Coarse fodder easy to digest by ruminants and production method of coarse fodder

A ruminant, digestible technology, applied in the field of ruminant breeding, can solve the problems of high water content, poor palatability, long processing time, etc., and achieve the effect of improving nutritional value, increasing porosity, and good digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

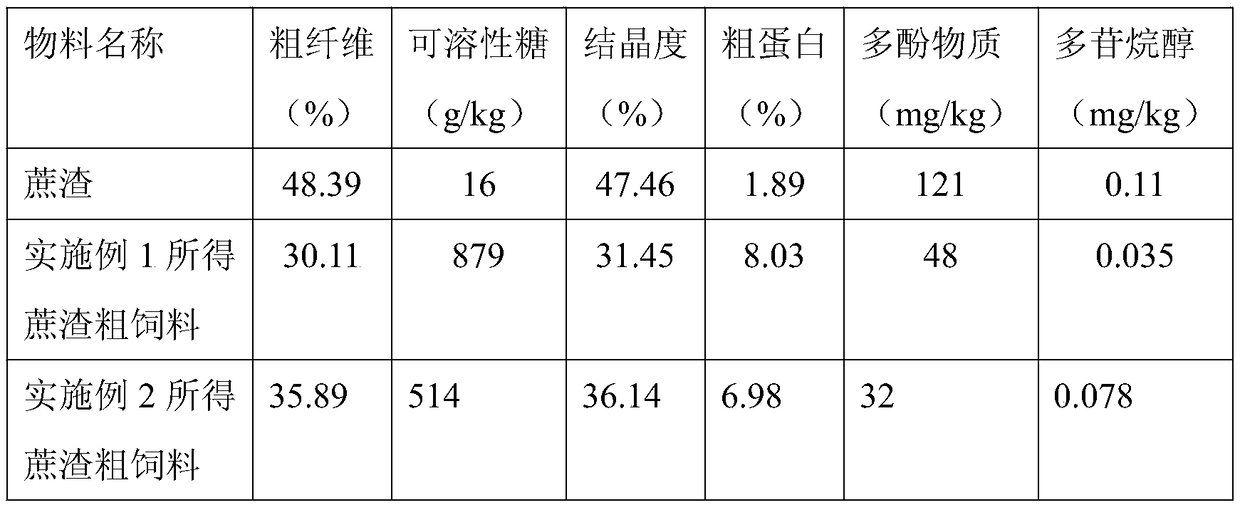

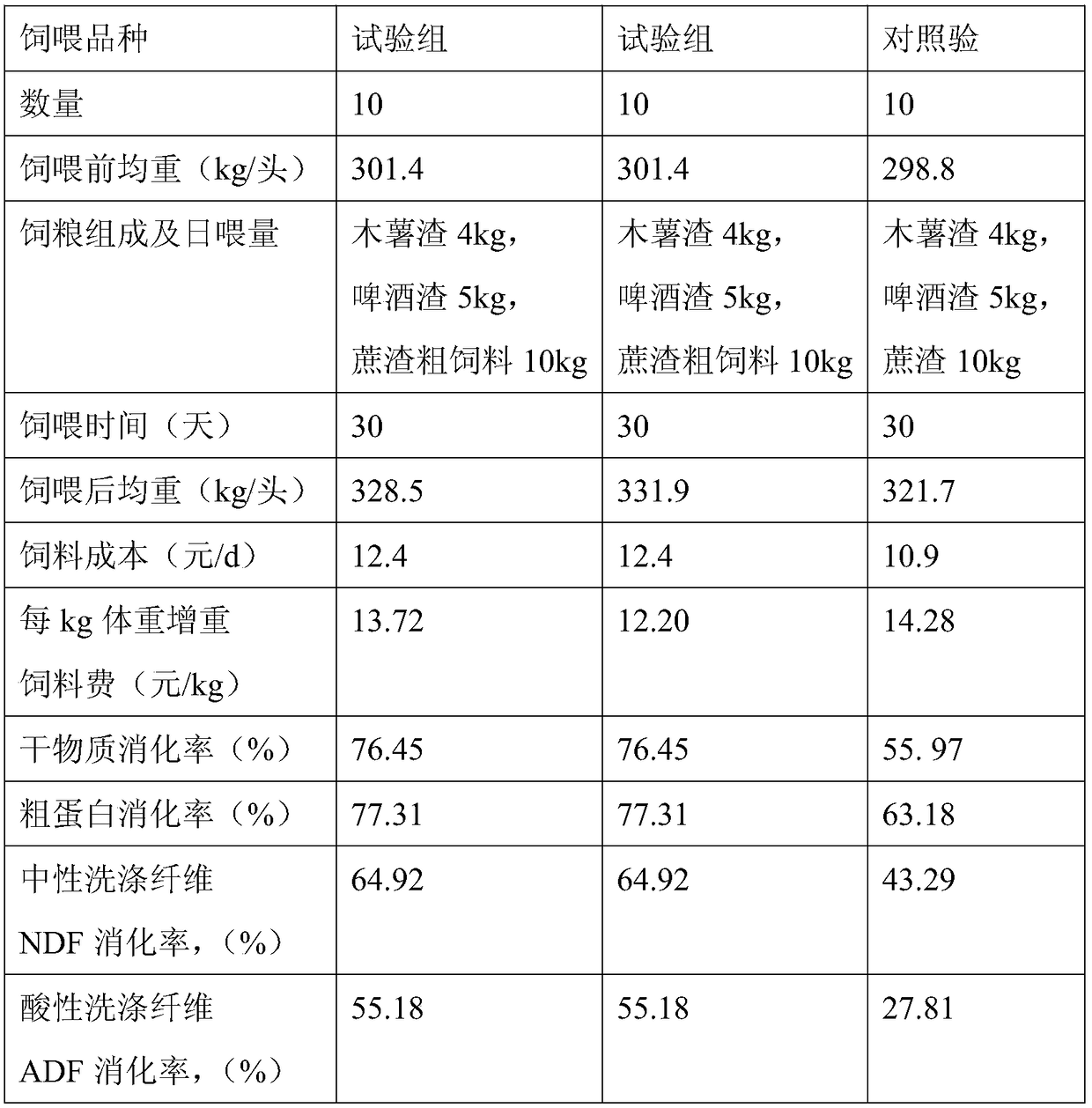

Embodiment 1

[0019] A kind of easy-to-digest bagasse roughage for ruminants, said feed comprises the following components in terms of weight percentage: bagasse 75%, molasses 4.5%, lime filter mud 3.0%, sugarcane juice membrane filter concentrate 13%;

[0020] In addition, it also includes fermented materials. According to the percentage of the weight of the above-mentioned raw material components, the added amount of various fermented materials is as follows: 0.15% of Lactobacillus, 0.30% of Bifidobacterium, 0.20% of Bacillus, 0.4% of Enterococcus faecium, Bacillus licheniformis 0.25%, phytase 0.20%.

[0021] The concentration of the molasses is 70°Bx, which is diluted to 55°Bx during use; the moisture content of the lime method filter mud is 38%, and the light conversion degree is 2.5%; the solid solution concentration of the sugarcane juice membrane filtration concentrated solution is 55°Bx, The solid particle concentration is 2.5%.

[0022] The preparation method of the digestible bag...

Embodiment 2

