Preparation method of lithium ion battery anode material

A technology for lithium-ion batteries and anode materials, which is applied in the field of preparation of anode materials for lithium-ion batteries, can solve problems such as poor conductivity of SiO materials, and achieve the goal of improving electronic conductivity, conductivity, and chemical and electrochemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

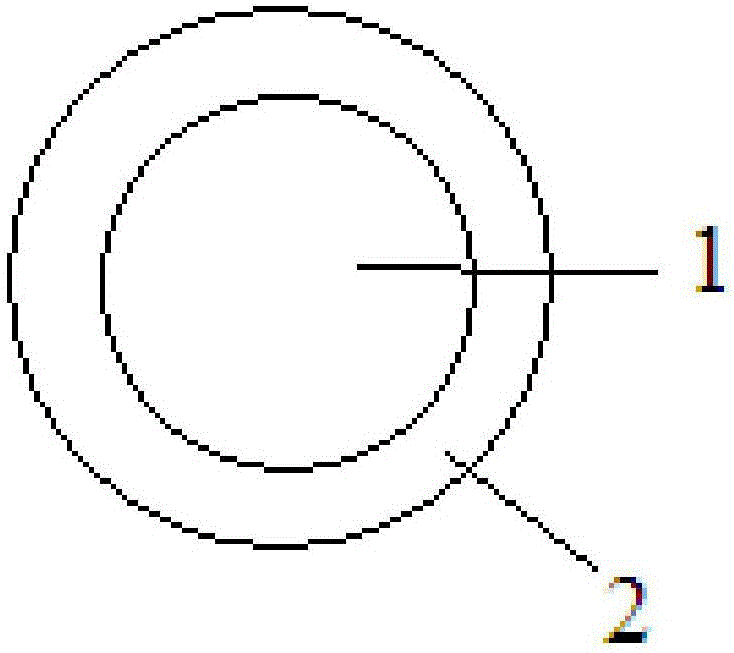

[0032] The preparation method of the lithium ion battery anode material provided in this embodiment, such as figure 1 As shown, the lithium-ion battery anode material includes a core layer 1 and a shell layer 2 coated outside the core layer 1, and the core layer 1 is SiO x , wherein, x is 0.5-2.0, the shell layer 2 is carbon, and the preparation method of the anode material at least includes the following steps:

[0033] Wash and dry the rice husks with water to remove dust and soil on the rice husks, then crush the rice husks so that the size of the rice husks is 1mm×1mm, place the rice husks in a high-temperature furnace, and heat them in a helium atmosphere. The temperature was raised to 800 °C at a rate of 25 °C / min, calcined for 10 min, and cooled to 30 °C naturally, then soaked and cleaned with a hydrochloric acid solution with a concentration of 0.1 mol / L at 30 °C, washed with deionized water, and then dried dry to obtain the anode material.

[0034] The BET specific ...

Embodiment 2

[0036] The preparation method of the lithium ion battery anode material provided in this embodiment, such as figure 1 As shown, the lithium-ion battery anode material includes a core layer 1 and a shell layer 2 coated outside the core layer 1, and the core layer 1 is SiO x , wherein, x is 0.5-2.0, and the shell layer 2 is carbon, and the preparation method of the anode material at least includes the following steps:

[0037] Wash and dry the rice husks with water to remove dust and soil on the rice husks, then crush the rice husks so that the size of the rice husks is 0.5mm×0.5mm, place the reed husks in a high-temperature furnace, Heat up to 1000°C at a rate of 15°C / min in an argon atmosphere, calcinate for 15 minutes, cool down to 35°C naturally, wash with a sulfuric acid solution with a concentration of 0.5mol / L at 35°C, and then wash with absolute ethanol , and then dried to obtain the anode material, and then the prepared anode material was placed in a high-temperature f...

Embodiment 3

[0040] The preparation method of the lithium ion battery anode material provided in this embodiment, such as figure 1 As shown, the lithium-ion battery anode material includes a core layer 1 and a shell layer 2 coated outside the core layer 1, and the core layer 1 is SiO x , wherein, x is 0.5-2.0, the shell layer 2 is carbon, and the preparation method of the anode material at least includes the following steps:

[0041] Wash and dry the rice husks with water first to remove dust and soil on the rice husks, then crush the rice husks so that the size of the rice husks is 100 μm×100 μm, and place the corn husks in a high-temperature furnace under nitrogen gas Under the atmosphere, the temperature was raised to 900°C at a rate of 20°C / min, calcined for 15 minutes, and cooled to 25°C naturally, then cleaned with a nitric acid solution with a concentration of 0.3mol / L at 40°C, washed with methanol, and then dried in the air. The anode material is obtained, and the prepared anode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com