Declinator used inertia measurement set integration device and error eliminating method

A technology of an inertial measurement component and an inclinometer, which is applied in the field of inertial measurement, can solve the problems that it is difficult to ensure the installation accuracy, the inclinometer accuracy is greatly affected by installation errors, and the structure is not compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

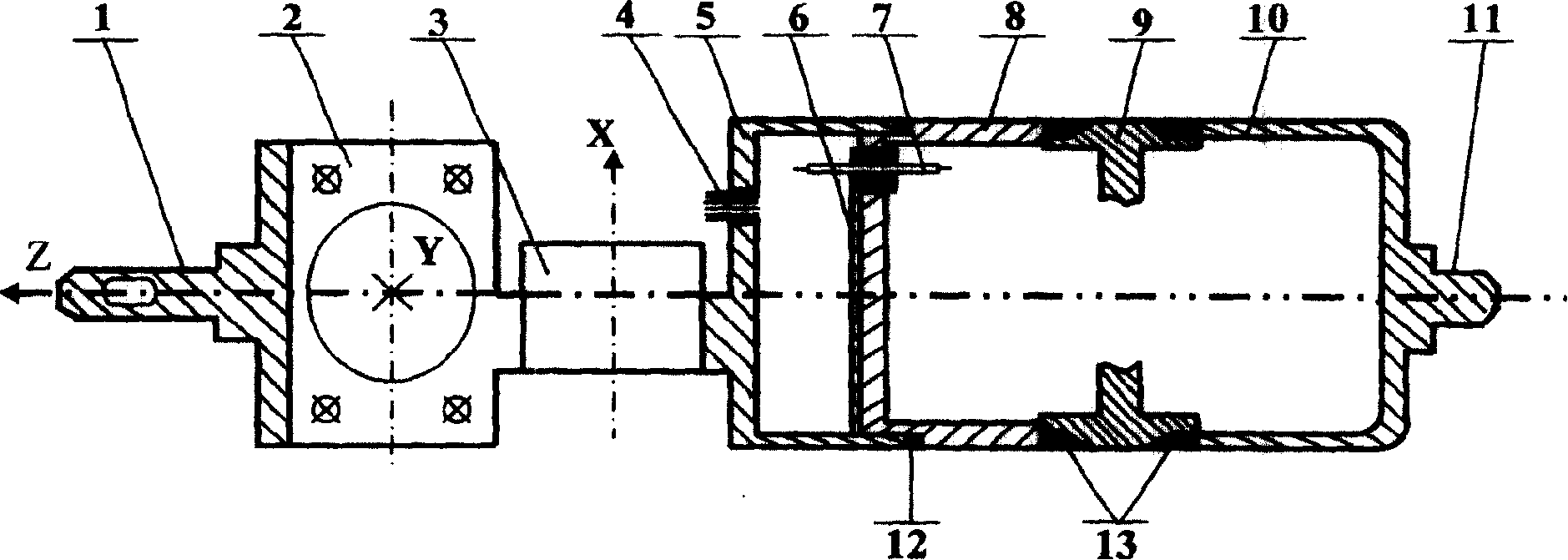

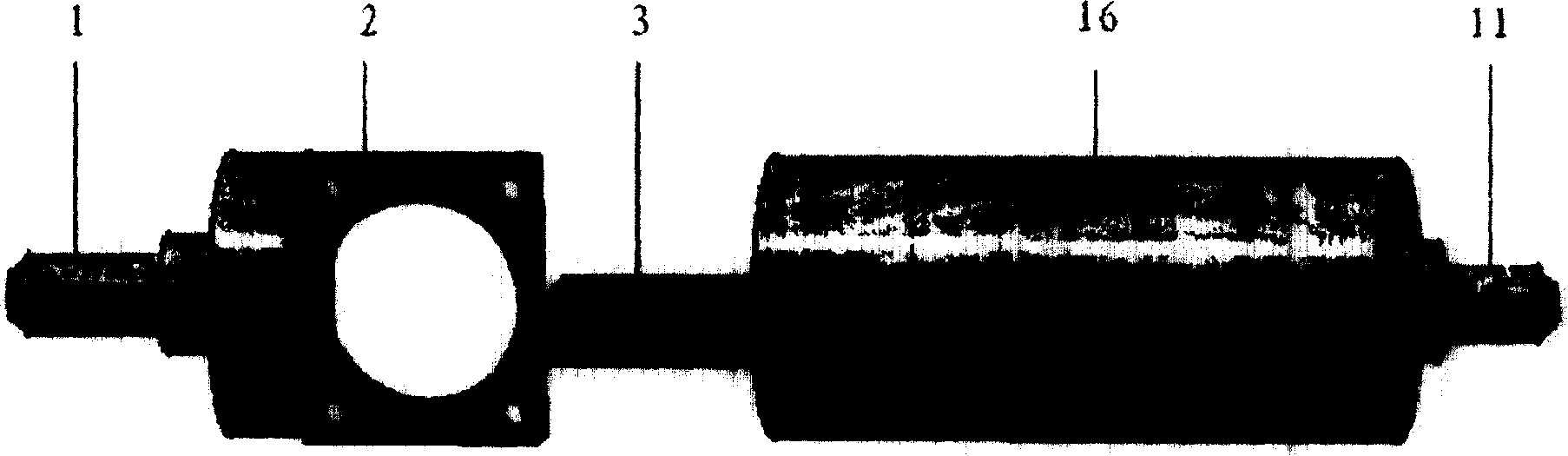

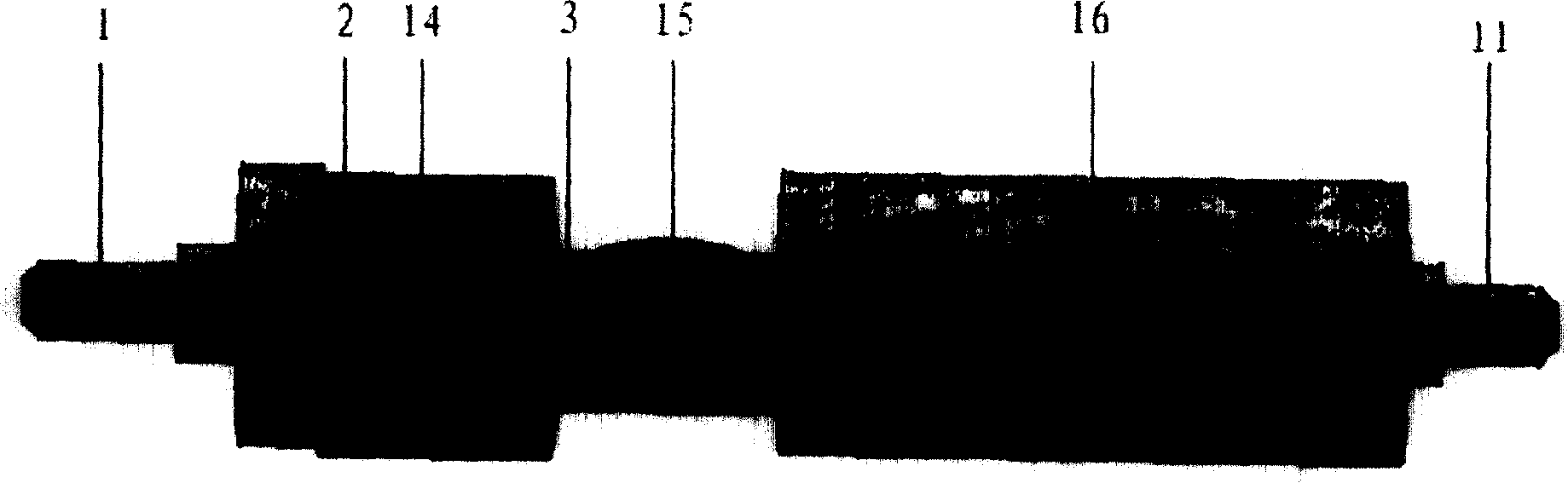

[0061] Such as figure 1 As shown, the present invention consists of a rear axle 1, a Y-axis accelerometer seat 2, an X-axis accelerometer seat 3, a gyro signal interface 4, a gyro rear cover 5, an insulating layer 6, an insulating terminal 7, a sealing cover 8, and a housing 9 , Inertial body front cover 10 and front axle 11, wherein rear axle 1 is connected with Y-axis accelerometer seat 2 and is perpendicular to each other, Y-axis accelerometer seat 2 is connected with X-axis accelerometer seat 3 and is perpendicular to each other, X-axis accelerometer The seat 3 is connected to the gyro back cover 5 and is perpendicular to each other, the gyro signal interface 4 is located in the gyro back cover 5; the rear axis 1, the Y-axis accelerometer seat 2, the X-axis accelerometer seat 3, the gyro signal interface 4 and the gyro back cover 5 It is integrated processing; the front shaft 11 is located at the rear end of the inertial body front cover 10, and the inertial body front co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com