A liquid nitrogen freezing crushing box for waste tires

A technology of liquid nitrogen freezing and waste tires, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve problems such as difficult, time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

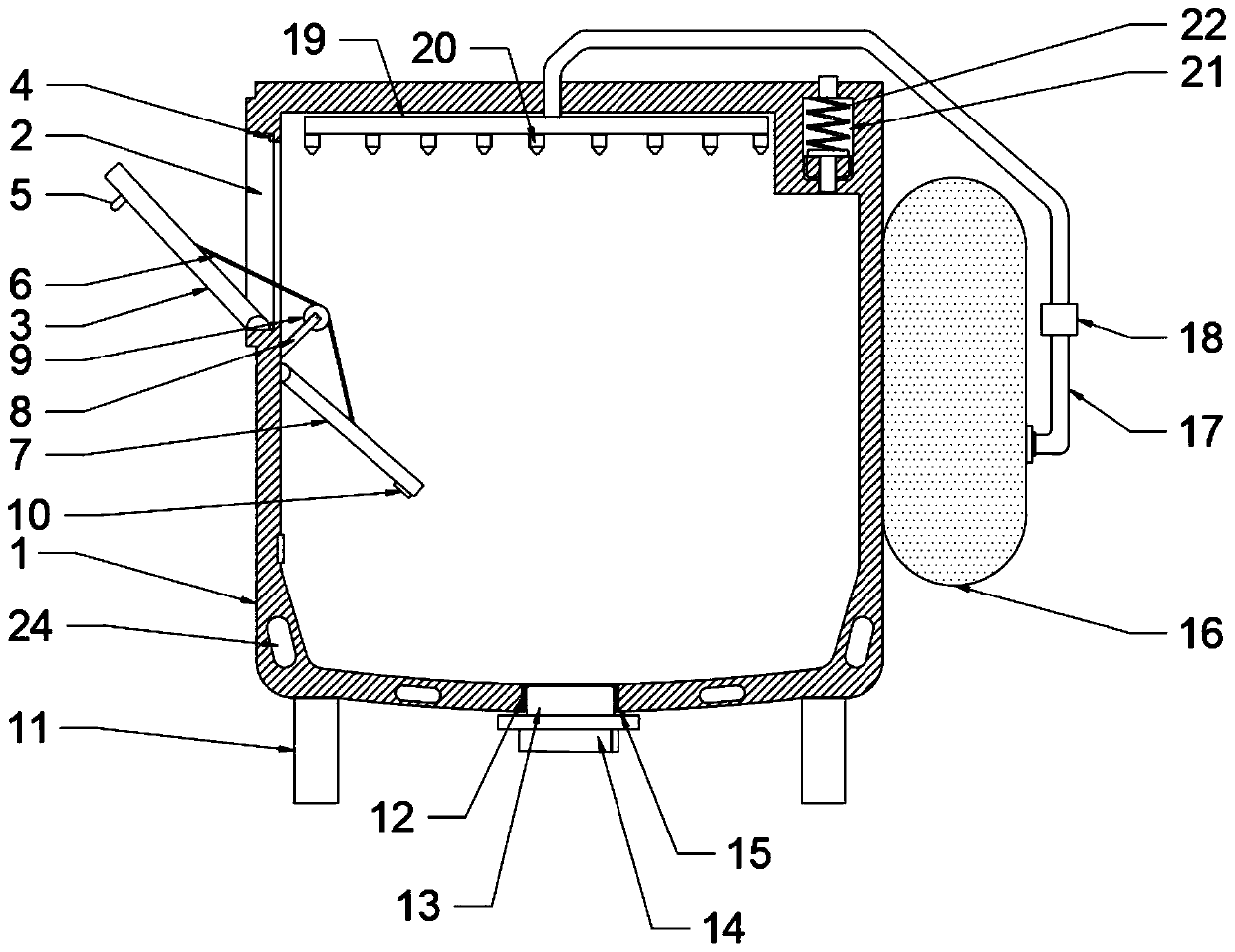

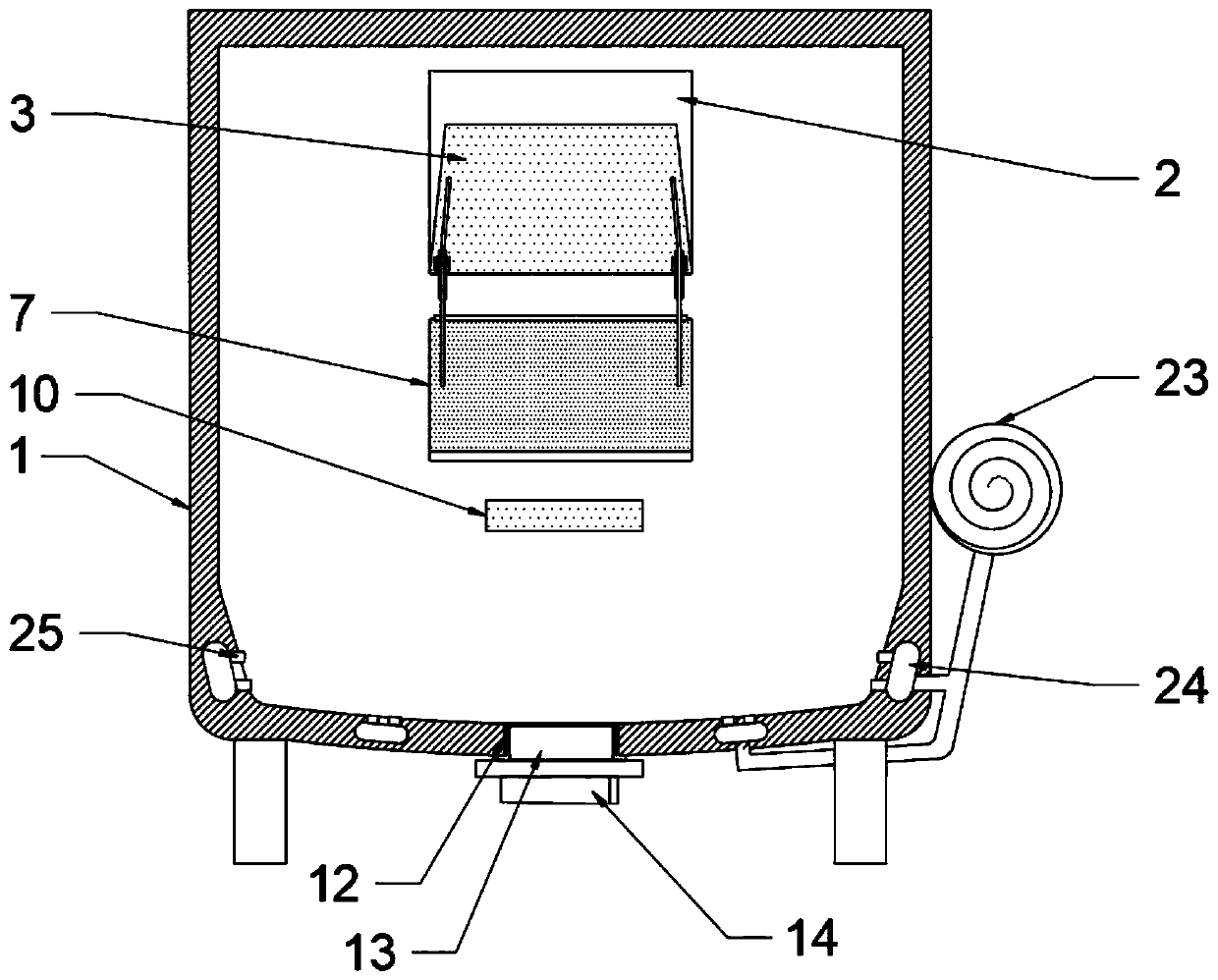

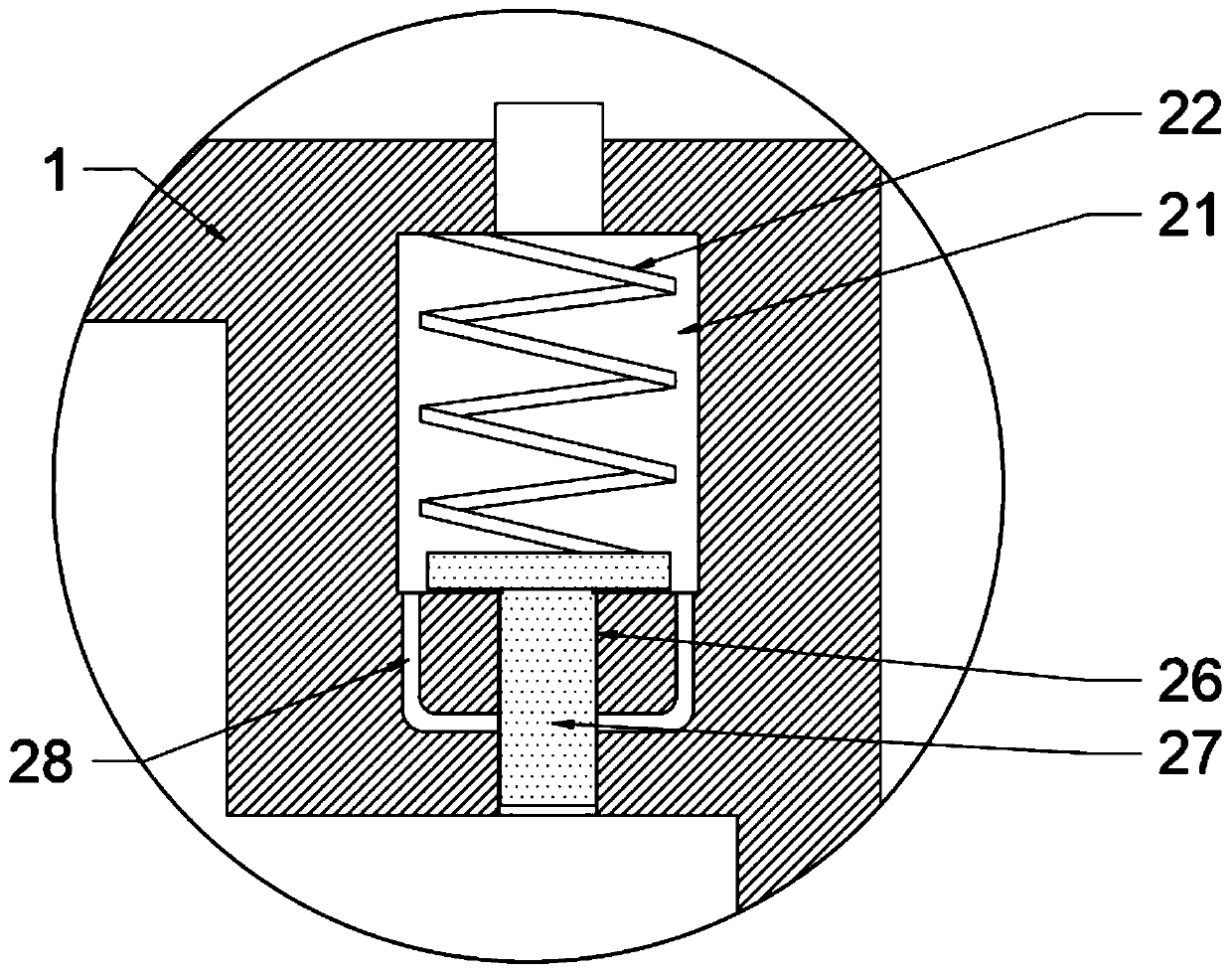

[0016] Such as Figure 1-Figure 3 A liquid nitrogen frozen crushing box for waste tires and its usage method are shown, including a box body 1, a feed port 2, a sealed door 3, a connecting rope 6, a slide plate 7, a bracket 8, a runner 9, a foot 11, and a discharge port 12. Sealing cover 13, high-pressure liquid nitrogen tank 16, nitrogen delivery pipe 17, solenoid valve 18, spray pipe 19, nozzle 20, decompression chamber 21, spring 22, fan 23, annular air pipe 24, spray head 25, exhaust Groove 26, sealing rubber rod 27 and bypass pipe 28, four legs 11 are evenly installed on the bottom of the box body 1, and a feed port 2 is provided above the side wall of the box body 1, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com