Reed with scale

A technology of scale and reed, applied in the field of loom reed, can solve the problems of affecting the weft insertion process, inaccurate measurement, affecting the performance of fabrics, etc., and achieve the effect of convenient post-process processing, accurate measurement, and convenient measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

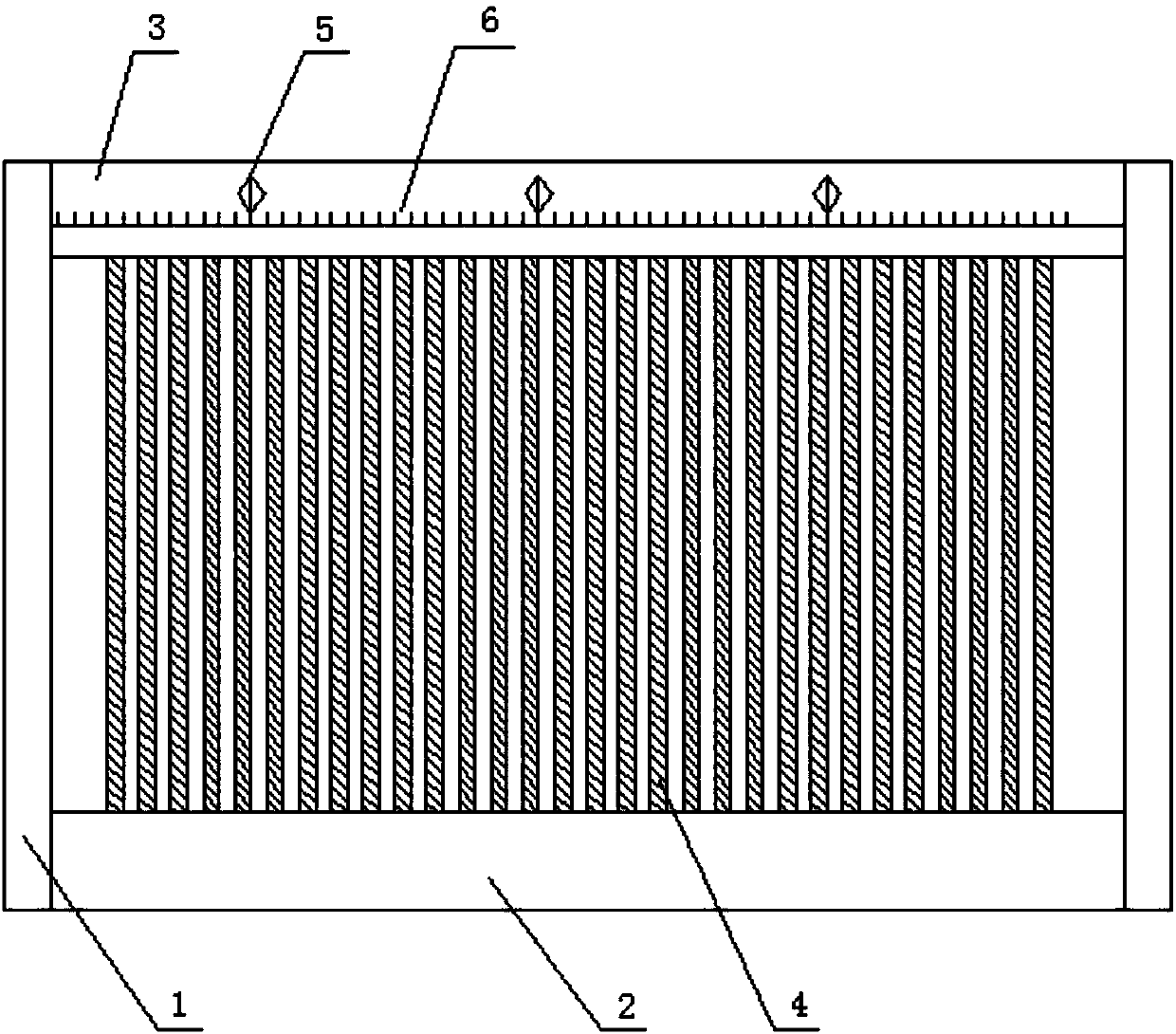

[0020] Such as figure 1 As shown, the scaled reed of the present invention includes a square frame formed by a reed beam and a horizontal plate 1, the reed beam includes an upper reed beam 2 and a lower reed beam 3, and the upper reed beam 2 and the lower reed beam Install parallel reed teeth 4 between the 3, the distance measuring ruler 6 is set on the upper reed beam 2, the auxiliary spraying position mark point 5 is set on the distance measuring ruler 6, and the initial scale of the distance measuring ruler 6 is located on the upper reed beam 2 The starting position of the first end; the scale of the distance-measuring ruler 6 is an imperial scale, and the marked scale of the distance-measuring ruler 6 is integrally formed with the reed beam.

[0021] The distance measuring ruler is used to provide accurate weft coordinates to facilitate the confirmation of warp yarn distribution density and reed width. The auxiliary spraying position marking point is used to mark the insta...

