Camera module, electronic device including the same, and method for positioning lenses of camera module

A camera and camera lens technology, applied in the camera body, TV, camera and other directions, can solve the problems of large thrust and large spring deformation, and achieve the effect of high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

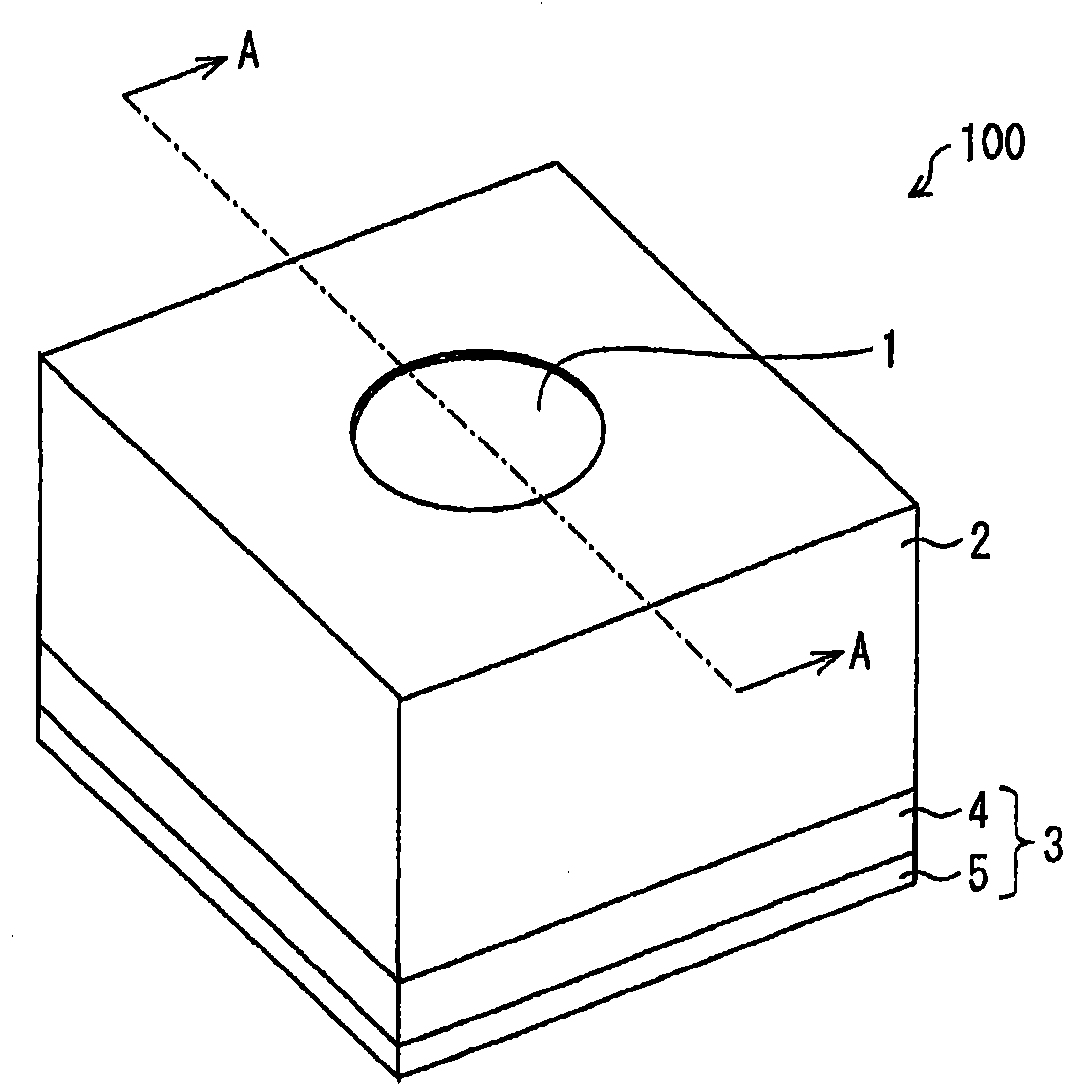

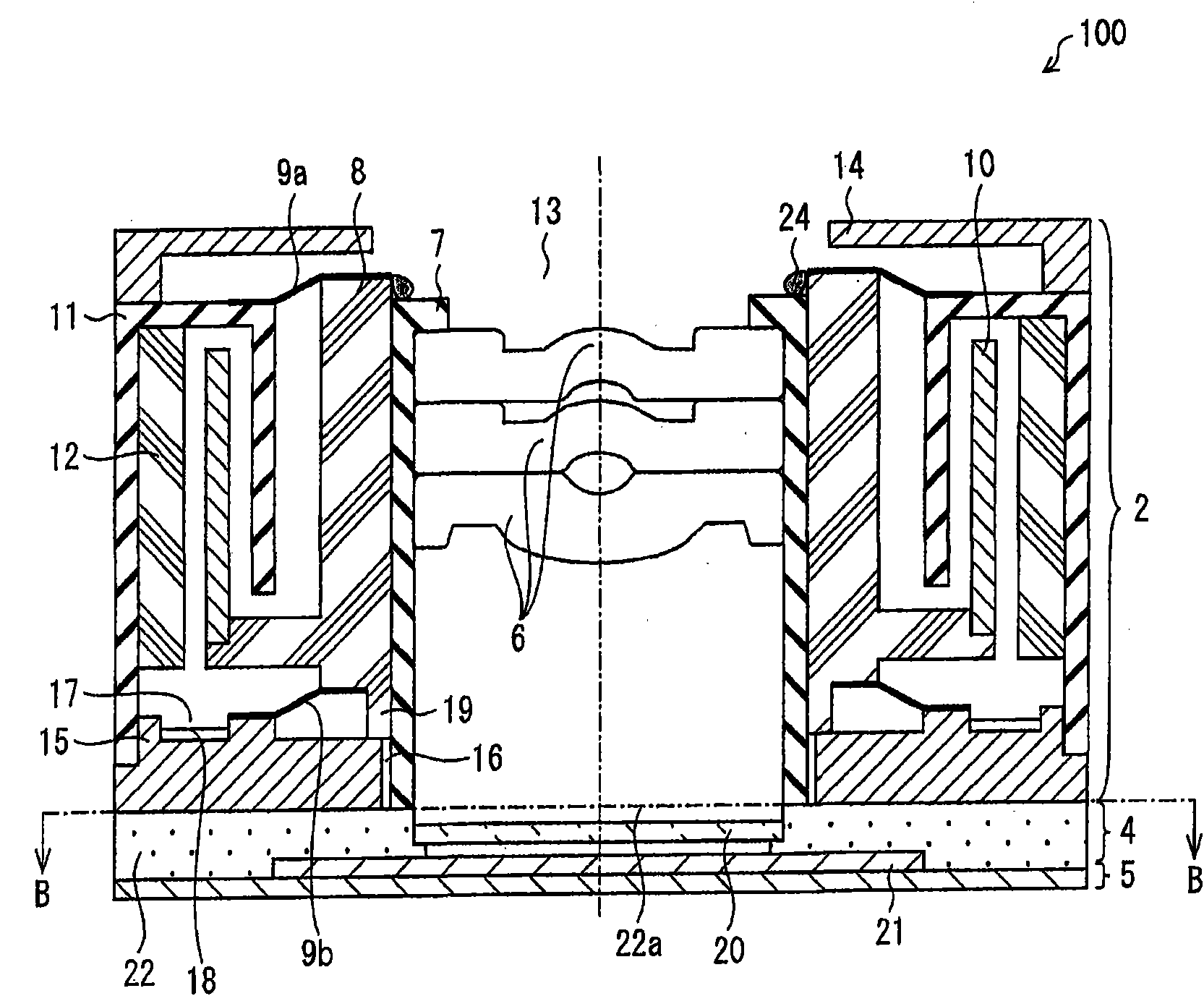

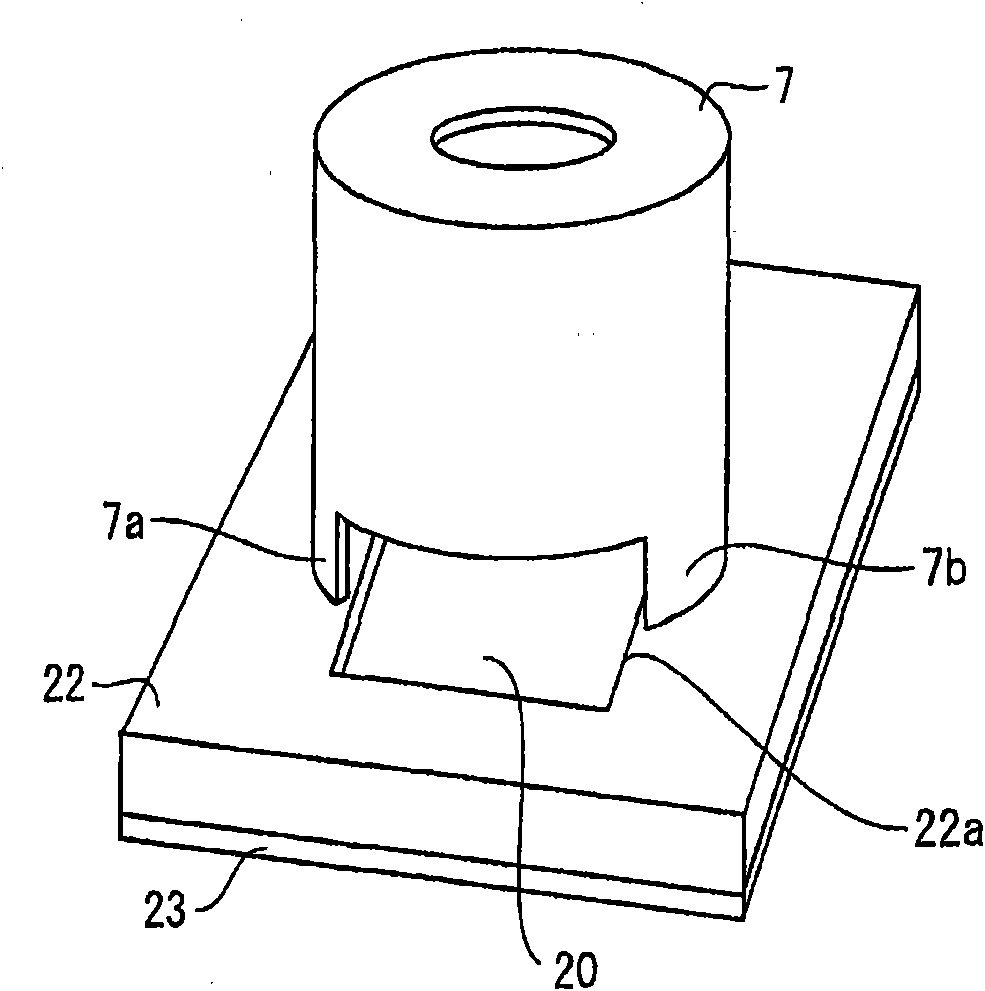

[0082] Below, based on Figure 1 to Figure 14 , Figure 16 ~ Figure 20 Embodiments of the present invention will be described.

[0083] figure 1 It is a perspective view of the camera module of this embodiment. The camera module 100 includes: an optical unit 1 as an imaging optical system; a lens driving device (lens driving unit) 2 that drives the optical unit 1 ; and an imaging unit 3 that photoelectrically converts light passing through the optical unit 1 . The optical unit 1 is held inside the lens driving device 2 . The imaging unit 3 is configured to include a sensor unit 4 and a substrate 5 on which the sensor unit 4 is mounted. The camera module 100 is configured by laminating the sensor unit 4 and the lens driving device 2 sequentially in the optical axis direction on the substrate 5 . In the following description, for convenience, the side of the optical unit 1 is referred to as the upper side, and the side of the imaging unit 3 is referred to as the lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com