Method for preparing large-size GaN self-support substrate

A self-supporting substrate, large-scale technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as lower yield, expensive laser lift-off technology, and affect device quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

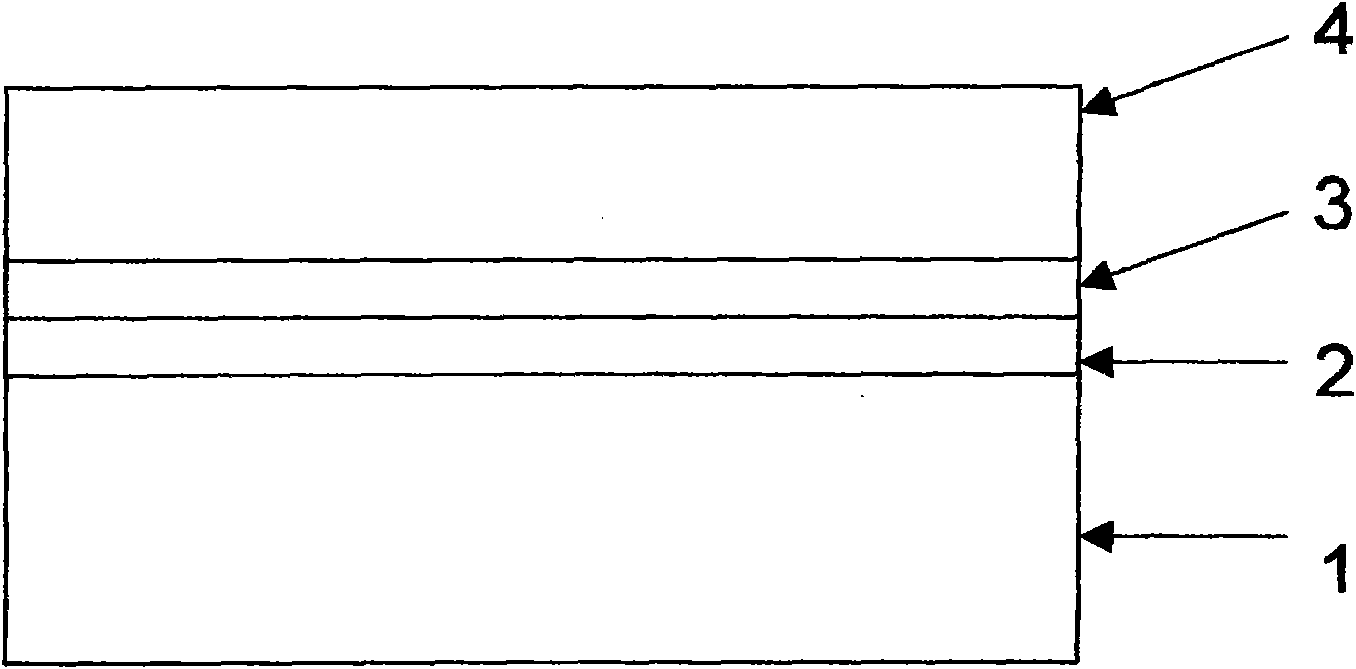

[0030] see figure 1 , figure 2 As shown, a method for preparing a large-scale GaN self-supporting substrate comprises the following steps:

[0031] Step 1: first grow a layer of ZnO film 2 on the substrate 1; wherein the materials for the substrate 1 for epitaxial self-supporting GaN thick film 4 are: sapphire, spinel, GaN, AlN, GaAs, Si , SiC, LiAlO 2 , LiGaO 2 , ZrB 2 or HfB 2 A kind of in, this example selects sapphire as substrate; Wherein the growth of ZnO film 2 adopts the method for metal source vapor phase epitaxy in this example, the source material that adopts in this method is metallic zinc and deionized water, metallic zinc and The reaction equation for deionized water is: This reaction is a reversible reaction. By constantly removing the tail gas and adjusting the flow rate of the source material and carrier gas, the reaction is controlled to achieve a dynamic balance, so that the metal Zn and H 2 O continuously reacts. The advantages of this method are ...

