Treatment method and treatment device for scums in milk industry wastewater

A treatment method and technology of treatment devices, which are applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve the problems of reducing the adjustment tank capacity of the adjustment tank, deterioration of anaerobic effluent quality, and substandard effluent. , to achieve the effect of reducing the probability of blockage, reducing maintenance workload and accelerating digestion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

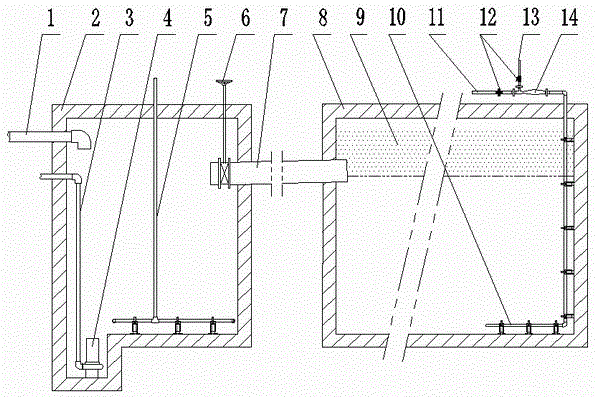

[0016] A treatment device for dairy wastewater scum comprises a regulating tank 8, a sludge tank 2, and connecting pipes 7 arranged at both ends of the regulating tank 8 and the sludge pond 2 respectively. The mouth of the connecting pipe 7 is higher than At the mouth of the sludge tank 2; the sludge tank 2 is provided with a residual sludge discharge pipe 1, a digested sludge discharge pipe 3, a lift pump 4 and an aeration pipeline 5; an air intake pipe is provided in the regulating tank 8 13. The water inlet pipe 11, the air-water mixing device 14 and the stirring pipe 10, the water inlet pipe 11 and the air inlet pipe 13 are respectively connected to the input end of the air-water mixing device 14, the output end of the air-water mixing device 14 is connected to the stirring pipe 10, and the air inlet pipe 13 And the water inlet pipe 11 is respectively provided with valve 12. The stirring pipe 10 is one or more single-point aeration stirring pipes 10 of Φ40-63 mm; the air-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com