[0037] A kind of easy-to-digest bagasse roughage for ruminants, said feed comprises the following components in terms of weight percentage: bagasse 85%, molasses 4.5%, lime filter mud 3.0%, sugarcane juice membrane filter concentrate 7.5%;

[0038] In addition, it also includes fermented materials. According to the percentage of the weight of the above-mentioned raw material components, the addition amount of various fermented materials is as follows: 0.25% of Lactobacillus, 0.6% of Bifidobacterium, 0.65% of Bacillus, 0.5% of Enterococcus faecium, Bacillus licheniformis 0.45%, phytase 0.55%.

[0039] The concentration of the molasses is 75°Bx, which is diluted to 60°Bx during use; the moisture content of the lime method filter mud is 40%, and the light conversion degree is 4.5%; the solid solution concentration of the sugarcane juice membrane filtration concentrated solution is 68°Bx, The solid particle concentration is 3.0%.

[0040] The preparation method of the digestible ...

Embodiment 3

[0067] A kind of easy-to-digest bagasse roughage for ruminants, said feed comprises the following components in terms of weight percentage: bagasse 78%, molasses 5%, lime filter mud 5%, sugarcane juice membrane filtration concentrate 12%;

[0068] In addition, it also includes fermented materials. According to the percentage of the weight of the above-mentioned raw material components, the addition amount of various fermented materials is as follows: 0.18% of Lactobacillus, 0.4% of Bifidobacterium, 0.35% of Bacillus, 0.43% of Enterococcus faecium, Bacillus licheniformis 0.3%, phytase 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com