Embodiment 2

[0036] see again figure 1 , figure 2 Shown, present embodiment 2 is basically the same as embodiment 1, and its difference is:

[0037] (1) The ZnO film 2 in step 1 is prepared by spray pyrolysis, and the prepared ZnO film 2 is a polycrystalline film with a thickness of 0.5 μm. The advantage of the spray pyrolysis method is that the growth temperature is low, the method is simple, and the cost is very low.

[0038] (2) In step 2, a metal-organic chemical vapor deposition method is used to grow a 500nm InGaN film at 600°C as a low-temperature buffer layer; the InGaN low-temperature buffer layer 3 helps to reduce the defect density of the GaN thick film 4, and improves the final result. Crystalline quality of large-scale GaN free-standing substrates.

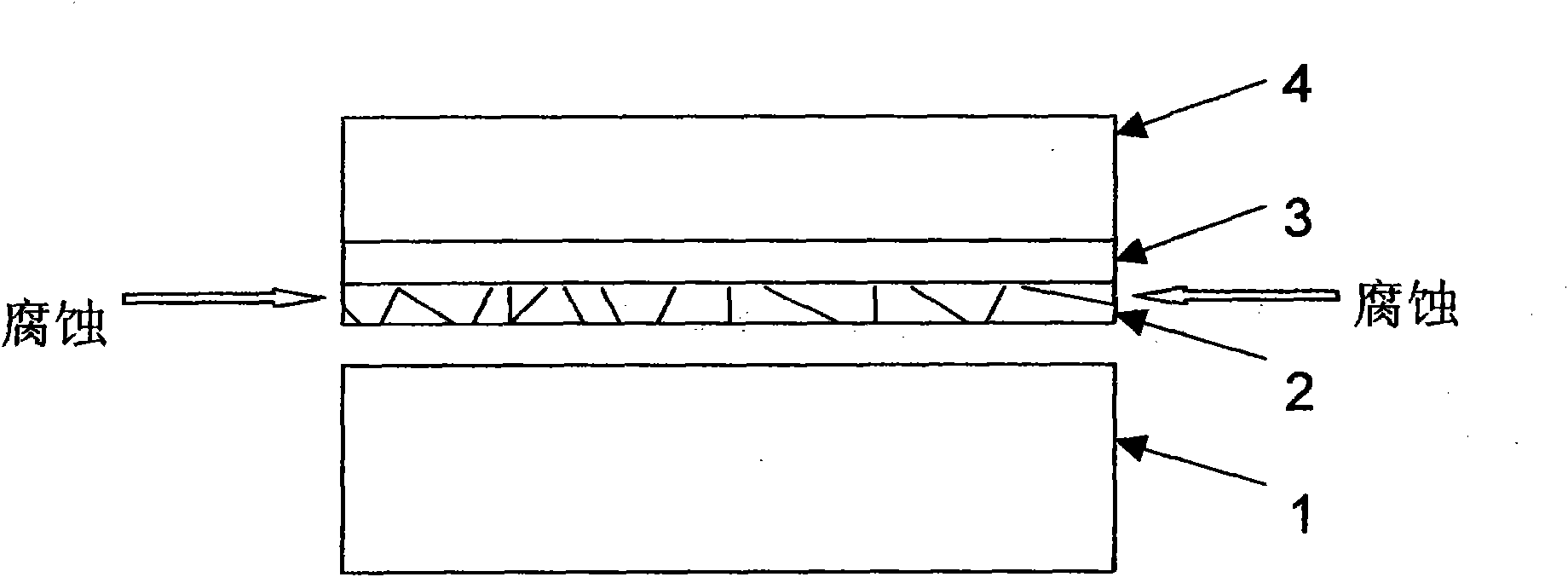

[0039] (3) High temperature corrosive gases HCl and NH in the hydride vapor phase epitaxy system during high temperature growth 3 pass figure 2 The direction indicated by the arrow etches the ZnO film 2 from the side. Becau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com