. First pipeline 7, water pump 8, water tank 9, cylinder 10, second motor 11, stirring rod 12, stirring chamber 13, partition plate 14, first baffle plate 15, dehumidification device 16, discharge port 17, preforming device 18. The second screw transmission rod 19, the third motor 20, the conveyor belt 21, the fourth motor 22 and the belt 23; the lower end of the device shell 2 is fixedly connected with several bases 1; the left upper end of the device shell 2 is provided with extrusion Crusher 5, a first motor 3 is provided below the extrusion crusher 5, the first motor 3 is connected to the device casing 2, and the output end of the first motor 3 is fixedly connected with a first screw tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com