Polygon mirror scanner motor

一种多角镜、扫描器的技术,应用在镜子、仪器、安装等方向,能够解决多角镜P变形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

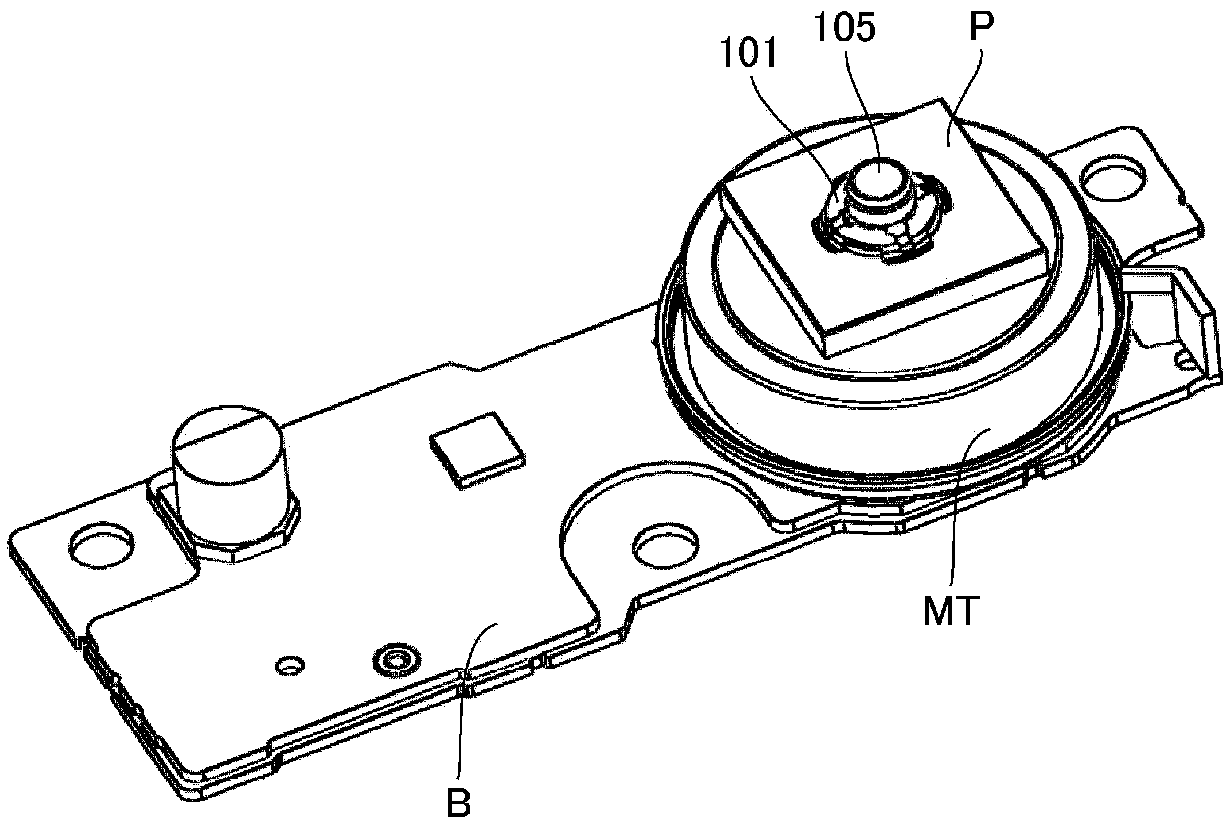

[0074] figure 1 It is a perspective view of a polygon mirror (polygon mirror) scanner motor in one embodiment of the present invention.

[0075] As shown in the figure, the polygon mirror scanner motor includes: a base part B on which a control circuit is formed, a motor MT, a sleeve 105 mounted on the rotating shaft of the motor MT, and a polygon mirror mounted on the supporting surface of the sleeve 105. The mirror P, and the mirror fixing spring 101 that presses the polygon mirror P from above to the supporting surface.

