The sweeper has a built-in dual-channel alternate vibration dust cleaning device

A dual-channel, sweeping machine technology, applied in the direction of road cleaning, cleaning methods, cleaning methods and appliances, etc., can solve the problems of low work efficiency, operation is greatly affected by human factors, etc., to achieve high work efficiency, reduce labor intensity and operation Probability of error, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

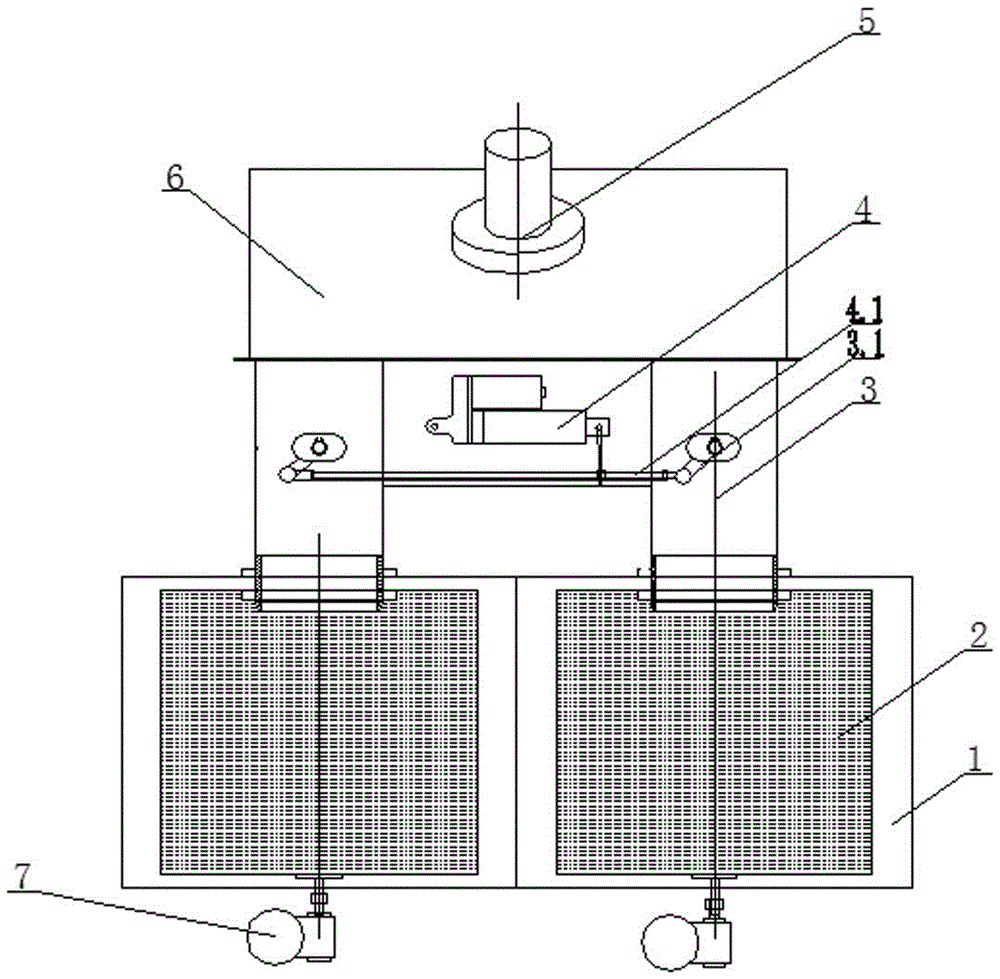

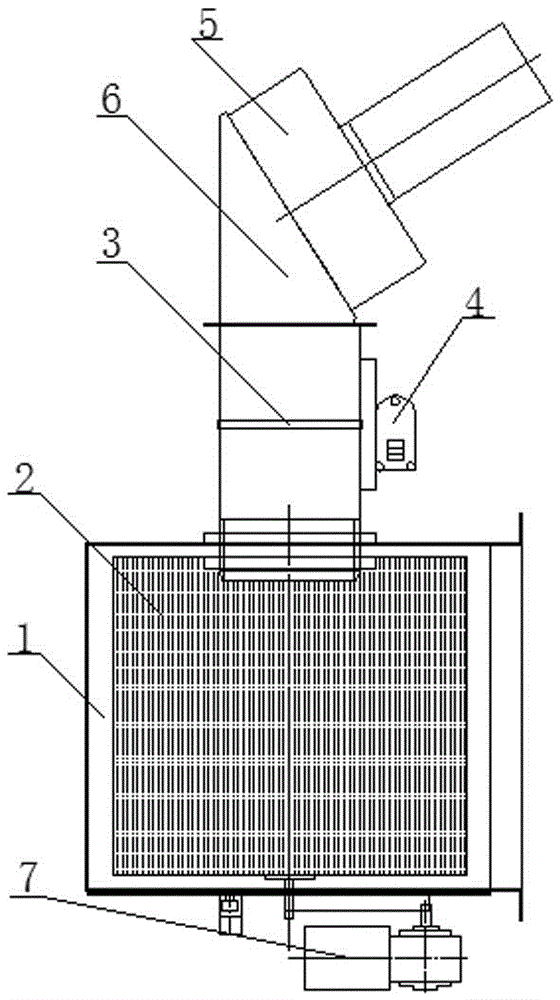

[0015] figure 1 The sweeping machine shown has a built-in dual-channel alternating vibration dust cleaning device, which includes a box body 1, an air filter 2, an air duct valve 3, an electric push rod 4, a fan 5, an air chamber 6 and a vibrator 7. The box body 1 is a double-cavity conjoined structure, with an air filter 2 built into the left and right chambers, and the interfaces of the two air filters 2 are drawn from the upper wall of the box body 1, and the exposed interfaces are equipped with air duct valves 3. The two air duct valves 3 installed side by side are connected and communicated with the air chamber 6, and this structure forms a double channel. The air chamber 6 is a thin-walled container, the front is centered and connected to the fan 5, and the air source introduced after the fan 5 is started enters the supporting ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com