Embodiment 2

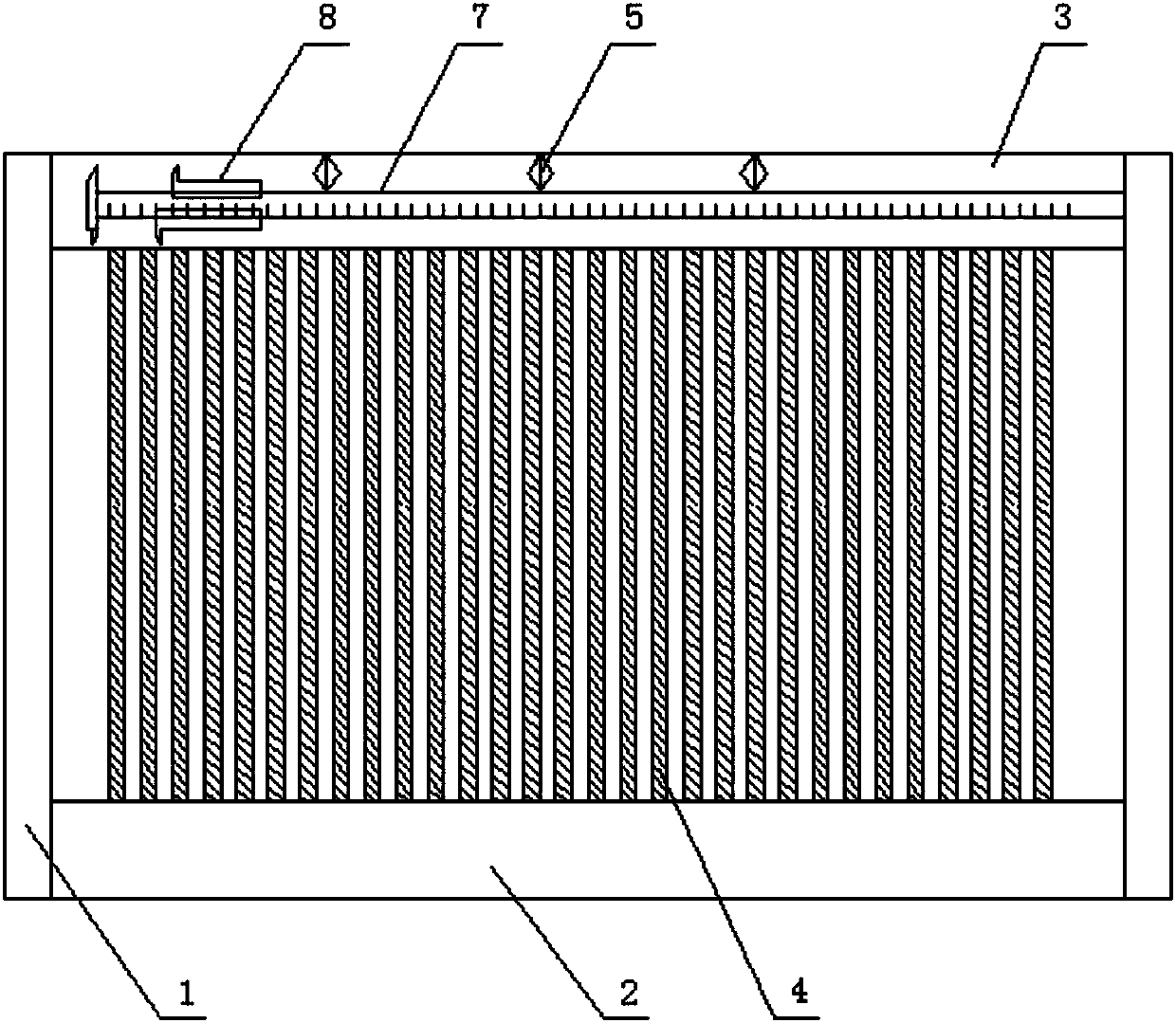

[0023] Such as figure 2 As shown, the scaled reed of the present invention includes a square frame formed by a reed beam and a horizontal plate 1, the reed beam includes an upper reed beam 2 and a lower reed beam 3, and the upper reed beam 2 and the lower reed beam 3, parallel reed teeth 4 are installed, a distance measuring ruler 6 is set on the upper reed beam 2, and auxiliary spray position marking points 5 are set on the distance measuring ruler 6, and the initial scale of the distance measuring ruler 6 is the same as that of the upper reed beam 2 The first reed tooth 4 of the first end is aligned; the scale of the distance measuring ruler 6 is a metric scale, the distance measuring ruler 6 is a vernier caliper, and the main ruler 7 of the vernier caliper is fixedly connected with the reed beam, and the vernier ruler 8 of the vernier caliper is along the main ruler 7 Sliding; the division value of the vernier caliper is 0.1mm.

[0024] The vernier caliper has high measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com