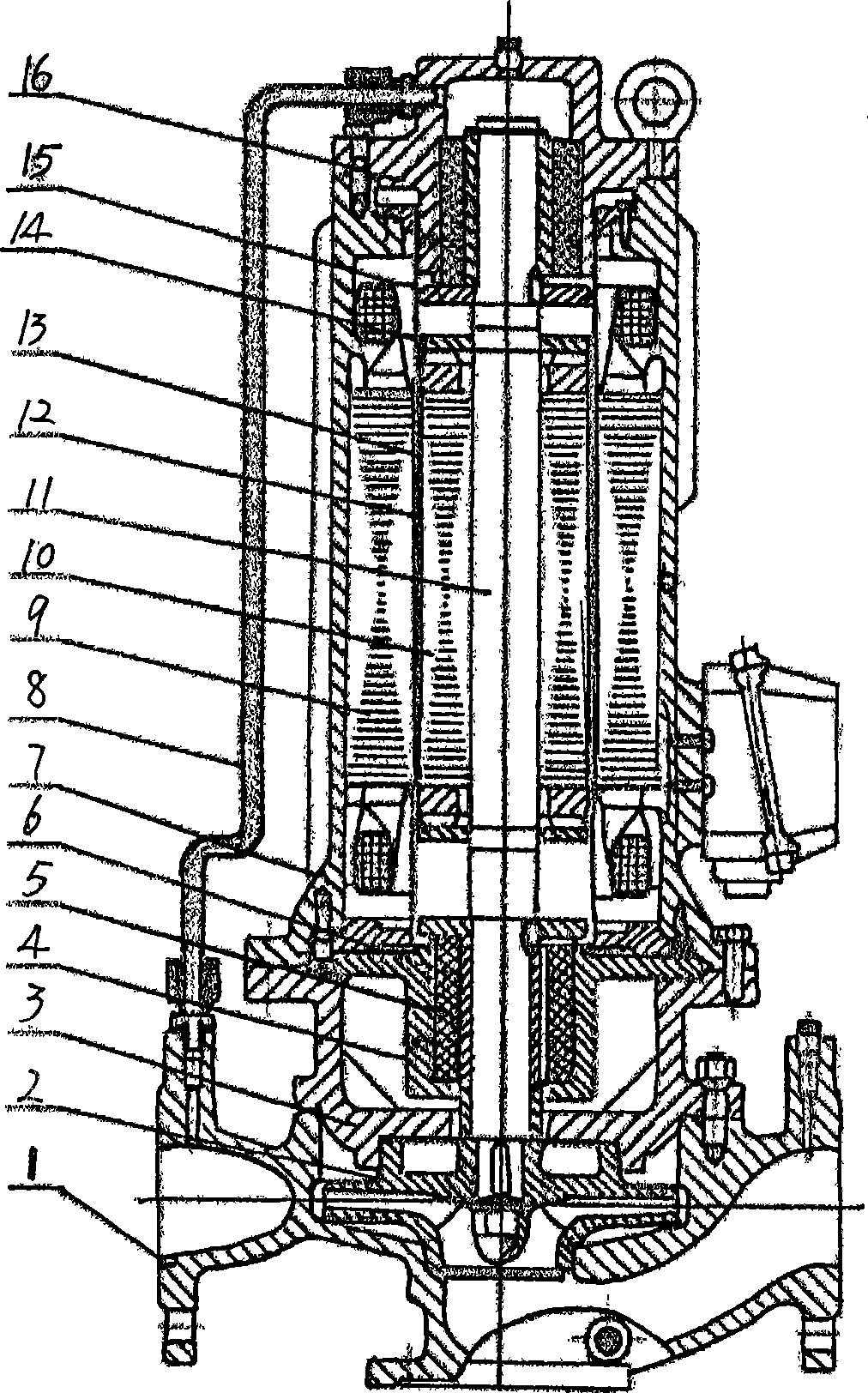

Vertical shield pump

A canned pump and vertical technology, which is applied to non-variable-capacity pumps, pumps, pump devices, etc., can solve the problems of easy corrosion of the rotor and stator, shorten the service life of the canned pump, and can not meet the sealing performance, and achieve a compact structure. , beautiful appearance, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] see figure 1 , the present invention is made up of water pump and canned motor two parts. The main parts of the water pump are impeller 2, pump body 1, sealing ring, and the main parts of the shielded motor part are composed of stator 9, rotor 10, shielding sleeve, bearing seat, bearing, cooling pipe 8, air release valve and other parts. The shielded motor uses insulated windings. The rotor 10 is composed of a stainless steel shaft and a cast aluminum rotor. In order to prevent the liquid from entering the stator and corroding the rotor, a stainless steel rotor shielding sleeve 12 and a stator shielding sleeve 13 are respectively installed on the inner diameter of the stator 9 and on the surface of the rotor. Sealing performance: There are heat-resistant O-ring seals at the connection between the flange of the pump body and the flange of the motor, the connection between the machine base and the bearing seat and the shield of the stator.

[0011] The pump impeller cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com