Brush bristle cutting device for processing of disc brush

A cutting device and disc brush technology, applied in the direction of bristles, brushes, applications, etc., can solve the problems of no collection of bristle debris, inconvenient installation of the brush disc, and the inability to trim the length of the bristles according to requirements, etc., to achieve Improve work efficiency, simple card connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] as attached figure 1 To attach Figure 5 shown

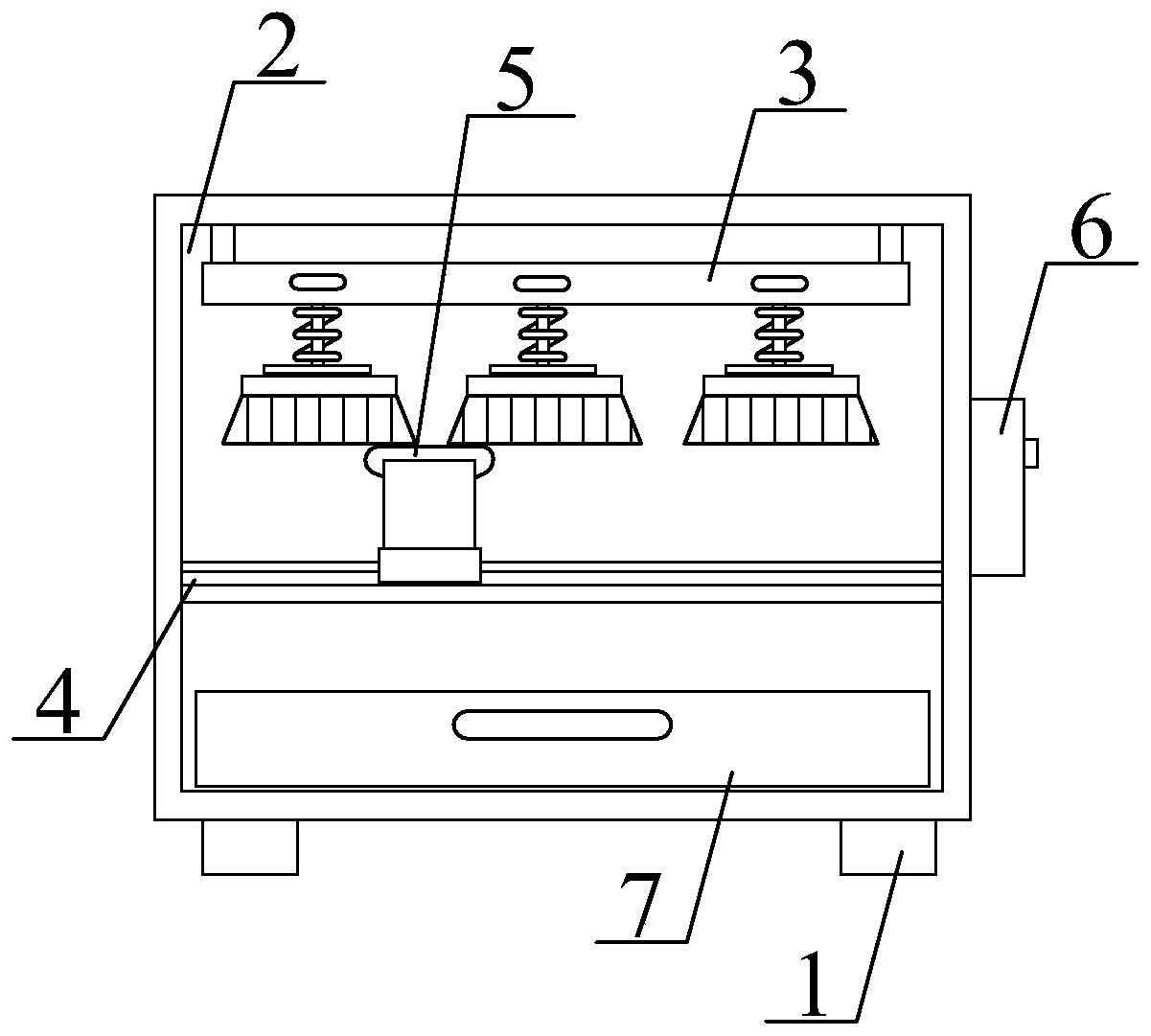

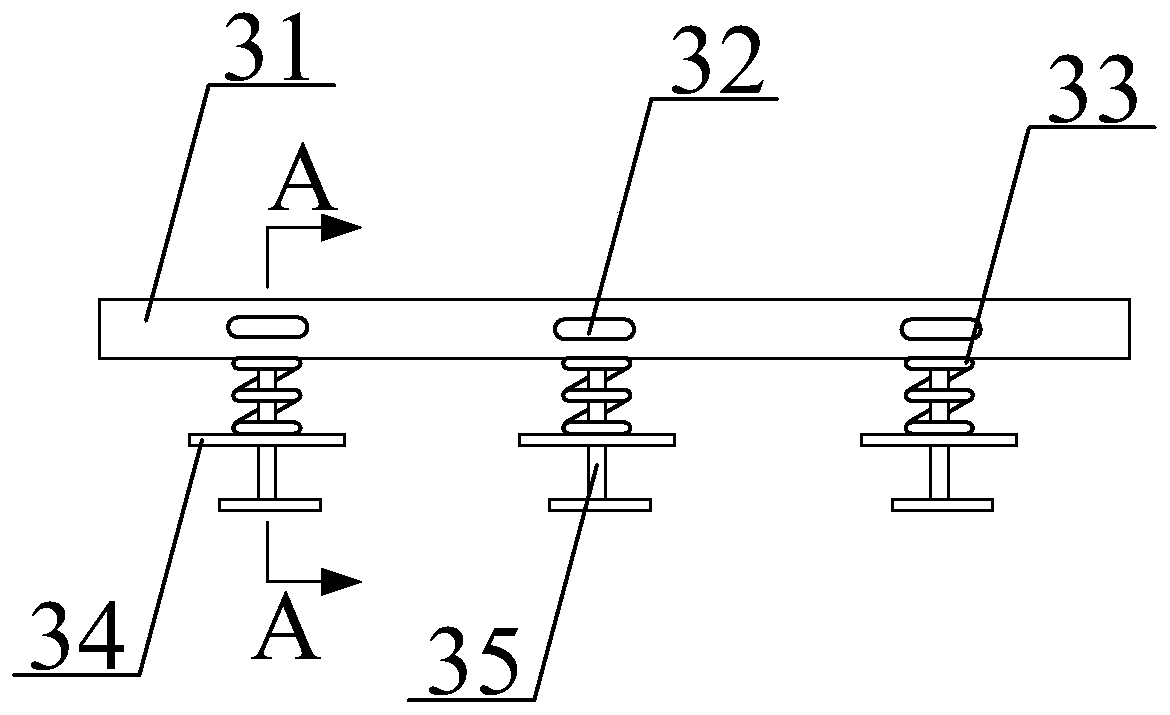

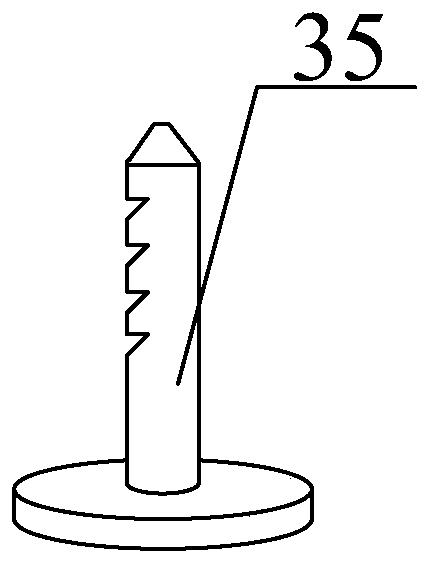

[0027] see figure 1 , a kind of bristle cutting device for disc brush processing, comprising a foot 1, a cabinet body 2, a brush disk fixing device 3, a linear motor 4, a hair trimming mechanism 5, a power distribution cabinet 6 and a slag collecting box 7, and a foot 1 adopts four pieces, which are respectively installed at the four corners of the bottom of the chassis body 2; the chassis body 2 is set in the shape of a rectangular box; the two ends of the brush plate fixing device 3 are installed on the top side inside the chassis body 2 through suspension bolts; 4 is set in the middle of the chassis body 2, and both ends are fixed with the chassis body 2 by bolts, and connected with the power distribution cabinet 6 by wires; the bristle trimming mechanism 5 is installed on the linear motor 4 by bolts; the power distribution cabinet 6 is installed by bolts On one side of the chassis body 2; the slag collecting box 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com