Plate cleaning device and plate cleaning method

A cleaning device and plate technology, applied in the cleaning/polishing of conductive patterns, secondary treatment of printed circuits, etc., can solve the problems of difficult removal of attachments and complex components, and achieve equipment integration with compact structure, improved economic benefits, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

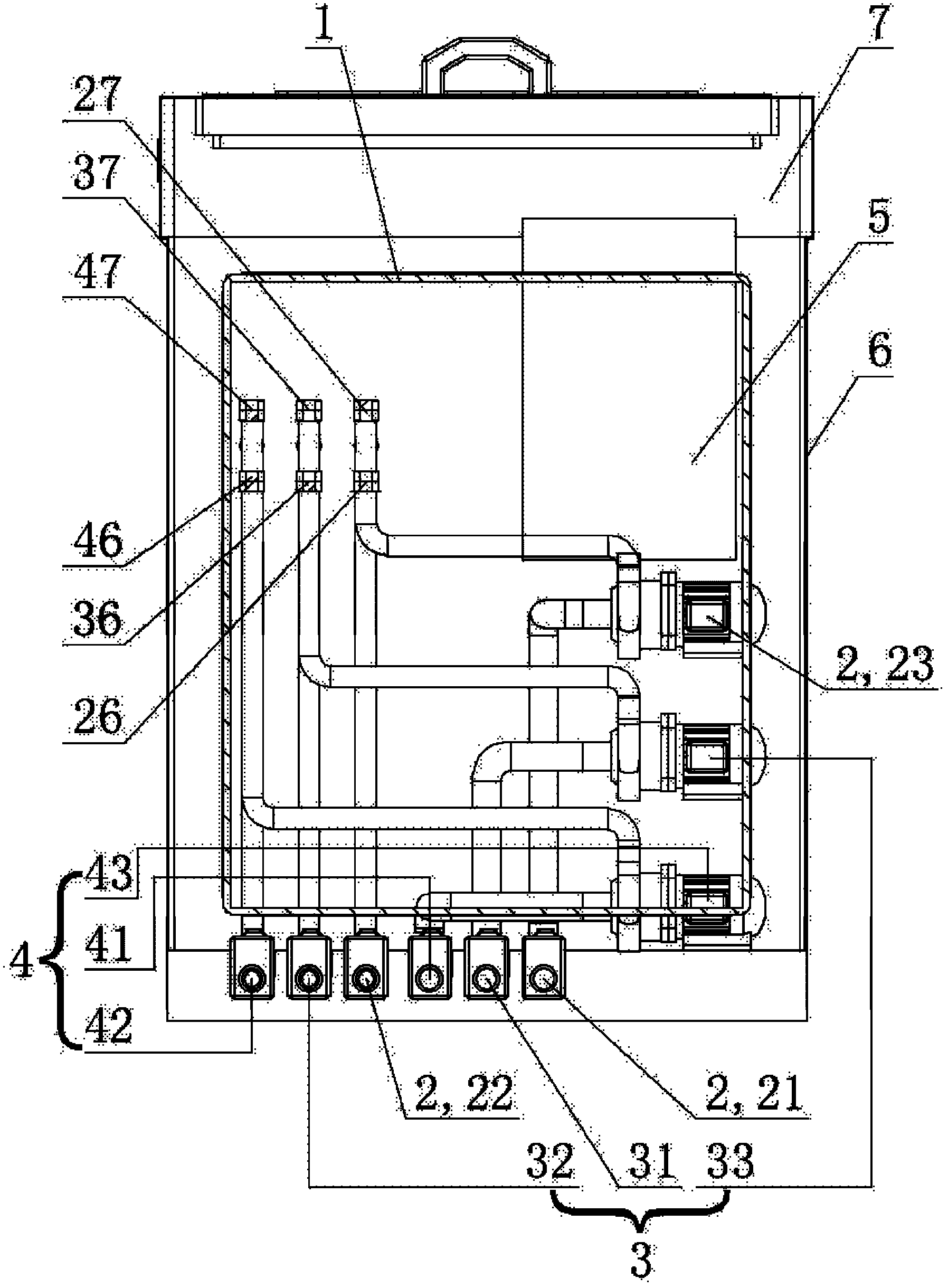

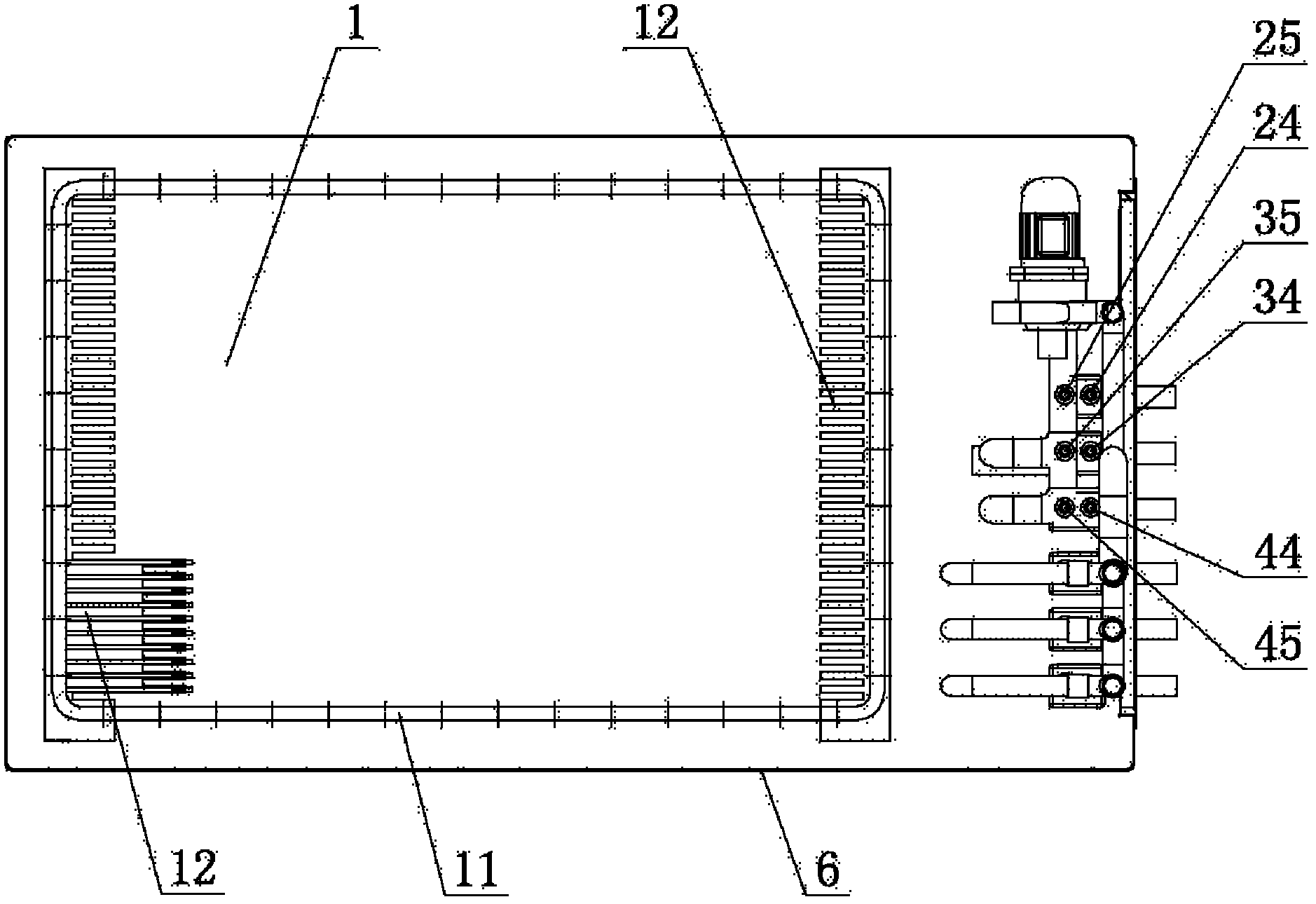

[0029] see figure 1 and figure 2 , The plate cleaning device of the embodiment of the present invention is mainly used to remove the crystalline substances attached to the surface of the plate, and is especially suitable for the cleaning of copper plates that use electrolytic methods to extract metallic copper in an alkaline etching solution. Liquid crystals, such as copper chloride and ammonium chloride crystals. The plate cleaning device includes: a cleaning bucket 1 , a pickling cycle system 2 , a cleaning cycle system 3 , a water washing cycle system 4 , an automatic controller 5 , an outer tub 6 and a cover plate 7 .

[0030] The washing tub 1 is arranged in the outer tub 6 . The pickling circulation system 2, the cleaning circulation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com