Waste glass pretreatment system applied to glass production

A technology for waste glass and glass, applied in grain processing, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve problems such as potential safety hazards and environmental pollution, and achieve the effects of stable operation, improved purity, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

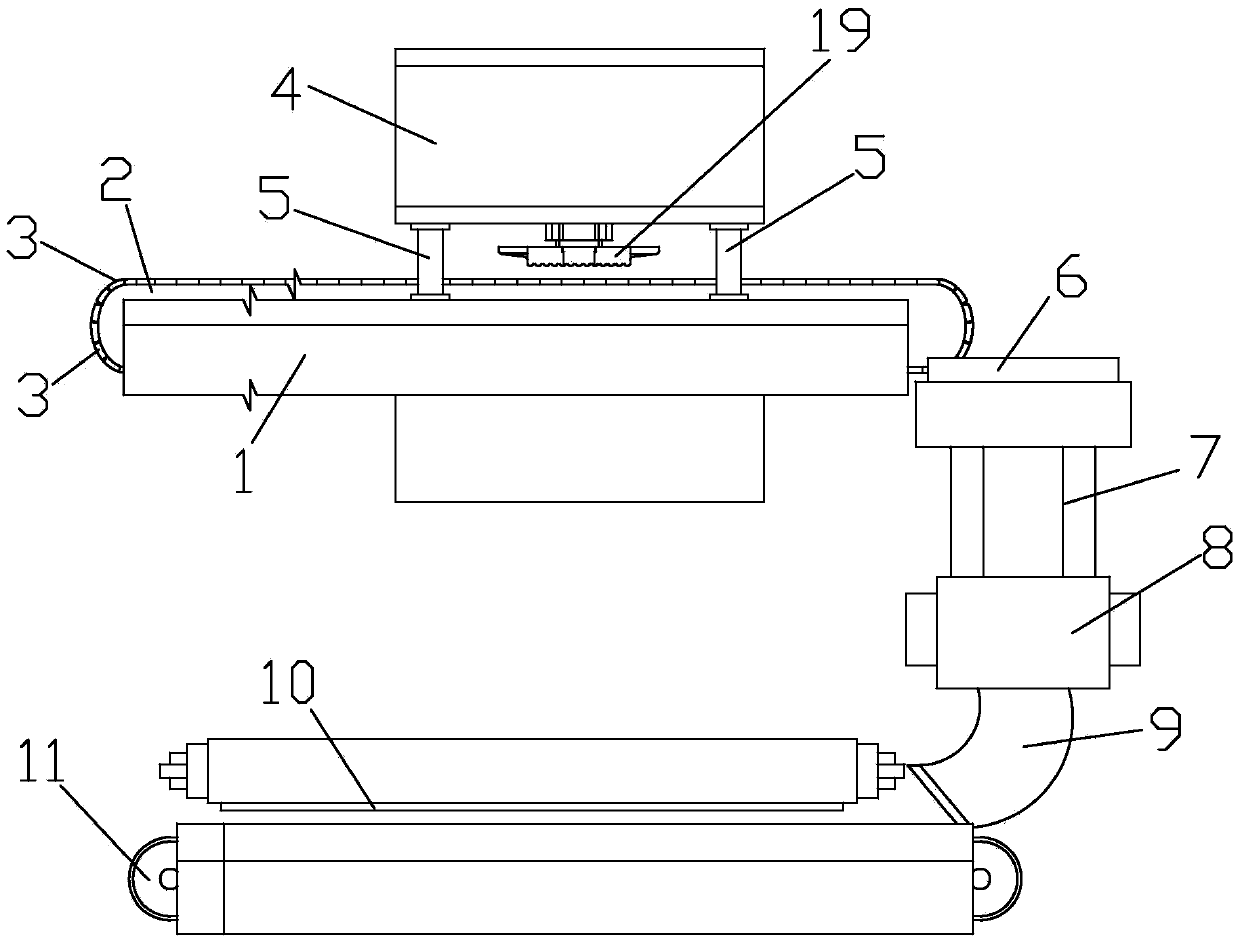

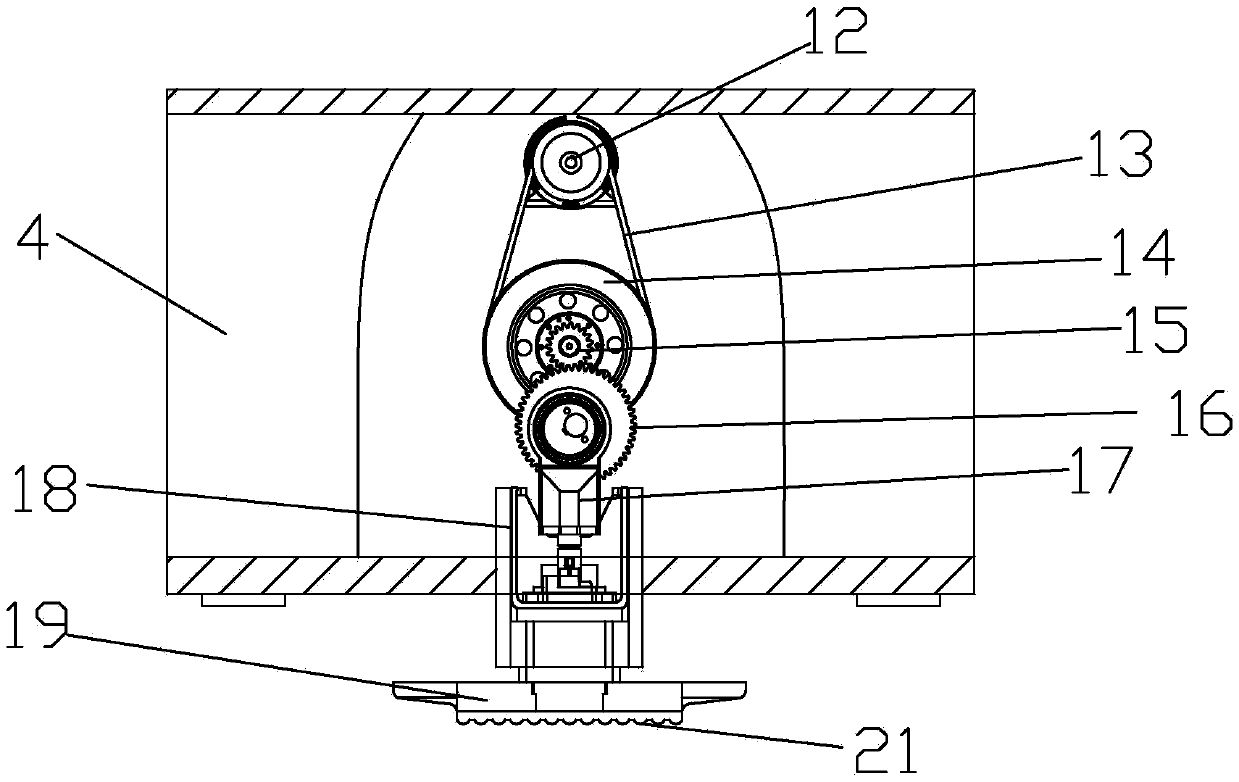

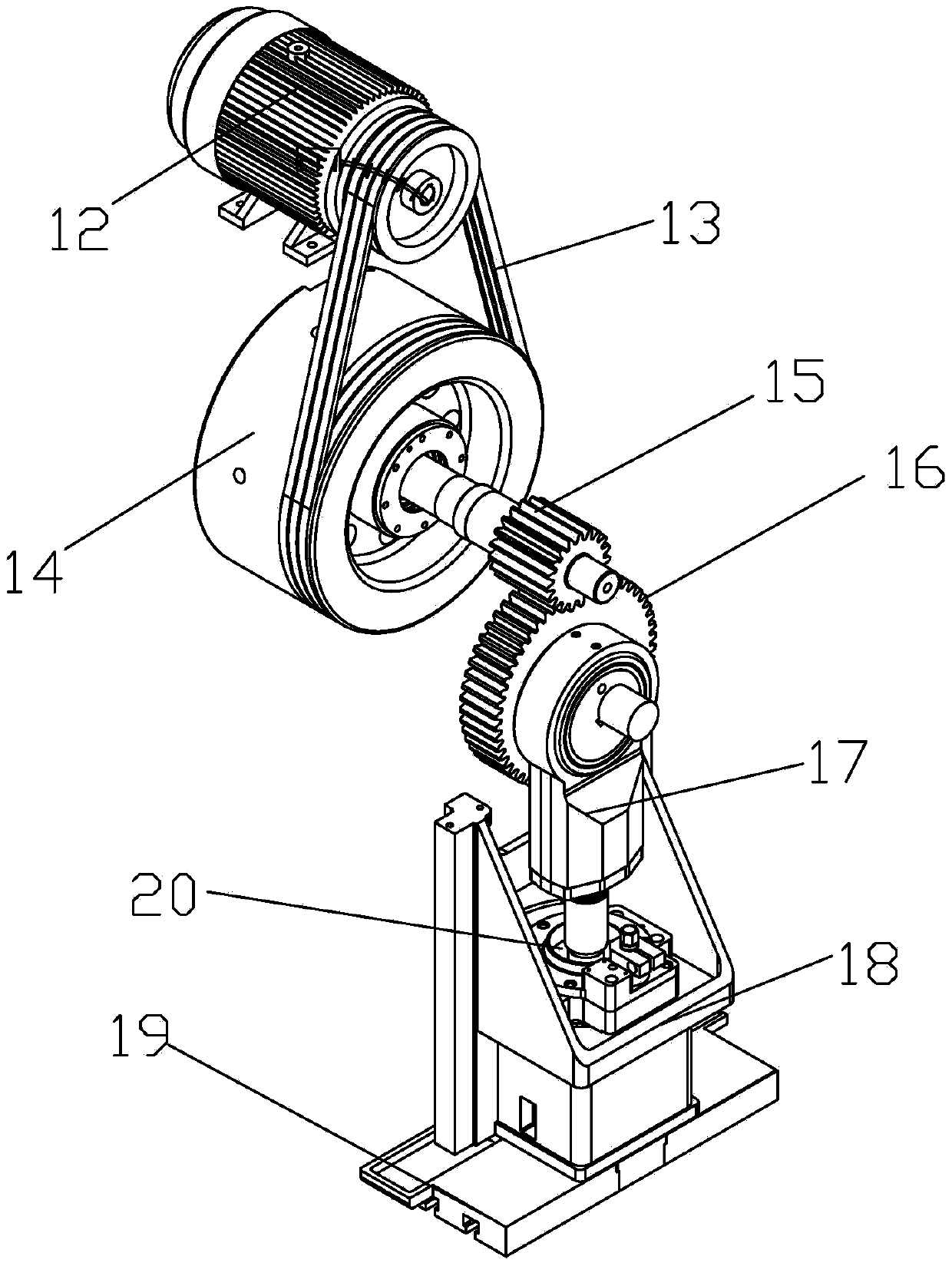

[0032] Such as Figure 1 to Figure 8 As shown, a waste glass pretreatment system used in glass production includes a primary crushing device, a secondary crushing device and a metal filter. The primary crushing device is the first device of the waste glass pretreatment system. The primary crushing device includes an upper frame 4 and a lower frame 1 , and a support rod 5 is arranged between the lower frame 1 and the upper frame 4 . The support rod 5 is used to connect the upper frame 4 and the lower frame 1, so as to increase the stability of the primary crushing device. The lower frame 1 is provided with a first-level guide belt 2, and a carrier plate 3 is laid on the first-level guide belt 2. Adjacent carrier plates 3 are movably connected, and the carrier plates 3 can be separated from each other at corners. This laying method is adopted to adapt to the first-level conduction band 2. The carrier plate 3 is used to carry waste glass. The waste glass is first placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com