Efficient pulverizer

A kind of pulverizer, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of incomplete pulverization, large waste of raw materials, prolonging pulverization cycle, etc., and achieve the effect of increasing pulverization rate, automatic continuous feeding, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

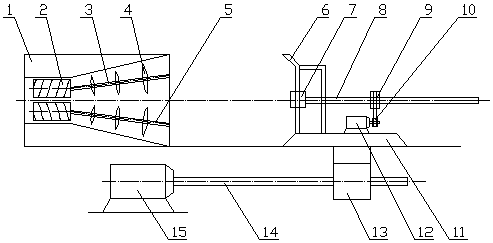

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] Such as figure 1 As shown, a high-efficiency pulverizer includes a propulsion part and a crushing box 1, and the propulsion part is composed of a large propulsion device and a small propulsion device.

[0012] Big propulsion device is made up of big propulsion motor 15, big screw mandrel 14, big screw mandrel nut 13, big push plate 6, push plate base 11, and big propulsion motor 15 links to each other with big screw mandrel 14, and described big screw mandrel 14 is equipped with A large screw nut 13 that can rotate and slide, said large screw nut 13 is fixedly connected with the push plate base 11, and the large push plate 6 is housed on the push plate base 11. When the big propulsion motor 15 starts, it drives the big screw mandrel 14 to rotate, thereby promoting the big screw mandrel nut 13, the push plate base 11 and the big push plate 6 to move left and right, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com