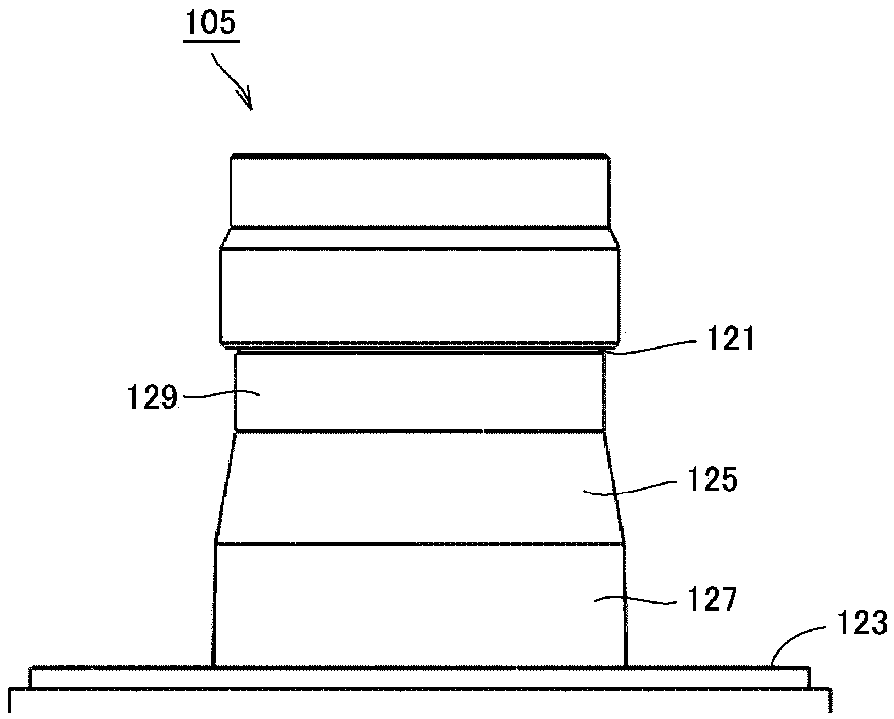

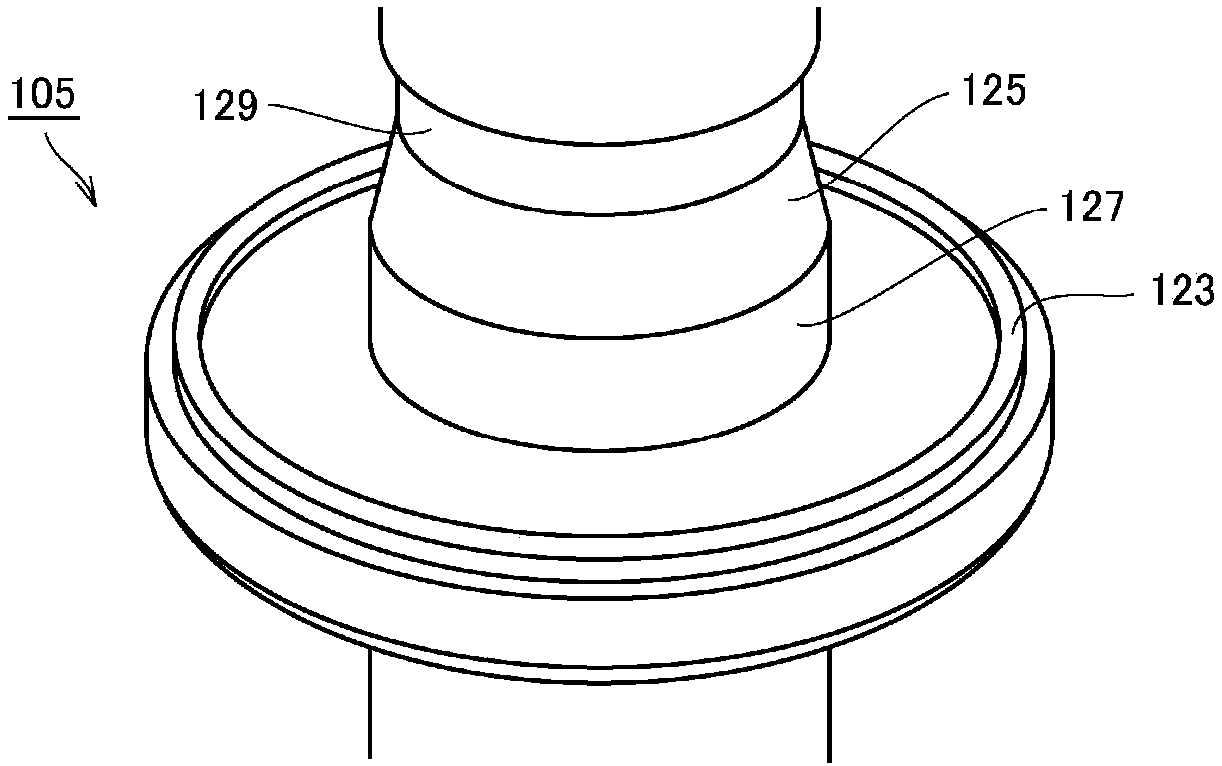

[0076] figure 2 yes figure 1 Side view of the sleeve 105 of the polygon mirror scanner motor. image 3 from an oblique view figure 1 Perspective view of a portion of the sleeve 105 of the polygon mirror scanner motor. Figure 4 from oblique view figure 1 Perspective view of a portion of the sleeve 105 of the polygon mirror scanner motor. Figure 5 is used for figure 1 The perspective cross-sectional view illustrating the construction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com