High-luster magnesium alloy surface treatment method

A surface treatment and magnesium alloy technology, applied in the field of high gloss magnesium alloy surface treatment, can solve problems such as surface treatment technology, intergranular corrosion, difficult to produce smooth surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

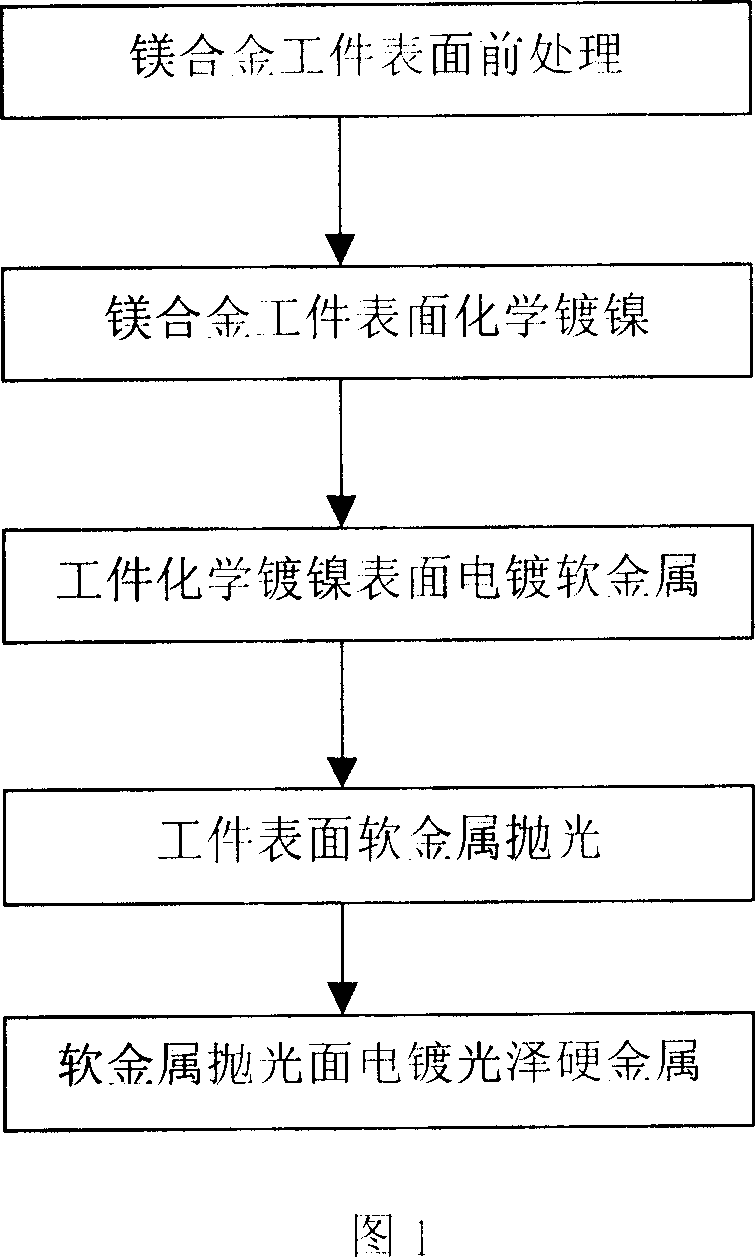

[0028] As shown in Figure 1, the magnesium alloy workpiece surface treatment method of the present invention is to process the magnesium alloy workpiece to be processed one by one according to the following steps, including: firstly, the pretreatment step is carried out on the surface of the magnesium alloy workpiece, and then the high adhesion is performed on the magnesium alloy surface Electroless nickel plating step, followed by electroplating soft metal step on the electroless nickel plated surface, then polishing step on the soft metal surface, and then electroplating glossy hard metal step on the polished surface, etc. The magnesium alloy workpiece processed by the present invention adopts American standard AZ61A (the composition is shown in Table 3), and its material and mechanical property specifications conform to ASTM B 90M-85, so as to verify the benefits that the present invention can produce. In addition, the size of the magnesium alloy workpiece is 10cm long * Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com